Professional Documents

Culture Documents

9 Huntress 1934 Method of Synthesis

9 Huntress 1934 Method of Synthesis

Uploaded by

fermin.saOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 Huntress 1934 Method of Synthesis

9 Huntress 1934 Method of Synthesis

Uploaded by

fermin.saCopyright:

Available Formats

The OXIDATION of 3-AMINO-

PHTHALHYDRAZIDE ("LUMINOL")

as a LECTURE DEMONSTRATION

of CHEMILUMINESCENCE*

ERNEST H. HUNTRESS, LESTER N. STANLEY, AND ALMON S. PARKER

Attention is directed to the most striking instance of compound^,^ notably (1) pchlorophenylmagnesium

chemiluminescence whuh appears to have b m observed bromide; (2) the Trautz-Schorigin6 oxidation of pyro-

and to the extraordinary advantages which the reaction gallol-formalin solutions in potassium carbonate by

possesses mer the conventional cases. A simple eco- means of 30% hydrogen peroxide (perbydrol); (3)

nomical two-stage synthesis of 3-aminophthulhydrazide is the oxidation%y means of hydrogen peroxide or halo-

described which readily gives excellent yields of +re gens of alcoholic alkaline solutions of lophine (2,4,5-tri-

product. Specifcc directions are given for demonstration phenylimidawle) or amarine (4,5-dihydro-2,4,5-tri-

of its brilliant chemiluminescence i n dilute aqueous al- phenylimidazole). It will readily be noted that even

kaline oxidizing agents. these reactions involve certain difficulties. For ex-

ample, some of the materials are unpleasant to handle

(e. g., chloropicrin is a lachrymator, Grignard reagents

are unstable and involve the use of ether solutions, 30%

T HE STUDY of chemical reactions in which visible

light is evolved a t ordinary or low temperatures

has largely been left to physics, physical .chemis-

hydrogen peroxide is dangerous to handle, unstable,

expensive, and not always readily accessible, amarine

and lophine not very readily preparable, and their

try, or biochemistry. Nevertheless, countless in-

oxidation in strong alcoholic alkali is not well suited

stances of such development of visible radiation are on

to convenient demonstration).

record and many (if not most) involve organic com-

pounds. However, in the vast majority of cases either In contrast to these difficulties the production of

the amount of light evolved is not impressive, or the chemiluminescent effects by means of the oxidation of

reaction is brought about only under inconvenient con- 3-aminophthalhydrazideposse& great advantage. The

ditions, or the substances involved are expensive or reaction is carried out in exceedingly dilute aqueous

difficultly accessible. Partly for these reasons general alkaline solution, it requires but the very mildest and

attention to the matter has been but occasional and the most easily accessible oxidants, it utilizes ordinary

most impressive and convenient illustration of the pharmaceutical (3%) hydrogen peroxide, and the

phenomenon appears to have been largely overlooked. essential reagent itself is naw readily obtainable.

Most chemiluminescent reactions are oxidations. Furthermore, the brilliance of tht effects which can be

Extensive rCsumCs of hundreds of inbvidual cases are produced far surpasses any of the other recorded cases.

already available.' Of the many instances of organic Dufford, Calvert, and Nightingale" state: "The

compounds of known structure given in these refer- [chemiluminescence from the] compound p-CICaHa-

ences there appears to be a small group which gives a MgBr is much brighter than any other so far found.

maximum of visible light. This group includes the Careful pyrometric measurements show that it is

following: (1) various reactions of Grignard com- brighter even than luciferm, except possibly for the

pounds, such as the Wedekindereaction between chloro- bright specks in the luciferin solution and therefore

piain and phenylmagnesium bromide in ether solu- probably the brightest case of chemiluminescence on

tion, the reaction of Grignard compounds with other record." We find, however, that the brilliance of light

nitro compound^,^ or the oxidation of various Grignard which is produced under optimum conditions from

the oxidation of "lnminol" renders that from this

* Contribution No. 101 from the Research Laboratory of Or- Grignard reagent dim by comparison.

ganic Chemistry, Massachusetts Institute of Technology, Cam-

bridge, Massachusetts. ' (a) EVANSAND DUPPORD,3. Am. C h m . Soc., 45, 278-85

(a) Truurz, Z. wiss. Phot., 2 , 217-23 (1904); (b) Z. phyn'k. (1923); (b) DUPFORD, CALVERT, AND NIGR~NGALE, ibid., 45,

Chcm., 53, 1-111 (1905); (c) HARVEY, 3. Biol. Chem., 31, 311-6 2058-72 (1923); (c) D~FFORD, NIGHTINGALE, AND CALVERT,

,---.,.

