Professional Documents

Culture Documents

M7 4 PDF

M7 4 PDF

Uploaded by

Linh ĐàoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M7 4 PDF

M7 4 PDF

Uploaded by

Linh ĐàoCopyright:

Available Formats

FORM TC-20

PRACTICAL EXERCISE SHEET

PHIẾU BÀI TẬP THỰC HÀNH

Title Avionic Test Equipment - Exercise 01 - Rev 00

Code AMB-M7.4-01 Applicable for: Cat B1,B2,B1+B2

Compliance with Avionic Test Equipment, code: AMB-M7.4

Description This exercise is designed for new technical engineer/technician in accordance with

the course curriculum “VAR Part 7 – Aircraft Maintenance Basic” at Module 7.

Duration Training hours: 18 hours Level: 2

Materials Document handout: Aircraft Maintenance Basic Training Manual Module 7.

Tool/equipment: I.A.W the following “1. JOB SET-UP INFORMATION”

Avionic Test Equipment - Exercise 01 Code: AMB-M7.4-01

Operation, function and use of avionic general test equipment: Current Clamp Meter

WARNING: Set function switch to the appropriate position before measuring.

When measuring volts do not switch to current/resistance modes.

Do not measure current on a circuit whose voltage exceeds 600V.

When changing ranges always disconnect the test leads from the circuit under test.

CAUTION: Improper use of this meter can cause damage, shock, injury or death. Read and

understand this manual before operating the meter.

Always remove the test leads before replacing the battery or fuses.

Inspect the condition of the test leads and the meter itself for any damage before

operating the meter. Repair or replace any damage before use.

Use great care when making measurements if the voltages are greater than 25VAC

rms or 35VDC. These voltages are considered a shock hazard.

Always discharge capacitors and remove power from the device under test before

performing Diode, Resistance or Continuity tests.

Voltage checks on electrical outlets can be difficult and misleading because of the

uncertainty of connection to the recessed electrical contacts. Other means should be

used to ensure that the terminals are not "live".

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

This device is not a toy and must not reach children’s hands. It contains hazardous

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 1 / 7

FORM TC-20

Avionic Test Equipment - Exercise 01 Code: AMB-M7.4-01

objects as well as small parts that the children could swallow. In case a child

swallows any of them, please contact a physician immediately

Do not leave batteries and packing material lying around unattended; they can be

dangerous for children if they use them as toys

In case the device is going to be unused for an extended period of time, remove the

batteries to prevent them from training

Expired or damaged batteries can cause cauterization on contact with the skin.

Always, therefore, use suitable hand gloves in such cases

See that the batteries are not short-circuited. Do not throw batteries into the fire.

Do not directly view or direct the laser pointer at an eye. Low power visible lasers do

not normally present a hazard, but may present some potential for hazard if viewed

directly for extended periods of time

1. JOB SET-UP INFORMATION

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY UNIT DESIGNATION

EX840 01 EA Extech EX840 CAT IV True RMS 1000A Clamp Meter.

Firgure 1. Clamp Meter

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 2 / 7

FORM TC-20

Avionic Test Equipment - Exercise 01 Code: AMB-M7.4-01

B. Comsumable Material

REFERENCE QTY UNIT DESIGNATION

No specific 01 OZ Mild Detergent

No specific 01 EA Damp Cloth

C. Expendable Parts

REFERENCE QTY UNIT DESIGNATION

No specific 01 EA Battery 9V

D. Referenced Information

REFERENCE DESIGNATION

M7.4 -MEASURING HIGH LUFTHANSA TECHNICAL TRAINING

CURRENTS (Current Clamp Meter)

(Current Clamp Meter) For the different fields of application, different current clamp meters

were

developed:

- For very high currents with corresponding large clamp.

- Milliammeter for small currents in lines that cannot be

disconnected.

Figure Ampere Clamp Meter

2. JOB SET-UP

A. Prepareation:

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 3 / 7

FORM TC-20

Avionic Test Equipment - Exercise 01 Code: AMB-M7.4-01

1. Current clamp

2. Clamp opening trigger

3. Data Hold Button

4. Mode

5. Peak

6. Range

7. DCA Zero

8. MIN/MAX

9. Backlit LCD Display

10. Test lead input jacks

11. IR thermometer and laser pointer (rear)

12. Backlight Button

13. Laser pointer button

14. Function switch

1. Starting

HOLD Data Hold

Minus sign Negative reading display

0 to 3999 Measurement display digits

ZERO Zero

P Peak value

AUTO Auto Range mode

DC/AC Direct Current / Alternating Current

MAX Max reading

MIN Min reading

Low battery

mV or V Milli-volts or Volts (Voltage)

Ohms (Resistance)

A Amperes (Current)

F Farad (Capacitance)

Hz Hertz (Frequency)

oF and oC Fahrenheit and Celsius units

(Temperature)

n, m, , M, k Unit of measure prefixes: nano, milli,

micro, mega, and kilo

Continuity test

Diode test

Laser pointer

2. Operation

A. Data Hold

To freeze the LCD reading, press the HOLD button. While data hold is active, the HOLD icon appears on

the LCD. Press the HOLD button again to return to normal operation.

B. Peak Hold

The Peak Hold function captures the peak AC or DC voltage or current. The meter can capture negative

or positive peaks as fast as 1 millisecond in duration.

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 4 / 7

FORM TC-20

Avionic Test Equipment - Exercise 01 Code: AMB-M7.4-01

1. Turn the function switch to the A or V position.

2. Use the MODE button to select AC or DC

3. Allow time for the display to stabilize.

4. Press and Hold the PEAK button until “CAL” appears in the display. This procedure will zero the range

selected.

5. Press the PEAK button, P max will display.

6. The display will update each time a higher positive peak occurs.

7. Press the PEAK button again, P min will display. The display will now update and indicate the lowest

negative peak.

8. To return to normal operation, press and hold the PEAK button until the P min or P max indicator

switches off.

Note: If the Function switch position is changed after a calibration the Peak Hold calibration must be

repeated for the new function selected.

C. MAX/MIN

1. Press the MAX/MIN key to activate the MAX/MIN recording mode. The display icon "MAX" willappear.

The meter will display and hold the maximum reading and will update only when a new“max” occurs.

2. Press the MAX/MIN key and “MIN” will appear The display icon "MIN" will appear. The meterwill

display and hold the minimum reading and will update only when a new “min” occurs

3. Press the MAX/MIN key and a blinking “MAX MIN” will appear. The meter will display thepresent

reading, but will continue to update and store the max and min readings.

4. To exit MAX/MIN mode press and hold the MAX/MIN key for 2 seconds.

D. Temperature Units (˚F / ˚C)

The temperature unit’s selection switch is located in the battery compartment. To change the units,

remove the battery door, lift out the battery and set the switch for the desired units.

