Professional Documents

Culture Documents

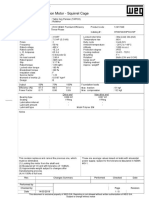

Series 381 TZK

Uploaded by

boroumandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 381 TZK

Uploaded by

boroumandCopyright:

Available Formats

S E R I E S “E L A S T O F A N”

excellent aerodynamics of the profile is also

beneficial for the noise emission.

ILMED is proud to introduce the new series

“Elastofan” model 36, specifically designed for

aircoolers, process coolers, wet cooling towers,

engine drive applications, radiators and other

industrial applications.

Resilient blade mounting : advantages

• Drastically reduces the blade bending

moment in both the vertical and the

horizontal plane.

• Drastically reduces the stresses in the

blade and in the hub.

Introduction • Drastically reduces the vibration

The new series “elastofan” is characterized by the transmitted by the blades to the hub.

elastic-damped connection of the blades to the • Drastically reduces the effect of high-

hub (resilient mounting system) : an elastomeric speed wind, severe wind gusts, and other

bushing provides the required elasticity and extreme operating conditions.

damping. The result is a light and very sturdy fan, • Reduces the mechanical noise

100% free from any resonance potential problem. transmitted by the structure through the

blades to the air.

• Eliminates resonant frequencies. Variable

frequency drives (VFD) can be operated

in the full speed. Range, from 0% to

100% : there are no critical speeds to be

avoided.

The blades utilize a new profile especially • The API Standard 661 requirement

designed for low Reynolds Numbers applications, (resonant frequency of the fan not to be

typical of fan blades operations. This profile within 20% of the blade pass frequency)

provides not only higher lift without the need of a is always satisfied.

flap, but also higher efficiency in the whole range • The elastomer provides both mechanical

of the operating aerodynamic angle of attack. The and acoustic damping for smoother and

quieter operation.

• The resilient mount is a fail-safe system: aluminum pivot. The pivot is connected to the hub

in case of failure of the elastomer the disk through an aluminium extruded spacer.

blade remains attached to the hub. The

fan can work in this condition for a period

of time sufficient for the anomaly to be

detected and corrected.

Fan components

Hub

The advanced elastomer chemical composition,

The hub assembly consists of a flanged hub boss

the elastomer pre-compression and the oversizing

bolted to the hub disk to which the fan blades are

of the elastomeric bushing guarantee the

connected. The hub boss accommodates a split

maximum strength and the longest fatigue life

taper bushing (Browning or equivalent); can also

even at high temperature.

be provided with cylindrical bore upon customer

request. Both hub boss and disk are made of high

quality carbon steel, preserved by cataphoresis.

Seal disk

Different hub sizes are available depending on the

A seal disk of proper diameter is provided to

number of blades and on the drive shaft diameter.

prevent back flow of air through the fan center to

the benefit of the fan efficiency. The seal disk is

made of steel and preserved by cataphoresis.

Resilient blade mount

Blade shaft

The resilient blade mount consists of :

The blade shaft connects the resilient mount to

_ an extruded aluminium clevis that

the blade profile. It is located in the clevis housing

accommodates the elastomeric bushing and

and is bolted to the clevis through a pillow block;

incorporates the blade shaft attachment and the

can be easily rotated to set the blade angle. It is

blade angle variation system.

provided with an innovative blade retention safety

_ an elastomeric bushing pressed into the housing

system. The blade shaft is made of high quality

of the clevis and provided with an extruded

carbon steel and is preserved by cataphoresis.

Blade profile Conservation of steel components : cataphoresis.

The blade profile, bolted to the blade shaft, is

Manually adjustable blade angle at stand still

made of high strength extruded aluminum alloy.

Blades are individually balanced to a master blade

Vertical spars stiffen the hollow profile and the

: they can be installed in any position on the hub

result is a light and very stiff

and are interchangeable between fans of same

structure

diameter.

Both clockwise and counter clockwise

configurations are available, in standard and

reverse configurations. Fans can be operated

either horizontally or vertically.

.

The blade is provided with caps at both ends; the

caps are made of plastic suitable to operate at

high temperature. The tip caps can be offered

either in standard configuration or in “winglet”

configuration to allow better performance and

efficiency and to reduce the noise emission by

about 2 dB.

