Professional Documents

Culture Documents

API 510 PC 20 Aug05 PTR 1 PDF

API 510 PC 20 Aug05 PTR 1 PDF

Uploaded by

Amal KaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 510 PC 20 Aug05 PTR 1 PDF

API 510 PC 20 Aug05 PTR 1 PDF

Uploaded by

Amal KaCopyright:

Available Formats

Professional Training and Consultation

API 510 Preparatory

20 -31 August 2005, Al-Khobar

Page 1 of 3

DAILY POINTS TO RECALL (DAY 1)

1. ASME codes edition is issued once in 3 years and addenda, once a

year – both on 1 July. Edition and addenda become effective on 1st

January of next year (i.e., 6 months after issue).

2. ASME Sec VIII Div.1 is Unfired Pressure Vessel and is applicable to

pressures exceeding 15 psig, and diameters above 6.0”. Pump and

turbine casings are excluded from scope.

3. Thickness of cylindrical shell t = __PR__ + C

SE – 0.6P

4. Longitudinal weld is more critical because it is subjected to double

the stress than Circ. Weld.

5. ‘Weld joint categories’ A, B, C, D – are based on joint locations in

the vessel and stress levels encountered weld Types’ (type 1, 2, 3

… etc.) describe the weld it self.

6. Depths of 2:1 Ellip and hemisph. heads are D/4 and D/2

respectively. (D= Head diameter.)

7. Weld Joint categories:

Category A: - All longitudinal welds in shell and nozzles.

- All welds in heads, Hemisph-head to shell weld

F:\015\FROM GUSAT\510 PC QA PR\API_510_PC_PTR_Updated\API_510_PC_20_Aug05_PTR_1.doc

12/10/2014 / 11:25:43 AM / NCD

Professional Training and Consultation

API 510 Preparatory

20 -31 August 2005, Al-Khobar

Page 1 of 3

DAILY POINTS TO RECALL (DAY 1)

Category B: - All circumferential welds in shell and nozzles,

- Head to shell joint (other than Hemisph.)

Category C and D are flange welds and nozzle attachment welds

respectively.

8. Weld Types:

Type 1: Full penetration welds ( Typically Double welded)

Type 2: Welds with Backing strip.

Type 3: Single welded partial penetration welds.

Type 4, 5, 6 are various Lap welds (rarely used)

9. For full penetration welds (type 1),

Joint efficiency, E= 100%, 85%, 70%,

For the radiography = Full, Spot, Nil respectively.

10. Radiography marking on name plates (typically for Type-1 welds)

RT-1: (E=1) All butt welds – full length radiography.

RT-2: (E=1.0) All Cat. A Butt welds Full length , Cat B,

spot

RT-3: (E=0.85) Spot radiography of both Cat A and B

welds

F:\015\FROM GUSAT\510 PC QA PR\API_510_PC_PTR_Updated\API_510_PC_20_Aug05_PTR_1.doc

12/10/2014 / 11:25:43 AM / NCD

Professional Training and Consultation

API 510 Preparatory

20 -31 August 2005, Al-Khobar

Page 1 of 3

DAILY POINTS TO RECALL (DAY 1)

RT-4: (E=0.7) Partial / No radiography

11. For seamless heads, E=1, If head to shell weld is fully radiographed

( if Cat. A), and at least spot radio graphed (if Cat. B)

12. For Welded Heads for E=1, all welds within the head require full

length radiography (since they are all Cat A welds) and head to shell

weld is fully radiographed (if Cat A), or at least spot radiographed

(if Cat. B)

13. Compared to Cylindrical shell, thickness of 2:1 Ellipsoidal head

is approx. same as shell, Hemisph. head approx. half and Torisph

head is 77% higher.

14. MAWP is calculated for: Working condition (Hot & Corroded). Vessel

MAWP is always taken at the top of the Vessel and is lowest of all

part MAWPs adjusted for static pressure.

F:\015\FROM GUSAT\510 PC QA PR\API_510_PC_PTR_Updated\API_510_PC_20_Aug05_PTR_1.doc

12/10/2014 / 11:25:43 AM / NCD

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Testing, Adjusting, and Balancing - TabDocument19 pagesTesting, Adjusting, and Balancing - TabAmal Ka100% (1)

- Perlen Poesie N°33 Juin 2017 PDFDocument100 pagesPerlen Poesie N°33 Juin 2017 PDFGermaine Dupont100% (15)

- Rotating Equipment Reliability PDFDocument8 pagesRotating Equipment Reliability PDFAmal KaNo ratings yet

- Rotating Equipment Reliability PDFDocument8 pagesRotating Equipment Reliability PDFAmal KaNo ratings yet

- Prophecies of Alois IrlmaierDocument9 pagesProphecies of Alois IrlmaierBranislav PopkonstantinovićNo ratings yet

- Main Engine Manual s70mcDocument287 pagesMain Engine Manual s70mcarun100% (1)

- Mini Project Report FinalDocument24 pagesMini Project Report FinalPrathamesh Parit100% (1)

- Blade VibrationDocument8 pagesBlade VibrationAmal Ka100% (2)

