Professional Documents

Culture Documents

Thermal Defect Analysis On Transformer Using A RLC PDF

Uploaded by

abu faizOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Defect Analysis On Transformer Using A RLC PDF

Uploaded by

abu faizCopyright:

Available Formats

Circuits and Systems, 2013, 4, 49-57

http://dx.doi.org/10.4236/cs.2013.41009 Published Online January 2013 (http://www.scirp.org/journal/cs)

Thermal Defect Analysis on Transformer Using a RLC

Network and Thermography

Geoffrey O. Asiegbu¹, Ahmed M. A. Haidar², Kamarul Hawari1

1

Faculty of Electrical and Electronics Engineering, University Malaysia Pahang, Kuantan, Malaysia

2

School of Electrical, Computer and Telecommunications Engineering, University of Wollongong, Wollongong, Australia

Email: geoffasi@yahoo.com

Received August 2, 2012; revised September 2, 2012; accepted September 10, 2012

ABSTRACT

Electrical transformers are vital components found virtually in most power-operated equipments. These transformers

spontaneously radiate heat in both operation and steady-state mode. Should this thermal radiation inherent in trans-

formers rises above allowable threshold a reduction in efficiency of operation occurs. In addition, this could cause other

components in the system to malfunction. The aim of this work is to detect the remote causes of this undesirable ther-

mal rise in transformers such as oil distribution transformers and ways to control this prevailing thermal problem. Oil

transformers consist of these components: windings usually made of copper or aluminum conductor, the core normally

made of silicon steel, the heat radiators, and the dielectric materials such as transformer oil, cellulose insulators and

other peripherals. The Resistor-Inductor-Capacitor Thermal Network (RLCTN) model at architectural level identifies

with these components to have ensemble operational mode as oil transformer. The Inductor represents the windings, the

Resistor representing the core and the Capacitor represents the dielectrics. Thermography of transformer under various

loading conditions was analyzed base on Infrared thermal gradient. Mathematical, experimental, and simulation results

gotten through RLCTN with respect to time and thermal image analysis proved that the capacitance of the dielectric is

inversely proportional to the thermal rise.

Keywords: Thermal Radiation; RLC Thermal Network; Thermography; Defect Analysis

1. Introduction great setback on production. So, causes of abnormal

thermal rise have to be addressed without hesitation.

Sustainability is the intermediary that runs between

Hence, RLCTN model is one of the appropriate measures

manufacturers of electrical equipments and her end-users.

taken to ensure equipment durability.

For sustainability to achieve its desired goal, electrical

Until date, many researchers have been battling with

power facilities should be able to satisfy the demands of

heat management in electrical equipments, which are a

the users. These does not mean that faults cannot occur in

vital phenomenon affecting equipments performance,

equipments at any given time, however, certain electrical

faults can be avoided while causes of the rest can be mi- sustainability and overall system efficiency. Generally,

nimized if attention to thermal effect is considered with increasing current I 2 R that generates undesirable ther-

utmost importance. In order to throttle thermal variations mal consequence in electrical equipments mainly occur

in transformers within a safe-steady-state, such current due to high current, and in some situations in the form of

dependent equipments also known as thermal producers free convection during thermal variations in the internal

should be monitored and assisted to function efficiently and external surfaces of the current conducting parts un-

within their life span. The aim of using the Resis- der different electrical loads and environment conditions

tor-Inductor-Capacitor Thermal Network (RLCTN) is to [2]. In many manufacturing operations, electrical power

track equipments exceeding thermal rise as early as pos- systems have been the fundamental pillars whose contri-

sible by examining effects of thermal capacitance and butions cannot be overemphasized; adherence to IEEE

thermal resistance on oil transformers. Secondly, to de- thermal evaluation regulations [3] will create an enabling

velop a mathematical model that helps in the study of environment for electrical facilities to function maxi-

thermal characteristics of oil distribution transformer mally.

components. Nearly every component gets hot before it Obviously, most system faults were discovered when

fails [1]. Therefore, abnormal thermal rise of even minor thermal variation significantly deviates from its normal

piece of component could result to sudden failure and thermal value(s). This can be figured out using delta T

Copyright © 2013 SciRes. CS

50 G. O. ASIEGBU ET AL.

criteria (∆T) [4], which are of two folds first: The thermal lightly scrutinizing appropriate electrical equipment in

value of equipment without thermal fault considered as order to pinpoint defective components and make ambi-

reference point is compared with other ensemble equip- ent temperatures evaluations of the power distribution

ment having similar load and similar environment condi- system. Should there be any thermal anomalies untimely

tion [5]. Next is where thermal variation (∆T) of electri- detected and uncorrected, such can be potentially haz-

cal equipment is compared between equipment and its ardous both to the equipment and to the user resulting to

ambient temperatures [6,7]. In RLCTN, various thermal system shutdown or failure [15].