E. LCD Backlight Button

The LCD is equipped with backlighting for easier viewing, especially in dimly lit areas. Press the

backlight button to turn the backlight on. Press again to turn the backlight off.

D. Automatic Power OFF

In order to conserve battery life, the meter will automatically turn off after approximately 25 minutes.

To turn the meter on again, turn the function switch to the OFF position and then to the desired function

position.

3. PROCEDURE

A. AC Current Measurements

WARNING: Ensure that the test leads are disconnected from the meter before making current

clamp measurements.

1. Set the Function switch to the AAC or ADC range.

2. Press the trigger to open the jaw. Fully enclose only one conductor. For optimum results, center the

conductor in the jaw.

3. The clamp meter LCD will display the reading.

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 5 / 7

FORM TC-20

Avionic Test Equipment - Exercise 01 Code: AMB-M7.4-01

B. DCA ZERO

The DC Zero feature removes offset values and improves accuracy for DC current measurements. To

perform a zero, select ADC and with no conductor in the jaw:

1. Press the DC ZERO button to zero the display. “ZERO” will appear in the display. The offset value is

now stored and removed from all measurements.

2. To view the stored value, press the DC ZERO button. “ZERO” will flash and the stored value will be

displayed.

3. To exit this mode, press and Hold the ZERO button until “ZERO” is no longer in the display.

C. AC/DC Voltage Measurements

1. Insert the black test lead into the negative COM terminal and the red test lead into the positive V

terminal.

2. Set the function switch to the VAC or VDC position.

3. Use the MODE button to select AC or DC Voltage).

4. Connect the test leads in parallel to the circuit under test.

5. Read the voltage measurement on the LCD display.

AC/DC Voltage Resistance Measurements

Measurements

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 6 / 7

FORM TC-20

Avionic Test Equipment - Exercise 01 Code: AMB-M7.4-01

D. Resistance Measurements

Note: Remove power before making resistance measurements

1. Insert the black test lead into the negative COM terminal and the red test lead into the positive

terminal.

2. Set the function switch to the position.

3. Touch the test probe tips across the circuit or component under test.

4. Read the resistance on the LCD display.

4. PRODUCTION REQUIREMENTS/ ASSESSMENT

A. Description of Maximum inputs of RMS 1000A Clamp Meter equipment? (2 points)

A. Perform the AC Current Measurements (2 points)

B. Perform the DC current measurements (2 points)

C. Perform the AC/DC Voltage Measurements (2 points)

D. Perform the resistance measurements (2 points)

5. CLOSE-UP

A. Make sure that the work area is clean and clear of tools and other items.

B. Clean Workshop

C. Put Workshop to Its usual condition

Prepared by: Vũ Văn Triển Date: …………..……….………

Evaluated by: Trần Minh Nghĩa Date: …………………………..

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 7 / 7

FORM TC-20

PRACTICAL EXERCISE SHEET

PHIẾU BÀI TẬP THỰC HÀNH

Title Avionic Test Equipment - Exercise 02 - Rev 00

Code AMB-M7.4-02 Applicable for: Cat B1,B2,B1+B2

Compliance with Avionic Test Equipment, code: AMB-M7.4

Description This exercise is designed for new technical engineer/technician in accordance with

the course curriculum “VAR Part 7 – Aircraft Maintenance Basic” at Module 7.

Duration Training hours: 18 hours Level: 2

Materials Document handout: Aircraft Maintenance Basic Training Manual Module 7.

Tool/equipment: I.A.W the following “1. JOB SET-UP INFORMATION”

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

Operation, function and use of avionic general test equipment: Measuring The Electrical Resistance

WARNING: Set function switch to the appropriate position before measuring.

When measuring volts do not switch to current/resistance modes.

Prior to connecting this instrument always ensure that the circuit under test is

electrically isolated. Connecting this instrument to circuits which have not been

isolated could lead to a hazard.

When changing ranges always disconnect the test leads from the circuit under test.

CAUTION: Improper use of this meter can cause damage, shock, injury or death. Read and

understand this manual before operating the meter.

Always remove the test leads before replacing the battery or fuses.

Inspect the condition of the test leads and the meter itself for any damage before

operating the meter. Repair or replace any damage before use.

This instrument has been designed and tested to comply with the Electromagnetic

Compatibility Directive 89/336/EEC and Low Voltage Directive 93/68EEC in

accordance with EN 61010 -1 :2001 Cat III <50V relating to the safety requirements

for electrical equipment for measurement, control and laboratory use. Before

connecting the instrument to the mains supply, please ensure the following safety

precautions have been read and understood.

Always discharge capacitors and remove power from the device under test before

performing Diode, Resistance or Continuity tests.

Voltage checks on electrical outlets can be difficult and misleading because of the

uncertainty of connection to the recessed electrical contacts. Other means should be

used to ensure that the terminals are not "live".

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

This device is not a toy and must not reach children’s hands. It contains hazardous

objects as well as small parts that the children could swallow. In case a child

swallows any of them, please contact a physician immediately

Do not leave batteries and packing material lying around unattended; they can be

dangerous for children if they use them as toys

In case the device is going to be unused for an extended period of time, remove the

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 1 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

batteries to prevent them from training

Expired or damaged batteries can cause cauterization on contact with the skin.

Always, therefore, use suitable hand gloves in such cases

See that the batteries are not short-circuited. Do not throw batteries into the fire.

Do not connect the power supply to, or operate this instrument with, the protective

covers removed. Component replacement and internal adjustments must be made

by qualified service personnel. Do not replace components with the power cable

connected. Under certain conditions, dangerous voltages may exist with the power

cable removed. To avoid injuries always disconnect power and discharge circuits

before touching them.

1. JOB SET-UP INFORMATION

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY UNIT DESIGNATION

DO7 Plus 01 set Cropico DO7 Plus Portable Ohmmeter.

Firgure 1. Cropico DO7 Plus Portable Ohmmeter

B. Comsumable Material

REFERENCE QTY UNIT DESIGNATION

No specific 01 OZ Mild Detergent

No specific 01 EA Soft Cloth

C. Expendable Parts

REFERENCE QTY UNIT DESIGNATION

Cropico part No. 01 EA rechargeable batteries

551A675

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 2 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

D. Referenced Information

REFERENCE DESIGNATION

M7.4 -MEASURING THE LUFTHANSA TECHNICAL TRAINING

ELECTRICAL RESISTANCE (Multimeter Digital / Analogue)

(Multimeter Digital / Analogue) - The conductor material in the aircraft wiring can break due to

vibration or through frequent bending (doors/panels). As a result, the

(Portable Ohmmeters) wiring system will no longer function.

- In order to locate such a failure, a measuring device capable of

measuring resistance is used. A so−called multimeter is generally

used for this purpose.

- The resistance to be measured can range up to 1 kilo−ohm.

- Breaks in the conductor often present themselves as so−called

loose contacts.

