Professional Documents

Culture Documents

Nitofill WS60

Uploaded by

Mansoor AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitofill WS60

Uploaded by

Mansoor AliCopyright:

Available Formats

Fosroc Nitofill WS60 constructive solutions

Crack injection resin for stopping water flow

Uses

Properties

For injecting into cracks in concrete to temporarily stop the

The following properties were obtained at a temperature of

flow of moving water. When used in conjunction with

20ºC unless otherwise specified.

Nitofill UR63*† provides an effective system for crack sealing

in wet conditions. Test method Typical results

Pot life in the

Advantages absence of water : 6-8 hours @ 20ºC

3-4 hours @ 35ºC

Reacts with water to produce water resistant foam to

Reaction time with water : 5 - 30 seconds dependent

stop water

on temperature

Rapid acting, to produce water stop against moving Specific gravity : 1.14 ± 0.06

water under pressure Density of foam : 0.025 g/cc

Re-injectable with Nitofill UR63 to form permanent seal Viscosity : 2 - 3 poise @ 20ºC

Description Design criteria

Nitofill WS60 two part liquid polyurethane is mixed in the Nitofill WS60 is designed to stop the movement of water in

proportions supplied and injected into cracks in concrete. It cracked concrete. Crack widths of between 0.2 mm and

reacts with moving water to form a foam barrier. Used in 5 mm can be treated dependent on water flow. Nitofill WS60

conjunction with Nitofill UR63 it forms a permanent seal in is not designed as a permanent solution to water movement

cracked concrete. and must be used in conjunction with other means of

permanently stopping the water flow. Other injection resin

Specification clause systems such as Nitofill UR63, Nitofill EPLV*†, should be

considered. Consult the local Fosroc office for further details.

Water-stopping crack injection resin

The foam water-stopping crack injection resin shall be

Nitofill WS60, a two part foaming liquid polyurethane. When

mixed in the proportions supplied and injected into cracks in

concrete, the resin shall react with moving water to form a

foam water-stopping barrier.

The water-stopping injection resin shall have the following

properties; pot life, in the absence of water, 6 - 8 hours at

20ºC, 3 - 4 hours at 35ºC; reaction time with water, 5 - 30

seconds, dependent on temperature; viscosity of 2 - 3 poise,

at 20ºC; specific gravity of 1.14 ± 0.06; foam density of

0.025.

When used in conjunction with Nitofill UR63, a flexible two

part polyurethane injection resin, it shall form a permanent

seal in cracked concrete.

Nitofill WS60

Fosroc Nitofill WS60

Instructions for use Nitofill WS60 application

Nitofill WS60 can be applied using either injection packers Thoroughly mix the accelerator with the base resin. Take care

fixed into holes drilled directly into the crack or drilled diago- to exclude moisture as much as possible and place in an

nally from concrete adjacent to the crack or by the fixing of enclosed container after mixing. There will be a skin on the

injection nipples bonded to the surface using Nitomortar FC*†. surface but the liquid underneath will be satisfactory for use.

On wide cracks and where there is a large flow of water the Nitofill WS60 should be used with standard injection equip-

use of Renderoc Plug*†, a rapid setting cement based, ment having closed containers. When flowing water has

water-stopping mortar, should be considered for initial control stopped re-inject with Nitofill UR63 to give a permanent seal.

of water.

Making good

Preparation

Remove the packers or nipples. Make good any holes or

If water flow permits, clean the surface adjacent to the cracks voids with Nitomortar FC and allow to cure. The Nitomortar

and remove any dust, unsound or contaminated material, FC can be ground off or softened with a blow lamp and

plaster, oil, paint, grease, corrosion deposits or algae. peeled off. Do not allow to burn.

