Professional Documents

Culture Documents

Fail Safe Air Package: Pinch Valve Technical Information

Uploaded by

enrique20Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fail Safe Air Package: Pinch Valve Technical Information

Uploaded by

enrique20Copyright:

Available Formats

Pinch Valve Technical Information

Fou

nded in 1953

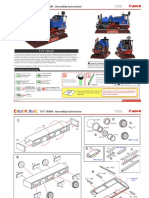

Fail Safe Air Package

Red Valve Company has designed a fail-safe air package for the Red Operation

Valve jacketed product line. The fail safe air package is a stand by The fail safe air package does not replace any Red Valve operating

system designed to actuate the pinch valve closed in the event of components. It is simply an isolated stand-by reserve air supply. Air

plant air failure. This system sold by Red Valve has sufficient stor- is locked into the tank and stored until plant air failure. Upon fail-

age capacity in the reserve air tank to close a Red Valve Pinch Valve ure of plant air or electricity the fail safe will “trip” and allow air to

in the event of air or electrical failure. close the Red Valve. Air pressure is admitted to the Red Valve

through a 3-way pilot valve or a solenoid valve depending on which

type of failure mode is desired and ordered.

The normal air line used to transport plant air to the Red Valve is

repiped through the fail safe pilot valve or solenoid valve. Only two

6 connections are required. The Red Valve will still function normal-

ly except air will be rerouted to pass through the pilot or solenoid

5 valve. Upon tripping, the normal air path is blocked and the isolat-

3 ed fail safe air passes to the Red Valve. If plant air or electric is

4 restored, the pilot or solenoid resets, flow path is restored and the

2 volume tank gradually fills with air which is locked in with a check

valve.

Connecting the fail safe solenoid valve or pilot valve correctly is crit-

TYPE A

1 PINCH VALVE ical. The Red Valve should be connected to the “cyl” ports.

7 Actuation air from a booster relay, 3-way valve, regulator, etc. is con-

nected to the “NC” (normally closed) ports. The “NC” will be open

when electric is applied to the solenoid or supply air is supplied to

1. Air storage tank the solenoid or supply air is supplied to the pilot valve.

2. Pressure gauge

3. 3-way solenoid valve or 3-way pilot valve (opens upon The chart on this page is provided as a guide in selecting the proper

power failure) size tank for a specific size valve. All tanks are oversized to allow for

4. Pressure reducing valve complete with gauge showing leakage, temperature changes and condensation. It is advisable that

pressure delivered to Red Valve charging air pressures be at least twice the required valve closing

5. Check valve on intake line of air tank pressure to insure sufficient volume to close the valves. This is cal-

6. Pressure switch and/or 3-way valve can be furnished at

culated by the Gas Law P1•V1 = P1•V2. P1•V1 is the initial charge

additional cost

tank, volume and pressure, and P2 •V2 are the final volume and

7. Type A Pinch Valve

pressure of the charge tank and valve combined.

Specifications Fail Close Air Package

TANK AIR CAPACITY VALVE AIR CONSUMPTION

VALVE RECOMMENDED GALLONS CU. IN. MAX. TANK WEIGHT OF DIAMETER VOLUME (In.3) VOLUME (In.3) VOLUME(In.3)

