Professional Documents

Culture Documents

Steel Frame Design PDF

Uploaded by

Nayeemuddin Khaja0 ratings0% found this document useful (0 votes)

23 views7 pagesOriginal Title

1. Steel frame design.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views7 pagesSteel Frame Design PDF

Uploaded by

Nayeemuddin KhajaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

This week we begin a

five-partserieson

developments in steel

and concrete

construction. Here,

Peter Trebiloock, Mark

Lawsonand Graham

Owens focus on long-

span structures for

commercial buildings.

1 Composite construction has

‘become the norm for medium: to

biti commercial buildings.

2 Space planning modules donot

‘change mach despite increasing

spans.

Peter Trebieockisan associate

architect at BDP and eensaltant

architect toSCI (he Stel

Construction Tstitue,

Mark Lavon eresearch manager

forbuildings at SCL

Graham Owen is acting eodrector

ofSCl

ak

soe ee

Init, St .

STRUCTURAL DEVELOPMENTS

1 STEEL FRAME DESIGN

Too many architects leave the determination

ofall structural matters to their consulting

engineer when, with some general

knowledge, valuable design timeeanbe

saved and eto spent inpursing

inappropriate or inadequate solutions

minimised. The aimaf this article isto

provide architects with guidanceon the

prime factors tobe considered, the options

available and the implications ofa given

choice of structure.

Composite construction

Composite construction entails the use of

sieel beams acting structurally withan

insitu lightly reinforced concrete slab o

steel decking used as permanent formwork.

Shear connectors are often used to develop

composite action between the conerete slab

and thesteel beams, Allmaterials act

together ‘compositely’ once the concrete has

gained sufficient strength, toprovidea

strong, efficient method of floor

construction, 1.

‘Today, over 50 per cent ofall eommercial

buildings are of eomposite construction

including over 80 per cent of buildings of five

storeys orhigher. The total office and retail

floorspace created inthis type of

construction is probably some 20 million sqm

overtthe past eight years.

‘The main reasons for using composite

construction in most instances are economic.

Faster erection facilitates earlier completion

which in turn reduces interest charges and

advances rental income. There can also be

savings in materials. A composite beam may

betwice the strength of the equivalent

non-composite beam in conventional

steelwork, but up to four times stiffer. This

means that shallower structural depths ean

be achieved using composite construction

Thispermits lower storey heights and

subsequent savingsin cladding costs or

rakes more room available for services

Within the same overall oor-to-floor height.

Although comparative design

demonstrates that savingsin steel weight

relative tonon-composite construction ean

'be80 t050 per cent, these savings do not

necessarily translate directly into overall

cost savings because of the need for shear

connectors, which arenecessary to develop

the composite action between the steel and

conerete. Nevertheless, savingsin the

overalleost of the superstructure (beams,

bs, columns) of atypieal building ean be

15.20 percent, not including the savings on

the cost ofthe external and internal fabric it

the shallower storey heightsare achieved.

Grid size

‘The choice of grid size (column spacing) is

important because although stee!is popular

due toits ability to span further than simple

reinforced concrete for the same structural

depth, costs per sq mise asthe column,

spacing increases. However, these

additional eosts may be smallin comparison

with the economic and funetional benefits

realised from greater areas of uninterrupted

useable floor space. Internal columns are

very unweleome in high-rise schemes, for

example, as they become so large in plan area

dueto high loading.

Column grids for many office

developments arein the6-9m range.

However, work patterns are evolving

rapidly due to changing commercial practice

and the advent of modern communications

and information technology, though the

1,5mmodule till dominates in space

planning terms,2. Today’sideal layout may

quickly become outdated and thereare many

iments for longer spans, particularly in

sal whenthey cabopeiove for on

modest premium, say 2t03 per cent ofthe

overall building cos.

‘A9m grid is more common today, anda

minimum standard in Stuart Lipton'srecent

schemes. Users and developers are

constantiy demanding more column-tree

space and 12-18m spansare becoming

inereasingly popular. Agents are finding.

column-free spaces easier tolet, especially in

the current market; they may well eommand

premium, A variety of structural solutions

forspans above 9m will be considered later.

