Professional Documents

Culture Documents

Ex Cap 6

Ex Cap 6

Uploaded by

Subhash Korumilli0 ratings0% found this document useful (0 votes)

69 views2 pagesOriginal Title

Ex cap 6

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

69 views2 pagesEx Cap 6

Ex Cap 6

Uploaded by

Subhash KorumilliCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

192 chapten 6 ELeMenTs oF Grain BOUNDARIES

Boundary

FIG. 6.34 As suggested by Aust,!* the overlapping of the atoms at the boundary could

be relieved by a relative translation of the lattices above and below the boundary

PROBLEMS

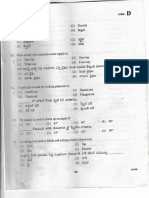

6.1 (a) Given a small-angle tilt boundary whose angle of

tilt is 0.1°, find the spacing between the dislocations in

the boundary if the Burgers vector of the dislocations is,

033m

(b) On the assumption that the dislocations conform to

the conditions involved in Eq. 4.20, that r” = 2,

3. x 10!° MPa and v= 0.3, deter

value for the surface energy of th

Your answer in both Jin? and ergsfem2

62 According to quantitative metallography, N,, the aver

age number of grain-boundary intercepts per unit length

of a line laid over a microstructure is directly related to S,,

de surface ates per unit volume, by the relation:

s,=2y,

(2) Determine th

Fig. 6.1 ifthe

(b) Assuming that the grain-boundary energy of zirco-

nium is about 1 Jim2, what would be the grain-boundary

energy per unit volume in J/m? of the zirconium in the

specimen?

1, for the micmnstmetnre in

tion of the photograph is 350x.

63. A very fine-grained metal may have a mean grain

intercept of the order of I mi 6 m, Assuming

rounder encesy of 0.0.3/u2", what

‘would be the approximate value of its grain-boundary

energy per unit volume? Give your answer in both J/in?

and calories per em’

64 (a) Consider Fig. 6.8. I the grain-boundary energy of a

Inundary between two iron erystals is 0.78.Him2, while

that between iron and a second phase patil is 0.40 Sm?

‘what angle @ should occur atthe junction?

(8) IF the surface energy between the iron and the second

phase particle were to be 0.35, what would the angle be?

65 The following data are taken from Jones, R. L. and

Conrad, H., TMS-AIME, 245 779 (1969) and give the flow

stress @, at A percent strain, ae a function of the grain size

of a very high purity titanium metal. Make a plot of &

versus d-!2, and from this determine the Hall-Petch

parameters k and a. Express k in N/m?

66 Plot the data of the preceding problem showing as

a function of d-!, as well as of d-™. Do these plots

Grain Size Stress,

in Micron, in mPa

1 22

20 279

33 255

indicate that there is some justification for Baldwin's

comments on the Hall-Peteh relationship (see Sec. 6.11)?

16.7 (a) With regard to the coincident site twist boundary.

ona (111) fee metal plane shown in Fig. 6.25, show using

the Ranganathan relationships (Eqs. 6.21, 6.22, and 6.23)

that a choice of x = 2 and y = 1 will also give this = 7

boundary.

(b) To what angle of twist does x = 2 and y = 1 correspond?

(0) Is the fact that x = 2 and y = 1 are able to produce an

equivalent coincident site boundary to that in Fig. 6.25,

related to the symmetty of the atomic arrangement cn

the (111) plane? Exp

{68 This problem concerns a coincidence site boundary en

4 (210} plane of a cubic lattice. Note that the determinaticn

does not depend on whether the lattice Is simple, face

Rerenences 193

‘entered, or body-centered cubic. It holds forall three eases.

‘The basic cell inthis plane has x ~ a and y = YBa. A coin

dence site lattice can be formed with x=2 and y= 1

Assuming a twist boundary, determi

(2) The twist angle @ for the coincidence structure.

(b) %, the reciprocal of the density of coincidence sites.

(©) Check your answer for @ and ¥ using two drawings

of the atomic structure as revealed on a (210) plane.

Note that this involves an array of rectangular cells in

wmien x = a andy = >a, where ais the lattice constant

of the crystal. In this operation, note that one drawing of

the structure should be made on tracing paper so that i

‘can be placed on and rotated over the other so as to

reveal the coincidence sites.

REFERENCES

1. Hirth, J.P, and Lothe, J., Theory of Dislocations, 2nd ee.,

p. 731, John Wiley and Sons, New York, 1982.

2. Kublmann-Wilsdorl, D., Mat. So. and F

86 53 (1987).

3 Hamen, Nand Kl

Eng,, 81 141 (1986).

vanneWilwlarf, Mat Si and

4, Rowenhorst, D. J., and Voorhees, R. W., Met. and Mt.

Trans, A, 368 2127 (2005).

5. Hull, B, Westinghouse Electric Corporation, Research

and Development Center, Pittsburgh, Pa. These expeti-

‘mental results were demonstrated at the Quantitative

Microscopy Symposium, Gainesville, Fla., Feb., 1961

6, DeHoll, R. T, and Rhines, F.N., Quantitative Microscopy,

McGraw-Hill Book Company, New York, 1968.

7. Pullman, R. L,, Trans. AIME, 197 447-53 (1953).

8. Hall, E. O., Pro, Phys, Soc. London, B64 747 (1951).

9, Peteh, N.J., J: Irom and Steel Inst, UTA 25 (1953).

10. Baldwin, WM, Je, Acta Met, 6 141 (1958)

IL. Sanders, P. G., Eastman, J. A., and Weertman, J.

‘Ada Mater, 45 4019 (1997).