Fixing injection packers Cleaning

The injection packers inserted into pre-drilled holes shall be Nitofill WS60, Renderoc Plug and Nitomortar FC should be

fixed at intervals along the length of each crack. The distance removed from tools, equipment and mixers with Fosroc

between each packer will depend upon the width and depth of Solvent 102 immediately after use. Hardened material can

the crack. Spacing shall be close enough to ensure that the only be removed mechanically.

resin will penetrate along the crack to the next point of

injection. This will normally be between 200mm and 500mm. Limitations

Where practical the surface of the cracks between the Nitofill WS60 is only to be used for temporary water-stopping.

packers shall be sealed with a band of Nitomortar FC, 30 to It should not be relied upon for permanent sealing. At high

40 mm wide and 2 to 3 mm thick. Both sides of any cracks water pressures, on wide cracks Nitofill WS60 may not be

which go all the way through a wall or slab shall be sealed this capable of stopping water and the local Fosroc office should

way. Please note: Where water flow is severe the Nitomortar be consulted. If any doubts arise concerning temperature,

FC application can be omitted. application or substrate conditions, consult the local Fosroc

office.

In the case of a wall or slab which is cracked all the way

through, packers shall be located on both sides with those at

Technical support

the back placed at midway points between those at the front.

Fosroc offers a comprehensive technical support service to

Where applicable, the Nitomortar FC shall be allowed to cure

specifiers, end users and contractors. It is also able to offer

for 8 hours at 35°C. At low ambient temperatures (5°C to

on-site technical assistance, an AutoCAD facility and dedicat-

12°C) the curing time will be extended and the applicator shall

ed specification assistance in locations all over the world.

ensure that the surface sealant has adequately cured prior to

continuing.

One end of the injection hose shall be attached to the lowest

packer on vertical cracks or to either end of horizontal cracks.

Each crack shall be treated in a single, continuous operation.

Sufficient material shall, therefore, be made ready prior to the

commencement of the work.

Nitofill WS60 - Page 2 of 4

Fosroc Nitofill WS60

Estimating Renderoc Plug contains cement powder which when mixed

or becomes damp releases alkalis which can be harmful to

Supply

skin. During use avoid inhalation of dust and contact with skin

Nitofill WS60 : 1 litre, 20 litre packs

and eyes. Wear suitable protective clothing, gloves and eye/

Nitomortar FC : 1 and 4 litre packs

face protection.

Renderoc Plug : 10 kg bags

Fosroc Solvent 102 : 5 litre cans The use of barrier creams provide additional skin protection.

Should accidental skin contact occur, remove immediately

Storage with a resin removing cream followed by soap and water. Do

not use solvent. In case of contact with eyes, rinse immedi-

Shelf life

ately with plenty of clean water and seek medical advice. If

All products have a shelf life of 6 months at 20ºC if kept in a swallowed seek medical attention immediately - do not

dry store in the original, unopened containers. induce vomiting.

Storage conditions Fire

Store in dry conditions in the original, unopened containers. If Nitofill WS60, Nitomortar FC and Renderoc Plug are

stored at high temperatures and/or high humidity conditions non-flammable.

the shelf life may be reduced to 2 to 3 months. Avoid storage

Fosroc Solvent 102 is flammable. Keep away from sources of

of material under direct sunlight.

ignition. No smoking. In the event of fire extinguish with CO2

or foam. Do not use a water jet.

Precautions

Flash points

Health and safety

Fosroc Solvent 102 : 33ºC

Nitofill WS60 contains isocyanate. May cause sensitisation by

For further information, refer to the Product Material Safety

inhalation. Nitomortar FC, and Fosroc Solvent 102 should not

Data Sheet.

come in contact with skin or eyes, or be swallowed. During

use avoid contact with skin and eyes and inhalation of vapour.

Some people are sensitive to resins, hardeners and solvents.

Wear suitable protective clothing, gloves and eye/face protec-

tion. Use only in well ventilated areas, if working in confined

areas, suitable respiratory protective equipment must be used.

The use of barrier creams provide additional skin protection.

Should accidental skin contact occur, remove immediately with

a resin removing cream followed by soap and water. Do not

use solvent. In case of contact with eyes, rinse immediately

with plenty of clean water and seek medical advice. If swal-

lowed seek medical attention immediately - do not induce

vomiting.

