Professional Documents

Culture Documents

Tablet SD

Uploaded by

Diah Siti FatimahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tablet SD

Uploaded by

Diah Siti FatimahCopyright:

Available Formats

Adisa et al

Tropical Journal of Pharmaceutical Research, February 2009; 8 (1): 43-51

© Pharmacotherapy Group,

Faculty of Pharmacy, University of Benin,

Benin City, 300001 Nigeria.

.

All rights reserved

Available online at http://www.tjpr.org

Research Article

Formulation and Evaluation of Solid Dispersions of

Furosemide in Sodium Starch Glycolate

Ganesh Chaulang*, Piyush Patel, Sharwaree Hardikar, Mukul Kelkar,

Ashok Bhosale, Sagar Bhise

Department of Pharmaceutics, S. G. R. S. College of Pharmacy, Saswad, Pune. (MS), India 412301

Abstract

Purpose: This investigation was carried out to determine if a solid dispersion of furosemide in sodium

starch glycolate (SSG) would enhance the dissolution properties of the drug.

Methods: Solid dispersion of furosemide in SSG was prepared in ratios of 1:1 and 1 (furosemide):2

(SSG) by kneading method. In each case, the solid dispersion was characterized by Fourier transform

infrared (FTIR) spectroscopy, differential scanning calorimetry (DSC), and X-ray diffraction (XRD) to

ascertain if there were any physicochemical interactions between drug and carrier that could affect

dissolution. Tablets containing the solid dispersion were formulated and their dissolution characteristics

o

compared with commercial furosemide tablets. The dissolution studies were performed at 37 ± 0.5 C

and 50 rpm in simulated gastric fluid (pH 1.2).

Results: FTIR spectroscopy, DSC, and XRD showed a change in crystal structure toward an

amorphous form of furosemide. Dissolution data indicated that furosemide dissolution was enhanced.

XRD, DSC, FTIR spectroscopy and dissolution studies indicated that the solid dispersion formulated in

1:2 ratio showed a 5.40-fold increase in dissolution and also exhibited superior dissolution

characteristics to commercial furosemide tablets.

Conclusion: Solid dispersion technique can be used to improve the dissolution of furosemide.

Keywords: Solid dispersion, Furosemide, Sodium starch glycolate, Dissolution enhancement,

physicochemical characterisation.

Received: 30 August 2008 Revised accepted: 20 October 2008

*Corresponding author: Tel. +91-9923968989, Fax +91-2115-222213, E-mail- ganesh_chaulang@rediffmail.com

Trop J Pharm Res, February 2009; 8 (1): 43

Chaulang et al

INTRODUCTION

Furosemide (FRMD) is 5-(aminosulphonyl)-4- EXPERIMENTAL

chloro-2-[(2-fuanyl-methyl) amino] benzoic

acid, and it is a potent high ceiling (loop) Materials

diuretic mainly used in the treatment of

1

hypertension . The drug has been classified Furosemide (FRMD) was gift sample from

as a class IV drug as per the Samruddha Pharmaceuticals, Thane,

biopharmaceutical classification system (BCS) Mumbai, and sodium starch glycolate (SSG)

as a result of its low solubility and oral was obtained from Loba Cheime, India.

bioavailability; one of the major causes of its Ethanol, Avicel PH102 and Crosscarmellose

2,3

low oral bioavailability is its solubility . sodium were purchased from Suchem Lab,

Ahemadabad.

Oral bioavailability of a drug depends on its

solubility and/or dissolution rate, and Preparation of furosemide-SSG solid

dissolution may be the rate determining step dispersion

for the onset of therapeutic activity. Therefore

efforts to increase drug dissolution of drug are A mixture (6g) of furosemide and SSG (1:1

often needed. Methods available to improve

and 1:2 by weight, respectively) was wetted

dissolution include salt formation,

with water-ethanol (1:1 ratio) till the slurry was

micronization and addition of solvent or

formed and kneaded thoroughly for 60 min in

surface active agents. Solid dispersion (SD) is

one of such methods and it involves a a glass mortar. The paste formed was dried

dispersion of one or more active ingredients in under vacuum (Conaform Vaccume dryer,

an inner carrier or matrix in solid state Patterson Industries, Canada.) for 24 h. The

prepared by melting, dissolution in solvent or resulting powder was passed through sieve

4

melting-solvent method . The technique has no. 60 (B.P. 2003) and stored in a desiccator

been used for a wide variety of poorly until further evaluation. Physical mixtures (PM,

5 6g) were also obtained by pulverizing and

aqueous soluble drugs such as nimesulide ,

6 7 8

ketoprofen , tenoxicam , nifedipine , carefully mixing furosemide and SSG (1:1 and

9

nimodipine . SD technology has been 1:2 ratio by weight, respectively) in a glass

successfully been used for improving the mortar. After a preliminary evaluation, it was

solubility of the drugs and hence found that solid dispersion prepared by

7 10

bioavailability, e.g., tenoxicam , tacrolimus , kneading in 1:2 (furosemide: SSG) ratio

11 12 13

indomethacin , ibuprofen , nilvadipine . showed higher dissolution; therefore, this solid

dispersion was used for the preparation of

The present work aims to evaluate the tablet formulations.

potential of the solid dispersion technique for

development of fast-dissolving tablets of Fourier transform infrared (FTIR) spectro-

FRMD using SSG as the hydrophilic carrier. scopy

Furthermore, this study seeks to investigate

kneading as a method for the preparation of FTIR spectra were recorded on samples

these binary systems as well as their solid

prepared in potassium bromide (KBr) disks

state characterization by employing analytical

using a Shimadzu Corporation (Koyto, Japan)

tools such as Fourier Transform infrared

facilty (model - 8400S). Samples were

(FTIR), X-ray diffraction (XRD) and differential

scanning calorometry (DSC). Furthermore, the prepared in KBr disks in a hydrostatic press at

possible mechanism of dissolution was 6-8 tons pressure. The scanning range was

-1

investigated. 500 to 4000 cm .

Trop J Pharm Res February 2009; 8 (1): 44

Chaulang et al

Differential scanning calorimetry (DSC) sodium. MD3 tablets contain same amount of

furosemide and magnesium stearate as MD1

DSC analysis was performed using METTLER plus 89 mg of Avicel PH102 and 40 mg of

DSC 30S, Mettler Toledo India Pvt. Ltd., Crosscarmellose sodium. The tablets were

0

Swizerland, using crucible Al 40µL, at of 10 C evaluated for hardness (Tablet hardness

/min heating rate, under nitrogen environment. tester, model no. C–WWTDH 500N, Campbell

0

The temperature range used was 0 – 400 C. Electronics, Mumbai), friability (Roche

Friabilator), weight variation, and drug

X-ray diffraction (XRD) content. In vitro dissolution studies on MD3

tablets and two commercial tablets of

X-ray powder diffraction patterns were furosemide containing 40mg of furosemide -

®

recorded on an X-ray powder diffraction formulation A (Lasix ) and formulation B

®

system (PANalytical Spectris Pvt. Ltd, (Salinex ), respectively - were carried out in

Singapore) using copper target, a voltage of 900mL of SGF (pH-1.2) as the dissolution

40 Kv and a current of 30 mA. The scanning media as described previously.

was done over 2θ range of 5º to 60º.

RESULTS

Dissolution rate studies

FTIR spectroscopy

The dissolution was studied with accurately

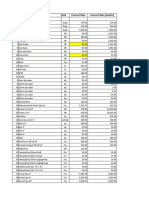

weighed amount of the formulations IR spectra of furosemide and its binary

(containing approx. 40 mg of furosemide) systems with SSG are presented in Figure 1.

using a USP apparatus II in 900 ml of Pure furosemide spectra showed sharp

simulated gastrointestinal fluid (SGF, pH 1.2) characteristic peaks at 3400.27, 3122.54,

–1

for one hour. The rotational speed of the 1665, and 1560 cm . The above

paddle was set at 50 rpm at 37 ± 0.5ºC. characteristic peaks appear in the spectra of