(1417) ibid., 47,95-102 (1925); ( d ) EVANSAND DIEPENHORST, ibid., 48,

( a ) WEDEKIND, Ber. deut. physik. Ges., 4 , 417 (1906); ( 5 ) 715-23 (1926).

Phyrik. Z . , 7 , 805 (1906); (6) Z . nuiss. Phot., 5, 29 (1907); ( d ) (a) TRAuTz, Z. Elcktrochem., 10, 593-6 (1904); (b) TRAWTZ

HECZKO, Chem.-Ztg.. 35, 199 (1911). AND SCHORIGIN, Z. tom. Phot., 3, 121-30 (1905-6).

(a) GILMAN, MCGLUMPW, AND FOTEERGILL, RCC.trav. chim., "(a) RADZISZEWSKI, Ber., 10, 70-5 (1877); (b) BHATNAGAR

49, 526-31 (1930); ( b ) 49, 726-8 (1930). AND MATHUR. Z. physik. Chem., 159, 454-8 (1932).

1 2

3-Aminophthalhydrazide (I), also referred to in the (Cf. Refs. 7, 8) and begins directly with 3-nitrophthalic

literature as 5-amino-1.4-dihydroxyphthalazine,*was acid.'3 It avoids the excess of expensive hydrazine re-

first reported by Schmitz' as the result of a long syn- quired by early investigators and uses only that amount

thesis starting with triethyl hemimellitate. Later actually needed for the heterocyclic ring. By sub-

stituting sulfide as the reducing agent it avoids the

0 ONa 0 difficulties attendant upon the separation of an am-

photeric reduction product from a stannous solution.

The new process is readily adaptable to the preparation

of large amounts of material, if desired, and gives ex-

cellent yields of pure product. The yield of 3-nitro-

phthalhydrazide is quantitative, its reduction to

aminophthalhydrazide is nearly so.

The PreNration of 3-Nitrophthu1hydrazide.-Bogert

and Boroschek,14who first reported this compound, and

Curtius and Sempers obtained it by heating the mono also Radulescu and AlexalZbevaporated the liquid ob-

ethyl ester of 3-nitrophthalic acid for ten hours with tained by adding to one mol of 3-nitrophthalic acid in

excess hot hydrazine hydrate. In 1928 Albrechtg alcohol one mol of hydrazine (in the form of hydrazine

drew attention to the chemiluminescence of the ma- hydrate solution), and heated the residue a t 250"

terial and carried out some spectral measurements. for a long time to form the cyclic hydrazide. We prefer

However, the actual method of preparation of his ma- the following method which avoids the use of hydrazine

terial was not given in the above reference but only hydrate, is more rapid, and gives quantitative yields.

in the dissertation10 itself. Starting from 3-nitro- Solid hydrazine sulfate (130 g. or 1 mol) and crys-

phthalic acid it passed successively through the diam- tallized sodium acetate (272 g. or 2 mols) are dis-

monium salt, 3-nitrophthalimide, 3-aminophthalimide, solved in 400 ml. of hot water and the clear solution

and finally 3-aminophthalhydrazide. No yields are added to solid 3-nitrophthalic acid (211 g. or 1 mol)

recorded in any of these steps and our attempts to use contained in an 8" porcelain evaporating dish. The

the method gave very unsatisfactory results. In 1929 latter is placed upon a tripod and evaporated as rapidly

Harvey," obtaining his material from Albrecht, ex- as possible over a free flame with constant stirring with

amined the chemiluminescence observed during elec- a flat porcelain spatula to avoid bumping or decom-

trolysis. During the progress of our present work a position. This operation requires about 1.5 hours and

statement1% appeared noting that 3-nitrophthalhy- is best conducted a t a hood in order to facilitate evapo-

drazide could be reduced to the amino compound by ration and to remove the acetic acid vapors. The

means of hydrogen sulfide, hut no details were given residual dry solid is removed from.the dish, ground to

nor yields stated. Apart from the above references no a fine powder, placed in a wide-mouthed flask or beaker,

further mention of 3-aminophthalhydrazide could be and heated for a t least three hours a t a temperature