- To verify these failures, an analogue measuring device is

recommended while simultaneously “shaking“ the line.

- To be able to check the electrical resistance, an electric circuit

must be produced. This can be realized by either using the ground

of the aircraft or with the help of an extension line.

Figure Multimeter Digital / Analogue

2. JOB SET-UP

A. Prepareration:

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 3 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

1. ON/OFF Switch

2. The Function Keypad F1-F5:

3. QWERTY Keypad The full QWERTY keypad

allows notes to be entered against logged

measurement values

4. Starts and stops the measurement in continuous

measurement mode. Triggers measurement in

single measurement mode.

5. Navigation and enter Key

6. LIMITS Pass / Fail LEDS

7. Power input socket

8. Charger status Indicator

9. USB Socket

10. RS232 Socket

11. Pt100 input Socket

12. Measurement input sockets

13. Measurement Display

1. Khởi động

A: Measurement Window:

+ Measured value with sign and

units.

+ The selected measurement range,

current and measurement mode.

+ RX+ and RX- value when in

average mode.

+ Compensated value and measured

Rx value plus temperature when in

temperature compensation mode.

B: Function Window:

+ Trigger mode selected

+ Limits status ( OFF, <<Hi>>,

<<Lo>> , >>OK<< ) C: Status Window:

+ Filter settings + Battery charge state in % of full charge

+ Settling settings + Memory number

+ Data Log Status + Remote status

+ Timer (if active) + Measure / Stop condition

D: Function Soft Keys - Five soft keys give access to setup

menus

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 4 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

To select and change a setting

proceed as follows:- PRESS F4

(SETUP) and the following screen

will display

2. Operation

A. F4 SETUP

To enter the configuration menu PRESS F4 (SETUP) the following can then be set.

B. Setting the DO7PLUS Measurement Configuration

To set or change a measurement configuration PRESS F3 (MENU) and the following screen will display

Where an item is highlighted with an arrow RANGE this

indicates that options are available for that parameter and

the right navigation

arrow should be pressed to reveal those options.

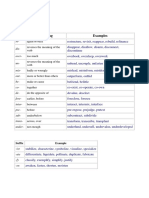

The table below shows the options available together with

a brief description

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 5 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 6 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 7 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

C. Setting the Instrument Range

Some of the measurement functions need to be

changed more frequently than others and these

may accessed directly, to change the RANGE

settings PRESS F1 and the following screen will

display.

F1 RANGE

The F1 function key will take you straight to the

range set-up menu.

- To select the highlighted range PRESS OK (F5)

or the carriage return key

- Pressing the left arrow will return you to the

measurement screen without selecting the new

highlighted range.

- Pressing F1 (ESC) escapes the range menu

and returns to the measurement screen without

updating the range.

AUTO RANGE Do NOT use Auto-range when measuring

Two modes of auto-range may be selected inductive devices e.g. motors and transformers.

AUTO1 where the DO7PLUS will start at the Fig Measuring ranges with maximum current and

highest range and work down. AUTO2 selects the resolution.

last range used and then ranges up or down.

HINT: The AUTO2 will often find the correct range

the fastest

AUTO1 will always start with the highest range

which uses the smallest measuring current

and will avoid overheating temperature sensitive

devices.

D. Setting the Measurement Current Mode

F2 Current

The F2 function key will take you directly to the measurement current set-up menu

- To select the highlighted mode PRESS OK (F5)

or the carriage return key

- Pressing the left arrow will return you to the

measurement screen without selecting the new

highlighted range.

- Pressing F1 (ESC) escapes the range menu

and returns to the measurement screen without

updating the range.

+ I The measurement current flows in the positive

direction AVERAGE The measurement is made with +I

- I The measurement current flows in the negative current then a second measurement with -I

direction current, and the average value of the two

measurements is displayed. The average

measurement will eliminate the effects of thermal

emf and is recommended for all resistive

measurements.

WARNING: The AVERAGE mode should NOT be used when measuring inductive samples

such as transformers or motor windings. In these cases use the +I mode which will give

continuous and uninterrupted measurement current, ensuring the inductance is fully charged

and the correct reading displayed.

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 8 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

3. PROCEDURE

A. Connecting to the DO7PLUS

The DO7PLUS uses a four terminal method of measurement which eliminates errors due to lead

resistance. The measuring leads plug into the four front panel safety sockets. The sockets are marked

+U, -U, +I, & -I. Connections to the resistance to be measured should be as per Fig:

Connection diagram

B. Connecting to the resistance

The Digital Microhmmeter DO7PLUS employs a four wire method of measurement, i.e. it is necessary to

make four connections to the resistance under test. The instrument is supplied with four leads; two for

the potential connections which are made across the test resistor at the points between which the

resistance is to be determined; and two for the current connections which connect the test resistor to the

current supply circuit.

Connect to the resistance under test as shown in figure 5.1.1, Cleanliness is important and if the sample

is not clean, a rub with an abrasive paper to remove oxides is recommended.

It is not always possible to use the combined current and potential crocodile clips (Kelvin clips), in which

case test leads with spade tags, or special fixtures may have to be made to suit the particular

application.

Diagram of different connection configurations

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 9 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

C. Resistance measurement

The DO7PLUS should be in the measurement [STOP] mode. In this mode the measuring current is

switched off and the current terminals are shorted internally. Connect the measuring leads as described

in section A. Before starting the measurement select the current mode required as described in section "

Setting the Measurement Current Mode". Select the range required see " Setting the Instrument Range"

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 10 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

or auto range.

WARNING the maximum measuring current is 10 Amp on the lowest measuring range ensure that the

current level selected will not damage the resistance being measured.

To start the measurement press the MEASURE button the measured resistance value will be displayed.

D. Resistance measurement with temperature compensation

Temperature compensation should be used when measuring the resistance of materials which have a

high temperature coefficient. Copper, for example, has a temperature coefficient of 0.3930%/K. The

value of the resistance measured will therefore vary with the temperature of the copper. To obtain

consistent and meaningful results, the resistance values may be related to a set ambient temperature,

normally 20C.

Example: Copper with a temperature coefficient of 3930ppm/k = 0.3930%/k

To measure with the temperature compensation, proceed as in 5.3 but in addition connect the

temperature sensor probe (see section 9 for accessories details and part numbers) to the front panel

socket. Select the temperature compensation measurement mode as described in 4.9.9. Alternatively, if

the ambient temperature is stable, a manual value may be entered, in this case a temperature sensor is

not required. The compensated resistance value will be displayed in large digits on the DO7PLUS

screen and the true measured resistance value will be shown in smaller digits below the main display.

The measured and set temperature will also be shown.