Aliquots (5ml each) were withdrawn at all binary systems at the same wave number

predetermined time intervals for 1h; sink indicating no interaction between the drug and

conditions were maintained. The samples the carrier (SSG).

were analyzed for drug content using a double

beam UV spectrophotometer (model no. UV Differential scanning calorimetry (DSC)

2401 PC, Shimadzu Corporation, Koyto,

Japan) at 274 nm DSC thermograms of furosemide, SSG as

well as their solid dispersions prepared by

Tablet preparation and characterization kneading method and physical mixing are

shown in Figure 2. Furosemide exhibited a

Tablets containing an equivalent of 40 mg of characteristic, sharp exothermic peak at 224.8

o

furosemide (SD2) were compressed on a 16- C which is associated with the melting point

station single rotary tabletting press (Type – of the drug and indicates the crystalline nature

CMD3 – 16, Cadmach Machinery Pvt. Ltd., of the drug; degradation was indicated by an

o

Ahemadabad) using an 8-mm standard flat endothermic peak at 280.2 C. However, the

punch by direct compression technique, at a characteristic exothermic peak, corresponding

compression pressure of 6 tons. Tablet to drug melting was broadened and shifted

formulations were code as MD1, MD2 and toward a higher temperature with reduced

MD3. MD1 tablets contain 80 mg of solid intensity in both physical mixtures and solid

dispersion two (SD2), 119 mg of Avicel PH102 dispersions. DSC studies also showed that

and 1 mg of magnesium stearate. MD2 tablets there no interaction between drug and carrier

contain the same amount of furosemide and at a molecular level in both the solid

magnesium stearate as MD1 plus 99 mg of dispersions and physical mixtures.

Avicel PH102 and 20 mg of Crosscarmellose

Trop J Pharm Res February 2009; 8 (1): 45

Chaulang et al

Figure 1: FTIR spectra of furosemide alone and with various binary mixture of SSG.

FMRD = Furosemide; PM1 = Physical Mixture One (1:1 ratio); PM2 = Physical Mixture Two

(1:2 ratio); SD1 = Solid Dispersion One (1:1 ratio); SD2 = Solid Dispersion Two (1:2 ratio)

PMRD

SSG

PM1

PM2

SM1

SM2

Figure 2: DSC curves of furosemide alone and various binary systems.

Trop J Pharm Res February 2009; 8 (1): 46

Chaulang et al

X-ray diffraction DISCUSSION

The x,-ray diffraction pattern of frusemide The solid dispersion was prepared and

exhibited sharp, highly intense and less characterized and the results showed that 1:2

diffused peaks indicating the crystalline nature solid dispersion (SD2) had a higher dissolution

of drug, as shown in Figure 3. It showed profile compared to other formulations. As

diffraction peaks at 2θ degree of 12, 18, 18.9, shown in FTIR spectroscopic studies, the

23, 24.7 and 28.6. However the x-ray spectra of pure drug, furosemide and solid

diffraction patterns of the physical mixture and dispersion were similar and the peak for pure

solid dispersion were simply a superimposition furosemide was also appeared in all the

of each component with with respect to the spectra of the binary mixtures. Thus, there

peaks of frusemide. Moreover, the relative was no interaction between the drug and the

intensity and 2θ angle of these peaks

carrier (SSG). DSC studies, on the basis of

remained practically unchanged. Thus, there o

the melting peak of furosemide (224.8 C),

was no amorphization of the drug and which

also indicate that there was not interaction

still retained its original crystalline form. IR and

DSC studies support the same hypothesis, between the drug and carrier. However, the

which is confirmed by x-ray diffractometry. characteristic melting peak broadened and

shifted toward a higher temperature with

Dissolution studies reduced intensity for both the physical

mixtures as well as solid dispersions. This

The dissolution profiles of the pure drug, may be attributed to high polymer

carrier (SSG) and binary systems are concentration and uniform distribution of the

presented in Figure 4. It is evident that the drug in the crust of the polymer, resulting in

solid dispersion (SD) technique improved the complete miscibility of the molten drug in the

dissolution rate of the drug to a great extent. polymer. The similarity in the DSC of the solid