found in the chemical literature. of 160 * lo0 in a suitable oil bath. During this opera-

tion the solid should frequently be stirred and if there is

THE PREPARATION OF 3-AMINOPHTHALHYDRAZIDE'

any tendency toward caking in the earlier part of the

baking it may be necessary to remove and powder the

We report here a method of preparation which avoids material before continuing. It is advfsable to measure

all the weaknesses of preceding procedures. The the temperature in the heated powder rather than

reaction involves first the preparation of 3-nitrophthal- externally and care must be taken not to overheat the

hydrazide and its subsequent reduction to 3-amino- mass. The escape of steam may also be facilitated by

phthalhydrazide by means of ammonium sulfide. The passing a gentle stream of air through the flask.

method avoids difficultly accessible starting materials When the heating is finished, remove the solid,

powder, and extract twice with 350 ml. of hot water to

* In the interest of assigning to this compound a simpler and remove sodium sulfate. The residual solid is then

more euphonious name we prefer to csll the material "luminol."

This associates it with the idea of luminescence and denotes its dried a t 105' to constant weight: yield, 206 g. 3-nitro-

enolic character. We do not regard as important the possible phthalhydrazide (99.5% theoretical). The product so

objection that the name might be confused with the hypnotic

"luminal." obtained is free from sulfate, melts 297' to 300' u.c.,

1 (a) SCHMITZ,Dissertation, Heidelberg. 1902; (6) Cf. and is sufficiently pure for reduction without further

Cun'crus AND Scmrrz, J. prakt. Chem., 91,46.97 (1915). treatment.f

CURTIUS AND SEMPER, Ber., 46,1162-71 (1913).

ALBREWIT, Z.physik. Chenz.. 136, 321-30 (1928). Reduction of 3-Nitrophthulhydrazide to 3-Amino-

' 0 ALBREWIT.Dissert~tion.Friedrich-Wilhelms Univ.. Berlin, -

1928. '3 "Organic syntheses," John Wiley & Sons, Iuc.. New York

"HARVEY,J . Phys. Chem.. 33, 145G9 (1929). City, 1927, Vol. 7, pp. 70-2.

1% (a) RnoaEscu am ALEXA.2. phy{k. C k m . , B8, 382-94 I4 BOGERT AND BOROSMEK, J. Am. Chem. SOC..23,750 (1901).

(1930); (b)Bull. soc. chim. RomSnia, 12, 140-63 (1930). $NOTE: Although BOGERT AND BonoscHEKU state that 3-

t Experimenters who may not care to prepare this substance nitrophthalhydrazide melts with decomposition at about 320"

we have consistently observed values close to 300' u s . FLADU-

for themselves can now obtain it from the Synthetic Organic

Chemicals Department of the Eastman Kodak Company, Roch- ~ s s c uAND ALEXAI~ give m. p. 310-311' but do not state

ester, N. Y. whether corrected or not.

In some runs all the sulfur remains in the excess sulfide

solution and a yield of very pure "luminol," as high as

64.5%, has been obtained directly a t this point.

The filtrate from this primary precipitate is then

acidified with a slight excess of glacial acetic acid and

the resultant precipitate of mixed sulfur and "luminol"

is filtered with suction, washed with water, and dried.

In order to free the aminophthalhydrazide from sulfur,

the crude mixture is stirred up with that amount of 5%

aqueous sodium hydroxide solution which would just

correspond to the assumption that the dry solid cou-

tained no sulfur. After stirring and very slight warm-

ing the solution is filtered from undissolved sulfur,

cooled to 0°, and stirred, and scratched. Presently

precipitation of the mono-sodium salt of 3-amino-

phthalhydrazide (II or Ila)+begins and increases for

some time. Finally, the solid is filtered with suction,

pressed as dry as possible on the filter, then washed

sparingly with dry alcohol or ether. It may then be

dried in the air, if it is to be preserved as the sodium salt.

If, however, it is desired to reconvert the substance to

"luminol" the original solid is not washed with alcohol

but is redissolved in water, and reprecipitated by adding

a slight excess of glacial acetic acid. The voluminous

flocculent precipitate is again filtered with suction,

washed free from sodium acetate with water, and dried.

The product so obtained is free from sulfur and melts a t

319-320' u.c.:

The color of the final 3-aminophthalhydrazide ap-

peared to vary according to the mode of precipitation

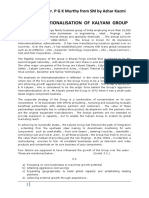

LIQUIDLIGHT from almost white to quite deep yellow.