nodes will be examined and analyzed with respect to This work presents a heat management system using

time until stability is maintained at certain thermal thre- RLCTN algorithm for pre-fault analysis of transformers

shold value. The eagerness that lead to the RLCTN re- and other similar electrical equipments under various

search came as a result of backdrops of some previous operating conditions. It was also targeted such that, the

researches [8-11] on electrical defect detection where gap between system components and thermal defect

critical sustaining issues where neither properly ad- monitoring against breakdown of system itself that defi-

dressed nor attended at all. Thermal fault detection is one nitely affects production is timely bridged. Hence, pre-

issue and detection of remote cause of the thermal fault is vention is better than cure. The proposed work takes the

another, the latter thermal problem is the focus of this advantage of using simple components comprising resis-

paper. tors, inductors and capacitors electrically connected to

At architecture design level, RLCTN will contribute to model the thermal effect on distribution transformer

the development of mathematical algorithm to study the components such as windings, core, and dielectrics dur-

thermal characteristics of oil distribution transformers ing operation and steady state. This paper is organized as

base on the Resistance-Inductance-Capacitance network follows: Section 2 presents an overview of RLCTN

[12]. The thermal fault model for transformers includes equivalent network and real time dynamic thermal gra-

abnormal thermal gradient caused by failures of capaci- dient. RLCTN thermal gradient and frequency responds

tance of dielectric property in the form of transformer oil, analysis and nodal analysis as it applies to transformer

cellulose paper and other insulators. The second impact are explained in Sections 3 and 4. Section 5 is all about

is in showing the application of RLCTN as a base foun- validation results and discussion of the proposed model

dation for extensive projects. To achieve the desired re- while Section 6 concludes the work.

sult and bring the proposition of this work to a logical

conclusion, this model is implemented into a simulator to 2. RLCTN Equivalent Analysis

study the effect of thermal events on the design of abnor- The RLCTN analysis is derived from a simple RLC elec-

mal thermal detection mechanism in a soft-real-time en- trical network. Table 1 shows the equivalence of con-

vironment such as electrical power distribution substation. cepts of the thermal RLCTN and the electrical RLC net-

Common methods of fault localization are reviewed work. Taking current {I} to represent heat transfer rate

such as digital control and advanced signal analysis algo- H q usually, current sources are heat producers, Volt-

rithms-based; this concentrates on the incorporation of age {V} to represent Temperature Variation {T}, Resis-

digital control, communications, and intelligent algo- tance {R} represents the Thermal Resistance TR ,

rithms into power electronic devices such as direct-cur- transformer oil and other dielectrics accounts for Ther-

rent-to-direct-current converters and protective switch- mal capacitance TC which is the active heat absorber

gears. These, enables revolutionary changes in the way (storage) while the transformer radiators represents the

electrical power systems are designed, developed, con- passive heat absorber like heatsink. This analogy is pos-

figured, and integrated in aerospace vehicles and satel- sible because the same Equations apply in each model.

lites [13], an active “collaboration” among modular com- As an example: In Ohms law V = IR has an equivalent

ponents to improve performance and enable the use of thermal Equation as T H q TR .

common modules, thereby reducing costs was developed. A thermal resistance represents the difference in tem-

The performance improvement goals include active cur- perature necessary to transfer a certain amount of heat;

rent sharing, load efficiency optimization, and active the unit for thermal resistance is ˚C/Watt. Physical prop-

power quality control. Artificial Intelligence (AI) was erties such as composition of the components in the sys-

another method developed to monitor, predict and detect tem, shape, surface area and the volume of the compo-

faults at an early stage in a particular section of power nents have big impacts on this value. A heat sink is de-

system. Here the detector only takes external measure- signed as thermal radiators, is a passive heat absorber

ments from input and output of the power system that element that radiate heat to the ambient through the body

was simulated using Artificial Neural Networks equiva- of oil distribution transformer. This should have a mini-

lent circuit developed to predict and detect fault [14]. mal thermal resistance value so that it can transfer a sub-

Every electrical thermographic examination aimed at stantial amount of heat without requiring a large differ-