Inarectangular gridit is most efficient to

design the more heavily loaded primary

beams tospan the shorterdistanees

between columns so that the depths of

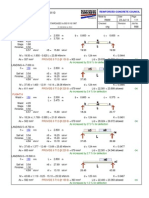

A1wApmiser

‘atte oat ef composite fons —

Column spacings Bux Gm grid Tem oon grid

Deck span 7 im 5.50

Seelteams 3s 46

Steel columns 10 i in

‘Trimmers, bracing, ote 4 4 4

Shear comectors 4 5 4

Eireprotection 10 2B 0

Steel decking and trimming 8 8 a

Gonerete WO) & mesh 16 16 fi

Totaly 0 units tT ant

Erectiontime(steelwork) Joo units 7 units “60 units

Construction time frame nd oor) 00 units SSunits 80

eeu

secondary and primary beams are similar.

Typical as-built costs ofthe 2

superstructure are in the range of £50-80/m'

depending on the complexity ofthe building,

Abreakdown of typical costs aid

‘construction times for composite floor

structures in medium-rise buildings is given

inthe table. The structural costs canbe up to

20per cent ofthe cost of the complete

scheme, but are typically about 15 per cent.

Composite beams

Composite beamsbehave essentially ikea

series of T-beams in which the conerete slab

acts.as the compression flangeand the

downstand sel section acts asthe tension-

resisting element. The structural connection

between the twomaterialsis made by shear

conneetors, Composite aetion serves to

increase both the strength and stiffness of

the steel section, permitting it to span

further or support heavier loads,

‘The overall structural depth not only

includes the steel section but also the

‘composite slab. For efficient design of

‘composite beamsit is often found that the

ratio of span to overal structural depthisin

the range o! 18-20. (Reinforved concrete

beamshavea 1:16-18.)

Composite decking

Thisis a profiled steel product, like roof

sheeting, but with embossments or other

‘mechanical means of improving the

conneetion between the decking and the

concrete placed on top ofit. Slab depths of

120-150mm are common today. Current

practiceisto design for the longest spans

which can be achieved without the need for

tengorary roping 3-9 mdeckspan

appears tobe the most popular,

Many deck profiles are availabe but

generally they are of two broad types -— the

Govetailand the trapezoidal. A 50!mm deep

Bflecanusalysuportiadsovera

mspan.

"The embosements or indentations inthe

profleareintended to improve the shear

Gand behaviour ofthe composite slabs. There

isno particular significance to the shape of

these embossments provided they are deep

enough toreduce the slip between the

concrete and the decking by a mechanism

Kenownas ‘mechonleal interlock.

Composite deckingis usually aid as long

sheets upto 12mlong andis fastened dows

atevery beam. Inthis way itoffers anumber

ofadvantages:

tit supports lads during construction

sitstablises the structural members and

stiffens the frame against wind loads

eit provides safe working platform

Siceasasatty net gabe ling objects

itacts as transverse reinforcement tothe

‘composite beams virtually eliminating the

Deed forlarge amounts reinforcement bars

tit dstributes shrinkagestrains, preventing

serious cracking of the concrete

‘eit develops composite action with the

onerete to resist the imposed latin

‘This formof construction ensures is

uickand easy to erect Large bundles of

Tecking can be lifted into place with limited

‘subsequent use of crane facilities. The extent

aferane use often determines the eriicl

path, soaserane use reducesso oes the

Srerallerection programine. Decking out

normally oecurschortiy after the math steel

members have been erected. Conerting is

Aone one rtivefoorstehind, aftershear

connectors, mesh reinforcement and edge

{rims have been positioned. Overall there

frefewer elementsom the etieal path, This

onstruction methodisnot very ssitiveto

the weather.

‘Shear connectors

Shear connectorsare usually 19mm in

diameter, 100mm long Studs with a formed

head and are individually welded through the

steel decking tothe steel flange by a hand-

operated welding gun, Each Weld takes

about twoto three seconds. The gun requires

2415 V 3-phase supply oramobile generator.

‘This on-site process cannot be used for

painted beams and is not reommended for

usein freezing conditions. Inssuch

circumstances the prewelding of studs may

beappropriate, Alternatively a shot-fired

connector could be used. This has the

advantage ofnot requiring site power and

can be used with painted beams. The shear

strength ofa 19mm diameter welded stud

can be up to 10tonnes compared to3.5 tonnes

forashat-fired connector, 4a-d,5.

Types of concrete

‘Twotypes of eonerete are used in the UK, a

lightweight aggregate concrete or the more

usual heavier version. The compressiye

strengths are typically 30 to 40 Nimm’. Both

canbe pumped into place, with the

lightweight conerete being easier to work.

opin

ie

ea

‘acd Typical details of deck

attachment to beams. s, double

‘stud but jin; typical end

cantilever; typical edge deta

side cantilever wth stub bracket.

