Professional Documents

Culture Documents

Jis G-3131-2010 PDF

Jis G-3131-2010 PDF

Uploaded by

Tri-Sure More Than Closures0 ratings0% found this document useful (0 votes)

11 views16 pagesOriginal Title

JIS G-3131-2010.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views16 pagesJis G-3131-2010 PDF

Jis G-3131-2010 PDF

Uploaded by

Tri-Sure More Than ClosuresCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

JIS

JAPANESE

INDUSTRIAL

STANDARD

Translated and Published by

Japanese Standards Association

JIS G 3131:

(JISF)

Hot-rolled mild steel plates, sheet

and strip

ICS 77,140.50

Reference number : JIS G 3131 : 2010 (E)

PROTECTED BY COPYRIGHT 9S

G 3131 : 2010

Date of Establishment: 1967-02-01

Date of Revision: 2010-10-20

Date of Public Notice in Official Gazette: 2010-10-20

Investigated by: Japanese Industrial Standards Committee

Standards Board

Technical Committee on Iron and Steel

JIS G 3131:2010, First English edition published in 2011-04

‘Translated and published by: Japanese Standards Association

41-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN

In the event of any doubts arising as to the contents,

the original JIS is to be the final authority

© JSA 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced oF

utilized in any form or by any means, electronic or mechanical, including photocopying and

‘microfilm, without permission in writing from the publisher,

Printed in Japan

KAAT

PROTECTED BY COPYRIGHT

G 3131: 2010

Contents

Page

Introduction “1

1 Scope 1

2 Normative references 1

3 Grade and symbols weed

4 Chemical composition - ae

5 Mechanical properties 2

5.1 Tensile strength and elongation 2

5.2 Bendability 2

6 Shape, dimensions, mass and tolerances 3

7 Oiling- 5

8 Appearance - 5

9 Tests en 5

9.1 Chemical analysis 5

9.2 Mechanical test a5

10 Inspection and reinspection 6

10.1 Inspection. 6

10.2. Re-inspection - “6

11 Marking “6

12 Items to be confirmed at the time of order aT

13 Report 7

Annex JA (informative) Comparison table between JIS and corresponding

International Standard 8

@

PROTECTED BY COPYRIGHT

G 3131 : 2010

Foreword

This translation has been made based on the original Japanese Industrial Standard

revised by the Minister of Economy, Trade and Industry through deliberations at

the Japanese Industrial Standards Committee as the result of proposal for revision

of Japanese Industrial Standard submitted by The Japan Iron and Steel Federation

(JISF) with the draft being attached, based on the provision of Article 12 Clause 1

of the Industrial Standardization Law applicable to the case of revision by the provision

of Article 14.

Consequently JIS G 3131:2005 is replaced with this Standard.

However, JIS G $131:2005 may be applied in the JIS mark certification based on

the relevant provisions of Article 19 Clause 1, etc. of the Industrial Standardization

Law until 19th October, 2011.

This JIS document is protected by the Copyright Law.

Attention is drawn to the possibility that some parts of this Standard may conflict

with a patent right, application for a patent after opening to the public, utility model

right or application for registration of utility model after opening to the public which

have technical properties. The relevant Minister and the Japanese Industrial Standards

Committee are not responsible for identifying the patent right, application for a patent

after opening to the public, utility model right or application for registration of utility

model after opening to the public which have the said technical properties

(ii)

PROTECTED BY COPYRIGHT

JAPANESE INDUSTRIAL STANDARD, SIS G 8131: 2010

Hot-rolled mild steel plates, sheet

and strip

Introduction

‘This Japanese Industrial Standard has been prepared based on the fourth edition

of ISO 3578 published in 2008 with some modifications of the technical contents.

The portions with continuous sidelines or dotted underlines are the matters in which

the content of the corresponding International Standard has been modified. A list of

modifications with explanations is given in Annex JA.

1 Scope

This Standard specifies the hot-rolled mild steel plates, sheets and strips (hereafter

referred to as

processing.

NOTE 1

NOTE 2

“steel sheets and strips”) intended for general fabricating purposes and

The steel sheet and strip may be descaled by pickling or shot blasting

after the hot-rolling operation on request by the purchaser.

‘The International Standard corresponding to this Standard and the sym-

bol of degree of correspondence are as follows:

ISO 3573:2008 Hot-rolled carbon steel sheet of commercial and draw-

ing qualities (MOD)

The symbols which denote the degree of correspondence in the con-

tents between the relevant International Standard and JIS are IDT.

(identical), MOD (modified), and NEQ (not equivalent) according to ISO/

IEC Guide 21-1.

2 Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. ‘The most recent editions of the standards

(including amendments) indicated below shall be applied.

JIS G 0320 Standard test method for heat analysis of steel products

JIS G 0404 Steel and steel products—General technical delivery requirements

JIS G 0415 Steel and steel products—Inspection documents

JIS G 8193 Dimensions, mass and permissible variations of hot rolled steel plates,

JIS Z 2201

JIS Z 2241

JIS Z 2248

sheets and strips

Test pieces for tensile test for metallic materials

Method of tensile test for metallic materials

Metallic materials—Bend test

3 Grade and symbols

The steel sheet and strip shall be classified into 4 grades, and their symbols shall

be as given in table 1

PROTECTED BY COPYRIGHT

2

G 3181: 2010

ble 1 Symbol of grade

Symbol of grade [Application thickness _mm Application

‘SPHC 1.2 or over up to and incl 14 | For commercial

‘SPHD 1.2 or over up to and incl. 1d _| For processing

SPHE 1.2 oF over up to and inel. 8

SPHF 1.4 or over up to and incl. 8

4 Chemical composition

‘The steel sheet and strip shall be tested in accordance with 9.1, and their heat analy-

sis values shall be as given in table 2

Table 2. Chemical composition

Symbol of grade

SPHC 012 max | 0.60 max. | 0.045 max, | 0.035 max

‘SPHD 0.10 max. | 0.45 max. | 0.035 max. | 0.035 max.

SPHE 0.08 max. | 040 max. | 0.030 max. | 0.030 max

SPHF 0.08 max. | 0.35 max. | 0.025 max, | 0.025 max

5 Mechanical properties

Tensile strength and elongation

‘The steel sheet and strip shall be tested in accordance with 9.2 and their tensile

strength and elongation shall be as specified in table 3. However, the values in table 3

shall be applied to those for delivery inspection "

Note" Steel sheets and strips may decrease the elongation by age hardening.

5.2 Bendability

When the SPHC steel sheet and strip are tested in accordance with 9.2 and the bend

test conditions specified in table 3, there shall not be any cracks on the outer surface

of the test piece,

NOTE: See 9.2.8 for the operation of bend test.

PROTECTED BY COPYRIGHT

3

3181 : 2010

‘able 3. Mechan:

properties*

[Symbol] Tensile Elongation ‘Tensile Bendability

of |strength™ % test

grade | Nimm? piece

Thick | Thick | Thick- | Thiek- | Thiel Bend-| Inside radius | Test

2 mm|16mm|20 mm|26 mm] 92 mm ane | Tick] The

toand | toand | to and | toand | toand

excl. | excl. | excl. | excl, | exe

1.6 mm|2.0 mm|2.5 mm| 32 mm|4.0 mm

3.2 mm] or over

SPHC | 270 min, [27 min,|29 min.) 29 min.|20 min.|31 min. [31 min,[No. 5, | 180° [Plat on] Thick-

in roll itself | nese

ing x05

direc

'SPHD | 270 min. [20 min, [32 min, [33 min, [35 min. [37 min. | 39 min

SPHE | 270 min. [32 min, [34 min.|35 min.|37 min. [39 min. [41 min -[-|[-

spur | 27

NOTE: 1 Nimm?=1MPa

Notes ®” The value specified in table 3 shalll not be applied to the irregular portions of both ends

of the steel strip.

0 min. [37 min.|38 min. [39 min. [39 min. [40 min, [42 min —~[-|[-

» The following may be applied as the upper limit of tensile strength as agreed between

the purchaser and the manufacturer

SPHC: 440 Nimm*, SPHD: 420 N/mm?, SPHE: 400 N/mm?, SPHF: 380 N/mm*

6 Shape, dimensions, mass and tolerances

‘The shape, dimensions, mass and their tolerances of the steel sheet and strip shall

conform to JIS G 3193. However, the tolerances on thickness shall be in accordance

with table 4 and the measurement of edge camber shall be carried out: when requested

by the purchaser,

With this respect, tolerances on length for the steel sheet and those on width for

the cut-edge steel sheet shall, unless otherwise specified, be in accordance with the

tolerance A of JIS G 3193. However, as for the width tolerance for slit material of

width less than 600 mm, tolerance C of JIS G 3198 shall be applied.