The results indicate that SD2 (79% of drug dispersions and physical mixtures suggests

dissolved in 60 min) showed the highest that the kneading process did not induce

dissolution rate, followed by SD1 with 65% of interaction at the molecular level neither did

drug dissolved over the same period. Physical the solid dispersion which is a physical

mixtures (PM) also improve dissolution rate mixture with the drug crystals highly dispersed

significantly (P <0.05) compared with the drug in the carrier. This was further confirmed by

alone. The order of dissolution rate is SD2 > XRD data. In diffractograms, the peak position

SD1 > PM2 > PM1 > drug alone. (angle of diffraction) is indicative of a crystal

structure and the peak height is a measure of

To formulate a tablet of furosemide, the SD2 the sample crystallinity. The diffractograms of

binary mixture was selected based on its in

pure furosemide and pure SSG exhibited a

vitro dissolution performance. MD3 tablets

series of intense peaks which are indicative of

showed the fastest disintegration (89 seconds)

their crystallinity. The diffractogram of physical

and this is attributed to inclusion of the

disintegrant, Crosscarmellose sodium, in the mixture was practically a simple superposition

formulation. In vitro dissolution studies for of each component, indicating the presence of

MD3 confirmed the results obtained with solid furosemide in a crystalline state and no

binary mixtures. MD3 tablets, like the formation of a new structure. This result

corresponding binary mixture, showed good supports the finding of FTIR spectra.

dissolution (73.9% in 60 min). When

compared with commercial tablets of The solid dispersions (1:1 and 1:2 ratios)

furosemide (see Figure 5), MD3 tablets were prepared showed a reduction in sharpness of

®

significantly better (P < 0.05) than Lasix the XRD peak intensity with the peak intensity

®

(2.34-fold) and Sanilex (3.44-fold). of 1:2 solid dispersion lower than the other.

Trop J Pharm Res February 2009; 8 (1): 47

Chaulang et al

FMRD

SSG

PM1

PM2

SD1

SD2

Figure 3: XRD spectra of furosemide alone and various binary systems

Trop J Pharm Res February 2009; 8 (1): 48

Chaulang et al

Figure 4: Dissolution profiles of furosemide and its binary systems with SSG.

(♦)- Furosemide, (■) - PM 1, (▲) - PM 2, (×) - SD 1, (●)-SD 2

Figure 5: Dissolution profiles of tablets containing solid dispersion and commercial tablets.

(■) – Formulation A; (▲) – Formulation B; (♦) – MD 3

Trop J Pharm Res February 2009; 8 (1): 49

Chaulang et al

This suggests that part of the drug structure ACKNOWLEDGEMENT

may have been converted to the amorphous

state, and this probably explains why the The authors thank Samruddha Pharmaceu-

dissolution of the drug was increased. The ticals, Thane, Mumbai for the gift of

order of dissolution rate is SD2 > SD1 > PM2 furosemide.

> PM1 > FRMD. Enhancement of the

dissolution of furosemide from the solid REFERENCES

dispersions can be ascribed to several

14,15

factors which affect the mechanism of 1. Murray MD, Haag KM, Black PK, Hall SD, Brater

dissolution rate improvement in solid DC. Variable furosemide absorption and poor

dispersion. Lack of crystallinity, i.e., predictability of response in elderly patient.

amorphization, increased wettability and Pharmacotherapy 1997; 17: 98 – 106.

dispersibility and particle size reduction are 2. Boles Ponto LL, Schoenwald RD. Furosemide: a

pharmacokinetic / pharmacodynamic review part

considered to be important factors for I. Clin. Pharmacokinet. 1990; 18: 381 – 408.

dissolution rate enhancement. As indicated by 3. Ozdmir N, Ordu S. Improvement of dissolution

the dissolution data of the physical mixtures, properties of furosemide by complexation with β-

improvement could be attributed to higher cyclodextrin. Drug Dev. Ind. Pharm.1998; 24 (1):

wettability and dispersibility. Dry mixing of 19 – 25.