19 Macninnra, RA. Harrledine PM. and Pande, C6

Acta Mater, 46.4527 (1998).

13. Chokshi, A. H., Rosen, A., Karch, J., and Gleiter,

Scripta Met,, 23 1679 (1989).

14. Mohamed, FA., and Chauhan, M., Met. and Mat

Trans, 37A 3555 (2006).

15, Andrievski, R.A., and Glezer, A. M., Scripta Mat, 44

1621 (2001).

16. Kronberg. M. L.. and Wilson. FHL. Trans. AIME, 185

501 (1949).

17. Ranganathan, ., Acta Cryst, 21197 (1966)

18, Aust, K. Ty Prog. ie Mat. Seip. 27 (1980).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Img 20201016 0002Document1 pageImg 20201016 0002Subhash KorumilliNo ratings yet

- Img 20201016 0006Document1 pageImg 20201016 0006Subhash KorumilliNo ratings yet

- T, L) Tuo": 5" 5 Q) Soot5Document1 pageT, L) Tuo": 5" 5 Q) Soot5Subhash KorumilliNo ratings yet

- Bs Od6: 3cD Scs IsDocument1 pageBs Od6: 3cD Scs IsSubhash KorumilliNo ratings yet

- TL) ) Ss - : ,: 5: - I0. (1t RL'::: - 3 5u-Rlr IDocument1 pageTL) ) Ss - : ,: 5: - I0. (1t RL'::: - 3 5u-Rlr ISubhash KorumilliNo ratings yet

- Lll:fi: l6x 2t (z7TDocument1 pageLll:fi: l6x 2t (z7TSubhash KorumilliNo ratings yet

- 1) 30" (2) 1) D (2) (3) 5. (1) Direction Q) Directions (4) (L) 6 (Q) (3) Oderef 'Document1 page1) 30" (2) 1) D (2) (3) 5. (1) Direction Q) Directions (4) (L) 6 (Q) (3) Oderef 'Subhash KorumilliNo ratings yet

- Img 20200706 0002 PDFDocument1 pageImg 20200706 0002 PDFSubhash KorumilliNo ratings yet

- Img 20201016 0004Document1 pageImg 20201016 0004Subhash KorumilliNo ratings yet

- Code'F) 9.) ) S5F,: (L Jig JigDocument1 pageCode'F) 9.) ) S5F,: (L Jig JigSubhash KorumilliNo ratings yet

- Lty (Rvc'Suoryur - Ffi: Urum - Ru Taoodu-,TooqDocument1 pageLty (Rvc'Suoryur - Ffi: Urum - Ru Taoodu-,TooqSubhash KorumilliNo ratings yet

- ,ii - L R:: (F 6f &.I, IDocument1 page,ii - L R:: (F 6f &.I, ISubhash KorumilliNo ratings yet

- Img 20200608 0002Document1 pageImg 20200608 0002Subhash KorumilliNo ratings yet

- Ri) Il T"-Fu'o F" 'Document1 pageRi) Il T"-Fu'o F" 'Subhash KorumilliNo ratings yet

- Assigment 3 PDFDocument5 pagesAssigment 3 PDFSubhash KorumilliNo ratings yet

- ,$vry'r F (Errlrd Q: ,,L, RyrraDocument1 page,$vry'r F (Errlrd Q: ,,L, RyrraSubhash KorumilliNo ratings yet

- Dummy PDFDocument1 pageDummy PDFSubhash KorumilliNo ratings yet

- Customer Receipt: Tag Account No. Licence Plate No. Vehicle Class Amount (RS.)Document1 pageCustomer Receipt: Tag Account No. Licence Plate No. Vehicle Class Amount (RS.)Subhash KorumilliNo ratings yet

- DinchakDocument1 pageDinchakSubhash KorumilliNo ratings yet

- Ade RojuDocument1 pageAde RojuSubhash KorumilliNo ratings yet

- Img 20200511 0001Document1 pageImg 20200511 0001Subhash KorumilliNo ratings yet

- Annual Report 2016 17Document60 pagesAnnual Report 2016 17Subhash KorumilliNo ratings yet

- Atoms, Radiation, and Radiation Protection: James E. TurnerDocument9 pagesAtoms, Radiation, and Radiation Protection: James E. TurnerSubhash KorumilliNo ratings yet

- Ce 371 Homework 4 1) A Plug in The Bottom of A Pressurized TankDocument4 pagesCe 371 Homework 4 1) A Plug in The Bottom of A Pressurized TankSubhash KorumilliNo ratings yet

- B.date of Written Test: C.venue of Written Test: D.reporting Time: 12.45 PM To 01.45 PM E.duration of Written Test: 2 Hours From 02.00 PM To 04.00 PMDocument2 pagesB.date of Written Test: C.venue of Written Test: D.reporting Time: 12.45 PM To 01.45 PM E.duration of Written Test: 2 Hours From 02.00 PM To 04.00 PMSubhash KorumilliNo ratings yet

- CH 14 Kinetics of Particles Work and EnergyDocument19 pagesCH 14 Kinetics of Particles Work and EnergySubhash KorumilliNo ratings yet

- RUCHISOYA 07092019220325 Letter To S E DTD 07092019 165 PDFDocument57 pagesRUCHISOYA 07092019220325 Letter To S E DTD 07092019 165 PDFSubhash KorumilliNo ratings yet

- Unit 8 Strain Energy: StructureDocument24 pagesUnit 8 Strain Energy: StructureSubhash KorumilliNo ratings yet