This photograph was taken in an otherwise absolutely dark Anal. Calcd. for CsH,N30z: C, 54.22, H, 3.98, N,

room by means of the light given off during the oxidation of

"lnminol" according to the method described in the accom- 23.73%; Found, C, 54.20,54.31, H, 4.48,4.62, N, 24.20,

panying article. 24.02; Neut. Equiv., Calcd. 177. Found 175.

phthalhydrazide ("Luminol").-The crude 3 - nitro- DEMONSTRATION OF CHEMILUMINESCENCE OF O-

phthalhydrazide (e. g., 192.5 g. or 0.93 mol) is then AMINOPHTHALHYDRAZIDE

gradually added in small increments to 1 liter of 6 N

ammonium sulfide solution.*, Vigorous spontaneous The chemiluminescence is produced by treatment

reduction occurs and the flask may r+equire considerable of a dilute aqueous alkaline solution of "luminol"

external cooling. After all the solid nitrohydrazide with (both) hydrogen peroxide and another oxidizing

has been added the resultant solution or suspension is agent. Strong radiation is not produced in the absence

kept at the boiling point for an hour while additional of any one of the four components, although "luminol"

hydrogen sulfide is passed into the mixture. During and dilute hydrogen peroxide give a very faint glow

the reduction the original nitrohydrazide finally com- even without the other .oxidizing agent. The re-

pletely dissolves; later, however, the precipitation of action occurs only in alkaline solution, and its intensity

the resultant "luminol" begins, and these two processes and duration vary with the alkalinity. Up to a cer-

may sometimes overlap in such a way that there is al- tain point the amount of light evolved increases with

ways some solid present in the flask. After the discon- increase in alkali concentration. The mode of evolu-

tinuance of the hydrogen sulfide treatment the solution tion of light appears to vary considerably with the na-

is boiled for an hour more to complete the reaction and ture of the oxidant apparently being most satisfactory

then allowed to stand until cold. The resultant yellow with very mild oxidizing agents. For demonstration

precipitate of mixed sulfur and "luminol" is filtered purposes we much prefer the use of potassium ferri-

with suction, thoroughly washed with water, and dried. -

- t Samples of the sodium salt (dried to constant weight at

* Nore: Thissolution is that available as a stock item in most 105:) were analyzed by igniting in porcelain cmcibles, and con-

laboratories. It may be prepared by passing hydrogen sulfide vertmg the ash to sodium sulfate. Calcd. for CaHsN10sNa:

gas into 200 ml. of 15 N ammonium hydroxide (sp. gr. 0.90) in a Na, 11.55%. Found: 11.77, 11.99.

bottle immersed in running water or ice water until the gas is no f The melting points reported in this paper were taken with a

longer absorbed; 200 ml. more of conc. ammonium hydroxide 360" melting-point thermometer used in a copper block of the

is then added and the solution diluted to one liter. Berl and Kuhlman type. Cf.Ber.. 60, 811-4 (1927).

cyanide as the oxidant, and the exyution of the Glass Company, No. 985, 12" diameter by 12" high),

experiment in any of the following ways. add about 14 liters of water and float in this water a

1 . Flask Method.-Provide two &liter, long-necked piece of ice of convenient size (e. g., a piece 8-10" on a

flat-bottomed flasks and arrange to mix their contents side). Have available a stout stirrer made from a t

by pouring through a large glass funnel into a 6-liter, least 10-mm. diameter glass rod. Provide also two

flat-bottomed, long-necked flask. In one of the small flat-bottomed flasks (A and B) to contain the

smaller flasks dissolve 0.2 g. of "luminol" in 20 ml. of reactants. In flask A dissolve 1.0 g. of "luminol" in

5% sodium hydroxide and dilute to 2 liters with water. 100 ml. of 5% sodium hydroxide. In flask B place a

In the other small flask dissolve 0.5 g crystals of potas- solution of 2.5 g. of potassium ferricyanide crystals in

sium ferricyanide in water, add 20 ml. of ordinary 3% 100 ml. of 3% hydrogen peroxide. After the room is

hydrogen peroxide, and dilute to 2 liters with water. completely darkened pour these two solutions together