Site welding of studs.

‘Web openings such as this canbe

‘sed for runing services of

‘modest se,

because ofits rounded ageregate. Although

thelightweightmixisabout percent more

expensive, thisis more than offset by the

savings resulting from the weight reduetion

ofthe floor.

However, suppliers ofready-mixed

conereteare sometimes reluctant to store

the more expensive lightweight aggregate

unless they are convinced they willenjoy a

Jargeand regular demand

Design methods and codes

‘Thedesign of omposite slabsis covered in

BS5960 Part 4:1982. Ironically, BS5950

Part, which deals with composite beams,

was only published in September 1990. As

1992approaches Eurocode dis being

repared. Itlargely reflects BS 5950 Part 3

Batwillaiso cover the design of eomposite

slabs and stee! decking.

Long:span alternatives

One ofthe principal advantages ofsteel over

conerete sits ability tospan further with

Jess material. Fabricated tapered girders,

haunched beams, parallel beam

composite trusses, stub girders and

+ castellated beams may allbe viable. The

optimum solution depends on:

spans of primary and secondary beams

span/depth ratio

necessity tocontribute to sway resistance

sross-sectional area of service ducts

location of major duets across span,

ding consideration of gener

distribution routes and erassover positions

@looseness of fit between serviees and

structure, especially important for shell and

core developments where particular tenants

may require additional servicing,

Ofeourseas spansincrease sodoes the

depth ofstructure, Toavoid inereasing the

floor-to-loor depth to accommodate the

integration of services, there area number of

solutions which ineorporate these services

within the overall structuralzone. Itisnow

almost inevitable that building services will

change significantly during the life ofa

‘commercial building whereas the structure

will not and the designer should take this

fundamental prineiple into aecount when

determining structural solutions,

inwebs of composite beams

is appropriate for lightly serviced

ings, and is one of the most commonly.

used methods of incorporating services

within thestrueturalzone, 6,7. Upto 70 per

cent of the depth of the beam can be safe

used provided that openingsare located

towards the centre of the span. The

advantage of this system is that

modest sized openimgs can be formed where

stubs leaving space for secondary

beams and services distribution

‘9 Castellated beams —long spans

with gt loads

LO Stub girder floor under

‘construction.

11 Haunching of beam at columa,

herein composite construction.

12 Haunched beams at Grand

Buildings, Trafalgar Square.

13 Typical tapered beam profiles

(Ward Structures) and bottom, an

‘example of running larger services

‘where the beam shallower in

‘order to minimise floor sandwich

depth

114 Example of tapered beam oor

structure.

15,16 Composite trus wth service

‘routes in principle and onsite.

0 AszeAptit

they areneeded. The composite action

around openings means that the loss of

strength ofthe beam dueto web openingsis

often not significant.

Castellated beams

Castellated beams have been used as

secondary beams in some buildings, but they

suffer from low shear resistance and cannot.

readily resist heavy point loads. They have

primarily been used aslong-span roof beams

where theirattractive shape s often

expressed architecturally. With only light

loading they can readily span 15 m without

intermediate supports, 9.

‘Stub girders

Inthissystem, tension is resisted by the

bottom chord (usually a stee! column section)

and compression resisted by the slab. Shear

istransferred by stubs on the bottom chord

and the slab openings are located adjacent to

the stubs. Secondary beams are designed as

continuous beams spanning over the bottom

chord. Stub girders are most efficient in the

12-15mspanrange, but they have been

designed up to27m span, 8, 10.

Haunched beams

Inthis system the beams are stiffened at the

connection with the column, thus minimising,

the structural depth and allowing the

servicesto pass underneath the beams,

11,12. (The main beams are usually too

shallow for holes tobe formed in the web.)

Unfortunately the column size increases

significantly and there may be difficulties in

arranging service around the haunehing.

Sometimes tis difficult to achieve continuity

at the corners ofthe building. Haunched

beams were used in the construction

of Grand Buildingsin Trafalgar Square

in London.

Tapered beams

Fabricated seetions are most likely tobe

‘economie for spans above 12m, These are

fabricated from steel plates rather than

standard sections. The taper of the bottom

flange is usually 5 to6°—such that the beam

depth is reduced by halfat the supports

relative tomid span, Services are located in

the triangular voids adjacent tothe columns,

43,14. (Foradetailed treatment of tapered

‘beams see AJ 1.10.86 p65.)