E. Effects of Lead Resistance

The DO7PLUS is a true four terminal measuring instrument and will, therefore, measure accurately with

long lead lengths. The DO7PLUS monitors the lead resistance and will display an error message if the

lead resistance exceeds the resistance values below. It is good practice to keep the lead lengths to a

minimum, this ensure that any magnetic fields and other environmental noise that may be present have

minimal effect. Sometimes long leads can’t be avoided and in these cases the cable resistance should

be kept to a practical minimum and not exceed the following:

- Current Leads Maximum resistance 60m each lead (120 m total)

- Potential leads Maximum resistance 1keach lead (2k total)

HINT: The accuracy of the measurement is not affected by different lead lengths, only by the resistance

of the leads.

4. PRODUCTION REQUIREMENTS/ ASSESSMENT

A. Perform the connection between DO7PLUS and the resistance IAW Diagram of different connection

configurations (4 points’; answer: as Diagram of connection Part 3.A-B)

B. Perform measuring the resistance (2 points; answer: perform and read out the measured resistance

value will be displayed)

C. Perform Resistance measurement with temperature compensation (2 points; answer: perform and

read out the measured resistance value will be displayed)

D. Understand of Effects of Lead Resistance (2 points; answer: In according with Part 3.E described)

5. CLOSE-UP

A. Make sure that the work area is clean and clear of tools and other items.

B. Clean Workshop

C. Put Workshop to Its usual condition

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 11 / 12

FORM TC-20

Avionic Test Equipment - Exercise 02 Code: AMB-M7.4-02

Prepared by: Vũ Văn Triển Date: …………..……….………

Evaluated by: Trần Minh Nghĩa Date: …………………………..

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 12 / 12

FORM TC-20

PRACTICAL EXERCISE SHEET

PHIẾU BÀI TẬP THỰC HÀNH

Title Avionic Test Equipment - Exercise 03 - Rev 00

Code AMB-M7.4-03 Applicable for: Cat B1,B2,B1+B2

Compliance with Avionic Test Equipment, code: AMB-M7.4

Description This exercise is designed for new technical engineer/technician in accordance with

the course curriculum “VAR Part 7 – Aircraft Maintenance Basic” at Module 7.

Duration Training hours: 18 hours Level: 2

Materials Document handout: Aircraft Maintenance Basic Training Manual Module 7.

Tool/equipment: I.A.W the following “1. JOB SET-UP INFORMATION”

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

Operation, function and use of avionic general test equipment: Measuring High−Ohm Resistance

(Insulation Measurement)

WARNING: Insulation measurement devices use potential values of up to1000 volts. Therefore,

all devices, engines, sensors, etc. must be disconnected from the wire prior to the

measurement.

Take extreme care when performing insulation measurements on semi−conductor

continuous loop fire detection systems since they will be destroyed through

excessive measuring voltages!

To avoid electric shock, injury, or damage to the Meter, disconnect circuit power and

discharge all high-voltage capacitors before testing resistance, continuity, diodes, or

capacitance.

Use the Meter only as specified in this manual or the protection provided by the

Meter might be impaired.

Do not use the Meter or test leads if they appear damaged, or if the Meter is not

operating properly. If in doubt, have the Meter serviced.

Always use the proper terminal, switch position, and range for measurements

before connecting Meter to circuit under test.

Verify the Meter’s operation by measuring a known voltage.

Do not apply more than the rated voltage as marked on the Meter, between the

terminals or between any terminal and earth ground.

Use caution with voltages above 30 V ac rms, 42 V ac peak, or 60 V dc. These

voltages pose a shock hazard.

Replace the battery as soon as the low battery indicator (b) appears.

Disconnect circuit power and discharge all high-voltage capacitors before testing

resistance, continuity, diodes, or capacitance.

Do not use the Meter around explosive gas or vapor.

When using the test leads, keep your fingers behind the finger guards.

Remove test leads from the Meter before opening the Meter case or battery door.

Never operate the Meter with the cover removed or the battery door open.

Comply with local and national safety requirements when working in hazardous

locations.

Use proper protective equipment, as required by local or national authorities when

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 1 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

working in hazardous areas.

Avoid working alone.

Use only the replacement fuse specified or the protection may be impaired.

Check the test leads for continuity before use. Do not use if the readings are high or

noisy.

CAUTION: To avoid a blown fuse, damage to the Meter, or serious personal injury, never

attempt to make a measurement with a test lead in an incorrect terminal.

Insulation Specifications

Measurement Range...........................................0.1 MΩ to 2 GΩ model 1587, 0.1

MΩ to 600 MΩ model 1577

Test Voltages ......................................................50, 100, 250, 500, 1000 V model

1587, 500 and 1000 V model 1577

Test Voltage Accuracy ........................................+ 20 %, - 0 %

Short-Circuit Test Current ...................................1 mA nominal

Auto Discharge....................................................Discharge time <0.5 second for C =

1 µF or less

Live Circuit Detection: .........................................Inhibit test if terminal voltage > 30 V

prior to initialization of test.

Maximum Capacitive Load..................................Operable with up to 1 µF load.

1. JOB SET-UP INFORMATION

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY UNIT DESIGNATION

Model 1587 01 set Insulation multimeter

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 2 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

Firgure 1. Model 1587 Insulation multimeter

B. Comsumable Material

REFERENCE QTY UNIT DESIGNATION

No specific 01 OZ Mild Detergent

No specific 01 EA Soft Cloth

C. Expendable Parts

REFERENCE QTY UNIT DESIGNATION

No specific 04 EA 1.5 V AA batteries

D. Referenced Information

REFERENCE DESIGNATION

M7.4 -MEASURING LUFTHANSA TECHNICAL TRAINING

HIGH−OHM RESISTANCE

(Isolation Tester)

(INSULATION

- Aircraft wires are protected by an insulation to prevent that a

MEASUREMENT)

connection is setup between the conductors among themselves and

between the conductors and the ground potential.

(Isolation Tester)

- This insulation may partially or completely lose its functionality

through environmental influences (humidity, ultraviolet radiation,

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 3 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

coldness, heat, etc.) as well as through chemicals existing in

aircrafts (oils, grease, hydraulic fluids, fluids used in lavatories,

etc.).

- Mechanical influences (abrasions) may also affect the insulation.

- To check the quality of the insulation, insulation measurements

are performed.

- For these measurements, a voltage higher than the rated voltage

is used −similar to the pressure test of a pipe line with an increased

pressure value.

- The measurement can be performed between two wires as well as

between a wire and ground.

-The insulation measurement is

performed with special

insulation testers or with

multimeters with an integrated

insulation test function.

Figure Isolation Tester

2. JOB SET-UP

A. Prepareration:

1. Rotary Switch Positions

Turn the Meter on by selecting any measurement

function.

