Professional Documents

Culture Documents

PKKKJKJGKGJHHJHK

Uploaded by

gkp0 ratings0% found this document useful (0 votes)

14 views1 pageOriginal Title

pkkkjkjgkgjhhjhk

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pagePKKKJKJGKGJHHJHK

Uploaded by

gkpCopyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 1

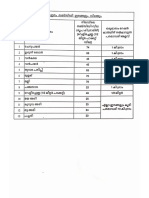

Constructing brick masonry circular manhole 1.

22 m internal dia at

bottom and 0.56 m dia at top in cement mortar 1:4 (1 cement :4

coarse sand) inside cement plaster 12 mm thick with cement mortar

1:3 (1 cement : 3 coarse sand) finished with a floating coat of neat

cement foundation concrete 1:3:6 (1 cement : 3 coarse sand : 6

graded stone aggregate 40 mm nominal size) and making necessary

channel in cement concrete 1:2:4 (1 cement : 2 coarse sand : 4

graded stone aggregate 20 mm nominal size) finished with a floating

coat of neat cement, all complete as per standard design :

Constructing brick masonry conical manholes 1.2M dia. at

bottom 0.56M. dia. at top, built in brick masonry

in cement mortar 1:3, plastered both inside and outside

with 20 mm thick cement mortar 1:2 and neat cement

rendering so as to give a smooth surface, including 300 mm

thick M.15 cement concrete in foundation and in

haunches and channels finished smooth with 20mm thick

cement plaster in cement mortar 1:1 and providing C.I. steps

(weighing 5.4 kg each) staggered at 300 mm. c/c including 75mm

wide vata all round the external portion of the manhole and the

foundation concrete in cement mortar 1:1 and supporting the incoming

pipes with brick masonry wherever necessary including C.I.

extra heavy duty (EHD) air-tight circular frame & cover (minimum 230 Kg.)

with hinge/chain resting on 30 cm high cement concrete M.20 cap with

necessary centering etc. all complete as per standard specifications and

directions including finishing the capwith cement plaster on both sides 1:2

and neat cement rendering so as to give a smooth surface in line

and level with the brick masonry surface and as per drawing in Dy. Ch.E.

(Sewerage) P&D's office without excavation depth upto 1.5 M.

(Depth of Manhole measured from top of manhole cover to Invert level

of manhole

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Energen Heat PumpDocument2 pagesEnergen Heat PumpgkpNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Kakuro - Volume 1&3 MergedDocument100 pagesKakuro - Volume 1&3 MergedgkpNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bath Fittings - Price List - 01.05.19Document56 pagesBath Fittings - Price List - 01.05.19gkpNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PriceList Jan2018Document3 pagesPriceList Jan2018gkpNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- October 2022 MalayalamDocument1 pageOctober 2022 MalayalamgkpNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- DR An Atf IcationDocument4 pagesDR An Atf IcationgkpNo ratings yet

- Scrurulating of CIBILDocument4 pagesScrurulating of CIBILgkpNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Experian Credit Report - Dispute Guide - 2022Document15 pagesExperian Credit Report - Dispute Guide - 2022gkpNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Wellmate Classic International CatalogueDocument2 pagesWellmate Classic International CataloguegkpNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Vathayasave VathayasaveDocument1 pageVathayasave VathayasavegkpNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Dranatfication PDFDocument3 pagesDranatfication PDFgkpNo ratings yet

- Design of Septic TankDocument9 pagesDesign of Septic TankSubrata Hait100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Nama RamayanamDocument3 pagesNama RamayanamgkpNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Manual Roof Drainage System HRWallingford SR620Document78 pagesManual Roof Drainage System HRWallingford SR620hillamngNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Nama RamayanamDocument2 pagesNama RamayanamgkpNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kakuro - Volume 1 - 11-20 PDFDocument80 pagesKakuro - Volume 1 - 11-20 PDFgkp0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Vathayasave Vathayasave PDFDocument1 pageVathayasave Vathayasave PDFgkpNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Kite ArramentDocument1 pageKite ArramentgkpNo ratings yet

- Vathayasave Benefits and UsesDocument1 pageVathayasave Benefits and UsesgkpNo ratings yet

- Mile To Go PDFDocument1 pageMile To Go PDFgkpNo ratings yet

- Mile To Go PDFDocument1 pageMile To Go PDFgkpNo ratings yet

- CorrectnessDocument1 pageCorrectnessgkpNo ratings yet

- Mile To GoDocument1 pageMile To GogkpNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mile To GoDocument1 pageMile To GogkpNo ratings yet

- Kind Approach PDFDocument1 pageKind Approach PDFgkpNo ratings yet

- Mile To GoDocument1 pageMile To GogkpNo ratings yet

- Kind Approach PDFDocument1 pageKind Approach PDFgkpNo ratings yet

- Kind ApproachDocument1 pageKind ApproachgkpNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Kind Approach PDFDocument1 pageKind Approach PDFgkpNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)