PROTECTED BY COPYRIGHT

4

G 3131: 2010

Table 4 Tolerances on thickness

Unit: mm.

‘Width

Tuickast Under 1200 | 1 200 or over to ] 1.500 or over to | 1800 or over to

and excl. 1500 | and excl. 1 800 | and incl. 2 300

Under 1.60 v0.14 10.15 0.16") =

1.60 or over to and exel. 2.00 10.16 2017 =0.18 10.21”

2.00 or over to and exel. 2.50 2047 0.19 =0.21 30.25"

2.50 or over to and exel. 3.15, 10.19 1021 0.24 10.26

8.15 or over to and exel. 4.00 10.21 1028 =0.26 10.27

4.00 or over to and exel. 5.00 20.24 1026 =0.28 40.29

5.00 or over to and excl, 6.00 1026 1028 £0.29) 1081

£6.00 oF over to and exel. 8.00 10.29 10.30 oat 10.35

£8.00 or over to and exel. 10.0 20.82 20.88 = 0.84 0.40

10.0 or over to and exel. 12.5 $0.35 +036 =0.37 3045

12.5 or over to and enel. 14.0, 1038 1039 0.40) 10.50

Tolerances on thickness shall be as follows.

— The thickness shall be measured at any point on the steel sheet and strip not less than 20 mm

from a side edge (width direction end part). For the steel sheet and strip under 40 mm in

width, measurement shall be made at the mid-width thereof.

— The values specified in table 4 shall not be applied to the irregular portions of both ends of

the steel strip.

— The tolerance on thickness of the steel sheet which is not manufactured from the steel strip

may be agreed between the purchaser and the manufacturer.

Notes *! The value shall be applied to the steel sheet and strip under 1600 mm in width

© ‘The value shall be applied to the steel sheet and strip under 2.000 mm in width.

As for the squareness of cut-edge steel sheet, the following method using the diagonal

line may be applied. However, when question arises, JIS G 3193 shall be applied

Obtain 1/2 of absolute value of the difference of two diagonal lines of steel sheet

(X, and X2 in figure 1) (|X;~X2|/2), and this value shall not exceed 0.7 % of measured

width W.

L (Length)

width)

W (Measured

Figure 1 Squareness of steel sheet (using diagonal line)

PROTECTED BY COPYRIGHT

5

G 3181: 2010

7 Oiling

Oiling shall be as follows unless otherwise specified.

a) Steel sheets and strips desealed by acid pickling or shot-blasting shall be oiled.

b) Steel sheets and strips as rolled shall not be oiled,

8 Appearance

The appearance of the steel sheet and strip shall be in accordance with clause 7 of

JIS G 3193. The repair by welding shall not be performed.

If necessary, the treatment of irregular portions of steel strip may be agreed be-

tween the manufacturer and the purchaser.

9 Tests

9.1 Chemical analysis

9.1.1 General requirements and sampling method for chemical analysis

‘The chemical composition of the steel sheet and strip shall be determined by heat

analysis, and the general requirements for chemical analysis and the sampling method

shall be as specified in clause 8 of JIS G 0404.

9.1.2 Analysis method

‘The method for chemical analysis shall be in accordance with JIS G 0320.

9.2 Mechanical test

9.2.1 General requirements for mechanical test

‘The general requirements for mechanical testing shall be in accordance with the

specifications in clause 7 and clause 9 of JIS G 0404. With this respect, the sampling

method shall conform to Class A of 7.6 of JIS G 0404, and the number of test pieces

and the sampling position shall be as follows:

a) Number of test pieces The number of test pieces shall be as follows.

1) For steel strip and cut lengths thereof One test piece each for tensile and

bend tests shall be taken from each test lot of the same heat rolled to the same

thickness. When the mass of one test lot exceeds 50 t, however, two sets of test

pieces shall be taken from the lot.