Copyright © 2013 SciRes. CS

G. O. ASIEGBU ET AL. 51

ence in temperature. Because of this, the air gap or space not new but an analytical algorithm that describes every

between the radiator fins, type of material and size are individual component with respect to the thermal char-

importantly considered. Capacitor in this thermal analy- acteristics of most current dependent or current sourcing

sis network plays the role of active heat absorber meas- equipment such as oil distribution transformer. In every

ured in Joule per degree centigrade, i.e., J/˚C. The ca- electrical distribution substation, there exists lots of heat

pacitance is a measure of the amount of thermal energy dissipating components comprising of instantaneous

that is stored or removed to increase or decrease the elements arranged for efficient generation of electric

thermal flow within the oil distribution transformer that power. RLCTN as the name implies is reasonably less

depends largely on the heat absorbent or storage capacity, cumbersome and less complexity due to small number of

type of materials such as oil viscosity, quality of cellu- components are used, which is quite imperative for on-

lous paper and conductor insulators, then volume and line computation and for prediction of future thermal

size of the oil container. The above analogy describes the variations at all levels. This thermal analysis incorporates

thermal properties as a system of linear differential equa- heat producers for example, transformer windings repre-

tions that will be detailed in the subsequent sections of sented as inductors; core represented as resistors and heat

this paper; a popular technique widely adopted in most absorbers such as transformer oil, cellulous insulators

circuitries, mainly in electrical and electronic engineering and other dielectric materials represented as capacitors.

designs. This very simple thermal RLCTN can analyze This thermal model analysis focuses on second-order

and predict the dynamic behavior of real-time oil distri- thermal networks, which are a set of component parame-

bution transformer as shown in Figure 1 [16]. ters that help to define the behaviors of individual com-

ponents of the system (oil transformer) consisting of re-

3. Thermal Gradient Analysis sistors, inductors and capacitors. By measuring the steps

RLCTN approach is used for instantaneous thermal and thermal behaviors, the heat transfer functions can be

analysis of electrical distribution substation transformer. determined. The ideology of RLCTN that depicts the

The idea of using RLCTN for analyzing thermal effect is thermal characteristics of oil transformer and its ambient

temperature is diagrammatically illustrated in Figure 2.

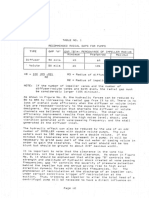

Table 1. Comparison of thermal network to electrical net- By varying the time and capacitance values, the circuit

work. bode plot can be generated. Referring to Figure 2,

RLCTN consist of a resistor of thermal resistance TR , a

Thermal Network Electrical Network

coil of thermal inductance TL , a capacitor of thermal ca-

Temperature T (˚C) Voltage V (Volt) pacitance TC and a temperature source TS connected

Heat Transfer Rate H q (Watt) Current I (Ampere) in series. If the quantity of heat absorbed by the capacitor

Thermal Resistance TR (˚C/Watt) Resistance R (Ohms) is TQ and the rate of heat flow in the thermal network is

Thermal Inductance TL Inductance L (Henry) H q , the temperatures across TR , TL , and TC are;

dH q TQ

Thermal Capacitance TC (J/˚C) Capacitance C (Coulomb/Volt) H qTR , TL and respectively.

dt TC

Temperature Source TS Voltage Source

Using thermal equivalent of Kirchhoff’s Law, the

Heat Source H S Current Source

temperature difference between any two points has to be

independent of the path used to travel between the two

points; the Equation (1) is of the form:

TQ

L t H qTL t

H qT t TS t (1)

TC

Assuming that TR , TL , TC and TS are known, this is

a differential equation in two unknown quantities, H q

and TQ . However, the two unknown quantities are

Figure 1. Dynamic thermal gradient of oil transformer. Figure 2. Ideology of RLCTN applied to transformer.

Copyright © 2013 SciRes. CS

52 G. O. ASIEGBU ET AL.

related by TR A Eo cos (9)

dTQ Now values of and A can be computed which is

H q t t

dt the thermal frequency and thermal gradient in the oil

so that, transformer analyzed in the RLCTN.

Dividing Equation (8) by (9),

TQ

TLTQ t TRTQ t t TS t

TC

(2)

tan

T L

2

1 TC tan 1 TL

1

(10)

TR TR TRTC

or, differentiating with respect to T Q and then substi-

tuting in

dTQ 4. RLCTN Nodal Analysis

t H q t , Applying nodal analysis to the RLCTN, this will make it

dt

possible to compute the heat flow rate at each junction of

Hq

TL H q t TR H q t t TS t (3) the RLCTN as a function of load and steady state, as-

TC suming a linear relationship between load and power

For an alternating temperature source TS , choosing dissipated with respect to time. From Figure 3, let t be

the initial time so that TS 0 0, TS t E0 sin t and time, Tmx, n,o temperatures at node m, n and o at instant x.

the differential equation is of the form, TRm ,n ,o the thermal resistance between nodes m, n, o, and

TCm ,n ,o the thermal capacitance at node m, n, o. H TxR

Hq m ,n ,o

TL H q t TR H q t t Eo sin t (4)

TC the heat flowing through thermal resistance TRm ,n ,o

Taking general solution of (4) by considering between node m, n, o at instant x, H Lx the heat flowing

H q P t A sin t with the thermal rise (A) and through thermal inductance TL at instant x and

the thermal gradient to be determined. That is, H TxC the heat flowing through thermal capacitance

m ,n ,o

guessing that the RLCTN responds to an oscillating ap- TCm ,n ,o at instant x and H m, n,o is heat flow rate across

plied temperature source with a heat flow that oscillates the nodes [18].

with the same rate [17]. For H q P t to be a solution, For each node except the reference node (G), the rate

temperature at node “P” (see Figure 2) has to be consid- at which heat is flowing H m, n,o in and out of each node is

ered in Equation (5) as, expressed as the algebraic sum of the heat flowing in or

out of a node equals zero. (By algebraic sum, it means

Hq P that the quantity of heat flowing into a node is to be con-

TL H q P t TR H q P t t Eo cos t (5)

TC sidered as the same quantity negative heat flowing out of

the node).