The Meter presents a standard display for that

function (range, measurement units, modifiers,

etc.). Use the blue button to select any rotary

switch alternate functions (labelled with blue

letters). Rotary switch selections are shown in

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 4 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

Figure and described in Table

2. The Buttons:

Use the buttons to activate features that augment

the function selected with the rotary switch. The

buttons are shown in Figure 2 and described in

Table

Table. Buttons

Table. Rotary Switch Selection

3. Understanding the Display

Display indicators are shown in Figure and

described in Table. Error messages that may

appear on the display are described in Table

Table. Display Indicators

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 5 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

Table. Error Messages

4. Input Terminals

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 6 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

1. Starting

A. Power-Up Options: Table Power-Up Options

Holding a button down while turning

the Meter on activates power-up

option. Power-up options allow you

to use additional features and

functions of the Meter. To select a

power-up option, hold down the

appropriate button indicated while

turning the Meter from OFF to any

switch position. Power-up options

are cancelled when the Meter is

turned OFF. Power-up options are

described in Table

Note:

Power Up options are active when

the button is pressed.

In the AutoHold mode, the Meter

holds the reading on the display until

it detects a new stable reading. Then

the Meter beeps and displays the

new reading.

• Press to activate Auto Hold.

appears.

• Press again or turn the rotary

switch to resume normal operation.

2. Operation

A. MIN MAX AVG Recording Mode To use MIN MAX AVG recording:

The MIN MAX AVG mode records • Make sure the Meter is in the desired measurement function

minimum and maximum input and range. (Auto ranging is disabled in the MIN MAX AVG

values. When the inputs go below mode).

the recorded minimum value or • Press to activate MIN MAX AVG mode. MINMAX

above the recorded maximum value, appears on the display.

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 7 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

the Meter beeps and records the • Press to step through the high (MAX), low (MIN),

new value. This mode can be used average (AVG), and present readings.

to capture intermittent readings, • To pause MIN MAX AVG recording without erasing stored

record maximum readings while you

are away or record readings while values, press . HOLD is displayed.

you are operating the equipment • To resume MIN MAX AVG recording, press again.

under test and cannot watch the HOLD turns off.

Meter. MIN MAX AVG mode can

also calculate an average of all • To exit and erase stored readings, press for one

readings taken since the MIN MAX second or turn the rotary switch.

AVG mode was activated.

The Meter tracks the minimum,

maximum, and average values for

each display which are updated 4

times per second.

B. Manual Ranging and Auto When you turn the Meter on, it defaults to Auto range and

ranging Auto Range is displayed.

The Meter has both Manual Range 1. To enter the Manual Range mode, press . Manual

and Auto range modes. Range is displayed.

• In the Auto range mode, the Meter

selects the range with the best 2. In the Manual Range mode, press to increment the

resolution. range. After the highest range, the Meter wraps to the lowest

• In the Manual Range mode, you range.

override Auto range and select the Note

range yourself. You cannot manually change the range in the MIN MAX AVG,

or Display HOLD modes. If you press while in MIN MAX

AVG, or Display HOLD the Meter beeps twice, indicating an

invalid operation, and the range does not change.

3. To exit Manual Range, press for one second or turn

the rotary switch. The Meter returns to Auto range and Auto

Range is displayed.

3. PROCEDURE

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 8 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

Figure Insulation Check Procedure

A. Test insulation

Insulation tests should only be performed on

dead circuits. Check the fuse before testing.

See Testing the Fuse later in this manual. To

measure insulation resistance set up the

Meter as shown in Figure and follow the steps

below:

1. Insert test probes in the + and - input

terminals.

2. Turn the knob to INSULATION position. A

battery load check is initiated when the switch

is moved to this position. If the battery fails,

the test and Bat appear in the lower

display. Insulation tests cannot be performed

until the batteries are replaced.

3. Press to select the voltage.

4. Connect the probes to the circuit to be

measured.

The Meter automatically detects if the circuit

is energized.

• The primary display shows - - - - until you

press and a valid insulation resistance

reading Figure. Testing Insulation

is obtained.

• The high voltage symbol along with a primary display of >30 V warns if voltage more than 30 V

ac or dc is present. In this condition, the test is inhibited. Disconnect the Meter and remove power before

proceeding.

5. Push and hold to start the test. The secondary display shows the test voltage applied to the

circuit under test. The high voltage symbol along with a primary display showing the resistance in MΩ

or GΩ appears. The icon appears on the lower portion of the display until is released.

When resistance is higher than the maximum display range, the Meter displays the > symbol and the

maximum resistance for the range.

6. Keep the probes on the test points and release the button. The circuit under test then

discharges through the Meter. The resistance reading appears on the primary display until a new test is

started or a different function or range is selected or > 30 V is detected.

B. Cleaning

Periodically wipe the case with a damp cloth and mild detergent. Do not use abrasives or solvents. Dirt

or moisture in the terminals can affect readings.

C. Testing the Batteries

To test the batteries, press and turn to the rotary switch to the INSULATION position. This initiates a

battery test and displays the charge level of the battery.

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 9 / 20

FORM TC-20

Avionic Test Equipment - Exercise 03 Code: AMB-M7.4-03

D. Testing the Fuse

Warning: To avoid electrical shock or injury,

remove the test leads and any input signals

before replacing the fuse.

Test the fuse as described below and shown in

Figure.

Replace the fuse as shown in Figure.

1. Insert a test probe in the input terminal.

2. Turn the rotary switch to the position and

verify the Meter is in Auto Range.

3. Insert the probe in the mA input terminal. If the

display reading is 0L, the fuse is bad and should

be replaced.

Testing the Fuse

E. Replacing the Batteries and Fuse

1. Remove the battery door by using a standard

screwdriver to turn the battery door lock until the

unlock symbol aligns with the arrow.

2. Remove and replace the batteries.

3. Replace the battery door and secure by turning

the battery door lock until the lock symbol aligns

with the arrow.

4. PRODUCTION REQUIREMENTS/ ASSESSMENT

A. Identify Insulation multimeter Specifications Model 1587 (2 points; answer: as detailed Part Caution)

B. Perform start-up with the Model 1587 Insulation multimeter (2 points; answer: described Part 2.A)

C. Perform Testing Insulation (2 points; answer: perform and read out the measured value will be

displayed)

D. Understand The MIN MAX AVG mode records (2 points; answer: perform and explain with multimeter

as Part Power-up described)

D. Practice the removal and installation of battery or fuse (2 points; answer: In according with Part 3.D, E

described)

5. CLOSE-UP

A. Make sure that the work area is clean and clear of tools and other items.

B. Clean Workshop

C. Put Workshop to Its usual condition

Prepared by: Vũ Văn Triển Date: …………..……….………

Evaluated by: Trần Minh Nghĩa Date: …………………………..

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 10 / 20

FORM TC-20

PRACTICAL EXERCISE SHEET

PHIẾU BÀI TẬP THỰC HÀNH

Title Avionic Test Equipment - Exercise 04 - Rev 00

Code AMB-M7.4-04 Applicable for: Cat B2,B1+B2

Compliance with Avionic Test Equipment, code: AMB-M7.4

Description This exercise is designed for new technical engineer/technician in accordance with

the course curriculum “VAR Part 7 – Aircraft Maintenance Basic” at Module 7.