2) For steel sheet (excluding cut lengths thereof) One test piece each for ten-

sile and bend tests shall be taken from each test lot of the same heat where the

maximum thickness of the steel sheet is within twice the minimum thickness

thereof. When the mass of one test lot exceeds 50 t, however, two sets of test

pieces shall be taken from the lot.

b) Sampling position and direction of tensile test and bend test pieces The

test piece shall be taken parallel to the rolling direction and the centre of the test

piece shall be at a quarter-width from a side edge. When it is infeasible to allow

the centre of the test piece to be at a quarter-width from a side edge, the sam-

pling should be performed as close to the aforementioned position as possible.

PROTECTED BY COPYRIGHT

6

G 3131: 2010

9.2.2 Tensile test

‘The tensile test shall be carried out as given in the following:

a) No.5 test piece specified in JIS Z 2201 shall be used.

b) The test method shall be as specified in JIS Z 2241

9.2.3 Bend test

‘The bend test shall be carried out as given in the following:

a) No. 3 test piece specified in JIS Z 2248 shall be used.

b)_ The test method shall be as specified in JIS Z 2248.

‘The bend test may be omitted®). However, when especially designated by the pur-

chaser, the test shall be performed.

‘The test_may be omitted by the decision of the manufacturer, but

bendability shail be s

10 Inspection and reinspection

10.1 Inspection

‘The inspection shall be carried out as follows.

a) The general requirements for inspection shall be as specified in JIS G 0404.

b) The chemical composition shall conform to the requirements specified in clause 4.

©) ‘The mechanical properties shall conform to the requirements specified in clause 5.

d) The shape, dimensions and mass shall conform to the requirements specified in

clause 6.

e) The appearance shall conform to the requirements specified in clause 8.

10.2 Re-inspection

‘The steel sheet and strip having failed to meet the requirements of the mechani-

cal test may be subjected to a retest for final acceptance according to the specifications

of 9.8 in JIS G 0404.

11 Marking

The steel sheet and strip having passed the inspection shall be marked with the

following details for each bundle by suitable means. The steel sheets which are not

bundled shall be marked for each sheet.

a) Symbol of grade

b) Heat number or inspection number

©) Dimensions

4) The number of sheets for each bundle or mass

e) Manufacturer's name or its abbreviation

PROTECTED BY COPYRIGHT

7

3181: 2010

12 Items to be confirmed at the time of order

To specify the requirement items specified in this Standard suitably, the following

information should be added to the specified items at the time of contract.

a) Necessary or not of pickling or shot-blast for descaling,

b) Type of edge (mill edge or eut edge),

©) Necessary or not of skin-pass,

d) Usage, method of forming (if possible) and so on.

18 Report

When requested by the purchaser in advance, the manufacturer shall submit an

inspection document including the test results. In the case, the report shall be in ac-

cordance with the requirements of clause 13 in JIS G 0404. The type of inspection

document shall be, unless otherwise specified, 2.3 or 3.1.B in table 1 of JIS G 0415.

PROTECTED BY COPYRIGHT

LOU

UHDIIKdOO KA GAL!

Annex JA (informative)

Comparison table between JIS and corresponding International Standard

JIS G 8181:2010 Hot-rolied mild steel plates, sheet and strip

ISO 3573:2008 Hot-rolled carbon steel sheet of commercial and

drawing qualities

(D) Requirements in JIS (11) Inter- | (11) Requirements in Inter [ (IV) Classification and details of (V) Justification for the

national | national Standard technical deviation between JIS and | technical deviation and

Standard the International Standard by clause | futture measures

number

No. and title | Contes Clause | Content Classifi- | Detail of technical

of clause No. cation by | deviation

clause

1 Scope __| Hot-rolled mild steel 1 Hot-rolled mild plates, | Alteration JIS has changed “for

plates, sheets and strips sheets and strips in- drawing” to “for process-

intended for general tended for general fab- ing’

fabricating purposes ricating purposes and

and processing are drawing are specified

specified,

2 Normative

references:

3 Grade and | Four types of grades are 1 Four types of grades are | Identical

symbols specified, specified,

4 Chemical | Chemical composition of 52 | Chemical composition of | Deletion | Four elements are almost | JIS has deleted regula-

composition | four elements C, Mn, P, four elements C, Mn, P, corresponding to JIS by | tions of the alloy ele-

S are specified. S and additional alloy the ISO standard, ‘ment.

elements are specified.

