Professional Documents

Culture Documents

Mapal Reamer - 5

Uploaded by

Anil KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mapal Reamer - 5

Uploaded by

Anil KumarCopyright:

Available Formats

REAMING | FINE BORING | Tools with guide pads 5

Back taper

The back taper on the insert has a major influence on the bore quality. Selection based on part requirements in consultation with MAPAL

MAPAL selects the optimal cassette back taper for the machining appli- depending on:

cation according to the demands of the material and the feed.

- Surface finish requirement (post machining e.g. honing)

- Material

- Feed

- Lead geometry of the cutting edge

- Stock removal

Back taper

Cassette B (with TEC indexable insert)

Influence of the back taper on the surface finish with constant feed per tooth

Cutting edge radius

R0.2

R0.4

R0.8

Requirements for defined rough

surfaces e.g. interference fits or

pre-machining for honing

Standard requirements in the area

of fine machining of bores (IT6)

High accuracy requirements on

the surface finish (other boundary

Surface roughness / Ra, Rz [μm]

conditions e.g. machine stiffness

must be met)

B D F H K M P R

Available cassette types

Back taper on the minor cutting edge [°] or [μm/mm]

You might also like

- SmartCheck en Broschuere ZOLLERDocument10 pagesSmartCheck en Broschuere ZOLLERAnil KumarNo ratings yet

- Planets: Keyphrases For Interpreting The 3-Part PuzzleDocument3 pagesPlanets: Keyphrases For Interpreting The 3-Part PuzzleAnil Kumar100% (1)

- ALPHAIMPRINTREPORTCateBlanchette PDFDocument14 pagesALPHAIMPRINTREPORTCateBlanchette PDFAnil KumarNo ratings yet

- Kannada - Zodiac Signs - Wikibooks, Open Books For An Open WorldDocument2 pagesKannada - Zodiac Signs - Wikibooks, Open Books For An Open WorldAnil Kumar100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Basic WeldingDocument40 pagesBasic WeldingAsad Bin Ala QatariNo ratings yet

- Webforge Galvanising PresentationDocument13 pagesWebforge Galvanising PresentationSagar MoreNo ratings yet

- 5000 XXXX HY80 HSLA100D1.1Document2 pages5000 XXXX HY80 HSLA100D1.1Danem HalasNo ratings yet

- CH - 3 Cast IronDocument21 pagesCH - 3 Cast IronMechanical BSIET100% (1)

- A 389 - A389m - 93 R98 Qtm4os05m1i5oaDocument3 pagesA 389 - A389m - 93 R98 Qtm4os05m1i5oaPatricia J ÁngelesNo ratings yet

- Fabrication of Quick Change Tool Post PDFDocument2 pagesFabrication of Quick Change Tool Post PDFBetty0% (1)

- MP250 ManualDocument13 pagesMP250 ManualfquenNo ratings yet

- Ultimate Retaining Ring GuideDocument72 pagesUltimate Retaining Ring GuidePrabhu MohanNo ratings yet

- Stabil Drill Roller ReamersDocument2 pagesStabil Drill Roller ReamersIMEDHAMMOUDANo ratings yet

- ISCAR Cutting Tools - Metal Working Tools - Grade - IC907 CNGG 432-PPDocument2 pagesISCAR Cutting Tools - Metal Working Tools - Grade - IC907 CNGG 432-PPqdarioNo ratings yet

- Gambar 24 Seat: Nomor Refere Nomor Part Nama Part KeteranganDocument2 pagesGambar 24 Seat: Nomor Refere Nomor Part Nama Part KeteranganShade CormacNo ratings yet

- Structural SteelDocument3 pagesStructural SteelNarendra PalandeNo ratings yet

- Experiment N04-Cup DrawDocument5 pagesExperiment N04-Cup DrawRandhir KyNo ratings yet

- Material Removal Processes (IM 213) : Arab Academy For Science, Technology, and Maritime TransportDocument22 pagesMaterial Removal Processes (IM 213) : Arab Academy For Science, Technology, and Maritime TransportNicolas EleftheriouNo ratings yet

- Product DesignDocument37 pagesProduct DesignyohannesNo ratings yet

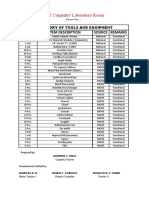

- Tools and Equipment InventoryDocument1 pageTools and Equipment Inventoryandrew indicNo ratings yet

- Aluminium Alloy en Aw 6063 Material Data Sheet AlumincoDocument1 pageAluminium Alloy en Aw 6063 Material Data Sheet AlumincoVinayak ImadiNo ratings yet

- A Sherline Factory Tour: (Click On Photo For Larger Image.)Document13 pagesA Sherline Factory Tour: (Click On Photo For Larger Image.)Anonymous hos8odNo ratings yet

- 2 Defects and DiscontinutiesDocument33 pages2 Defects and DiscontinutiesSandip GhimireNo ratings yet

- Hot Chamber Die Casting MachineDocument3 pagesHot Chamber Die Casting MachineAnand BossNo ratings yet

- Casting MachinesDocument11 pagesCasting Machines张豫鹏No ratings yet

- Summary of Bolt TensioningDocument16 pagesSummary of Bolt Tensioningpedro ylarretaNo ratings yet

- Camworks 2020: Virtual MachiningDocument18 pagesCamworks 2020: Virtual MachiningIonutNutuNo ratings yet

- Shot PeeningDocument5 pagesShot PeeningRam KumarNo ratings yet

- Sheet 1 PED 232 2nd Year 2017Document2 pagesSheet 1 PED 232 2nd Year 2017MhmdKordyNo ratings yet

- Concrete Anchor InfoDocument3 pagesConcrete Anchor InfosjnicholsonNo ratings yet

- A.6 Coating System No. 6: Title: Coating and Painting Specification Rev.: Date: Doc. No.: 05-1 - EPC-SV-AEI-M-SA-00001Document1 pageA.6 Coating System No. 6: Title: Coating and Painting Specification Rev.: Date: Doc. No.: 05-1 - EPC-SV-AEI-M-SA-00001Tien Tran Kha TienNo ratings yet

- Threading Catalog: CAT2016THD FRONTCOVER - Indd 1 8/24/16 10:37 AMDocument156 pagesThreading Catalog: CAT2016THD FRONTCOVER - Indd 1 8/24/16 10:37 AMagung wijayaNo ratings yet

- Casting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006Document56 pagesCasting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006anand_lmlNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet