Professional Documents

Culture Documents

EEX20208, Troubleshooting Transformer Problems

Uploaded by

ashraf scottOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EEX20208, Troubleshooting Transformer Problems

Uploaded by

ashraf scottCopyright:

Available Formats

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

Troubleshooting Transformer Problems

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramcoís employees.

Any material contained in this document which is not already in the public

domain may not be copied, reproduced, sold, given, or disclosed to third

parties, or otherwise used in whole, or in part, without the written permission

of the Vice President, Engineering Services, Saudi Aramco.

Chapter : Electrical For additional information on this subject, contact

File Reference: EEX20208 W.A. Roussel

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

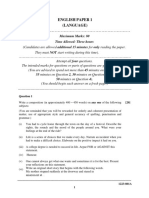

CONTENTS PAGES

COMMON TRANSFORMER PROBLEMS ............................................................. 1

Insulating Oil Problems........................................................................................ 1

Overloading and/or Excessive Heat...................................................................... 2

Bushing and Insulator Problems........................................................................... 3

COMMON TAP CHANGER PROBLEMS............................................................... 4

Control Circuit Failure......................................................................................... 4

Raise Failures................................................................................................. 4

Lower Failures............................................................................................... 4

As-Is-Failure.................................................................................................. 5

DETECTING TRANSFORMER PROBLEMS ......................................................... 6

Routine Inspection and Testing............................................................................ 6

Troubleshooting Flowcharts ................................................................................ 7

CORRECTING TRANSFORMER PROBLEMS ...................................................... 8

Insulating Oil Problems........................................................................................ 8

Overloaded and/or Hot Transformers................................................................... 8

Bushing and Insulator Problems........................................................................... 8

WORK AID 1: TROUBLESHOOTING CHARTS FOR DETECTING

COMMON TRANSFORMER PROBLEMS ............................................................. 9

WORK AID 2: METHODS OF CORRECTING COMMON

TRANSFORMER PROBLEMS...............................................................................10

GLOSSARY ............................................................................................................12

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

COMMON TRANSFORMER PROBLEMS

Transformers are some of the most reliable pieces of electrical equipment. With normal routine

maintenance, transformers can give 20-30 years of service. Problems normally fall into one of

three categories:

• Insulating oil problems

• Overloading and/or excessive heat

• Bushing and insulator problems

Insulating Oil Problems

Insulating oils decay, and eventually lead to premature transformer failures for two reasons:

• Contamination

• Deterioration

Oils are considered contaminated when they contain moisture or other foreign substances that are

not products of oil oxidation. Deterioration refers to the process of oil oxidation. Deterioration

begins as soon as new oil is placed in the transformer.

For a detailed explanation of how insulating oil decays, refer to Chapter 8, part 3 of “A Guide to

Transformer Maintenance”. Pages 180-187 explain the following topics:

• Basic Factors in Oil Deterioration

- Oxygen

- Catalysts

- Accelerators

• Transformer Oil Decay Products

- Early Deterioration Stages

- Final Visible Stage (Sludge)

- The Mechanics of Sludge Formation

Saudi Aramco DeskTop Standards 1

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

Overloading and/or Excessive Heat

The cause of approximately 90% of all cellulose insulation deterioration is operating transformers

at elevated temperatures. Elevated temperature can be caused by one, or a combination of the

following:

• Excessive load

• Excessive ambient temperature

• Cooling system problems

• Sludged oils

• Dark colored exterior paints

Load and ambient temperature are closely related in their effect on transformer operating

temperature. For a constant transformer load, higher ambient temperature lead to higher

operating temperatures.

A number of cooling system problems can cause high operating temperatures:

• Closed radiator valves

• Dirty or clogged cooling fins

• Broken or improperly set cooling fans/pumps

• Cooling control circuit failure

Sludged oils cause overheating because sludge inhibits the heat transfer capability of oil. Since

one of the functions of insulating oil is to cool the transformer, a loss in heat transfer capability

will lead to overheating.