Composite trusses

‘The benefits of composite action inthis

instance lead to areduction in the sizeof the

topchord and permit offset ofthe bracing

member from its regular position where this

‘would, say, interfere with a servicesroute.

Itisalso possible to provide a greater zone

for services by omitting bracing members at

mid span. The main disadvantage of the truss

is the expense of fabrication and additional

fire protection. Composite trusses re only

likely to be the preferred solution forspansin

exeess of 2m, 15,16

Parallel beam systems

Inthis method developed by consulting

engineer Peter Brett, the primary or spine

‘beams are arranged in pairs with one beam

passing either side ofeach column, Shear s

transferred intothe columnsby means of

brackets. The secondary or'rib beams pass

over the spine beams at right angles, 17.

Because ofthis continuity, beam lengths are

only limited by handling and transportation

requirements. The piece’ count is

significantly lower than for conventional

construction saving both erection time

and costs.

Superficially this approach appears to lead

todeeper construction. But because ofits

continuity, both primary and secondary

|

17 Aparalel beam system, where

members do not haetobe cut to

bay size lenths,

1BThe ASW-Cuble system,

providing alarge clear service void,

Srectalinear cousin ofthe

{tiangulated space frame though

the surface can act compastely

witha concrete or,

‘beams ean be very shallow for their spans

and overall depths are comparable with

conventional construction. Its suitable for

spansupto 15m.

“Aunique steel and conerete flooring.

system will be launched in 1991. The

ASW-Cubic system isa two-layer structural

grillage of steel members made up ina

modular arrangement from standard steel

sections and bolted together onsite, 18. It

mits alarger, regular zone for services

Between the structural layers thansome of

the other beam arrangements. Todateit has

‘been used for long-span roof applications

suchas the award-winning 170m span

Stansted Airport jumbo jet hangar, but will

beapplicable to commercial buildings

providing greater floor spans in

twodirections while offering a smaller

depth to: span ratio,

he difference bet ween the flooring and

roofing systemsis that forthe floor the top

chords ofthe framework are embedded in,

and act compositely with, aconerete floor

slab. Thisallows the use of shallower

overall onstruction depth than the roof but

retains the facility for services installation in

the void between conerete slab and

suspended ceiling. Construction of the

conerete floor slab follows established

techniques for constructing metal deck

‘composite flooring but omits the time

coneumingand expensive installation of

shearstuds.

Vibration response

Asspans inerease soo concerns about

possible floor vibrations in high specification

commercial buildings. Contrary to what

right be expected, long-span composite

beamsare no more prone to vibration

problems than others because composite

action increases the monolithie behaviour of

the whole structure.

Thenatural frequency of efficiently

designed composite beamsis common

the range of 4 to Geycles/see, decreasing with

increasing span. Similar values are

appropriate for non-composite beams, which

willbe deeper and heavier than composite

‘beams for the same loading and span

characteristics. A lower limit of natural

frequency of cycles/see can be used in

long-span composite buildings, provided

cheeks are made on the likely response of the

structure (see the Steel Construction

Institute's Design guide on the vibration.

offtoors)..

‘The natural frequency of atypical

composite floor structure should not exceed

4 eyclesisee without doing more detailed

calculations ofthe structural response.

(People walk at 1-2 eycles/see.) The vibrati

Frequency can be tested by special

though thisisrarely necessary. Care should

be taken when delicate machinery needs to

beinstalled.

Vertical cores

‘These not only provide forstairs lift shafts,

service ducts, toilet accommodation and so

on, They usually act asa key vertical

structural element offering lateral stability

tothe main structural frame, Concrete cores

canbe slowerto construct and openings for

doorways and service penetrations must be

carefully predetermined as later alterations

may be expensive and dificult. The number

‘and size of the openings may be limited due to

structural requirements. That they donot

require additional fire protection isa strong

advantage and perhaps explains why

they are the most common farm of core

inthe UK.

Vertical steel bracing or plated steel cores

are usually easier and quicker toerect, are

lightweight and can be prefabricated. Zones

for services and door openings should be

positioned in general termsat anearly stage

inthe design although exaet dimensioningis

not required until later provided that bracing

members remain unaffected, 19abc, 20.

Steel cores can be built simultaneously

with the main frame whereas conerete ones

‘must generally be built inadvance. Itis not

‘unusual fora building to have more than one

type of core depending upon the structural

requirements nd relative positions of the

coreson plan. Thefire prot

coresis the most diffieult problem to salve.

Often the steelworkis protected by a fire

protecting wall.