A sin t

TL 2 A sin t TR A cos t

TC HTx Cm ,n ,o

H TxC

m ,n ,o

H TxL H m, n ,o 0 (12)

Eo cos t Eo cos t

Equation (14) represents the conservation of heat energy,

(6) it means that heat can neither be created nor destroyed ra-

Hence, ther can be converted from one form to another in a node

1 2 hence heat cannot be bunched up. Expressing the heat at

TL A sin t TR A cos t junction m and the entire junction o in terms of the nodal

C

T (7)

temperature at each end of the junction using Ohm’s Law

Eo cos t Eo sin sin t

I V R thermal equivalent H q T TR where H q

Matching coefficients of sin t is the Heat flow rate, T is the temperature and TR is the

and cos t on the left and right hand sides yields, thermal resistance. Equation (13) is of the form,

1 Tmx, n ,o

TL A Eo sin

2

(8)

x

H qTR

(13)

m , n ,o TRm ,n ,o

TC

Eo

T 2 1 T

TR 2 2 A Eo A

2

(11)

L

L

2

TL 2 1 TC TR 2 2

Copyright © 2013 SciRes. CS

G. O. ASIEGBU ET AL. 53

fluke thermal camera is used to obtain the thermal effect

on the inductors and the corresponding thermal values

respectively. Other numerical values such as heat flow

rate and quantity of heat absorbed or removed by the

dielectric (capacitance C) components are read through

Figure 3. RLCTN nodal analysis. the external LCD on the module panel. The experimental

numerical values are tabulated in Tables 2-5 as well as

As well, the resultant temperature can be computed as the graphical bode plot in Figures 4-9. Often times, vali-

follows: dation procedures suffer inconsistencies in the model, in

the measurements, and in the assigned values of the con-

Tmx, n,o H Txm ,n ,o TRm ,n ,o (14) stants. The mathematical model suggests that the tem-

From Equations (13) and (14) above there is relation perature changes transiently. Corresponding bode plot

between the thermal resistance, temperature and heat are made on the collected TR , TL and TC temperatures

flow rate. In other words, the rate at which heat flows as well as the heat flow rate across nodes m, n, and o. It

downward out of node (m, n and o) for instance depends was observed that the graphs replicate what the mathe-

on the temperature difference Tmx, n,o and the corre- matical model suggests. After the adjustments of the

sponding thermal resistance TRm ,n ,o component at each thermal capacitance parameters, the system was moni-

tored closely with different loads, initial temperatures,

junction. Taking the first order differential Equation, the

heart flowing through thermal capacitors as well as their

respective dissipated temperatures are computed as

shown in Equation (15). Heat flowing through capacitor

at node m, n and o is,

dTCxm ,n ,o

H TxC TCm ,n ,o (15)

m ,n ,o dt

Equation (16) is a discrete variable from Equation (15).

Equation (16) will be used to compute the temperature at Figure 4. 3-phase electrical module of purely resistive, ca-

instant x + 1 from the temperature at instant x. Equation pacitive and inductive load.

(16) is constantly repeated for each interval ∆t, for all

nodes in the system, until a threshold is reached at an Table 2. A RLC experimental thermal analysis result.

instant. Equation (16) expresses the behavior and storage

Quantity of Heat (J)

capacity of the energy component (capacitor) used in this Time (s) TC (j/˚C)

R L C

model with respect to time, that is, the ability of the

component to absorb heat under load and steady state. 0 149.4 10 0 10

Equation (16) will be used to compute the temperature at 300 132.8 20 5 20

instant x + 1 from the temperature at instant (x). To com- 600 116.2 30 5 30

pute the temperature of a node, this process (Equation 900 83 40 5 40

(16)) is constantly repeated for each interval ∆t, for all nodes 1200 66.4 45 10 50

in the system, until a threshold is reached at an instant. 1500 49.8 55 10 55

1800 32.2 60 10 65

H TxC m ,n ,o t

Tmx,n1,o Tmx, n,o (16) 2100 16.6 60 10 65

TCm ,n ,o

Table 3. A LC experimental thermal analysis result.

