Professional Documents

Culture Documents

UniSim Feedwater Heater Modeler PIN PDF

Uploaded by

Mai Xuân HoàngOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UniSim Feedwater Heater Modeler PIN PDF

Uploaded by

Mai Xuân HoàngCopyright:

Available Formats

UniSim® Feedwater Heater Modeler

The Challenge Improved process operations – UniSim Feedwater Heater

Modeler provides the benchmark to assess the effects of

Pre-heating water delivered to a steam generating boiler is an

operational changes for load optimization and fouling.

important process in a power plant operation. Optimizing such

process will have a direct impact on the energy consumption and

Increased engineering efficiency – The complex interaction of

the overall efficiency of the plant operation.

the de-superheating, condensing and sub-cooling zones with the

The Solution: UniSim Feedwater Heater Modeler high-pressure feedwater on the tube-side is modeled with rigor in

a user-friendly tool.

UniSim Feedwater Heater Modeler is a unique modeling tool for

power plant feedwater heaters, making allowance for the Features

particular shell and tube geometry used for de-superheating

This modeling tool has two operating modes:

condensing, and sub-cooling the steam heat source. It helps

reduce the irreversibility involved in steam generation and Checking / Rating – Used for troubleshooting, identifying

therefore improves the thermodynamic efficiency of the system. operating constraints, and assessing the impact of fouling on

This leads to reduced plant operating costs, and also reduces the plant efficiency.

risk of thermal shock to the boiler metal when the feedwater is

introduced back into the steam cycle. Simulation – Used for identifying optimized heater configuration

or revamping/retrofitting existing equipment to improve energy

Benefits efficiency.

Improved design – UniSim Feedwater Heater Modeler is a It supports most of the commonly used heater orientations:

comprehensive, easy-to-use tool for the design of feedwater

heaters. It enables more efficient design of new heaters and cost-

effective revamp studies. It can also augment or replace in-house

tools that are difficult to use and expensive to maintain and

update.

More Information

For more information on UniSim, visit

www.honeywell.com/ps/UniSimDesign With user-specified condensing section operating pressure,

or contact your Honeywell account required heat transfer rate for each zone, drains and feedwater

manager. outlet temperatures, the program will perform checking/rating

calculation and determine required surface area for each zone. In

Automation & Control Solutions the simulation mode, it will calculate the heat transfer rate and

Process Solutions outlet conditions with user-specified heater geometry, extraction

Honeywell steam inlet state, feedwater mass flowrate and inlet conditions.

1860 W. Rose Garden Lane

Phoenix, AZ 85027

PN-10-16-ENG

Tel: 800-822-7673 July 2010

© 2010 Honeywell International Inc.

www.honeywell.com/ps

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Cruisair Air ConditioningDocument32 pagesCruisair Air ConditioningcombaheeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Asme Introduction & Inspection of Pressure Vessel: (ASME Section VIII Div. 1, Ed. 2015)Document47 pagesAsme Introduction & Inspection of Pressure Vessel: (ASME Section VIII Div. 1, Ed. 2015)TayfunwNo ratings yet

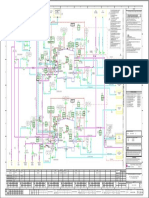

- SPI Instruments in SP-P&ID PDFDocument30 pagesSPI Instruments in SP-P&ID PDFAldi Riri SukirmanNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- Ken Yeang - Service Cores-Wiley (2000) PDFDocument97 pagesKen Yeang - Service Cores-Wiley (2000) PDFKh Md Arik Al Mosabbir100% (2)

- Bs en 378 3 2016Document30 pagesBs en 378 3 2016Dave Williams100% (1)

- PBR 01 TechDocument43 pagesPBR 01 TechJapojh GiptrdNo ratings yet

- Facility Preventive Maintenance ChecklistDocument5 pagesFacility Preventive Maintenance ChecklistFaisalNo ratings yet

- Nozzle PDFDocument8 pagesNozzle PDFtavo1293No ratings yet

- PV Elite 2011Document21 pagesPV Elite 2011chagar_harshNo ratings yet

- UniSim Fired Process Heater Modeler PINDocument2 pagesUniSim Fired Process Heater Modeler PINMai Xuân HoàngNo ratings yet

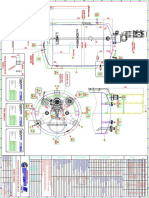

- 0-006023-Ga Drawing-07-Rev03Document1 page0-006023-Ga Drawing-07-Rev03Mai Xuân Hoàng100% (1)

- 01 - TrueTech Technology Introduction - ENDocument14 pages01 - TrueTech Technology Introduction - ENMai Xuân HoàngNo ratings yet

- Seminar PVEliteDocument13 pagesSeminar PVEliteMai Xuân HoàngNo ratings yet

- 01 - TrueTech Technology Introduction - ENDocument14 pages01 - TrueTech Technology Introduction - ENMai Xuân HoàngNo ratings yet

- 0000 1 08 32505Document1 page0000 1 08 32505Mai Xuân HoàngNo ratings yet

- UniSim Shell Tube Exchanger Modeler PINDocument2 pagesUniSim Shell Tube Exchanger Modeler PINMai Xuân HoàngNo ratings yet

- UniSim Design Heat Exchangers PINDocument5 pagesUniSim Design Heat Exchangers PINMai Xuân HoàngNo ratings yet