Duration Training hours: 4 hours Level: 2

Materials Document handout: Aircraft Maintenance Basic Training Manual Module 7.

Tool/equipment: I.A.W the following “1. JOB SET-UP INFORMATION”

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

Operation, function and use of avionic general test equipment: Measuring Low−Ohm Connections

(Bonding/Groundings)

WARNING: METRA HIT 27EX is a milliohm-meter with 4-pole measurement, which is designed

for deployment in potentially explosive environment. In accordance with directive

2014/34/EU the device is approved for being used in explosive, gaseous

atmospheres (IIA T4) with ambient temperatures between – 10 °C and +50 °C.The

device conforms to the following standards:

– EN 60079-0:2012 + A11:2013

– EN 60079-11:2012

It bears CE certification number, type INERIS 05ATEX0040, which has been

conferred by the Inner is certification authority.

Shock Hazards: Avoid working alone when taking measurements which involve

shock hazards. Be certain that a second person is present.

Meanings of symbols on the instrument:

Warning concerning a source of danger (attention: observe

documentation!)

Ground

Continuous, doubled or reinforced insulation

Indicates EC conformity

Symbol for explosion protection:

Electrical equipment for intended use in potentially explosive

environments per EN 60079-11

This device may not be disposed of with the trash. Further

information regarding the WEEE mark can be accessed on the

Internet at www.gossenmetrawatt.com by entering the search term

’WEEE’.

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 11 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

CAUTION: The milliohm-meter described herein is a portable instrument which can be held in

one hand during measurements.

The milliohm-meter may only be operated with the included or with type-tested

batteries, as specified in the Characteristic Values.

The milliohm-meter may only be operated with closed housing. The instrument

must be removed from the potentially explosive environment before opening the

housing to replace batteries or fuses.

Only the type-tested fuses specified in the Characteristic Values may be used.

The milliohm-meter may only be used to perform such measurements as

described

The limits of the overload capacity may not be exceeded. Refer to the

“Characteristic Values” for overload values and overload duration.

Downloaded from www.Manualslib.com manuals search engine 6 GMC-I

Messtechnik GmbH

Measurements may only be performed within the indicated ambient conditions.

See page 29 for operating temperature range and relative humidity.

The instrument may not be used in a dusty atmosphere.

No maintenance operation may be performed in potentially explosive atmospheres

(cleaning, replacement of batteries, opening the device, etc.

1. JOB SET-UP INFORMATION

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY UNIT DESIGNATION

METRA HIT 27EX 01 set Milliohm-meter

Firgure 1. METRA HIT 27EX Milliohm-meter

B. Comsumable Material

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 12 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

REFERENCE QTY UNIT DESIGNATION

No specific 01 OZ Mild Detergent

No specific 01 EA Soft Cloth

C. Expendable Parts

REFERENCE QTY UNIT DESIGNATION

No specific 04 EA batteries

D. Referenced Information

REFERENCE DESIGNATION

M7.4 -MEASURING LUFTHANSA TECHNICAL TRAINING

LOW−OHM CONNECTIONS

A lot of connections in aircrafts serve the purpose of introducing

(BONDINGS/GROUNDINGS)

electricity into the structure (groundings) or which connect large

conductive parts of the structure with one another (bonding).

These connections must be of high quality to prevent a possible

resistance and the formation of corrosion on these areas.

In order to check the quality of these connections, their resistance

value must be checked.

However, the standard measurement method via the ohmmeter/multi-

meter two−wire measurement is not suitable in this case due to the

very low resistance values to be measured. The resistance values of

the measurement line and of the interface to the resistance to be

measured highly influence the measurement current compared to the

influence of the resistance to be measured. That way no suitable result

can be obtained.

For that reason, the Kelvin measurement method, also called

four−wire measurement, was developed. Here, two test leads supply a

specific current which flows through the connection to be measured.

Two further test leads measure the voltage drop directly on the

resistance to be measured. The resistance value is then determined

through the two values of the supplied current and the measured

voltage drop.

One advantage of this measurement method is that the measurement

device locates faulty transitions to the resistance to be measured by

detecting that the measurement current does not flow. The fact that

the voltage drop is measured instead of the flowing current is another

advantage since the resistance of the measurement lines no longer

influences the result

Measurement Devices for

Bonding/Groundings

- For low resistance

measurements, special

measurement devices are

used.

One of these devices is the

bonding meter. By now the

bonding measurement has

been integrated in multi-

meters as special function by

manufacturers for

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 13 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

measurement devices.

Figure Bonding Meter

Bonding Meter for High

Measurement Currents

To increase the

measurement quality, the

measurement current can be

increased. This method is

used by aircraft

manufacturers in a way that

a minimum measurement

current is necessary for

specific measurements. This,

on the other hand, puts

specific requirements on the

measurement devices since

the provision of the

measurement current

requires a corresponding

stable current supply in the

device. Therefore individual

measurement devices are

required for these special

measurements. Those

devices can supply

Figure High current Bonding meter

measurement currents of up

to 10 ampere.

2. JOB SET-UP

A. Prepare:

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 14 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

1. Interface selection of the device

1 Display (LCD)

2 ON|OFF key for ON / OFF (ON short:

instrument ON → ON short: background

illumination ON → OFF short: background

illumination OFF → OFF long: instrument OFF)

Operating mode menu: open submenus /

acknowledge entries.

3 DATA|CLEAR key for the functions save/delete

measured value. Operating mode menu:

Selection of individual menu items against

direction of flow, increase values.

4 MAN|AUTO key for manual measuring range

selection. Operating mode menu: Selection of

individual menu items in direction of flow

decrease values

5 MENU/ESC. Operating mode menu: Exit menu

level and return to a higher level, exit parameters

configuration without saving data

6 LED OK blinks: valid measured value

7 LED ERROR blinks: incorrect connection

8 Connector jacks *

2. Symbols used in the Digital Display:

Table. Interface selection of the device

1 Main display with decimal point.

2 Auxiliary displays.

3 Milliohm-meter in continuous operation,

ON blinks at transmission frequency in

transmission mode.

4 REM: Memory mode operation, disappears

after communication via the interface is ended by

means of key or switch operation.

5 ZERO: Zero balancing.

6 MAN: Manual measuring range selection.

7 Unit of measure.

8 Low battery voltage, replace batteries

* I- Measurement input

U- Sense – for 4-wire measurement

U+ Sense + for 4-wire measurement

I+ mΩ; Ω measurement input

Table. Symbols used in the Digital Display

1. Start

A. Insert Batteries: E. Switching the Instrument Off Manually

Remove the instrument from the ➭ Press the ON|OFF key until OFF is shown on the display.

potentially explosive environment

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 15 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

before opening. Shutdown is acknowledged with two, brief acoustic signals.

