Professional Documents

Culture Documents

TS-MEP-MECH-07-Rev 00 - Method Statement For Installation & Testing of Domestic Water Supply Pipe (PPR, Copper & Pex) & Insulation Work

Uploaded by

senthilkumar_542571750%(2)50% found this document useful (2 votes)

195 views21 pagesOriginal Title

TS-MEP-MECH-07-Rev 00 - Method Statement for Installation & Testing of Domestic Water Supply Pipe (PPR, Copper & Pex) & Insulation Work

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

50%(2)50% found this document useful (2 votes)

195 views21 pagesTS-MEP-MECH-07-Rev 00 - Method Statement For Installation & Testing of Domestic Water Supply Pipe (PPR, Copper & Pex) & Insulation Work

Uploaded by

senthilkumar_5425717Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 21

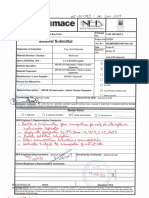

Kempinski Business Bay Hot!

Technical Submittal

scription

TathodSttemanforinstalation & nga

of Submittal: Testing of Domestic Water Supply Pipe

(eR, Copper & Pex) & insulation Work He

1 oamnmat ity

1) teinaiows C] Goes:

Ol tothe

5 were

1 mea rase oy

November 2016

[Received by NEB New pow Be)

\-y- | Mumace iil

‘SOBHA ENGINEERING AND CONTRACTING LLC. DUBAI - UAE

METHOD STATEMENT FOR INSTALLATION AND TESTING OF DOMESTIC WATER SUPPLY PIPE (PPR,

"COPPER & PEX ) & INSULATION WORK

Reviewed | Checked by | Approved

by Description

mr

ne.

reo | SER | vero

x enn [|

Tagena tes

Document No,

‘renner

SECL

‘CONTENTS:

10

20

20

40

50

60

70

80

80

100

10

130

140

150

160

70

180

score

DEFINITIONS / ABBREVIATION

DocuMeNTATION

carcuarion

SUPERVISION

SAFETY ARRANGEMENT

EQUIPMENTS:

PERSONAL PROTECTIVE EQUIPMENT (PP)

‘TRAINING

HOUSE KEEPING

COMMUNICATION

WELFARE FACILITIES

MATERIALS

HANOUING AND STORAGE

EXECUTION

‘COMPLETION OF WRK.

EMERGENCY ARRANGEMENTS

arTaciENTS

MAN:

‘score

“his method statement deta the method of nstalloton nd testing of Domestic waters supply

pipe werks fer Project: KEMPINSKT BUSINESS BAY HOTEL (Proposed 28+-G+23+Roof),

Pot # 246-690, Business Bay, Dubai UAE

DEFINITIONS & ABBREVIATIONS

(CONTRACTOR SSOBHA ENGINEERING AND CONTRACTING L.C

ss Safety Engineer

Hse Heath safety and Environment

Pec Project Engineer Ci

MEP CONTRACTOR. ‘SOBHA ELECTROMECHANICAL WORKS LLC

Projet Manager

(RC Engineer

Projet Eine Plumbing

Paanbing Superior

Inspection and Test lan

Method statement

Matera Approval heck

Project Quality lon

Work inspection Request

ee

ver

Ps

me

Ms

mas

ror

wir

ma ater inspection request

mimace

MN |<

3, REFERENCE DOCUMENTS

+ Speceaton

+ Approved shop dreninas

‘Approved materia subrital

+ Rls assessment

+ Manuacturer recommendation for instaeton and safety precautions

+ Dubal Municip regions

4. CIRCULATION

- om

+ ae

+s

5. SUPERVISION

5.1, PROJECT MANAGER (MEP)

‘+ Tobe the focal pont for interfaces and ether communications with the Company 8 Hain

contactor a5 required during execton of work. He shal ensue that sdequate quay

‘measure ae beng undertaken, He shoud ao ensure tat the reper tol ad tacks ae

‘atablefor the tiny completion of the ob n a quality manner.

5.2. QA/QCENGINEER

+ Stall ensure

inepectons ar conducted as per the correct specations,PQP & TPs

+ To ensire al epedtions, prope to & takes and manpower ae usd at al stages of

+ To ensure al caret sues of procedures approved Mater, shor drawings and

Standards are aval at the pont of tse He should abo ensure the weeks eames wth

the contract requirements /approved shop cravings. He shal be responstle fr te toa

‘ual contol for Insasaton werk Inte wh Company for epecsen of ation wor

‘Inspect for any damage dung shipping handing and storage of maria

1+ Monitor the quality of work 8 ensue that futiment of specified requement and that a

oly record lated to the work ae complet,

Hainan Comprehensive

on and test recor for any further documentation

PaaS

VAN |S.) ss

53.

54

PROJECT ENGINEER

Reviews the Method Sttement before starting the work, explins the same to the

‘subordinates and prepares program forthe daly Job. Aware ofall cde of practices,

‘Standards & Spoctetons ana HEE plan and to appreciate the worfrce to perform a time

Bound and quity jo. PEP shod ensure that safety measures ave taken to avoid ay

Unerpectad events. Ene the approved cavlled documents are used for execton of

‘works at ste He shoul ensire that any minor deviation approved by Engineer frm the

‘pproved shop dauing shall be refacted on the as bull drawings and signed by the

Contactor and consutant and. maitan the record of Red te marked crawing for

preparation of as bu draw.

PLUMBING SUPERVISOR

nau all safety equipment, proper tol takes are avaiable atthe point of we. Aare

ofa procedures, were methoarstructions, quay requirement f the time completion

of te ob and exp tothe tsk ore for execwon ofthe jb. Sxectes all cvs 2

er the conrat requirements, oppleable code of procce and azreved shop drawings

nour the approved cotoled documents ae used for exciton oF works at ste

[SAFETY ARRANGEMENTS,

“Toot box ak has to be conducted and ll the hazards have tobe Wentied before starting

the work

irk permits shal be sued from HSE department as requred ike werk incon space,

ot wk, pressure testing, Inte ight wrk, Workin shat ec

Personnel Protective Equipment’ (PPE) to be wom by the tsk foe during execution at

Ste

‘lear the obras frm the sucunding area to avo Neor misses and acer.

‘Warning sans ae barcades wil be provided wherever i required.

Manufacturer's recommendation has to be flowed on heath and safety wile during

Installation.

ay process adopted and may havea partic safety risk wl be assessed and adresse

as required.

EQUIPMENTS.

Cert Seating

Measuring Tape

Stndrd teeniian Tool box

Pipe cuter acksaw bade

Pipe fiter hand tool

VAN

ls Stee

30,

n.

2.

7 Pipe ining welding machine

PERSONAL PROTECTIVE EQUIPMENT'S

+ Safety Hemet,

Safety Shoes.

+ High visti ace,

+ Gloves

‘TRAINING

‘+ Toolbox tak shall be conducted befor starting othe work.

‘+ Hazard dentition and risk assessment sheet shall be explained to all warkers before

Stating ofeach actvty by PS

“+ Firat Aid Tring shal be conducted by HSE Department to a spe eam to attend any

emergency cases.

+ Tradesman performing the descrbed work wil be plumbing techicans/Pumbers. It

deemed necessary spect teanindvidias wil undergo further Valting and awareness

‘rogram forte acy by producon/Qualty Assrance Deportes.

HOUSEKEEPING

A work place where service personal are werking wil be cleared of al scrap mater

traxringGean and heslthy werk envionment aswel a to manta fee access nd egress

inthe event of emergency

‘COMMUNICATION

+The method statement and related rk assessment shall be communicated to the team

whi il err the Jo.

+ Any changes at ste de to adel ste conten must be discussed with project engineer

‘and wil eommaneate to consultant for advice and approval pir to inplementaton of

wok

+ Plumbing Supervisor/Foremen wil communicate from werk area t ste ofe via mobile

pone,

WELFARE FACILITIES

+ Use ste wear faites

+n summer season ORS shal be provided to workers as requred

1d-y break shall be provided as por Dubs munity Ging Pea seer

13, MATERIALS.

Poproved PPR ples; PEK ples and figs.

114, HANDLING AND STORAGE.

When offloading pipes sha be lovered to the ground ether manual or wth mechanical ad

[ke crane depending on te quartty ofthe plpe and should not be dope to the round.

{A pipes shal be store in proper storage contin, which ae ree from dust, sunight and

‘tere temperatres and a per manufacturer recommenaton

Fer temporary storage tinber supports stall be provided neath th pipe wth minimum

‘Spacing f 3m. Closer suppers wl be requed fer ses below 160m.

Fer ong term storage, the ppe Sal be stacked in racks with adequae spacing and supports

‘Rw ger ameter lp paced a the bot as shown in belo aur.

Pipes shal be gen adequate support a al ines and sal be stacked ona fat surface ree

‘ram any sharp objets.

pes shall not be stored under direct sung to aved ultra Weletdexradation.

Larger ppe sins of ticker css sal aways be placed atthe btom.

Hening

MN ==: “

45, EXECUTION.

15.1, PRE-INSTALLATION CHECK.