When hoth solutions are ready for use, grasp one flask over the surface of the cake of ice in such a manner

in each hand, have the room completely darkened, and that they mix in more or less concentrated form before

then pour the contents of the two smaller flasks simul- being diluted with the surrounding water. The pur-

taneously through the funnel into the large flask. Re- pose of the ice is not to cool the mixture but merely to

action begins as soon as the liquids mix in the funnel convince the audience that the reaction can proceed a t

and continues in the large flask for many minutes. 0°C. After the reaction mixture has diffused into the

After the initial development of light has begun, swirl main body of solution, stir the jar contents vigorously

the contents of the large flask and add a small quantity and add additional solid potassium ferricyanide (crys-

of solid crystals of potassium ferricyanide. The bril- tal or powder) or alkali, or hoth as desired.

liance increases considerably and can be still further 3. Spray Method.-A third novel way in which the

improved by gradual addition of further amounts of reaction can be made to produce beautiful eEects in-

5% sodium hydroxide solution. The concentrations volves the mixing of sprays of the separate stock solu-

here recommended are such that the light intensity first tions. For this purpose we have found most satis-

produced is fairly small, for the increased brilliance factory a commercial device widely used in textile mill

which is produced by the further addition of oxidant humidifying systems under the name N-Type Humidi-

and of alkali is very beautiful. Enough light is pro- fiers."? Two of these vest-pocket size units are held in

duced in the experiment so that as soon as it is under suitable clamps so inclined that the resultant sprays

way the demonstrator can easily locate his materials intersect some distance above the lecture table: by

in the otherwise darkened room. Since the evolution means of rubber tube connections the humidifiers are

of light continues for some minutes it is perfectly connected to a source of compressed air.$ By means of a

feasible to allow the larger flask to circulate through suitable short length of mbber tubing each unit is fur-

the audience to demonstrate that no appreciable heat ther arranged to aspirate up the corresponding solution

effect is developed. from a stock bottle placed belowit. With a little care

In order to show the dependence of light production to be certain that the spray guns are operating a t

upon the alkalinity of the solution, swirl the luminescent equal rates, and variation of the stock solutions ac-

contents of the large flask and slowly pour in dilute (6 N ) cording to the desired effect, the resultant mist may vary

hydrochloric acid until light evolution stops. If then from a barely perceptible luminous cloud to an ex-

the solution be immediately made alkaline again with ceedingly brilliant fountain reminiscent of a pyro-

the 5% alkali the luminescent reaction recommences technical display. In using this method the alkali

and continues until either the "luminol" & the oxidant concentration must be adjusted to a point where it does

is exhausted. Another way of demonstrating this not annoy the audience.

same point is to use in flask A, not the alkaline solution 4. The Cloth Method.-The very simplest and often

of "luminol," but simply a water solution of 0.25 g. of most effectiveexperiment is merely to soak an ordinary

the "luminol" sodium salt. (See above.) Under white laboratory towel in a literpf 0.1% luminol solu-

these circumstances no significant luminescence occurs tion containing 5 to 10 cc. of 5% sodium hydroxide

on mixing until after free alkali has also been supplied. and 5 to 10 cc. of 3% hydrogen peroxide, wring out

2. The Jar Method.-For demonstration to large most of the excess liquid, and then pour directly on the

audiences the following variant of the experiment may towel 2.5% potassium ferricyanide solution. The

be employed. Provide a large pyrex jar (e. g., Corning towel then glows like a live coal and on further wring-

-.

'These experiments were included in a demonstration of iue vields liquid drops which elow like fire.

chemilumine&ence shown at the Society of Arts Popular Science

Lecture on Fehruaty 15, 1931, and also at a meeting of the

Northeastern Section of the American Chemical &kty held t These can be obtained from the Parks-Cramer Company of

at the Massachusetts Institute of Technology on April 29, 1933. Boston. Mass.