Only use the included type-tested F. Switching the Milliohm-meter Off Automatically –

batteries. “SLEEP MODE“

Note: The instrument is switched off automatically if none of the

As a result of internal voltage keys are activated for approximately 10 minutes. Shutdown

monitoring, the instrument may is acknowledged with a brief acoustic signal.

respond as follows if the battery

Transmission mode: In this case, checking is first

voltage level is low:

performed

– Cannot be switched on

to determine whether or not the sampling rate has been set

– Shuts back down immediately to a value of greater than 10 s. The instrument is switched

– Shuts back down immediately when off after 10 minutes, but the instrument is reactivated 10s

a load is applied in the mΩ range. before data is to be saved to memory. The instrument is then

If this is the case, replace the switched back off again.

batteries. In the transmission mode, the instrument can be manually

B. Switching the Instrument On activated with the ON|OFF key. After activation of this type,

Manually: the instrument returns to the “SLEEP MODE”.

Press the ON|OFF key. If the instrument is to be fully shut down, it must first be

activated and then switched off with the ON|OFF key. This

As long as the key is held depressed,

ends both memory mode and transmission mode operation.

all of the segments at the LCD are

illuminated. The LCD is shown on. We recommend setting the instrument to continuous

Power-up is acknowledged with a operation for transmission mode operation.

brief acoustic signal. The instrument The continuous operation mode is not effected by automatic

is ready for use as soon as the key is shutdown.

released. Disabling Automatic Shutdown

B. Switching the Instrument On

The instrument can be set to continuous operation.

with a PC:

After transmission of a data frame ➭ Press and hold the MENU/ESC key and then switch the

from the PC, the milliohm-meter is instrument on by pressing the ON|OFF key. Continuous

switched on. operation is indicated at the display with the symbol.

C. Switching the Instrument On Switching LCD Illumination On and Off

Automatically: ➭ Briefly press the ON|OFF key after the instrument has

The milliohm-meter is switched on already been switched on.

automatically in the transmission and Illumination is switched off automatically after approximately

memory modes. 2 minutes.

Note: Note: Electrical discharge and high frequency interference

Electrical discharge and high may cause incorrect displays to appear, and may disable the

frequency interference may cause measuring sequence. In such cases, switch the instrument

incorrect displays to appear, and may off and back on again in order to reset.

disable the measuring sequence. In If the problem persists,

such cases, switch the instrument off 1 leave the potentially explosive environment,

and back on again in order to reset. If

2 disconnect the instrument from the measuring circuit

the problem persists, briefly dislodge

before opening.

the batteries from the connector

contacts. 3 Briefly dislodge the batteries from the connector contacts.

D. Setting Time and Date

2. Opearation - Selecting Measuring Functions and Measuring Ranges

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 16 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

A. Automatic Measuring Range

Selection

The milliohm-meter is equipped with

auto-ranging for all measuring

ranges. Auto-ranging is active as

soon as the instrument is switched

on. The instrument automatically

selects the measuring range which

allows for highest possible resolution

for the applied quantity.

The instrument automatically

switches to the next highest or next

lowest measuring range for the

following measured quantities:

B. Manual Measuring Range

Selection

Auto-ranging can be deactivated and

measuring ranges can be selected

manually in accordance with the

following table.

The manual mode is deactivated by

pressing and holding the

MAN|AUTO key (approx. 1s) or by

switching the instrument off and then

back on again.

Note!

If the red ERROR LED lights up and

OL is shown on the display during

manual measuring range selection,

you should switch to the next higher

range.

3. PROCEDURE

Figure Bonding metering

Operating the Bonding Meter

With the four−wire measurement, it is important that the voltage test leads are closer to the resistance to

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 17 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

be measured than the current−supplying test leads. In addition, with combined test handles, the voltage

test leads are to be labeled with “P“ for potential or with “+“, and the current test leads with “C“ for

current. When using the Metrahit 27EX, the two longer test spikes measure the voltage.

Test Leads

Based on the minimum measurement current, the bonding meter can detect whether the test leads

properly come in to contact with the resistance to be measured or not. If this is not the case, the device

displays an error message. This message may be different depending on the type of device.

The T 477 W indicates the faulty contact via flashing decimal points on the display. The Metrahit 27EX

on the other hand, shows the flashing message “LEADS OPEN“.

If this error message occurs, the connections of the measurement line must be checked and possibly

remaining paint layers, oxide films, or similar, have to be removed. Only when no error messages are

displayed, realistic results can be obtained.

NOTE: After the measurement it is necessary to protect the bare test points against corrosion again.

Milliohm Measurement (4-Pole-Measurement)

F. Compensation of Cable Resistance

Electrical resistance is a dipole quantity which can generally only be measured using two poles. This

is accomplished by directing a measuring current of predetermined magnitude through the device

under test, and measuring the resultant voltage drop. The respective resistance value is derived from

the quotient of these two values.

The two points between which voltage is measured are decisive as regards the results of the

measurement. All resistances between these two points add to the measured resistance value.

These include contact resistance, as well as cable resistance. If a very low resistance value needs to

be measured, for example contact resistance at a contactor with a value of only a few milliohms, the

points between which voltage is measured must be moved out of the measuring instrument and

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 18 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

positioned as closely as possible to the device under test.

For this reason, the measuring instrument is equipped with separate jacks for current feed and

voltage measurement.

This type of 4-pole connection is known as connection according to Kelvin.

KC4 Kelvin clips and KC27 Kelvin probes (available as accessories) allow for easy, correct

connection.

G. Measurement with Kelvin Probe KC27

H. Thermo-voltage Compensation

Thermo-voltages which occur as a result of material and temperature differences may distort

measurement results. For this reason, the instrument is equipped with automatic thermos-voltage

compensation in the relevant measuring ranges.

After switching on the milliohm-meter, “ is displayed, indicating that an automatic thermos-voltage

compensation for the 30 mΩ and 300 mΩ measuring ranges will be performed in the background for all

future measurements. ZERO signals that the value of the thermos-voltage has already been taken into

account for the indicated measuring result.

After the first measurement – lift the test probe from the measuring point “ disappears to facilitate

the reading of the measured values. The automatic thermos-voltage compensation remains activated.

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 19 / 20

FORM TC-20

Avionic Test Equipment - Exercise 04 Code: AMB-M7.4-04

I. Milliohm Measurement with ≤ 100 mA

DC [mΩ]

➭ Make sure that the device under test is

voltage-free.

➭ Connect the device under test as shown.

KC4 Kelvin clips and KC27 Kelvin probes

(available as accessories) allow for easy, correct

connection. Resistance at the current jacks

should amount to < 1 Ω.

➭ If applicable, select the desired measuring

range using the MAN|AUTO key: 30 mΩ, 300

mΩ, 3 Ω or 30 Ω.