Dark colored exterior paint is not a problem in Saudi Aramco because it is not allowed.

Hot or overloaded transformer problems can be detected by a number of different ways including:

• Operating logs

• Temperature indicators

• Oil analysis for sludge and combustible gases

• In-Service and Out-of-Service cooling system inspections

Saudi Aramco DeskTop Standards 2

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

Bushing and Insulator Problems

Most bushing and insulator problems result from contamination due to natural deposits like early

morning dew, salt, fog, and industrial pollution. When bushings and insulators become

contaminated, other problems result like:

• Noisy substations

• Insulating surface damage

• Partial discharge (corona)

• Flashover

Bushing and insulator problems can be detected three ways:

• Visual Inspection

• Audible Inspection

• Infrared Inspection

For a detailed explanation of what causes these problems, refer to Chapter 8, Part 3 of “A Guide

to Transformer Maintenance”. Pages 651-661 explain the following topics:

• The Contamination Problem

- Types of Contaminants

- Dynamics of Contamination Collection

• Theory of Contamination Flashover

- The Flashover Process

• Other Undesirable Effects of Insulator Contamination

- Corona Manifestations

- Corrosion of Metalwork

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

COMMON TAP CHANGER PROBLEMS

Most tap changer problems result from a component failure in the control circuit. The only other

type of tap changer problem would be a mechanical failure in the drive mechanism, and these are

rare.

Control Circuit Failure

There are three common control circuit failure modes:

• Raise Failures

• Lower Failures

• As-Is-Failures

There is no single procedure available to troubleshoot these failures, because each tap changer

manufacturer does not use the same control circuit. The sections that follow give generic causes

and indications. The manufacturer’s technical manual should be referenced for specific

procedures.

Raise Failures

A raise failure occurs when the tap changer runs to its maximum upper limit. This condition is

indicated by high secondary voltage, high circulating current, and the position indicator at

maximum. This condition is normally caused by a failed limit switch, failed relay, or a failed

sensing circuit.

Lower Failures

This condition is like a raise failure, except that the tap changer runs to its maximum lower limit.

This condition is indicated by low secondary voltage, high circulating current, and the position

indicator at minimum. This condition also is caused by failed limit switches, failed relays, or failed

sensing circuits.

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

As-Is-Failure

As-is-failures occur when the tap changer does not run up or down. This type of failure is

sometimes difficult to diagnose because there may not be any abnormal indications. If the supply

voltage and load remain constant after the failure, the indication should remain normal. If the

supply voltage and load do change after the failure, there may be high circulating currents.

Secondary voltage will fluctuate with input voltage and load.

If the tap changer does not operate in either manual or automatic, the cause is normally a loss of

power to the motor, or a motor control circuit problem. If the tap changer operates in manual,

but not automatic, several problems are possible. Examples are:

• Loss of the sensing signal

• Defective bandwidth control

• Defective time delay circuit

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

DETECTING TRANSFORMER PROBLEMS

There are really only two ways to detect transformer problems:

• Wait until a failure occurs

• Preventive maintenance

Problems detected due to failures normally are more severe, more expensive, and more likely to

cause permanent damage. Preventive maintenance normally finds problems at an early stage,

where they can still be corrected before permanent damage occurs.