Nitofill WS60 - Page 3 of 4

Fosroc Nitofill WS60

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

waterproofing membranes & waterstops

joint sealants & filler boards

cementitious & epoxy grouts

specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and refurbish-

ment of damaged concrete. Fosroc’s ‘Systematic Approach’

to concrete repair features the following :

hand-placed repair mortars

spray grade repair mortars

fluid micro-concretes

chemically resistant epoxy mortars

anti-carbonation/anti-chloride protective coatings

chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of

Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

United Arab Emirates Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

www.fosroc.com

UAE/0316/19/D

You might also like

- Stopping Water Flow with Nitofill WS60Document4 pagesStopping Water Flow with Nitofill WS60Vincent JavateNo ratings yet

- Nitofill WS60Document3 pagesNitofill WS60talatzahoorNo ratings yet

- Nitofill WS60: Uses PropertiesDocument4 pagesNitofill WS60: Uses PropertiesVenkata RaoNo ratings yet

- Nitofill WS60 : Crack Injection Resin For Stopping Water FlowDocument4 pagesNitofill WS60 : Crack Injection Resin For Stopping Water FlowmilanbrasinaNo ratings yet

- Flexible Crack Injection ResinDocument3 pagesFlexible Crack Injection ResinrayNo ratings yet

- Fosroc Nitofill UR63: Flexible Polyurethane Injection Resin SystemDocument4 pagesFosroc Nitofill UR63: Flexible Polyurethane Injection Resin SystemVincent JavateNo ratings yet

- FosrocNitofill UR63Document4 pagesFosrocNitofill UR63aahtagoNo ratings yet

- Nitofill UR63Document4 pagesNitofill UR63Mansoor AliNo ratings yet

- Nitofi LL UR63: Solvent Free, Two Part Polyurethane Resin For Sealing CracksDocument3 pagesNitofi LL UR63: Solvent Free, Two Part Polyurethane Resin For Sealing CracksFaisal FaizNo ratings yet

- Nitofill WS60Document3 pagesNitofill WS60Balasubramanian AnanthNo ratings yet

- Nitofill ws60Document4 pagesNitofill ws60pravi3434No ratings yet

- Nitofill UR63 : Flexible Polyurethane Injection Resin SystemDocument4 pagesNitofill UR63 : Flexible Polyurethane Injection Resin SystemmilanbrasinaNo ratings yet

- Tds Nitofill Pu 1f SeaDocument3 pagesTds Nitofill Pu 1f SeaSales PPINo ratings yet

- Nitofill Ur63 PDFDocument3 pagesNitofill Ur63 PDFtalatzahoorNo ratings yet

- Flexible polyurethane crack injection resinDocument4 pagesFlexible polyurethane crack injection resinpravi3434No ratings yet

- Nitofill WS60: Rapid Foaming and Setting Resin For Stopping Flow of Water Instructions For Use of Nitomortar PEDocument2 pagesNitofill WS60: Rapid Foaming and Setting Resin For Stopping Flow of Water Instructions For Use of Nitomortar PEaneesh kapaNo ratings yet

- Nitofill WS60Document2 pagesNitofill WS60aneesh kapaNo ratings yet

- Nitotile UwDocument2 pagesNitotile UwVincent JavateNo ratings yet

- Nitofill WS60: Constructive SolutionsDocument2 pagesNitofill WS60: Constructive SolutionsrayNo ratings yet

- Nitofill Ur63Document3 pagesNitofill Ur63Balasubramanian AnanthNo ratings yet

- Nitofill UR63: Solvent Free, Two Part Polyurethane Resin For Sealing Cracks Application InstructionsDocument2 pagesNitofill UR63: Solvent Free, Two Part Polyurethane Resin For Sealing Cracks Application Instructionsaneesh kapaNo ratings yet

- Elastomeric cement coating for water structuresDocument4 pagesElastomeric cement coating for water structuresade fauziNo ratings yet

- Nitofill EPLVDocument4 pagesNitofill EPLVSanthosh ParanjothiNo ratings yet

- Nitoflor Quartztop: Monolithic Surface Hardening Compound For Concrete Floors UsesDocument2 pagesNitoflor Quartztop: Monolithic Surface Hardening Compound For Concrete Floors UsestalatzahoorNo ratings yet

- Fosroc Nitoflor EU10: Constructive SolutionsDocument4 pagesFosroc Nitoflor EU10: Constructive SolutionsVincent JavateNo ratings yet