Te)

10g: Te

3

() Requirements in JIS (ID) Inter- | (111) Requirements in Inter IV) Classification and details of (V) Justification for the

national | national Standard technical deviation between JIS and | technical deviation and

Standard the International Standard by clause | future measures

number

No. and title | Content Clause | Content. Classifi- | Detail of technical

of clause No. cation by | deviation

clause

5 Mechani- | Tensile strength, elon. 5.6 | Tensile strength and | Addition | In ISO, bendability was | Responding to the dele

cal proper

ties

gation and bendability

are specified

elongation are specified.

Alteration

deleted at the revision,

JIS and ISO differ in

tensile strength and

elongation. ISO specifies

ngth by the

upper limit, contrary to

the lower limit in JIS. It

was permitted in JIS to

apply the upper limit

values of ISO according

to the age

ement.

tion of bendability in

ISO, bendability was

specified in JIS to be

applied when required

JIS and ISO also differ

in the shape of the test

piece and the tensile

direction,

ape,

di

mass and

tolerances

he shape, dimensions,

mass and their toler-

ances are specified

6

Tolerane

‘of the shape

and dimensions are

specified,

tis required to specify

the inside diameter, the

maximum outside diam-

eter and the maximum

mass of the coil

Alteration

Deletion

Inds

are greater or smaller

compared to those in

180,

In JIS there is no d

scription of the inside

diameter and the maxi

mum outside diameter of

the coil

some tolerances

“JIS and 180 differ in the

tolerances.

‘The inside diameter and

the maximum outside

diameter of the coil are

the matters of contract

and deleted

7 Oiling

8 Appear-

‘The oiling is specified.

"The appearance is

specified,

44

The oiling is specified.

The appearance is

specified,

Tdentical

Addition

TnJIS treatment of

irregular portions is,

specified,

ele D

102: Te

6

LLOUd

3

(1) Requirements in JIS (U1) Inter- | (11) Requirements in Inter- | (IV) Classification and details of (V) Justification for the

national | national Standard technical deviation between JIS and | technical deviation and

Standard the International Standard by clause | future measures

number

No. and title | Content Clause | Content Classifi- | Detail of technical

of clause No. cation by | deviation

clause

9 Tests Analytical test, tensile 53 | Analytical test is speci- | Identical

test and bend test are fied

specified. 7 Sampling frequeney of | Identical

the tensile test piece is

specified,

8 rnsile test method is | Alteration | The tensile direction is | Modification of the ten

specified, the rolling direction in | sile direction will cause

JIS and perpendicular to | the confusion in the mar-

the rolling direction in| ket.

180.

10:1 Inspee- | Inspection is specified = |[- Addition | JIS specifies ins This is the unique con-

tion in one integrated clause, | figuration to JIS.

while ISO specifies it in

each clause,

102 Re Reinspection and the 9 Reinspection is speci- | Identical

inspection | judgement are specified. fied

10 | Judgement of the Identical

reinspection is speci

fied

11 Marking | Marking of five items is 14 | Marking of seven items [Deletion | In ISO, marking of the | In JIS, the number of

specified, is specified number of the standard _| the standard ean be re-

and the order number | placed by the symbol of

are specified in addition | grade. The order number

to five items in JTS. is a matter of contract

and is deleted,

12 Items to | Confirming items at the 15 [Information of 12 items [Deletion | InJIS, a part of items | InJIS, items related to

be confirmed

at the time

of order

time of ordering as four

items are specified

to be supplied by the

purchaser is specified

are deleted.

quality are specified

)

or

loz: Tete

LHDLIRdOD KA AHL!

(D) Requirements in JIS (U1) Inter- | (1) Requirements in Inter- IV) Classification and details of (V) Justification for the

national | national Standard technical deviation between JIS and | technical deviation and

Standard the International Standard by elause | future measures,

number

Content Clause | Content Classifi- | Detail of technical

No. cation by | deviation

clause

13 Report _ | The report is specified, = [Noitem Addition | In JIS, the report is For addition of the speci

specified, fication of the report,

proposal will be submit.

ted to 180,

= = a Terms and definitions | Deletion | In JIS, terms and defini- | Terms are defined in JIS

are specified. tions are deleted. G 0203,

= — 12 [Inspection observed by [Deletion | Inspection observed by | The products eovered by

the purchaser is speci the purchaser is deleted | this Standard are for

fied in JIS, general use and it is not

required.