Routine Inspection and Testing

The purpose of doing routine inspections and testing is to identify problems early, before an actual

breakdown happens. Breakdown maintenance is always more costly in terms of equipment

damage and lost production, than are scheduled repairs. Just doing the inspections and tests is

not enough. Keeping a running record of the results for each transformer is just as important. A

good maintenance history record for a transformer would include the following:

• Daily Operating Logs

• In-Service Inspection Reports

• Out-of-Service Inspection Reports

• Record of any special testing done

• Record of any repairs done

These records play three key roles in detecting transformer problems:

• Indicate problems that need immediate attention

• Indicate potential problems - trend analysis

• Indicate probable cause of failures - failure analysis

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

Troubleshooting Flowcharts

Operating indications, and records of inspections and tests, give indications or symptoms of

problems. They do not always directly identify what the problem is. Finding the actual problem

from indications or symptoms can be done several ways:

• Using experience

• Using knowledge of the equipment to systematically find the problem

• Using troubleshooting aids (Flowcharts, Guides)

Troubleshooting flowcharts and guides often are available to speed up the process of locating

common problems. Troubleshooting flowcharts and guides give the steps to systematically find

problems from indications or systems. Work Aid 1 gives a list of the troubleshooting flowcharts

available in “A Guide to Transformer Maintenance”. These flowcharts were developed to help

find common transformer problems. More troubleshooting flowcharts and/or guides may be

included in the manufacturer’s technical manual for each individual transformer.

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

CORRECTING TRANSFORMER PROBLEMS

Once a transformer problem is identified, the right corrective action must be taken to fix the

problem. The sections that follow give information on the recommended methods of correcting

common transformer problems.

Insulating Oil Problems

For information on the general guidelines for correcting insulating oil problems, refer to

Chapter 7, Part 1, of “A Guide to Transformer Maintenance”. Pages 471 and 472 give the basic

methods of correcting the common problems.

Overloaded and/or Hot Transformers

Saudi Aramco’s conservative transformer sizing practice eliminates most of the overloading

problems found in North America. If overloading problems do occur, pages 595-597 of “A Guide

to Transformer Maintenance” gives information on the seven alternative approaches to correct the

problem. Work Aid 2 contains information on how to correct overheating problems that do not

result from overload conditions.

Bushing and Insulator Problems

Most bushing and insulator problems result from contamination. The obvious way to correct this

problem is to remove the contamination. Chapter 8, part 3 of “A Guide to Transformer

Maintenance” describes the practical methods of removing contamination. Read pages 663-676

for information on the following topics:

• Hand Wiping

• Periodic Insulator Washing

• Dry Air-Blasting with Non-Abrasive Material

• Use of Silicone Dielectric Compounds

• The Final Decision

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

WORK AID 1: TROUBLESHOOTING CHARTS FOR DETECTING COMMON

TRANSFORMER PROBLEMS

This Work Aid is designed to help the Participants in doing Exercise 1. The page numbers in

this Work Aid refer to pages in the text, “A Guide to Transformer Maintenance”.

1. Troubleshooting Chart for Oil Tests - Page 799

• Troubleshooting Chart for Rapid Oil Color Changes - Page 800

• Troubleshooting Chart for Low Dielectric Strength - Page 801

• Troubleshooting Chart for High IFT and High N/N - Page 802

• Troubleshooting Chart for Gassing Transformers - Page 803

2. Troubleshooting Chart for Overloaded and/or Hot Transformers - Page 804

3. Troubleshooting Chart for Bushings and Insulators - Page 805

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

WORK AID 2: METHODS OF CORRECTING COMMON TRANSFORMER

PROBLEMS

This Work Aid is designed to help the Participants in doing Exercise 2.

1. Insulating Oil Problems

• Refer to pages 508 and 509 of “A Guide to Transformer Maintenance” for a chart

that lists the various oil purifications methods, what they remove, and when they

can be used.

2. Overloaded and/or Hot Transformers

A. Overloaded

• Reduce load

• Add a transformer in parallel

• Add external oil cooler

• Install cooling fans

• Install new transformer

B. Hot Transformers

• Open clogged or shut radiator valves if applicable

• Desludge oil if applicable

• Degas oil if applicable

• Change air filter if applicable

• Install sun shield

3. Bushing and Insulator Contamination

A. Hand Wiping

• Transformer must be deenergized

• This method will remove dust and other surface pollutants

• This method is tedious, time consuming, and expensive (due to downtime)

• This method is used when high pressure washing can not be used, bushings

and insulators are inaccessible, or they are too close to energized

equipment.