- Rapid Foaming Resin Stops Water FlowDocument2 pagesRapid Foaming Resin Stops Water FlowVenkata Raju KalidindiNo ratings yet

- Low viscosity epoxy crack injectionDocument4 pagesLow viscosity epoxy crack injectionaahtagoNo ratings yet

- Non-shrink underwater groutDocument4 pagesNon-shrink underwater grouttin aungtunNo ratings yet

- (PDS) Conbextra STDDocument3 pages(PDS) Conbextra STDPritha DasNo ratings yet

- Fosroc Nitocote CM210: Uses Standards ComplianceDocument4 pagesFosroc Nitocote CM210: Uses Standards ComplianceSaif SNo ratings yet

- Bituproof 40SDocument2 pagesBituproof 40Sosama mohNo ratings yet

- TDS Fosroc Nitocote CM210 India3Document4 pagesTDS Fosroc Nitocote CM210 India3reshmitapallaNo ratings yet

- Technical Mortar for Injection and GroutingDocument3 pagesTechnical Mortar for Injection and GroutingMuhsin KhanNo ratings yet

- PlastijointDocument4 pagesPlastijointm.elsanee.cubicNo ratings yet

- Nitocote SN511Document2 pagesNitocote SN511Gibbs PerNo ratings yet

- BituproofDocument2 pagesBituproofMohammed OmerNo ratings yet

- TDS Nitoflor Hardtop Saudi ArabiaDocument4 pagesTDS Nitoflor Hardtop Saudi ArabiaMohammed OmerNo ratings yet

- Fosroc Nitocote CM210: Flexible Cementitious Waterproof Coating Uses PropertiesDocument4 pagesFosroc Nitocote CM210: Flexible Cementitious Waterproof Coating Uses PropertiesPunyawich FungthongjaroenNo ratings yet

- Nitoflor EPU100Document4 pagesNitoflor EPU100Allan DerickNo ratings yet

- Nitomortar UA 0610 PDFDocument2 pagesNitomortar UA 0610 PDFsiranepNo ratings yet

- Fosroc NitDocument2 pagesFosroc NitItok VictorNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290shanon33No ratings yet

- Nitofill EPLVDocument4 pagesNitofill EPLVMansoor AliNo ratings yet

- Nitoproof 110 PDFDocument2 pagesNitoproof 110 PDFmilanbrasinaNo ratings yet

- Nitocote SN522: Constructive SolutionsDocument2 pagesNitocote SN522: Constructive Solutionsمحمد عزتNo ratings yet

- Masterflex 801 Asean 0509Document2 pagesMasterflex 801 Asean 0509Andri AjaNo ratings yet

- Nitoflor RoctopDocument2 pagesNitoflor Roctopm.elsanee.cubicNo ratings yet

- Nitotile EN : Constructive SolutionsDocument2 pagesNitotile EN : Constructive SolutionsmilanbrasinaNo ratings yet

- Fosroc Nitoproof 10: Constructive SolutionsDocument2 pagesFosroc Nitoproof 10: Constructive SolutionsmangjitNo ratings yet

- Fosroc Nitoflor EU5: Constructive SolutionsDocument3 pagesFosroc Nitoflor EU5: Constructive SolutionsVincent JavateNo ratings yet

- NITOPROOFDocument4 pagesNITOPROOFTejinder KumarNo ratings yet

- Nitoseal PU40Document2 pagesNitoseal PU40Syed AbuthahirNo ratings yet

- Nitotile GroutDocument2 pagesNitotile GroutVincent JavateNo ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELmilanbrasinaNo ratings yet

- Nitoflor FC130: Water Based, Epoxy Resin Floor and Wall CoatingDocument3 pagesNitoflor FC130: Water Based, Epoxy Resin Floor and Wall CoatingBintang AtdiNo ratings yet

- Nitoflor Hardtop S Jan 2009 PDFDocument3 pagesNitoflor Hardtop S Jan 2009 PDFAlexander IgnatiusNo ratings yet