2 A0eapeion

18

19abe Steel-braced core

configurations. bracing with

ny

bracing which s convenient for door

=)

Sie

“be

Steel plate cores may be used where more

stiffhessis required than with the usual k’

braced cores. The stiffened plates are more

akin to bridge construction than to buildings,

and are more efficient when designed for

heavy shearloads.

Fire protection

Current Building Regulations require all

structural steel which supports more than

the roof ofa building or isused in buildings of

more than one storey tobe protected ayainst

fire. This can be achieved by encasing the

steel neoncrete or protecting it by the

application of sprayed insulation,

{ntumeseent coatings, insulated blankets,

‘board casings or ined metal casings. The

choice depends on matters such as cost,

whether the steel will remain exposed

visually, what other elements will be fixed to

the members (such as partitions), how long

the method will take and whether it can be

satisfactorily executed simultaneously with

othersite activities,

Ttisnot unusual forthe perimeter

steelwork tobe encased inconerete,

regardless of the method used elsewhere due

toconerete'shigh durability in this

potentially corrosive conditions along the

cladding ine, Hollow steel sections, ifused

may be filled with concrete or water to

improve their fire resistance but interflling

for fire protection has only been used on one

‘major project todate.

Steel members ean be delivered tosite

pre-encased where later shuttering around

sections would prove difficult. However, this,

often eaves pockets around the joints which

require time-consuming mamual filling,

‘Typically 40 per cent of steelwork used in

modern buildings is protected by spray-

applied material which isusually the

cheapest method, 40 per cent by board

casings, and 10 per cent iseneased in

conerete, particularly perimeter members

and columns. Intumescent paint isonly used

onabout 2 percent of total application but,

thisis likely toincrease as off-site painting

‘becomes more accepted and paint

thicknesses, and hence costs, are reduced

Spray material is most inconvenient when it

420

isapplied adjacent to perimeter areas where

cladding tradesare performing their workat

thesame time.

Despite the decreasing costs offre

protection the need tofire protect steels,

Viewed by the majority ofits specifiersasits

major weakness, as the processis disruptive

and isa separate and additional site activity.

‘The controversial proposals to change the

Building Regulations relating to fire safety

may reduce the degree of protection

required and/or provide alternative ways of

achievingit. The draft amendments

suggested eliminating all four-hour and most

two-hour fire-resisting periods, exeept in

high buildings, increasing compartment

sizes, allowing the greater use of

combustible materials and redueing the

levels of structural fire resistance, However,

due tothe level ofprotest at these

government measures, which also

include greater reliance upon active fire

protection ystems, no changes will be

introduced without further detailed

consideration,

Future systems

Most ofthe alternatives discussed above

relate tothe choice of floor systems which in

‘one way or another are supported by a grid of

columns. The resulting visual effect is

usually lost or suppressed behind suspended

ceilings and under raised fcors. This isnot

necessarily undesirable but it may become

possible to express the structure ifarchitects

and engineers develop other systems which

canbe implemented by fabricators and

rectors.

Overview

Steel and composite construction providea

freedom to span longer distances more

economically in commercial buildings.

Seleetion of the optimum system depends on

balancingarchitectural, structural, services

and cost erteria, and on evaluating the

options early enough in design. Barly advice

‘onseleetion and detailed design information

‘ean be obtained from the Stee! Construction

Institote’spublieationsand its Advisory

Service (O34 23345).

Met apniven sa

B19q26

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CivilCAD 2012 User Manual English Rev1Document423 pagesCivilCAD 2012 User Manual English Rev1Victor Armando Muñoz PurillaNo ratings yet

- Timber Column Design To Bs5268-2:2002: Project Job RefDocument2 pagesTimber Column Design To Bs5268-2:2002: Project Job RefZayyan RomjonNo ratings yet

- 1 Way Continous SlabDocument5 pages1 Way Continous SlabZayyan RomjonNo ratings yet

- Lesson 6Document12 pagesLesson 6Zayyan RomjonNo ratings yet

- CraneDocument81 pagesCraneZayyan RomjonNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Zayyan RomjonNo ratings yet

- RCC21 Subframe AnalysisDocument9 pagesRCC21 Subframe AnalysisZayyan RomjonNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)Zayyan RomjonNo ratings yet

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignZayyan RomjonNo ratings yet

- REINFORCED CONCRETE STAIRCASES To BS 81101997Document3 pagesREINFORCED CONCRETE STAIRCASES To BS 81101997Victor CruzNo ratings yet