Hardware

Standard : carbon steel, electro-galvanized

Optional : stainless steel

Fan specification

Series model no. of blades fan diameter

ELASTOFAN 36 3 to 10 5 to 18 ft

Maximum tip speed :

12000 to 14000 ft/min (61 to 71 m/sec)

depending on fan diameter

Operating temperature

Standard -20 to +120 °C (-4 to +248°F)

Upon request -46 to +120 °C (-50 to +248°F)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Roland Service Manual Vs540iDocument296 pagesRoland Service Manual Vs540iJohn Swanson100% (1)

- 320B Excavator Hydraulic SystemDocument4 pages320B Excavator Hydraulic Systemjohn ayengah100% (2)

- K To 12 Smaw Welding Learning ModuleDocument11 pagesK To 12 Smaw Welding Learning ModuleJha Zel89% (9)

- Hydraulic LiftDocument15 pagesHydraulic LiftKartik YadavNo ratings yet

- Blind Flange Thickness CalculationDocument1 pageBlind Flange Thickness CalculationNopparutNo ratings yet

- CROSSRAIL Lea Crossing Bridge Wind Load CalculationsDocument12 pagesCROSSRAIL Lea Crossing Bridge Wind Load Calculationsbdjokovic8396No ratings yet

- API Standard 560: Fired Heaters For General Refinery ServiceDocument1 pageAPI Standard 560: Fired Heaters For General Refinery ServiceJogn SmitNo ratings yet

- How to Operate a Clausing-Colchester 15 in Lathe ManualDocument67 pagesHow to Operate a Clausing-Colchester 15 in Lathe ManualMike100% (2)

- Chimney ReferenceDocument1 pageChimney ReferenceNarasimman NarayananNo ratings yet

- Anoptimal Design For Axial-Flow Fan Blade - Theorical and Experimental StudiesDocument10 pagesAnoptimal Design For Axial-Flow Fan Blade - Theorical and Experimental StudiesweNo ratings yet

- Parallel Compressor Load SharingDocument2 pagesParallel Compressor Load Sharingejzuppelli8036No ratings yet

- Quebec Drivers HandbookDocument58 pagesQuebec Drivers Handbookdrivershandbooks88% (34)

- APPENDIX 2 11.003. Power Plant Documents PDFDocument164 pagesAPPENDIX 2 11.003. Power Plant Documents PDFGilberto YoshidaNo ratings yet

- Hydraulic System Schematic (Transmission) : Operación de SistemasDocument3 pagesHydraulic System Schematic (Transmission) : Operación de Sistemascristian chuquicondor torresNo ratings yet

- DX55W Control Valve KVSE72Document34 pagesDX55W Control Valve KVSE72Zawminhtun100% (1)

- Bi 1 7Document1 pageBi 1 7boroumandNo ratings yet

- Turbo 142 2 021004Document14 pagesTurbo 142 2 021004boroumandNo ratings yet

- Fan Design Software Specialist Sydney AustraliaDocument1 pageFan Design Software Specialist Sydney AustraliaboroumandNo ratings yet

- PTEC-ICEM CFD 14.5 Tutorial Files PDFDocument326 pagesPTEC-ICEM CFD 14.5 Tutorial Files PDFDragos PastravNo ratings yet

- Types of Rotary Screw CompressorsDocument4 pagesTypes of Rotary Screw CompressorsboroumandNo ratings yet

- 20180929043537761Document6 pages20180929043537761boroumandNo ratings yet

- s11630 010 0001 0 PDFDocument6 pagess11630 010 0001 0 PDFboroumandNo ratings yet

- Screw CompressorDocument8 pagesScrew CompressorboroumandNo ratings yet

- AdvancedMachineryDynamicscoursecontent PDFDocument2 pagesAdvancedMachineryDynamicscoursecontent PDFboroumandNo ratings yet

- Module 8 Speed 2019 PDFDocument39 pagesModule 8 Speed 2019 PDFboroumandNo ratings yet

- Module 8 Speed 2019 PDFDocument39 pagesModule 8 Speed 2019 PDFboroumandNo ratings yet

- Project Standards and Specifications Flow Measurment Rev01Document10 pagesProject Standards and Specifications Flow Measurment Rev01sairam2234No ratings yet

- s11630 010 0001 0 PDFDocument6 pagess11630 010 0001 0 PDFboroumandNo ratings yet

- General Characteristics: SMR 80 SMR 100 SMR 150 SMR 200 SMR 250 SMR 300 SMR 350Document1 pageGeneral Characteristics: SMR 80 SMR 100 SMR 150 SMR 200 SMR 250 SMR 300 SMR 350boroumandNo ratings yet