drug with a hydrophilic carrier results in 4. Chiou WL, Riegelman S. Pharmaceutical

greater wetting and increases surface applications of solid dispersion systems. J Pharm

Sci.1971; 60: 1281-1302

available for dissolution by reducing interfacial

5. Babu GV, Kumar NR, Himasankar K, Seshasayana

tension between hydrophobic drug and A, Murthy KV. Nimesulide-modified gum karaya

dissolution media. During dissolution studies, solid mixtures: preparation, characterization and

it was noted that drug carrier systems sank formulation development. Drug Dev Ind

immediately, whereas the pure drug keeps Pharm.2003; 29: 855-864.

floating on the surface for a longer time 6. Rogers JA, Anderson AJ. Physical characteristics

and dissolution profiles of ketoprofen-urea solid

interval. MD3 tablets showed higher dispersions. Pharm Acta Helv.1982; 57: 276-281.

dissolution than the commercial frusemide

7. El-Gazayerly ON. Characterization and evaluation of

tablets. Superdisintegrants accelerate tenoxicam coprecipitates. Drug Dev Ind

disintegration of tablets by virtue of their ability Pharm.2000; 26: 925-930.

to absorb a large amount of water when 8. Vippagunta SR, Maul KA, Tallavajhala S, Grant

exposed to an aqueous environment. The DJW. Solid-state characterization of nifedipine

absorption of water results in the breaking of solid dispersions. Int J Pharm 2002; 236:111-123

tablets and therefore faster disintegration. 9. Murali Mohan Babu GV, Prasad CHDS, Ramana

Murthy KV. Evaluation of modified gum karaya as

Rapid disintegration is reported to accelerate carrier for the dissolution enhancement of poorly

dissolution. water soluble drug nimodipine. Int J Pharm 2002;

234:117.

CONCLUSION 10. Yamashita K, Nakate T, Okimoto KA. Establishment

of new preparation method for solid dispersion

formulation of tacrolimus. Int J Pharm 2003;

This study shows that the dissolution rate of

267:79-91.

furosemide can be enhanced cosiderably by

11. Makiko F, Hideko O, Yu suke S, Honami T, Masuo

formulating in it as a solid dispersion in SSG K, Yoshiteru W. Preparation, characterization, and

using a kneading method. Incorporation of tableting of a solid dispersion of indomethacin with

superdisintegrants in the solid dispersions crospovidone. Int. J. Pharm 2005; 293: 145–153.

played a critical role in dissolution 12. Loganathan S, Maimaran S, Rajasekaran A, Reddy

enhancement. It may be feasible to prepare MVP, Sulaiman A. The effect of solid dispersions

on (solubility) dissolution rate of ibuprofen. The

suitable formulations of frusemide solid Eastern Pharmacist. 2000; 513: 115 - 116.

dispersions as fast dissolving tablets. 13. Hirasawa NI, shise S, Miyata H, Danjo K.

Physiochemical characteristics and drug release

studies of nilvadipine solid dispersions using

Trop J Pharm Res February 2009; 8 (1): 50

Chaulang et al

water insoluble polymer as carrier. Drug. Dev. Ind. via camphor sublimation. Pharm. Tech. 2005; 32:

Pharm 2003; 29 (3): 339-344. 68 – 78.

14. Martinez-Oharriz MC, Rodrig-Espinosa C, Martin C, 17. Verreck G, Six K, Mooter GVD, Baert L, Peeters J,

Goni MM, Trosllarduya MC, Sanchez, M. Solid Brewster ME. Characterisation of solid

dispersions of diflunisal-PVP: Polymorphic and dispersions of Itraconazole and HPMC prepared

amorphous states of the drug. Drug. Dev. Ind. by melt extrusion part-I. Int. J.Pharm. Sci 2003;

Pharm 2002; 28(6): 717-725. 251: 165-174.