5. Results and Discussion Heat Flow Rate (W)

Time (s) TC (j/˚C)

m n o

5.1. Experimental Validation

0 149.4 20 10 20

The experiment to validate this model involves the fol- 300 132.8 30 25 30

lowing: a 3-phase electrical module of purely resistive, 600 116.2 40 35 40

inductive and capacitive load with the following specifi-

900 83 55 55 55

cations: 7 heating elements rated value 2 KW each, 7

1200 66.4 65 60 65

inductors with rated value 2 KVA each and 7 capacitors

1500 49.8 80 80 80

with rated value 2 KVAR each (see Figure 4). There are

7 load steps ranging from step one to step seven, loads 1800 32.2 95 90 85

are increased after 300 seconds time interval. A Ti25 2100 16.6 95 90 85

Copyright © 2013 SciRes. CS

54 G. O. ASIEGBU ET AL.

Table 4. A LC experimental thermal analysis result.

Quantity of Heat (J)

Time (s) TC (j/˚C)

R L C

0 149.4 0 0 0

300 132.8 1 10 10

600 116.2 1 10 10

900 83 1 10 10

1200 66.4 2 20 20

1500 49.8 2 20 20

Figure 7. Effect of insufficient thermal resistance TR on

1800 32.2 2 20 20

2100 16.6 3 30 20 the winding L .

Table 5. A RL experimental thermal analysis result.

Quantity of Heat (J)

Time (s) TC (j/˚C)

R L C

0 149.4 20 30 3

300 132.8 40 60 5

600 116.2 90 60 8

900 83 80 120 11 Figure 8. Effect of thermal capacitance TC degradation on

1200 66.4 90 150 13

the winding L .

1500 49.8 110 180 15

1800 32.2 130 200 18

2100 16.6 130 200 21

Figure 5. Effect of heat absorbed by dielectric TC and

Figure 9. Thermal gradient with respect to time at

core TR on the winding.

TC 49.8 J C, TR 14 kC W and TL 14 .

The experimental values in Table 2 show the effect of

varying the thermal capacitance on the RLC components,

the higher thermal capacitance value the lower heat dis-

sipation on the RLCTN components and vice vase. More

explanation about this is graphically illustrated in Figure

5. This Figure shows the effect of quantity of heat ab-

sorbed by the dielectric (C) components on winding (L).

Figure 6. Heat flow rate across nodes m, n, o in the As defined in Section 2, the combination of thermal

RLCTN. components: the dielectric materials TC and the core

TR resulted in logarithmic drop of winding tempera-

different time intervals and different environment condi- ture TL . Hence, more heat is been radiated to the am-

tions. All the validations were much similar to the mathe- bient through the transformer radiator as illustrated in

matical model. Figure 2.

Copyright © 2013 SciRes. CS

G. O. ASIEGBU ET AL. 55

The values in Table 3 also show the effect of varying ties. In these scenarios, the time constant (i.e., the time it

thermal capacitance on the thermal nodes (m, n, and o) as takes for the transformer winding to achieve its highest

shown in Figure 3. This explains the higher thermal ca- stable temperature) changes from 0 second to 10 seconds

pacitance the slower heat flow rate to the node junc- as shown in Figures 9-11, respectively, even though the

tions and vice vase. In the case transformers, this reduces final temperature is the same. Statistically, in consumer

the risk of arc flash between phases or phase and neutral or industrial applications, a transformer temperature rise

[19-21]. Figure 6 replicates the nodal analysis method of about 40˚C to 50˚C may be acceptable, resulting in a

well defined in Section 3 and thermal equivalent of Kir- maximum internal temperature of about 100˚C (trans-

chhoff’s Law, stating that temperature difference be- formers’ temperature rise limit). However, it may be

tween any two points has to be independent of the path wiser to increase the capacitance as well as the core size

used to travel between the two points. Figure 6 graphi- in other to obtain reduced temperature rise and reduced

cally illustrates that the heat flow rate across the nodes losses for better power supply efficiency.

were linearly increased and stabilized at about 1750 sec

time interval.

In Table 4, it is seen that there was insufficient ther-

mal resistance TR which represent the transformer

core. Here it was observed that the transformer winding

(L) temperature increased to about 30˚C irrespective of

the high thermal capacitance value TC . Figure 7

shows the graphical illustration.

The experimental value in Table 5 shows the effect of

thermal capacitance TC degradation, which represents

the dielectrics of a transformer such as oil. Here also it is

seen that the transformer dielectric TC materials have

decreased in its heat absorption capacity causing the Figure 10. Thermal gradient with respect to time at

winding L temperature to rise so high up to 180˚C at TC 199.2 J C, TR 14 kC W and TL 14 .

1500 sec irrespective of the high thermal resistance value

TR . Figure 8 graphically show the effect of thermal ca-

pacitance TC degradation.