- Conplast WP 421 PDFDocument2 pagesConplast WP 421 PDFharsoNo ratings yet

- Fosroc Nitoproof 810 TDSDocument3 pagesFosroc Nitoproof 810 TDSPang Chong HengNo ratings yet

- Asphalt Defect, Causes and RemediesDocument5 pagesAsphalt Defect, Causes and RemediesMansoor AliNo ratings yet

- 07Document8 pages07Mansoor Ali0% (1)

- 02 (2) Dubai-Traffic Control Device ManualDocument7 pages02 (2) Dubai-Traffic Control Device ManualMansoor AliNo ratings yet

- Interview Preparation UAEDocument136 pagesInterview Preparation UAEMansoor AliNo ratings yet

- Dubai-Traffic Control Device ManualDocument3 pagesDubai-Traffic Control Device ManualMansoor Ali50% (2)

- Bridge SpecificationDocument56 pagesBridge SpecificationMansoor AliNo ratings yet

- Renderoc RSXtraDocument4 pagesRenderoc RSXtraMansoor AliNo ratings yet

- Renderoc SXtraDocument2 pagesRenderoc SXtraMansoor AliNo ratings yet

- 01 (2) Dubai-Traffic Control Device ManualDocument3 pages01 (2) Dubai-Traffic Control Device ManualMansoor AliNo ratings yet

- Renderoc PuttyDocument2 pagesRenderoc PuttyMansoor AliNo ratings yet

- Renderoc TGXTRADocument2 pagesRenderoc TGXTRAMansoor AliNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Renderoc FCXtraDocument4 pagesRenderoc FCXtraMansoor AliNo ratings yet

- Renderoc SPXtraDocument2 pagesRenderoc SPXtraMansoor AliNo ratings yet

- Renderoc PlugDocument2 pagesRenderoc PlugMansoor AliNo ratings yet

- Renderoc LAXtraDocument2 pagesRenderoc LAXtraMansoor AliNo ratings yet

- Renderoc SDocument2 pagesRenderoc SMansoor AliNo ratings yet

- Renderoc LA55Document2 pagesRenderoc LA55Mansoor AliNo ratings yet

- Renderoc HSDocument2 pagesRenderoc HSMansoor AliNo ratings yet

- Renderoc HSXtraDocument2 pagesRenderoc HSXtraMansoor AliNo ratings yet

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusMansoor AliNo ratings yet

- Renderoc BFDocument2 pagesRenderoc BFMansoor AliNo ratings yet

- Renderoc La80Document2 pagesRenderoc La80Mansoor Ali0% (1)

- Nitowrap FRCDocument2 pagesNitowrap FRCMansoor AliNo ratings yet

- Renderoc BF2Document2 pagesRenderoc BF2MOHAMED.NOUSAR100% (1)

- Renderoc LADocument2 pagesRenderoc LAMansoor AliNo ratings yet

- Nitomortar SDocument4 pagesNitomortar SMansoor AliNo ratings yet

- Renderoc FCDocument4 pagesRenderoc FCMansoor AliNo ratings yet

- Nitomortar TSDocument2 pagesNitomortar TSMansoor AliNo ratings yet

- Nitoprime ZincrichDocument4 pagesNitoprime ZincrichMansoor AliNo ratings yet

- PIPE AND TUBE - Comparison of SpecificationsDocument4 pagesPIPE AND TUBE - Comparison of Specificationsnate anantathatNo ratings yet

- Lec 21 Brayton CycleDocument18 pagesLec 21 Brayton CycleJunaid KhanNo ratings yet

- Pros & Cons of Centralized Vacuum SystemsDocument66 pagesPros & Cons of Centralized Vacuum SystemsDjapaNo ratings yet

- Mud WeightDocument21 pagesMud WeightDelphine KonanNo ratings yet

- NMAT Physics Practice Questions Set 3Document10 pagesNMAT Physics Practice Questions Set 3Nurshayma JalilNo ratings yet

- XC2002 Brief Manual: ResetDocument6 pagesXC2002 Brief Manual: Resetعبدالمهيمن ميناNo ratings yet

- Rajagiri Public School Unit Test PhysicsDocument3 pagesRajagiri Public School Unit Test PhysicsNITHINKJOSEPHNo ratings yet