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

B. High Pressure Washing

• Transformer may be energized or deenergized

• This method will remove only water soluble and non-adhering

contamination. It will not remove hardened salt or cement dust.

• This method is much faster than hand wiping

C. Dry Air-Blasting With Non-Abrasive Material

• Transformer may be energized or deenergized

• This method will remove all insoluble particulate contaminations including:

- Metallic oxides

- Cement dust

- Chemicals

- Salt cake

- Acid

- Smog

- Other pollutants

• This method is very effective and economical

D. Use of Silicone Dielectric Compounds

• Transformer must be deenergized to apply compound.

• Compound is applied to clean insulators and bushings to protect against

contamination buildup.

• This method is normally used in environments that contain salt-cake or

cement dust.

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Electrical

Troubleshooting Transformer Problems

GLOSSARY

appropriate Correct, right

improperly Not right for the circumstances

indicated Shown, pointed out

Saudi Aramco DeskTop Standards 12

You might also like

- CSE11603, Soils (Geotechnical) Investigations and ReportsDocument11 pagesCSE11603, Soils (Geotechnical) Investigations and Reportsashraf scottNo ratings yet

- LAB10607, Oil Industry Applications of Aas Aes TechniquesDocument16 pagesLAB10607, Oil Industry Applications of Aas Aes Techniquesashraf scottNo ratings yet

- COE10801, Protective Coatings and LiningsDocument8 pagesCOE10801, Protective Coatings and Liningsashraf scottNo ratings yet

- AGE10705, Geology For Engineers and Scientists Geologic Map ReadingDocument13 pagesAGE10705, Geology For Engineers and Scientists Geologic Map Readingashraf scottNo ratings yet

- COE10307, Underwater NDTDocument9 pagesCOE10307, Underwater NDTashraf scottNo ratings yet

- EXXON 16, Exxon Chemical and Mechanical Cleaning Manual, Chemical DisposalDocument6 pagesEXXON 16, Exxon Chemical and Mechanical Cleaning Manual, Chemical Disposalashraf scottNo ratings yet

- EXXON 01, Exxon Chemical and Mechanical Cleaning Manual, IntroductionDocument3 pagesEXXON 01, Exxon Chemical and Mechanical Cleaning Manual, Introductionashraf scottNo ratings yet

- COE10608, Failure Analysis ReportDocument6 pagesCOE10608, Failure Analysis Reportashraf scottNo ratings yet

- EXXON 14, Exxon Chemical and Mechanical Cleaning Manual, Cleaning Non MetallicsDocument9 pagesEXXON 14, Exxon Chemical and Mechanical Cleaning Manual, Cleaning Non Metallicsashraf scottNo ratings yet

- Exxon IP 4-5-1 Steel StacksDocument3 pagesExxon IP 4-5-1 Steel Stacksashraf scottNo ratings yet

- Exxon IP 4 6 2 Supporting StructuresDocument5 pagesExxon IP 4 6 2 Supporting Structuresashraf scottNo ratings yet

- Exxon IP 4 6 1 Reinforced ConcreteDocument2 pagesExxon IP 4 6 1 Reinforced Concreteashraf scottNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 3-IBM-RB - Sales - Selling Ibm Innovative SolutionsDocument226 pages3-IBM-RB - Sales - Selling Ibm Innovative Solutionsjusak131No ratings yet

- Handley MouleDocument4 pagesHandley MouleAnonymous vcdqCTtS9No ratings yet

- (Historical Materialism Book Series 32) Lapavitsas, Costas - Financialisation in Crisis (2012, Brill Academic Pub)Document276 pages(Historical Materialism Book Series 32) Lapavitsas, Costas - Financialisation in Crisis (2012, Brill Academic Pub)monikaNo ratings yet