15. Ford JL. The current status of solid dispersions. 18. Xianhong W, Fei T, Zhijun J, Ziuyang L. Preparation

Pharm Acta Helv 1986; 61:69-88 and study the 1:2 inclusion complex of carvedilol

16. Adel MA, Semreen M, Mazen KQ. with β-cyclodextrin. J. Pharm. Bio. Anal. 2004;

Superdisintegrants for Solid Dispersion: To 34: 517-523.

produce rapidly disintegrating Tenoxicam tablets

Trop J Pharm Res February 2009; 8 (1): 51

Chaulang et al

Trop J Pharm Res February 2009; 8 (1): 52

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Homework stresses and strains analyzed with KENPAVE softwareDocument17 pagesHomework stresses and strains analyzed with KENPAVE softwareRobel TeweldeNo ratings yet

- Vdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsDocument1 pageVdocuments - MX Elcometer Fitz Atlas 2 of Coating DefectsEdgarDavidDiazCamposNo ratings yet

- Experiment 9Document6 pagesExperiment 9clairedemotica100% (1)

- Chemistry 318: Ir, MS, Uv, NMR SpectrosDocument17 pagesChemistry 318: Ir, MS, Uv, NMR Spectrosaamer_shahbaaz0% (4)

- Ternary MeloxicamDocument8 pagesTernary MeloxicamDiah Siti FatimahNo ratings yet

- SoluplusDocument14 pagesSoluplusDiah Siti FatimahNo ratings yet

- Ex 1 11 12Document11 pagesEx 1 11 12Umme FarwahNo ratings yet

- 1-8 MethodsValidationDocument40 pages1-8 MethodsValidationMuhammadAmdadulHoqueNo ratings yet

- Zhang2012 PDFDocument7 pagesZhang2012 PDFDiah Siti FatimahNo ratings yet

- WHO Bio-Safety ManualDocument186 pagesWHO Bio-Safety ManualrggefrmNo ratings yet

- Pharma Ingredients & Services: SoluplusDocument8 pagesPharma Ingredients & Services: SoluplusDiah Siti FatimahNo ratings yet

- Linearitas dan akurasi kuersetinDocument3 pagesLinearitas dan akurasi kuersetinDiah Siti FatimahNo ratings yet

- Delivery System. USA: Lippincoctt Williams & WilkinsDocument1 pageDelivery System. USA: Lippincoctt Williams & WilkinsDiah Siti FatimahNo ratings yet

- Sinadinos Christa - Herbal Support For HypothyroidismDocument11 pagesSinadinos Christa - Herbal Support For HypothyroidismDiah Siti FatimahNo ratings yet

- Kurbak NA KDocument2 pagesKurbak NA KDiah Siti FatimahNo ratings yet

- Kelompok 2 - CFTDocument9 pagesKelompok 2 - CFTDiah Siti FatimahNo ratings yet

- Final Community Herbal Monograph Rheum Palmatum L Rheum Officinale Baillon Radix - en PDFDocument9 pagesFinal Community Herbal Monograph Rheum Palmatum L Rheum Officinale Baillon Radix - en PDFDiah Siti FatimahNo ratings yet

- Level 2 Lesson 4: ExampleDocument3 pagesLevel 2 Lesson 4: ExampleNurul HusnaNo ratings yet

- Kepmenkes 187-2017 Formularium Ramuan Obat Tradisional Indonesia 3Document1 pageKepmenkes 187-2017 Formularium Ramuan Obat Tradisional Indonesia 3Diah Siti FatimahNo ratings yet

- Laporan Praktikum Farmakoterapi Penyakit Infeksi, Gangguan Imunologi Dan OnkologiDocument1 pageLaporan Praktikum Farmakoterapi Penyakit Infeksi, Gangguan Imunologi Dan OnkologiDiah Siti FatimahNo ratings yet

- G MR X ML: Ph-PkaDocument2 pagesG MR X ML: Ph-PkaDiah Siti FatimahNo ratings yet