- Black Holes Are Some of The Strangest and Most Fascinating Objects in Outer SpaceDocument3 pagesBlack Holes Are Some of The Strangest and Most Fascinating Objects in Outer SpaceAnurag RanaNo ratings yet

- Fluid Mechanics Lecture Notes on Ideal FlowDocument22 pagesFluid Mechanics Lecture Notes on Ideal FlowAlsharksi AviationNo ratings yet

- Cpe Saunders Hc4 Diaphragm 214s425 FL en A4 2018-02-07Document2 pagesCpe Saunders Hc4 Diaphragm 214s425 FL en A4 2018-02-07francis chundalNo ratings yet

- Physical Optics: 18 March 2021Document37 pagesPhysical Optics: 18 March 2021Luo MarkNo ratings yet

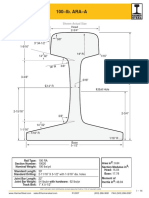

- 100 Lb-Yd ARA-ADocument1 page100 Lb-Yd ARA-ADario Bravo BordaNo ratings yet

- Gravimetric Analysis: Dr. Mohammed Najim Al-Hialy College of Pharmacy University of MosulDocument43 pagesGravimetric Analysis: Dr. Mohammed Najim Al-Hialy College of Pharmacy University of MosulMarci MunirNo ratings yet

- Flow NetsDocument30 pagesFlow NetsBobby AguilarNo ratings yet

- Dundu 2011Document15 pagesDundu 2011fahmi aballiNo ratings yet

- OceanofPDF - Com Tales of The Sun Eater Vol 3 - Christopher RuocchioDocument210 pagesOceanofPDF - Com Tales of The Sun Eater Vol 3 - Christopher Ruocchiounknown manNo ratings yet

- Constitutive Modelling For Geologic MaterialsDocument4 pagesConstitutive Modelling For Geologic MaterialsAnonymous qTP5oq7gNo ratings yet

- 1.1 Exponents PracticeDocument7 pages1.1 Exponents Practicesophia onuNo ratings yet

- Mounting Instructions - Montageanleitung - Notice de Montage - Istruzioni Per Il MontaggioDocument162 pagesMounting Instructions - Montageanleitung - Notice de Montage - Istruzioni Per Il MontaggioIn UnivacNo ratings yet

- Product Update 2010 - Smmsi Outdoor UnitsDocument3 pagesProduct Update 2010 - Smmsi Outdoor UnitssnowwooNo ratings yet

- Floating-Roof Tank Heel Reduction Options and Heel Turnover EmissionsDocument15 pagesFloating-Roof Tank Heel Reduction Options and Heel Turnover EmissionsHamid MansouriNo ratings yet

- Catalogo Centaflex Serie ADocument15 pagesCatalogo Centaflex Serie ACarlos Gallardo LagosNo ratings yet

- 105mm Enhanced GunDocument38 pages105mm Enhanced Gungrindormh53100% (1)

- FEM Analysis of RC BeamsDocument80 pagesFEM Analysis of RC BeamsWilliam Gomez ZabaletaNo ratings yet

- Effect of PH On Caffeine ExtractionDocument20 pagesEffect of PH On Caffeine ExtractionKarol Buda100% (8)

- OfficeServ 7070 Installation Manual (ED (1) .01)Document85 pagesOfficeServ 7070 Installation Manual (ED (1) .01)imella17100% (4)

- Testing of soft foams: Market, Strength, Standards and PracticeDocument53 pagesTesting of soft foams: Market, Strength, Standards and PracticeGustavo LealNo ratings yet

- Metal Injection Moulded Stainless Steel Prealloy Master Alloy TechniquesDocument7 pagesMetal Injection Moulded Stainless Steel Prealloy Master Alloy TechniquesTae-Shik YoonNo ratings yet

- Mechanical Characteristics of Overhead LinesDocument13 pagesMechanical Characteristics of Overhead LinesMizanur RahmanNo ratings yet

- Control de Flama Honeywell 215Document12 pagesControl de Flama Honeywell 215Moreno NuevoNo ratings yet