5.2. Verification of Simulation

The RLCTN was simulated with Multisim software in

order to verify the results of the experiment performed in

the power system laboratory using RLC electrical mod-

ule and thermal imager. Comparing Figures 9-11 it is

obvious that the lager the thermal capacitance slower the

transient response time that is, the rate at which tem-

perature rises is much slower and vice vase. With refer-

ence to the model in Figure 2, the effect of RLC pa- Figure 11. Thermal Gradient with respect to time at

rameters used are considered with three different values TC 348.6 J C, TR 14 kC W and TL 14 .

of thermal capacitance at constant thermal resistance and

thermal inductance values: 49.8 J/˚C, 199.2 J/˚C, 348.6

J/˚C and 14 k˚C/W and 14 TL for thermal capacitance

of transformer components for instance winding, core, oil

and radiator. For this simulation, there are set initial con-

ditions namely, the winding temperature = 38˚C, the core

surface temperature = 25˚C, the oil temperature = 15˚C

and radiator temperature = 8˚C. These mentioned schemes

shows the rate of temperature rise of an oil transformer

that means the higher the thermal capacitance the slower

the rate of temperature rise. In other words, the capacity

of the oil and radiators to absorb heat emitted by the

winding and core depends on the dielectric property such Figure 12. IRT color gradient of 7 transformers depicting

as volume, type of material, air space, and other proper-

Copyright © 2013 SciRes. CS

56 G. O. ASIEGBU ET AL.

gradual degradation of dielectric materials TC . http://www.ndted.org/EducationResources/CommunityCo

llege/Other%20Methods/IRT/IR_Applications.htm

[2] M. Matian, A. J. Marquis and N. P. Brandon, “Applica-

5.3. Thermal Gradient tion of Thermal Imaging to Validate a Heat Transfer

An analytical IRT thermography is characterized with a Model for Polymer Electrolyte Fuel Cells,” International

thermogram showing visible spectrum image, as indi- Journal of Hydrogen Energy, Vol. 35, No. 22, 2010, pp

12308-12316. doi:10.1016/j.ijhydene.2010.08.041

cated in Figure 12. As stated in Section 3, thermal im-

ages of pure inductive load were captured from real time [3] Infraspection Institute, “Standard for Infrared Inspection

of Electrical Systems & Rotating Equipment,” In: Infras-

operating transformers during validation process. This

pection Institute, Infrared Training and Infrared Certifi-

shows the effect of dielectric failure (thermal capacitance cation, Infraspection Institute, Burlington, 2008.

fault) on transformers. It was observed that as the ther-

[4] T. M. Lindquist, L. Bertling and R. Eriksson, “Estimation

mal capacitance value is decreasing, the transformer of Disconnectors Contact Condition for Modeling the Ef-

temperature increase and vice vase. The color gradients fect of Maintenance and Ageing,” Power Tech IEEE

of the IRT image in Figure 12 depict severity of dielec- Conference, St. Petersburg, 27-30 June 2005, pp. 1-7.

tric abnormal condition that is thermal capacitance fault. [5] N. Rada, G. Triplett, S. Graham and S. Kovaleski,

This also shows how suitable dielectric materials can “High-Speed Thermal Analysis of High Power Diode

improve efficiency transformers by removing substantial Arrays,” Solid-State Electronics ISDRS, Vol. 52, No. 10,

amount of heat emitted by winding and core to the am- 2008, pp. 1602-1605. doi:10.1016/j.sse.2008.06.009

bient through the transformer radiators. [6] Y. Cao, X. M. Gu and Q. Jin, “Infrared Technology in the

Fault Diagnosis of Substation Equipment,” China Inter-

6. Conclusion national Conference on Electricity Distribution, Guang-

zhou, 10-13 December 2008, pp. 1-6.

In this paper, a mathematical model capable of describe- [7] A. M. A. Haidar, G. O. Asiegbu, K. Hawari and F. A. F.

ing thermal characteristics of oil transformer was pre- Ibrahim, “Electrical Defect Detection in Thermal Image,”

sented. The model can adequately represent thermal cha- Advanced Materials Research, Vol. 433-440, 2012, pp

racterristics of each component in the transformer under 3366-3370.

load, steady state operation, and abnormality in the di- [8] Y. Cao, X. M. Gu and Qi Jin, “Infrared Technology in the

electric components such as the transformer oil, cellulose Fault Diagnosis of Substation Equipment,” Technical

insulator, and other peripherals. This model is simple, Session 1 Distribution Network Equipment, Shanghai

accurate and easy to be applied for measuring the thermal Electric Power Company Shanghai Branch Southern

Power, 200030, SI-17 CP1377, CICED2008.