SIZE PACKAGE CAPACITY CAPACITY PRESSURE SYSTEM (LBS.) & LENGTH TO FILL VALVE TO CLOSE TOTAL

1" 700-3 3 669 165 20 6-1/2" x 25" 3.6 3.1 6.7

1-1/4" 700-3 3 669 165 20 6-1/2" x 25" 5.4 5.9 11.3

1-1/2" 700-3 3 669 165 20 6-1/2" x 25" 11.3 9.9 21.2

2" 700-3 3 669 165 20 6-1/2" x 25" 25.7 22.6 48.3

3" 700-12 12 2700 165 40 12" x 37" 69.3 67.8 137

4" 700-12 12 2700 165 40 12" x 37" 161 126 287

6" 700-30 30 6800 200 100 16" x 40" 462 452 914

8" 700-30 30 6800 200 100 16" x 40" 900 884 1,784

10" 700-60 60 13700 200 190 20" x 51" 1,650 1,507 3,137

12" 700-60 60 13700 200 190 20" x 51" 2,111 2,352 4,463

14" 700-80 80 18400 200 300 20" x 63" 3,0111 3,694 6,705

16" 700-80 80 18400 200 300 20" x 63" 5,900 5,469 11,396

18" 700-120 120 27600 200 400 24" x 69" 8,311 7,939 16,250

20" 700-120 120 27600 200 400 24" x 69" 9,930 10,807 20,737

24" 2-700-120 240 55200 200 800 24" x 69" 16,304 18,457 34,761

30" 3-700-120 360 82800 200 1200 24" x 69" 29,710 33,929 63,639

Red Valve Company, Inc. • 700 North Bell Avenue, Carnegie, PA 15106 • 412-279-0044 • Fax 412-279-7878 • www.redvalve.com

You might also like

- APCO Air Valve 613Document4 pagesAPCO Air Valve 613jones0055No ratings yet

- Reliableb1acc 1Document6 pagesReliableb1acc 1salajeanuNo ratings yet

- Control Valves: Block 6 Control Hardware: Electric/Pneumatic ActuationDocument112 pagesControl Valves: Block 6 Control Hardware: Electric/Pneumatic ActuationSumedha ChathurangaNo ratings yet

- I & M Mark 57: Ideal InstallationDocument4 pagesI & M Mark 57: Ideal Installationbenzerga karimNo ratings yet

- WW 83q Iom EnglishDocument5 pagesWW 83q Iom EnglishmecanicoNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve ASiddharth GupteNo ratings yet

- Cav - Valvulas. Mariposa - CavitacionDocument6 pagesCav - Valvulas. Mariposa - CavitacionzmudioNo ratings yet

- Consolidated Sterilizer FM: Boston, MA (617) 782-6072 Model: SSR-3A-ADVPB Serial No.: 101910 Jacket Pressure 25-28psiDocument58 pagesConsolidated Sterilizer FM: Boston, MA (617) 782-6072 Model: SSR-3A-ADVPB Serial No.: 101910 Jacket Pressure 25-28psiNguyen TriNo ratings yet

- Solenoid White PaperDocument16 pagesSolenoid White PaperRahul PatilNo ratings yet

- Valvula de Diluvio Watts 100d-bDocument2 pagesValvula de Diluvio Watts 100d-bLuis Carlos Figueroa Pinto100% (3)

- On - Off ValveDocument5 pagesOn - Off Valvekresimir.mikoc9765No ratings yet

- ACV 113-6RFP Specification SheetDocument4 pagesACV 113-6RFP Specification SheetWattsNo ratings yet

- Aeroplane Visual Landing Gear System With Tyre Inflation SystemDocument48 pagesAeroplane Visual Landing Gear System With Tyre Inflation SystemANAND KRISHNANNo ratings yet

- 1.07 K Controls E-Training - Solenoid Control of Pneumatic Actuators PDFDocument8 pages1.07 K Controls E-Training - Solenoid Control of Pneumatic Actuators PDFShantanu RoyNo ratings yet

- Control Valves Sizing & SelectionDocument76 pagesControl Valves Sizing & SelectionABVSAI100% (6)

- Autotrol Performa Valve With 400 Series Control Installation InstructionsDocument24 pagesAutotrol Performa Valve With 400 Series Control Installation InstructionsWattsNo ratings yet

- 205 Drag Valves For Boiler Feedpump RecirculationDocument6 pages205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590No ratings yet

- Model 115-3: Digital Electronic Control ValveDocument36 pagesModel 115-3: Digital Electronic Control ValveBruno GonçalvesNo ratings yet

- PS-203 Rev B LO Range ManualDocument16 pagesPS-203 Rev B LO Range ManualRussbelth OrtegaNo ratings yet

- Electri RelifDocument18 pagesElectri Relifsuleman247No ratings yet

- PIlot Operated Safety ValveDocument6 pagesPIlot Operated Safety ValveTrisha SalinasNo ratings yet

- Deluge Valve Modelh5Document16 pagesDeluge Valve Modelh5Mariana HusainNo ratings yet

- Ss 03037Document6 pagesSs 03037Necati Yunus OrbayNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- 08-Conv Valves Product InfoDocument18 pages08-Conv Valves Product Infoakrk777No ratings yet

- Control ValveDocument102 pagesControl ValveAnil Bag100% (2)

- Instructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Document2 pagesInstructions: For Chilled Water Buffer Tank Maintenance MODELS: CVU/CVL 120 - 1000Vũ Đình QuangNo ratings yet

- Air Release Valve Sizing Chart - How To Choose The Right ValveDocument6 pagesAir Release Valve Sizing Chart - How To Choose The Right ValveopetakyNo ratings yet

- Scuba BuildDocument9 pagesScuba BuildLlamarama5000No ratings yet

- Singer Valve 106 206 F Type 4 IOM Operation GuideDocument4 pagesSinger Valve 106 206 F Type 4 IOM Operation GuideSijo JoyNo ratings yet

- Control Valves in Process PlantDocument8 pagesControl Valves in Process Plantmukramah.yusufNo ratings yet

- Sea Clone 100Document8 pagesSea Clone 100chris77779No ratings yet

- Pneumatic Solenoid Control Box - 2Document4 pagesPneumatic Solenoid Control Box - 2Jose luis ConsuegraNo ratings yet

- Heating System DesignDocument19 pagesHeating System Designmarkbrennan1No ratings yet

- Test Bench For Safety ValveDocument8 pagesTest Bench For Safety ValvekhairurNo ratings yet

- Air ValvesDocument13 pagesAir Valvesdiadam07No ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve APatel MehulkumarNo ratings yet

- Solenoid Control Valve: Installation / Operation / MaintenanceDocument2 pagesSolenoid Control Valve: Installation / Operation / Maintenanceahmsa.morsyNo ratings yet

- Elisator Running and MaintenanceDocument20 pagesElisator Running and MaintenanceOnofrei GabrielNo ratings yet

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

- IOM Manual For Air Cylinder Operated ValvesDocument21 pagesIOM Manual For Air Cylinder Operated Valvesjhon riosNo ratings yet

- Apco Air Valve Guide 610Document12 pagesApco Air Valve Guide 610Gusu SCNo ratings yet

- Piping Interview QuestionsDocument6 pagesPiping Interview Questionssumit_b123No ratings yet

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaNo ratings yet

- 10 ValvesDocument23 pages10 ValvesPower PlantNo ratings yet

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocument14 pagesInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickNo ratings yet

- M622-175+500 Fluid Loss Operation ManualDocument11 pagesM622-175+500 Fluid Loss Operation ManualKevinGandjarAdiwidjajaNo ratings yet

- Valve Maintenance1Document11 pagesValve Maintenance1mister pogiNo ratings yet

- Operation and Maintenance Manual: AA-75CFDocument12 pagesOperation and Maintenance Manual: AA-75CFjcgm2209No ratings yet

- ValvesDocument44 pagesValvesأحمد محمد قدريNo ratings yet

- hd127 Double Interlock Elec Elec Release - 2Document6 pageshd127 Double Interlock Elec Elec Release - 2Benny Kurniawan LimNo ratings yet

- Deluge Valve HD FireDocument14 pagesDeluge Valve HD FireKeshodbana KeshodNo ratings yet

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveEduardo CastilloNo ratings yet

- Hoja de Datos - 116-4FCDocument2 pagesHoja de Datos - 116-4FCHenry Garavito RamirezNo ratings yet

- General Purpose Hydraulic Valves: Electric Float Control ValveDocument2 pagesGeneral Purpose Hydraulic Valves: Electric Float Control Valvevelikimag87No ratings yet

- Fire Alarm ValveDocument2 pagesFire Alarm ValveasdthuNo ratings yet

- Potter - Purgador de Aire PAARDocument3 pagesPotter - Purgador de Aire PAARJames HansonNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Installation: Pinch Valve Technical InformationDocument1 pageInstallation: Pinch Valve Technical Informationenrique20No ratings yet

- Type A Air Operated Pinch Valves Specification #RV-ADocument2 pagesType A Air Operated Pinch Valves Specification #RV-Aenrique20No ratings yet

- MX8000PRINTDocument4 pagesMX8000PRINTenrique20No ratings yet

- Toytrain I e A4 PDFDocument22 pagesToytrain I e A4 PDFenrique20No ratings yet

- A Report On Traffic Volume StudyDocument33 pagesA Report On Traffic Volume StudyManoj Durairaj100% (1)

- 8.2.2.2.1.1 Batch Operation ManagementDocument10 pages8.2.2.2.1.1 Batch Operation ManagementbernardNo ratings yet

- Fundamentals of Physics Sixth Edition: Halliday Resnick WalkerDocument4 pagesFundamentals of Physics Sixth Edition: Halliday Resnick WalkerAhmar KhanNo ratings yet

- Reaktor 5 Core Manual EnglishDocument210 pagesReaktor 5 Core Manual EnglishmonistoNo ratings yet

- 20CB PDFDocument59 pages20CB PDFChidiebere Samuel OkogwuNo ratings yet

- FAQs - G7, GRACoL, ISO 12647-2 PDFDocument5 pagesFAQs - G7, GRACoL, ISO 12647-2 PDFSappiETC50% (2)

- 1 s2.0 0304386X9190055Q MainDocument32 pages1 s2.0 0304386X9190055Q MainJordan Ulloa Bello100% (1)

- Reverse Engineering Cheat SheetDocument1 pageReverse Engineering Cheat Sheetalfredhitchcock_007100% (2)

- 1922 A Textbook of Balochi LanguageDocument228 pages1922 A Textbook of Balochi LanguageAnonymous 0ywnNS29EGNo ratings yet

- Psychometric Development and Validation of GaslightingDocument15 pagesPsychometric Development and Validation of GaslightingYang ZhangNo ratings yet

- Integrals - Integral Calculus - Math - Khan Academy PDFDocument7 pagesIntegrals - Integral Calculus - Math - Khan Academy PDFroberteleeroyNo ratings yet

- A B C D: Choose Only One Answer For Each QuestionDocument10 pagesA B C D: Choose Only One Answer For Each QuestionAchitt AchitNo ratings yet

- Research FinalDocument29 pagesResearch FinalLaw VesperaNo ratings yet

- Mathematical Analysisand Optimizationfor EconomistsDocument4 pagesMathematical Analysisand Optimizationfor EconomistsGuillermo GómezNo ratings yet

- Grade 10 CH 6 Assertion Reason QuestionsDocument5 pagesGrade 10 CH 6 Assertion Reason QuestionsVidhun 8ANo ratings yet

- Numerical ModelDocument61 pagesNumerical ModelAlbert AguileraNo ratings yet

- OVA37066E: Product Data SheetDocument2 pagesOVA37066E: Product Data SheetFred BionNo ratings yet

- Comparative Study of Steel Structure With and Without Floating Columns in EtabsDocument13 pagesComparative Study of Steel Structure With and Without Floating Columns in EtabsBehroz BehzadNo ratings yet

- Rekonfigurasi Jaringan Distribusi Radial Untuk Mengurangi Rugi Daya Pada Penyulang Jatirejo Rayon Mojoagung Menggunakan Metode BinaryDocument4 pagesRekonfigurasi Jaringan Distribusi Radial Untuk Mengurangi Rugi Daya Pada Penyulang Jatirejo Rayon Mojoagung Menggunakan Metode BinaryNurindra CahyantaNo ratings yet

- Strain STREMADocument6 pagesStrain STREMAChavin StormNo ratings yet

- DIO 1000 v1.1 - EN Op ManualDocument25 pagesDIO 1000 v1.1 - EN Op ManualMiguel Ángel Pérez FuentesNo ratings yet

- Case StudyDocument10 pagesCase StudyVintage ArtNo ratings yet

- Script Track IP TermuxDocument5 pagesScript Track IP TermuxAsepNo ratings yet

- Presentation5 EV ArchitectureDocument26 pagesPresentation5 EV ArchitectureJAYKUMAR MUKESHBHAI THAKORNo ratings yet

- Plate - 3 (FLOT)Document2 pagesPlate - 3 (FLOT)patrick dgNo ratings yet

- UNIT 10 (Using Modifiers To Describe Hobbies and Interests)Document2 pagesUNIT 10 (Using Modifiers To Describe Hobbies and Interests)Julian Jaramillo Angel50% (2)

- AWK - WikipediaDocument1 pageAWK - WikipediachassisdNo ratings yet

- Coding Assignment 18-WPS OfficeDocument9 pagesCoding Assignment 18-WPS Officetamj tamjNo ratings yet

- Full U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeDocument4 pagesFull U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeSanjib MandalNo ratings yet

- Python Unit 1Document18 pagesPython Unit 1Rtr. Venkata chetan Joint secretaryNo ratings yet