Photographs of some of the effects obtained were printed in the f NOTE: If a compressed air tap is not available it is possible

Technology Rmiew, 35, 282 (May, 1933), by whose permission to utilize a commercial tank of oxygen or nitrogen, provided that

they are here reproduced. a suitable reducing valve is attached to it far regulation.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Austin Custom Brass MouthpiecesDocument4 pagesAustin Custom Brass MouthpiecesÍtalo R. H. FerroNo ratings yet

- Basic CalculusDocument324 pagesBasic CalculusOrley G Fadriquel73% (11)

- Trade Test Prep PlumbingDocument2 pagesTrade Test Prep PlumbingChikondi KanamaNo ratings yet

- US Botanical Gardens Greenhouse Manual PDFDocument76 pagesUS Botanical Gardens Greenhouse Manual PDFLinda Mirelez-Huca100% (1)

- Management Accountants. Classify Each of The End-Of-Year Games (A-G) As (I) AcceptableDocument3 pagesManagement Accountants. Classify Each of The End-Of-Year Games (A-G) As (I) AcceptableRhea OraaNo ratings yet

- Soft Starter Panel Data SheetDocument4 pagesSoft Starter Panel Data Sheetjay PrakashNo ratings yet

- Camless EnginesDocument4 pagesCamless EnginesKavya M BhatNo ratings yet

- Manitou MT 14 18 ENDocument16 pagesManitou MT 14 18 ENIonut MoiseNo ratings yet

- Case THE INTERNATIONALISATION OF KALYANI GROUP Module 2Document2 pagesCase THE INTERNATIONALISATION OF KALYANI GROUP Module 2vijay50% (2)

- NitaiDocument622 pagesNitaiNitaiChand DasNo ratings yet

- Wonderware Intouch Compact Edition: Paul EdwardsDocument22 pagesWonderware Intouch Compact Edition: Paul EdwardsNurdeny PribadiNo ratings yet

- Arizona State Funds Book-Sources and UsesDocument726 pagesArizona State Funds Book-Sources and UsesBarbara EspinosaNo ratings yet

- KS2 - 2000 - Mathematics - Test ADocument20 pagesKS2 - 2000 - Mathematics - Test Ahenry_g84No ratings yet

- Research Paper On Voice TechnologyDocument8 pagesResearch Paper On Voice Technologyafnhgssontbxkd100% (1)

- Raft Cards and Student Centered TechnologyDocument13 pagesRaft Cards and Student Centered Technologyapi-269476681No ratings yet

- Confined Space Safety ChecklistDocument2 pagesConfined Space Safety ChecklistOul-kr Oul-krNo ratings yet

- It's Just A MovieDocument10 pagesIt's Just A MoviepicilohatNo ratings yet

- 4BE0 01 Rms BengaliDocument13 pages4BE0 01 Rms BengaliJohn HopkinsNo ratings yet

- 8051 Microcontroller Book PDFDocument26 pages8051 Microcontroller Book PDFswati pasiNo ratings yet

- Aco TD DWG BasementDocument73 pagesAco TD DWG Basementloc khaNo ratings yet

- Environmetal Science Ste 7 Quarter 1 Module 1 2Document7 pagesEnvironmetal Science Ste 7 Quarter 1 Module 1 2LA SamonteNo ratings yet

- Dokumen - Tips - Test Report Iecen 60 335 2 64 Part 2 64 Particular 1 of 109 Test Report IssuedDocument109 pagesDokumen - Tips - Test Report Iecen 60 335 2 64 Part 2 64 Particular 1 of 109 Test Report IssuedLamber LiNo ratings yet

- Chesner, C. A., & Rose, W. I. (1984) - Geochemistry and Evolution of The Fuego Volcanic Complex, GuatemalaDocument20 pagesChesner, C. A., & Rose, W. I. (1984) - Geochemistry and Evolution of The Fuego Volcanic Complex, GuatemalaMaferVázquezBautistaNo ratings yet

- Speed and Delay Study:introductionDocument8 pagesSpeed and Delay Study:introductionYashita SinghNo ratings yet

- 07 5123 06 Zigbee Cluster Library SpecificationDocument869 pages07 5123 06 Zigbee Cluster Library SpecificationMarcelo do ValleNo ratings yet

- Tecco System: Ruvolum Workshop - Armin RodunerDocument95 pagesTecco System: Ruvolum Workshop - Armin RodunerNam TrinhNo ratings yet

- REM 182 - 142 - Quiz 3 Subdivision DevelopmentDocument6 pagesREM 182 - 142 - Quiz 3 Subdivision DevelopmentRichard Villaverde100% (1)

- Mosfets Ic Basics Gate Problems Part II 001Document22 pagesMosfets Ic Basics Gate Problems Part II 001ayush guptaNo ratings yet

- Data Driven Fault DetectionDocument12 pagesData Driven Fault DetectionRita AppiahNo ratings yet

- Chapter 1 OutlineDocument3 pagesChapter 1 OutlineConi ChanNo ratings yet