➭ Contact the measuring point.

The green LED OK must light up.

Note!

If the measuring current is interrupted during 4-wire-mΩ-measurement or if the fuse F1 is defective,

the message flashes on the display and the red LED ERROR lights up.

4. PRODUCTION REQUIREMENTS/ ASSESSMENT

A. Identify multi-meter Specifications METRA HIT 27EX (2 points; answer: as detailed Part Caution

&Warning)

B. Perform start-up with the METRA HIT 27EX multi-meter (2 points; answer: described Part 2.A)

C. Understand of Selecting Measuring Functions and Measuring Ranges (2 points; answer: perform and

explain with multi-meter as Part Power-up described).

D. Perform Measurement with Kelvin Probe KC27 (2 points; answer: perform and read out the measured

value will be displayed).

E. Perform Milliohm Measurement with ≤ 100 mA DC [mΩ] (2 points; answer: In according with Part 3.D

described)

5. CLOSE-UP

A. Make sure that the work area is clean and clear of tools and other items.

B. Clean Workshop

C. Put Workshop to Its usual condition

Prepared by: Vũ Văn Triển Date: …………..……….………

Evaluated by: Trần Minh Nghĩa Date: …………………………..

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 20 / 20

FORM TC-20

PRACTICAL EXERCISE SHEET

PHIẾU BÀI TẬP THỰC HÀNH

Title Avionic Test Equipment - Exercise 05 - Rev 00

Code AMB-M7.4-05 Applicable for: Cat B2,B1+B2

Compliance with Avionic Test Equipment, code: AMB-M7.4

Description This exercise is designed for new technical engineer/technician in accordance with

the course curriculum “VAR Part 7 – Aircraft Maintenance Basic” at Module 7.

Duration Training hours: 3 hours Level: 2

Materials Document handout: Aircraft Maintenance Basic Training Manual Module 7.

Tool/equipment: I.A.W the following “1. JOB SET-UP INFORMATION”

Avionic Test Equipment - Exercise 05 Code: AMB-M7.4-05

Prepared by: Vũ Văn Triển Date: …………..……….………

Evaluated by: Trần Minh Nghĩa Date: …………………………..

ISS. 01, REV. 00 - DATE: 15 MAY 2018 PAGE 1 / 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Amplivox CA850 Series 3 Operating Manual Issue 11Document26 pagesAmplivox CA850 Series 3 Operating Manual Issue 11PraistonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wood Heating GB PDFDocument124 pagesWood Heating GB PDFghost2011No ratings yet

- Effect of Heat and Air On A Moving Film of Asphalt (Rolling Thin-Film Oven Test)Document6 pagesEffect of Heat and Air On A Moving Film of Asphalt (Rolling Thin-Film Oven Test)intanmizwarNo ratings yet

- 3RD Exam Reviewer IgDocument5 pages3RD Exam Reviewer IgFebemay LindaNo ratings yet

- The Business Students Guide To Sustainable Management Principles and Practice 2Nd Edition Molthan Hill Full ChapterDocument56 pagesThe Business Students Guide To Sustainable Management Principles and Practice 2Nd Edition Molthan Hill Full Chapterpatricia.short935100% (6)

- National Transmission Corp. v. de Jesus PDFDocument4 pagesNational Transmission Corp. v. de Jesus PDFJerald Oliver Macabaya0% (1)

- Difference Between Organizations and InstitutionsDocument8 pagesDifference Between Organizations and InstitutionsGil PendragonNo ratings yet

- Chapter III - 1.2 Solution of The Assignment ModelDocument24 pagesChapter III - 1.2 Solution of The Assignment ModelMiks EnriquezNo ratings yet

- Template Inventory of Roads With The LGU JurisdictionDocument4 pagesTemplate Inventory of Roads With The LGU JurisdictiongreteNo ratings yet

- Masen Noor IVDocument277 pagesMasen Noor IVVeintidós MarzoNo ratings yet

- Preeth-Formats of WalmartDocument8 pagesPreeth-Formats of WalmartPreeth ChilveryNo ratings yet

- UntitledDocument22 pagesUntitledAgapitoNo ratings yet

- Operations Strategy: David A. Collier and James R. EvansDocument47 pagesOperations Strategy: David A. Collier and James R. EvansSeanmigue TomaroyNo ratings yet

- WORD BUILDING - Prefixes & Suffixes PDFDocument5 pagesWORD BUILDING - Prefixes & Suffixes PDFGöksu ÇavuşoğluNo ratings yet

- Workshop 3 - MathsDocument9 pagesWorkshop 3 - MathsMABEL XIMENA GONZALEZ PEREZNo ratings yet

- Mosquito Word SearchDocument3 pagesMosquito Word SearchZeida Rojas BastidasNo ratings yet

- SONA February 2023 CommitmentsDocument32 pagesSONA February 2023 CommitmentsjanetNo ratings yet

- Fm-Ul AtexDocument1 pageFm-Ul AtexPrem KumarNo ratings yet

- Toeic Writing EssayDocument37 pagesToeic Writing EssayThư NguyễnNo ratings yet

- Design Principles For Connected DevicesDocument37 pagesDesign Principles For Connected Devicesநட்ராஜ் நாதன்No ratings yet

- 966 HWLDocument10 pages966 HWLHamdy KhattabNo ratings yet

- A Mixed Integer Linear Program For Airport Departure SchedulingDocument13 pagesA Mixed Integer Linear Program For Airport Departure SchedulingDang Khoa NgoNo ratings yet

- Ehsen Shaikh: Instructions For AS Practicals Type I QuestionsDocument5 pagesEhsen Shaikh: Instructions For AS Practicals Type I QuestionsiYaasirNo ratings yet

- Walter and Millers Textbook of Radiotherapy Radiation Physics Therapy and Oncology 8Th Edition Edition Paul Symonds All ChapterDocument68 pagesWalter and Millers Textbook of Radiotherapy Radiation Physics Therapy and Oncology 8Th Edition Edition Paul Symonds All Chapterrobert.clark290100% (6)

- Hitachi Tu-Hd1000Document47 pagesHitachi Tu-Hd1000Javier Sanchez SanchezNo ratings yet

- Hager EG100 Timer User ManualDocument2 pagesHager EG100 Timer User Manualmcprinter100% (1)

- Account StatementDocument132 pagesAccount StatementBASHA SHAFIQNo ratings yet

- Deltares License Management - Installation ManualDocument45 pagesDeltares License Management - Installation ManualAnne PutriNo ratings yet

- Part B Unit 5: EntrepreneurDocument38 pagesPart B Unit 5: EntrepreneurFire ShettyNo ratings yet

- Pocket PDF January AffairscloudDocument91 pagesPocket PDF January AffairscloudRAVI KUMAR JHAJHARIANo ratings yet