- Delivery System. USA: Lippincoctt Williams & WilkinsDocument1 pageDelivery System. USA: Lippincoctt Williams & WilkinsDiah Siti FatimahNo ratings yet

- EulaDocument1 pageEulaKaran PujaraNo ratings yet

- JadwalDocument2 pagesJadwalDiah Siti FatimahNo ratings yet

- IlkesDocument7 pagesIlkesDiah Siti FatimahNo ratings yet

- 1 s2.0 S1359431123015909 MainDocument33 pages1 s2.0 S1359431123015909 Mainfabio1199No ratings yet

- FT Ingesco PDC Une enDocument2 pagesFT Ingesco PDC Une enM &MNo ratings yet

- Steel SectionsDocument33 pagesSteel Sectionssam_antony2005No ratings yet

- Septic Tank and Soakage Pit1Document4 pagesSeptic Tank and Soakage Pit1Ovindi WimalarathnaNo ratings yet

- Casting Steel Alloys PDFDocument6 pagesCasting Steel Alloys PDFIAmaeyNo ratings yet

- Module 34 Strains On Any Given Plane Using Mohr's CircleDocument6 pagesModule 34 Strains On Any Given Plane Using Mohr's CircleFaryal BatoolNo ratings yet

- Polymers: Modeling of Flexible Polyurethane Foam Shrinkage For Bra Cup Moulding Process ControlDocument13 pagesPolymers: Modeling of Flexible Polyurethane Foam Shrinkage For Bra Cup Moulding Process ControlMansi ChaudhariNo ratings yet

- Underground Waste DisposalDocument39 pagesUnderground Waste Disposala4abhirawatNo ratings yet

- Ideal Gas Law 5684f195af3e6Document38 pagesIdeal Gas Law 5684f195af3e6Jose GulitiwNo ratings yet

- Experiment On Single PieceDocument3 pagesExperiment On Single PieceZatchBell100% (4)

- Heat TransferDocument27 pagesHeat TransferOmar EzzatNo ratings yet

- List of Approved Materials (Civil)Document3 pagesList of Approved Materials (Civil)xyzhynNo ratings yet

- Qdoc - Tips Tablas GpsaDocument8 pagesQdoc - Tips Tablas GpsaDavid AL'varado ValenciaNo ratings yet

- Chapter 7 - Strain EnergyDocument35 pagesChapter 7 - Strain EnergyWee Soon Chai100% (1)

- Annual Foreign Trade Statistics (2074-75)Document1,545 pagesAnnual Foreign Trade Statistics (2074-75)Ajay GauroNo ratings yet

- TDS - Tergito HXDocument2 pagesTDS - Tergito HXmyunggooNo ratings yet

- SKF - Large Diameter Seals - 6404 EngDocument116 pagesSKF - Large Diameter Seals - 6404 EngDiegoAlvarezHuguezNo ratings yet

- CIVIL MATERIAL RATESDocument25 pagesCIVIL MATERIAL RATESNishan GajurelNo ratings yet

- ASTM A615 Physical TestDocument44 pagesASTM A615 Physical TestSasha BrausNo ratings yet

- Boiler Operation and Safety GuideDocument19 pagesBoiler Operation and Safety GuidemarlpatsNo ratings yet

- Spec PDFDocument1 pageSpec PDFcrysNo ratings yet

- The Influence of XC Polymer-On Drilling Fluid Filtercake Properties and Formation DamageDocument10 pagesThe Influence of XC Polymer-On Drilling Fluid Filtercake Properties and Formation Damageمنتظر محمد عليNo ratings yet

- SDS - Chemrock 958aDocument1 pageSDS - Chemrock 958amangengueyNo ratings yet

- CP 675 T-Firestop Board MSDSDocument3 pagesCP 675 T-Firestop Board MSDSErik RodríguezNo ratings yet

- Et ChantsDocument5 pagesEt ChantsVenkatakrishna.ANo ratings yet

- VacuumDocument18 pagesVacuumHyma Prasad GelliNo ratings yet

- Post TensioningDocument2 pagesPost TensioningJay ReyesNo ratings yet