- Microsoft Word - Endodontic - MishapsDocument20 pagesMicrosoft Word - Endodontic - MishapsShufeiNo ratings yet

- Assistant Director (Environment) BPS-17Document23 pagesAssistant Director (Environment) BPS-17nomanNo ratings yet

- Sample - Pipe Manufacturer Data SheetDocument22 pagesSample - Pipe Manufacturer Data SheetAmal KaNo ratings yet

- 3 s2.0 B9780884156864500508 MainDocument4 pages3 s2.0 B9780884156864500508 MainAmal KaNo ratings yet

- General Pta Action Plan Sy 2021-2022Document2 pagesGeneral Pta Action Plan Sy 2021-2022Cathy AP90% (10)

- Weldable Clips - W10: Raillok™ SeriesDocument2 pagesWeldable Clips - W10: Raillok™ SeriesBorislav StoychevNo ratings yet

- TechA Calculo NPSHDocument140 pagesTechA Calculo NPSHAmal Ka100% (1)

- C2 2005Document268 pagesC2 2005Geoffrey Wood100% (3)

- PVC Piping Systems-PPFADocument40 pagesPVC Piping Systems-PPFAAmal KaNo ratings yet

- 04 Todd BurlingameDocument9 pages04 Todd BurlingameAmal KaNo ratings yet

- 2014 CompassDocument540 pages2014 CompassAmal KaNo ratings yet

- Xylem Guide To BlowersDocument11 pagesXylem Guide To BlowersAmal KaNo ratings yet

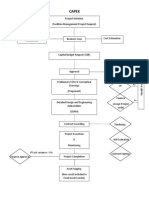

- CAPEXDocument1 pageCAPEXAmal KaNo ratings yet

- Water Hammer in Irrigation SystemsDocument6 pagesWater Hammer in Irrigation SystemsAmal KaNo ratings yet

- Vibration Acceptance CriteriaDocument3 pagesVibration Acceptance CriteriaAmal KaNo ratings yet

- Thesis AndreArsenio TUD FinalDocument166 pagesThesis AndreArsenio TUD FinalAmal KaNo ratings yet

- TemplateDocument2 pagesTemplateAmal KaNo ratings yet

- 570 Sample Questions Rev 061815Document2 pages570 Sample Questions Rev 061815Amal KaNo ratings yet

- QA SNT Amdt 1Document2 pagesQA SNT Amdt 1raj2404No ratings yet

- Je SeroDocument10 pagesJe SeroSitha WisesaNo ratings yet

- Post Launch Memorandum Report For Mercury-Atlas No. 5 (MA-5)Document136 pagesPost Launch Memorandum Report For Mercury-Atlas No. 5 (MA-5)Bob Andrepont100% (1)

- Business PlanDocument46 pagesBusiness PlanJhon Fernan MadolidNo ratings yet

- Star Wires India LimitedDocument10 pagesStar Wires India LimitedDesh Deepak0% (1)

- Assignment For Diwali BreakDocument16 pagesAssignment For Diwali BreakArshNo ratings yet

- Freedom Electronics Co. New ProfileDocument2 pagesFreedom Electronics Co. New ProfileDutta SauravNo ratings yet

- OSHA/AWS/ANSI Shade Selector For WeldingDocument1 pageOSHA/AWS/ANSI Shade Selector For WeldingShabas Lukkumanil HakkimNo ratings yet

- General Pumps - Firefighting RangeDocument32 pagesGeneral Pumps - Firefighting RangeSigma MansorNo ratings yet

- Optoma ES522 (DP-2400) EX532 (DP-3400) ServiceManual 20090630Document123 pagesOptoma ES522 (DP-2400) EX532 (DP-3400) ServiceManual 20090630Rafael PlazaNo ratings yet

- Neogene PeriodDocument20 pagesNeogene PeriodErikh James MestidioNo ratings yet

- Radiographs in PeriodonticsDocument14 pagesRadiographs in Periodonticsyuanyuan100% (1)

- Application Note CORR-4 PDFDocument15 pagesApplication Note CORR-4 PDFaneesh19inNo ratings yet

- Daftar Pustaka: Biostratigraphy, Proc - First Int. Conf. Planktonic Micro Fossilles, E.JDocument3 pagesDaftar Pustaka: Biostratigraphy, Proc - First Int. Conf. Planktonic Micro Fossilles, E.JDaniel Indra MarpaungNo ratings yet

- Math Week 3Document6 pagesMath Week 3Sharmain CorpuzNo ratings yet

- SPRO74 78 94 98 Series JDocument483 pagesSPRO74 78 94 98 Series JRosiane MarcelinoNo ratings yet

- 09 082Document22 pages09 082Gerson FloresNo ratings yet

- Inventory ManagementDocument18 pagesInventory ManagementNeha Gupta100% (1)

- WAO FarmingDocument4 pagesWAO FarmingrrevanNo ratings yet

- Presentasi Indolakto Ahu Dan ChillerDocument16 pagesPresentasi Indolakto Ahu Dan ChillerVincent JonathanNo ratings yet

- Winsor Pilates - Tips, and Some Exercises To DoDocument8 pagesWinsor Pilates - Tips, and Some Exercises To DoudelmarkNo ratings yet