impact on transformer. It provides an easy way of pre-

dicting transformer’s thermal status. So, it allows me- [9] J. G. Smith, B Venkoba Rao, V. Diwanji and S. Kamat,

“Fault Diagnosis—Solation of Malfunctions in Power

chanisms like thermal throttling and load balancing to be

Transformers,” Tata Consultancy Services Limited, Vol.

more dynamic, rather than merely reacting to the situa- 10, No. 1, 2009, pp. 1-12.

tion when the temperature reach a critical point. Fur-

[10] R. M. Button, “Soft-Fault Detection Technologies De-

thermore, the algorithm is efficient enough to allow dy- veloped for Electrical Power Systems,” 2005.

namic recomputation of the transformer temperatures http://powerweb.grc.nasa.gov/elecsys/

during operation. The captured thermal image brings the [11] Martin Technical Electrical Safety & Efficiency, “Infra-

qualitative thermal image analysis of the model showing red Thermography Inspection,” 2012.

the thermal effect of gradual degradation of dielectric http://www.martechnical.com/infrared_inspections/electri

materials been represented as thermal capacitance TC cal_infrared_inspection_service.php

in the RLCTN. Within the limits of experimental errors, [12] G. Biswas, R. Kapadia, D. Xu and W. Yu, “Combined

it was observed that the RLCTN model effectively ana- Qualitative—Quantitative Steady-State Diagnosis of Con-

lyzed the thermal degradation of transformer dielectrics tinuous-Valued Systems,” IEEE Transactions on Systems,

with respect to time. Also the mathematical results repli- Man, and Cybernetics—Part A: Systems and Humans,

cate the simulation and experimental results, as it showed Vol. 27, No. 2, 1997, pp. 167-185.

doi:10.1109/3468.554680

that thermal capacitance of dielectrics is inversely pro-

portional to the transformer thermal rise. [13] N. Radaa, G. Tripletta and S. Graham, “High-Speed

Thermal Analysis of High Power Diode Arrays,” Solid-

State Electronics ISDRS, College Park, 12-14 December

REFERENCES 2007.

[14] K. C. P. Wong, H. M. Ryan and J. Tindle, “Power System

[1] D. Susa, M. Lehtonen and H. Nordman, “Dynamic Ther-

Fault Prediction Using Artificial Neural Networks,” In-

mal Modeling of Distribution Transformers,” IEEE Trans-

ternational Conference on Neural Information Processing,

actions on Power Delivery, Vol. 20, No. 3, 2005, pp

Hong Kong, 24-27 September 1996, Article ID: 17762.

1919-1929.

Copyright © 2013 SciRes. CS

G. O. ASIEGBU ET AL. 57

[15] M. S. Jadin, S. Taib, S. Kabir and M. A. B. Yusof, “Im- [18] A. P. Ferreira, D. Mossé and J. C. Oh, “Thermal Faults

age Processing Methods for Evaluating Infrared Thermo- Modeling Using a RC Model with an Application to Web

graphic Image of Electrical Equipment,” Progress in Farms,” 19th Euromicro Conference on Real-Time Sys-

Electromagnetics Research Symposium Proceedings, tems (ECRTS 07), Pisa, 4-6 July 2007, pp. 113-124.

Marrakesh, 20-23 March 2011, p. 1299. [19] M. Holt, “Understand the National Electricity Codes,”

[16] Electric Power Engineering Center “Guide to Power Cengage Learning, Delmar, 2002.

Transformer Specification Issues,” University of Canter- [20] R. W. Hurst, “Electrical Safety and Arc Flash Hand-

bury, 2007. book,” Vol. 6, Electricity Forum, 2007.

http://www.scribd.com/doc/65031914/EPECentre-Guide- http://www.meisterintl.com/PDFs/Electrical-Safety-Arc-F

to-Transformer-Specification-Issues lash-Handbook-Vol-5.pdf

[17] K. Harwood, “Modeling a RLC Circuit’s Current with [21] T. Crnko and S. Dyrnes, “Arcing Flash/Blast Review with

Differential Equations,” 2011. Safety Suggestions for Design and Maintenance,” Pro-

http://home2.fvcc.edu/~dhicketh/DiffEqns/Spring11proje ceeding of the IEEE conference on Industry Technical,

cts/Kenny_Harwood/ACT7/KennyHarwoodFinalProject. Atlanta, 19-23 June 2000, pp. 118-126.

pdf

Copyright © 2013 SciRes. CS

You might also like

- Vane Pass FrequencyDocument2 pagesVane Pass Frequencyabu faizNo ratings yet

- Just Right, Just in Time: Condition-Based Maintenance (CBM)Document23 pagesJust Right, Just in Time: Condition-Based Maintenance (CBM)abu faizNo ratings yet

- L5Document1 pageL5abu faizNo ratings yet

- Asme Viii - MT Apendix 6Document2 pagesAsme Viii - MT Apendix 6abu faizNo ratings yet