- 0000 1 08 32503Document1 page0000 1 08 32503Mai Xuân HoàngNo ratings yet

- UniSim Plate Heat Exchanger Modeler PINDocument2 pagesUniSim Plate Heat Exchanger Modeler PINMai Xuân HoàngNo ratings yet

- Chapter 8Document22 pagesChapter 8Mai Xuân HoàngNo ratings yet

- UniSim Process Pipeline Modeler PINDocument2 pagesUniSim Process Pipeline Modeler PINMai Xuân HoàngNo ratings yet

- 0000 1 08 32502Document1 page0000 1 08 32502Mai Xuân HoàngNo ratings yet

- 0000 1 08 31804Document1 page0000 1 08 31804Mai Xuân HoàngNo ratings yet

- 0000 1 08 32504Document1 page0000 1 08 32504Mai Xuân HoàngNo ratings yet

- Bae Realistic Simulation Safety Eval Mine Design 1 09 FDocument2 pagesBae Realistic Simulation Safety Eval Mine Design 1 09 FMai Xuân HoàngNo ratings yet

- Chapter 6 PDFDocument64 pagesChapter 6 PDFMai Xuân HoàngNo ratings yet

- 0000 1 08 31902Document1 page0000 1 08 31902Mai Xuân HoàngNo ratings yet

- Chapter 9Document16 pagesChapter 9Mai Xuân HoàngNo ratings yet

- Chapter 12Document20 pagesChapter 12Mai Xuân HoàngNo ratings yet

- Chapter 10Document42 pagesChapter 10Mai Xuân HoàngNo ratings yet

- Chapter 4Document36 pagesChapter 4Mai Xuân HoàngNo ratings yet

- Chapter 5 PDFDocument17 pagesChapter 5 PDFMai Xuân HoàngNo ratings yet

- Mac 2009Document60 pagesMac 2009Ridwan Pramudya100% (1)

- Mebs7014 2223 06Document72 pagesMebs7014 2223 06Yuki ChanNo ratings yet

- Vaillant Commercial Range BrochureDocument45 pagesVaillant Commercial Range Brochureandreiasbd100% (1)

- Mark RMB 15-25 IVR ENG 6999200470Document6 pagesMark RMB 15-25 IVR ENG 6999200470RUDRA MORENo ratings yet

- Service Manual Gaggia Brera 03-12-09Document42 pagesService Manual Gaggia Brera 03-12-09sasizzo78No ratings yet

- Ems Load CalculatorDocument9 pagesEms Load CalculatorOhnad NatocNo ratings yet

- CV SampleDocument2 pagesCV SampleHary Suryo WibowoNo ratings yet

- Service Manual: Split TypeDocument109 pagesService Manual: Split TypebpowleyNo ratings yet

- Aquafree BrochureDocument2 pagesAquafree BrochureCatalin DragomirNo ratings yet

- BITZER Output Data: Created On: 07/01/2022 18:34:22Document9 pagesBITZER Output Data: Created On: 07/01/2022 18:34:22Dwi AGrNo ratings yet

- CatalogIA PDFDocument74 pagesCatalogIA PDFOctavian TaviNo ratings yet

- University of The East - Manila: Design of A Centralized Air Conditioning System For A Convention CenterDocument11 pagesUniversity of The East - Manila: Design of A Centralized Air Conditioning System For A Convention CenterKADESHCHINO SARANGAYANo ratings yet

- Protecting Against Overpressure 6-01Document8 pagesProtecting Against Overpressure 6-01MEGAN ASBROCKNo ratings yet

- E-Catalague 2020 JuneDocument66 pagesE-Catalague 2020 Juneapi-404330673No ratings yet

- Section 2: Normal ProceduresDocument16 pagesSection 2: Normal Proceduresandres felipe sandoval porrasNo ratings yet

- 7kholvwrinhzprgho Dqg%Dvhprgho: (Applicable Models)Document447 pages7kholvwrinhzprgho Dqg%Dvhprgho: (Applicable Models)kamchingacNo ratings yet

- LS1 - Analysis of Air-Conditioning Processes PDFDocument4 pagesLS1 - Analysis of Air-Conditioning Processes PDFdildin01No ratings yet

- Chapter 7 - Mechanical Ventillation and Smoke Control SystemsDocument23 pagesChapter 7 - Mechanical Ventillation and Smoke Control SystemsBalgo BalgobinNo ratings yet

- Technical Manual: Split Unit Air Conditioner Wall Mounted J & F Series - Cooling Only & Heatpump (50Hz)Document61 pagesTechnical Manual: Split Unit Air Conditioner Wall Mounted J & F Series - Cooling Only & Heatpump (50Hz)donatien FokamNo ratings yet

- Split Type Room Air Conditioner Wall Mounted Type: Downloaded From Manuals Search EngineDocument25 pagesSplit Type Room Air Conditioner Wall Mounted Type: Downloaded From Manuals Search EnginePauloNo ratings yet

- MC Series Gas-Fired Heating Appliance: User ManualDocument10 pagesMC Series Gas-Fired Heating Appliance: User ManualFaceLikeABowlOfMudNo ratings yet

- Spilt AC Repairing and ServicingDocument9 pagesSpilt AC Repairing and ServicingCA Sunil Mehta TohanaNo ratings yet

- Guide: RefrigerantDocument5 pagesGuide: RefrigerantBaljeet SinghNo ratings yet

- M03-08-2021 - Nivel Ii - Lado ADocument13 pagesM03-08-2021 - Nivel Ii - Lado AArturo ValladaresNo ratings yet