- Build Pulse Oximeter InstructionsDocument3 pagesBuild Pulse Oximeter InstructionsPrabhuDevNo ratings yet

- Mana Paribhsha RSBKDocument31 pagesMana Paribhsha RSBKlohiyakankshaNo ratings yet

- Bamuoingaythienquan NguyenduynhienDocument9 pagesBamuoingaythienquan NguyenduynhienFLed NguyenNo ratings yet

- Cape Physics U1 Ia BookletDocument10 pagesCape Physics U1 Ia Bookletedgeboy47100% (2)

- LAC Intraregional IRF GuideDocument81 pagesLAC Intraregional IRF GuideMario Cortez EscárateNo ratings yet

- Iranian Food Enquiries ReportDocument22 pagesIranian Food Enquiries Reportswapnilrane03100% (1)

- W 2HotlineContacts2019 - 0 2 PDFDocument3 pagesW 2HotlineContacts2019 - 0 2 PDFNathan Townsend Levy100% (1)

- Data CollectionDocument4 pagesData CollectionjochukoNo ratings yet

- BEETLE /M-II Plus: POS System For The Highest Standards of PerformanceDocument2 pagesBEETLE /M-II Plus: POS System For The Highest Standards of PerformanceHeather JensenNo ratings yet

- Sodium Lignosulfonate MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesSodium Lignosulfonate MSDS: Section 1: Chemical Product and Company IdentificationYasdiOKNo ratings yet

- Parts List of Engine Assy Ofdz-00536Document1 pageParts List of Engine Assy Ofdz-00536CwsNo ratings yet

- Benefits of sponge cities in managing urban stormwater and floodingDocument3 pagesBenefits of sponge cities in managing urban stormwater and floodingShivamNo ratings yet

- Cram v. The Fanatic Group - ComplaintDocument44 pagesCram v. The Fanatic Group - ComplaintSarah BursteinNo ratings yet

- Feaps PortfolioDocument17 pagesFeaps Portfolioapi-317208189No ratings yet

- Thermodynamics 1 Initial Draft 1Document230 pagesThermodynamics 1 Initial Draft 1john pakinganNo ratings yet

- "Employee Payroll Management System": Miss - Priyanka Abhaynath YadavDocument31 pages"Employee Payroll Management System": Miss - Priyanka Abhaynath Yadavhabeb TubeNo ratings yet

- Oil and Gas FieldDocument5 pagesOil and Gas FieldMuhammad SyafiieNo ratings yet

- ISC 2023 English Language Question PaperDocument5 pagesISC 2023 English Language Question PaperMohit JoshiNo ratings yet

- Trade BW Logistic ExtractionDocument54 pagesTrade BW Logistic Extractionlittlebros100% (1)

- Pizza Hut Training Manual FinishedDocument34 pagesPizza Hut Training Manual FinishedEdilson MaziveNo ratings yet

- ENGG378 - 948 HydroPower-Lecture - 1 - 2019 PDFDocument34 pagesENGG378 - 948 HydroPower-Lecture - 1 - 2019 PDFJ CNo ratings yet

- Mic520 525 530 eDocument86 pagesMic520 525 530 eMaia Naiara BarrientosNo ratings yet

- Ginger by NcipmDocument53 pagesGinger by NcipmAbhishekNo ratings yet

- D 3 Econo SPP 2110 1 eDocument123 pagesD 3 Econo SPP 2110 1 eMargarida MoreiraNo ratings yet

- Chap 7Document35 pagesChap 7Nizar TayemNo ratings yet

- Solution:: Ex 3.3 Consider The Following Parallelograms. Find The Values of The Unknowns X, Y, ZDocument9 pagesSolution:: Ex 3.3 Consider The Following Parallelograms. Find The Values of The Unknowns X, Y, ZpadmaNo ratings yet

- Asia Pacific Chemicals 181302Document52 pagesAsia Pacific Chemicals 181302sealaishaniNo ratings yet