- ADRE SXP and 408 DatasheetDocument33 pagesADRE SXP and 408 Datasheetabu faizNo ratings yet

- Iris Power TGA B Brochure of PD AnalyzerDocument6 pagesIris Power TGA B Brochure of PD Analyzerabu faizNo ratings yet

- Contoh Perhitungan Maintenance Factor - GER3620Document3 pagesContoh Perhitungan Maintenance Factor - GER3620abu faizNo ratings yet

- Magnetic Particle TestDocument17 pagesMagnetic Particle Testabu faizNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Physics STPM HEAT TRANSFERDocument23 pagesPhysics STPM HEAT TRANSFERRed Jagung Fish100% (3)

- NPN Silicon: Semiconductor Technical DataDocument5 pagesNPN Silicon: Semiconductor Technical DataDaniel y NinaNo ratings yet

- Efacec2009 CFD Core TypeDocument10 pagesEfacec2009 CFD Core TypedgtzagaNo ratings yet

- 2019 Recitation Chap 3 - RevDocument21 pages2019 Recitation Chap 3 - RevGullNo ratings yet

- STK416 130Document12 pagesSTK416 130Tecmicro Gonzalez100% (1)

- Application Note AN2263Document38 pagesApplication Note AN2263balu928No ratings yet

- Data SheetDocument4 pagesData SheetVibhor KumarNo ratings yet

- TLV 320 Aic 3268Document263 pagesTLV 320 Aic 3268Manu MathewNo ratings yet

- Ads 1298Document80 pagesAds 1298Juan GiraldoNo ratings yet

- Power Transformer DesignDocument13 pagesPower Transformer Designswiss22100% (1)

- Infineon IHW30N160R5 DataSheet v02 - 02 ENDocument15 pagesInfineon IHW30N160R5 DataSheet v02 - 02 ENuripdwNo ratings yet

- Lecture 2 ConductionDocument177 pagesLecture 2 ConductionqistinaNo ratings yet

- 2 - Conduction - One DimensionalDocument26 pages2 - Conduction - One DimensionalPratiksha GoreNo ratings yet

- LM 26480Document42 pagesLM 26480Laiq AhmedNo ratings yet

- LP8550 High-Efficiency LED Backlight Driver For Notebooks: 1 Features 3 DescriptionDocument49 pagesLP8550 High-Efficiency LED Backlight Driver For Notebooks: 1 Features 3 DescriptionLuis M GonzálezNo ratings yet

- Transmitacia TermicaDocument11 pagesTransmitacia TermicaJennipher LizbethNo ratings yet

- Ir 2111Document15 pagesIr 2111Miltongrimi GrimilNo ratings yet

- Data Sheet DiodaDocument2 pagesData Sheet Diodamuhammad bayuNo ratings yet

- IPS511/IPS511S: Fully Protected High Side Power Mosfet SwitchDocument13 pagesIPS511/IPS511S: Fully Protected High Side Power Mosfet SwitchWelleyNo ratings yet

- SPP11N60C2, SPB11N60C2 SPA11N60C2 Cool MOS™ Power TransistorDocument15 pagesSPP11N60C2, SPB11N60C2 SPA11N60C2 Cool MOS™ Power TransistorCarlos Ruiz DiazNo ratings yet

- HT QB A2Document27 pagesHT QB A2Shakil MaddilaNo ratings yet

- NTE2395 Mosfet N-CH, Enhancement Mode High Speed Switch: FeaturesDocument3 pagesNTE2395 Mosfet N-CH, Enhancement Mode High Speed Switch: FeaturesAbel RodriguezNo ratings yet

- RT8901 RichtekDocument10 pagesRT8901 RichtekHamza Abbasi AbbasiNo ratings yet

- 601 00526 PB137 Datasheet PDFDocument14 pages601 00526 PB137 Datasheet PDFfpacioni44No ratings yet

- Buk453 100aDocument7 pagesBuk453 100amicrowave440No ratings yet

- Auirgps4067d1 3 PDFDocument13 pagesAuirgps4067d1 3 PDFrocaoNo ratings yet

- Datasheet DiacDocument4 pagesDatasheet DiacOrlandoTobonNo ratings yet

- SiC-MOSFET and Si-IGBT-Based DC-DC Interleaved ConDocument21 pagesSiC-MOSFET and Si-IGBT-Based DC-DC Interleaved Conprabhu rachutiNo ratings yet

- Determination of Thermal and Physical PRDocument10 pagesDetermination of Thermal and Physical PRJoshuaNo ratings yet

- STMicroelectronics - L4931 Regulador de Voltaje Lineal 5V 250maDocument38 pagesSTMicroelectronics - L4931 Regulador de Voltaje Lineal 5V 250masxmxxlNo ratings yet