- SKF bearing grease selection chart guideDocument1 pageSKF bearing grease selection chart guideAhmedNo ratings yet

- 12417048Document6 pages12417048boroumandNo ratings yet

- 2017 Quick Purchasing Guide Tap SelectionDocument11 pages2017 Quick Purchasing Guide Tap SelectionboroumandNo ratings yet

- Prospective Passenger Vehicle DriverDocument32 pagesProspective Passenger Vehicle DriverMd. Manik HossainNo ratings yet

- Ni-284-1 Lot#6 036108-10 - WDocument1 pageNi-284-1 Lot#6 036108-10 - WboroumandNo ratings yet

- Mat Conv GuideDocument2 pagesMat Conv GuideOvidiu FatiNo ratings yet

- PaperDocument10 pagesPaperboroumandNo ratings yet

- LetDocument5 pagesLetboroumandNo ratings yet

- Stool Culture: BackgroundDocument1 pageStool Culture: BackgroundboroumandNo ratings yet

- Configurer Le Proxy Windows 10 AnglaisDocument2 pagesConfigurer Le Proxy Windows 10 AnglaisboroumandNo ratings yet

- 0002Document1 page0002boroumandNo ratings yet

- Samba Tower pipe insulation documentDocument7 pagesSamba Tower pipe insulation documentAamer Abdul MajeedNo ratings yet

- Francis Urbines Litostroj Power Product SheetDocument2 pagesFrancis Urbines Litostroj Power Product SheetНенад АритоновиќNo ratings yet

- RUKO 1 - Sheet - ARS-14 - Denah Pola Lantai - LT 1Document1 pageRUKO 1 - Sheet - ARS-14 - Denah Pola Lantai - LT 1Cindar TengikNo ratings yet

- Metode Pemboran Air TanahDocument25 pagesMetode Pemboran Air TanahDwi Dandy HNo ratings yet

- Design and Fabrication of Trenching Machine: Amal.M.S, Vimal Cherian Joseph Jose, Texo JoseDocument4 pagesDesign and Fabrication of Trenching Machine: Amal.M.S, Vimal Cherian Joseph Jose, Texo JoseSarath Philip Mathew VenkadathNo ratings yet

- Revent Store InventoryDocument1 pageRevent Store Inventorysabir hussainNo ratings yet

- Catalog 2013 (Eng)Document20 pagesCatalog 2013 (Eng)Maldwin MenorcaNo ratings yet

- BalancingmanDocument9 pagesBalancingmanapi-697931486No ratings yet

- Concrete S - A - G: Earth ChamberDocument4 pagesConcrete S - A - G: Earth ChamberSyahirul ErulNo ratings yet

- Jarvis: Model EBS - 1, - H and - HS Electric Beef Brisket, Horn and Hog Splitting SawsDocument12 pagesJarvis: Model EBS - 1, - H and - HS Electric Beef Brisket, Horn and Hog Splitting SawsLilian KuhnenNo ratings yet

- Kelly Valve: When Ordering Please SpecifyDocument8 pagesKelly Valve: When Ordering Please SpecifyAhmad Reza FarokhiNo ratings yet

- Products: Fire Fighting Security SystemsDocument24 pagesProducts: Fire Fighting Security SystemsTomislav PanovNo ratings yet

- Time Frame Pekerjaan Perbaikan DozerDocument9 pagesTime Frame Pekerjaan Perbaikan DozerZulkifli HaidarNo ratings yet

- Skillmech: Miscellaneous Suction (Emergency Gen.) Waste Oil Pressure SuctionDocument1 pageSkillmech: Miscellaneous Suction (Emergency Gen.) Waste Oil Pressure Suctionashier dave calulotNo ratings yet

- R Designs V150, V200 & V300: Type Vee-Ball Forward FlowDocument1 pageR Designs V150, V200 & V300: Type Vee-Ball Forward FlowmarsulexNo ratings yet

- Proposed House For MR Nadun: Structural DrawingsDocument22 pagesProposed House For MR Nadun: Structural DrawingsSamitha SoysaNo ratings yet

- Asme UvDocument2 pagesAsme UvkokoNo ratings yet

- ISAIME - Ario - UI - TIG Welding Speed-FinalDocument9 pagesISAIME - Ario - UI - TIG Welding Speed-FinalAgus WidyiantoNo ratings yet

- Spindle Speed MechanismsDocument4 pagesSpindle Speed MechanismsGomathi SankarNo ratings yet