Overall degree of correspondence between JIS and International Standard (SO 3573 :2008): MOD

NOTE 1 Symbols in sub-columns of classification by clause in the above table indicate as follows:

Identical: Identical in technical contents.

— Deletion: Deletes the specification item(s) or content(s) of International Standard.

— Addition: Adds the specification item(s) or content(s) whieh are not included in International Standard,

— Alteration: Alters the specification content(s) which are included in International Standard

NOTE 2 Symbol in column of overall degree of correspondence betwe

—_MOD: Modifies International Standard

1 JIS and International Standard in the above table indicates as follows:

16D

O02 : Te

1

Errata for JIS (English edition) axe printed in Standardization 2nd Quality Control, published

monthly by the Japanese Standards Association, and also provided to subseribers of JIS (Bng

lish edition) in Monehly Informacion

Errata will be provided upon request, please contact

Standards Publishing Department, Japanese Standards Association

Akasaka, Minatoku, Tokyo, 107°8440 JAPAN

FAN, 03-3583-0462

PROTECTED BY COPYRIGHT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Perhitungan Kekuatan Curtain Wall Proyek Bandara Sultan Hasanuddin Makasar PDFDocument17 pagesPerhitungan Kekuatan Curtain Wall Proyek Bandara Sultan Hasanuddin Makasar PDFBoby PrimatamaNo ratings yet

- Brosur Stahlton Shell Beams Brochure FINALDocument7 pagesBrosur Stahlton Shell Beams Brochure FINALBoby PrimatamaNo ratings yet

- Laporan Perhitungan Struktur Gardu Listrik Fix R1Document62 pagesLaporan Perhitungan Struktur Gardu Listrik Fix R1Boby PrimatamaNo ratings yet

- Brosur LionBrick Kap 10m3 Type A 1Document1 pageBrosur LionBrick Kap 10m3 Type A 1Boby PrimatamaNo ratings yet

- Mulion Dan TransomDocument10 pagesMulion Dan TransomBoby PrimatamaNo ratings yet

- Perencanaan Konstruksi Beton BertulangDocument36 pagesPerencanaan Konstruksi Beton BertulangBoby PrimatamaNo ratings yet

- MK 006 Metode Pilecap Dan Tiebeam 1Document4 pagesMK 006 Metode Pilecap Dan Tiebeam 1Boby PrimatamaNo ratings yet

- Table: Base Reactions Outputcase Casetype Globalfx Globalfy Globalfz Globalmx GlobalmyDocument6 pagesTable: Base Reactions Outputcase Casetype Globalfx Globalfy Globalfz Globalmx GlobalmyBoby PrimatamaNo ratings yet

- Metode Kerja SupercordekDocument9 pagesMetode Kerja SupercordekBoby PrimatamaNo ratings yet

- Desain Base PlateDocument3 pagesDesain Base PlateBoby PrimatamaNo ratings yet

- MATERI HABIBIE RAZAK - Sertifikasi Insinyur Profesional Indonesia, CPD & Sertifikasi Internasional - Balikpapan 190317Document51 pagesMATERI HABIBIE RAZAK - Sertifikasi Insinyur Profesional Indonesia, CPD & Sertifikasi Internasional - Balikpapan 190317Boby PrimatamaNo ratings yet

- Metode Bekisting Kolom 6m Sekali CorDocument1 pageMetode Bekisting Kolom 6m Sekali CorBoby Primatama100% (1)

- Kamus Bahasa Jepang Untuk Orang BodohDocument20 pagesKamus Bahasa Jepang Untuk Orang BodohAjeng RospratamiNo ratings yet

- Metode Perbaikan BetonDocument12 pagesMetode Perbaikan BetonBoby PrimatamaNo ratings yet

- Bab V Pendimensian Batang PDFDocument42 pagesBab V Pendimensian Batang PDFBoby PrimatamaNo ratings yet

- MULTIVER-Spontaneous Glass Breakage-Causes Solution enDocument7 pagesMULTIVER-Spontaneous Glass Breakage-Causes Solution enBoby PrimatamaNo ratings yet

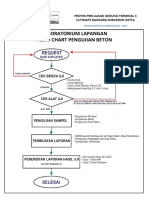

- Flowchart Uji Beton LabDocument1 pageFlowchart Uji Beton LabBoby PrimatamaNo ratings yet