+ Ensue that al HSE equements at st are implemented in acordance with project set plan,

+ Ensue that the latest reviion of the approved shop droning stampsd with “ISSUED FOR

CONSTRUCTION” boing used. Te latest craig shel be issued tothe ecncerned peopl and the

‘iperended draw shal be sumendered to the document controler. Not hat any reason the

raving are subject to reion; work should not to proceed in these areas unl an update drawing

bho been used, Any devaton shal be nimated tothe engines for appro

‘+ Ensure that all materials used have pase receling laspedtion (MIR) In accordance with A

procedures and are nether damaged nor defedve. Ary non-conforming ates must be bold

by storekeeper end retumed to quoratine area mn accardance with procedure

7

Faas ati

‘Eroue Gat al Planes and hebas are avare ofthe corect mataials Fanding and wtaaton

procedure to ensure best quay of werkmarship. Trang shall be proved by manufacturer 3

nd wan requ,

Ensure thatthe flor fished level & grid reference are proven st by the surveying team.

(Check an ensure tht pipe of proper sie and fing is slected as pr schedule,

(On Technkal Rooms, Mechanical Rooms, elecrcal rooms, plant rooms et. secure "Work to

Proceed’ pri rm te main contactor pir ta canmencing of work.

Installation of Domestic Ht & Cold Water Piping (PPR/COPPER Pipes).

Ensure ony approved drovings and mater are used for isan.

‘Mark the plpereuting onthe Soto sab or a requ, duly cordnatd wth other serves and

235 per approved layout drawings.

Install hangers and supports wth approved materi

‘Te spacing of the supports forthe vertical and horizontal pipes shall be in ccordoce with the

approved details drawings and standards as appabl

‘The ppes sal be installed a designate levels as per the coordinated ay,

“The pipes ae cut to required length, and ll sharp edges ad burs sal be removed

Al safety measures tobe taken fo ison welding of PPR.

Use proper sie offen weld bushes for jltng of PPR pipes and iting while ring.

nse manufactures recommended tml for heating and hand pressing,

‘Al vahes shal be nstated In an easly sczessielcation and adequate spce shal be avaible or

‘maintenance

PVE wl be Ital! 2s par manufacture’ intructons a lecatlons aponbved en approved shop

ravings.

Isolating vahes sal be installed as per approved rang.

Make sue that water hammer arrestor installed nal open crcut water system. It must be selected

{as per approved shop drags

Make sire that the water meter installed as per manufacturer recommendation and as per

approved shop drawings

Ensure thatthe Bacon preventer installed in horzotal or verte postin as pe approved shop

srewings.

[Ai pipe ons shal be let exposed unt satstactary completion of host pressure testing,

‘The ple werk, vahes ete, shall be Kentied a= per specfictens and manutocturer

recommendation.

‘Aker Instalaton ientcaton label to be done for ll ver supply ie ONS (Cold woter Supp).

Hus (Ht water suply) & HWR(Het water retur.

‘SUPPORT SPACING DETAILS.

PIPE SIZE IN(Mm) | suPPORT spAciNG | THREADROD SIZE

‘sino

. PEs i co

z eave SO 1000 6

PPR Pines jointing method.

‘+ Before joining, the pipes and mings shel be checked for defects and te jltng surfaces are

eared thor,

‘+ Manufacture’ instalation procedure sal be folbned for ning the pipes.

‘+The PP pipes shal be jones by Elect fsion welding by sutably qualified and sled tradesmen.

‘+ ipes wil be ct to square before assembly of tings & al burs to be rubbed,

‘+ nsert pipe othe socket vith sigh sting action to full socket depth to check the ment.

“+ Remove the pes from the socket and heat using he fusion welding plate

“+ Once plpes ae heated eet in tothe sacket and ao to cal in erder form a perfect Joint.

“+The surfaces ofthe pipes and fing must be dean and witout blemish. Ends must be cebn cut at

right angles,

‘+ Before caning cut welding, check thatthe ply-fuson deve operates correctly and that reaches

the requlred welding temperatre

+ Welding & cared out heating simultaneously the male and female parts tobe joined together.

(Once the welding temperatures eached,coupng sexed out to btn tight ne.

+ Pe and ting ae inserted to the eige of the matrix and held steady without rotating once the

heating as been completed the parts are exacted fom the eating Wement and rapidly ote

aly, 50 as nat to ceate an excasive seam

-Conoes Pipes iointina method,

‘+ Sef Jong, the pipes and tings shal be checked for defects and the joing surfaces are

eared thorough.

+ Manufacturer’ installation procedure shal be folomed fr ning the pipes.

‘+ Soldering/ Brain jo wl be done as per speiation suppers recommextation.

415.2 Installation of Domestic Hot & Cold Water Piping (PPR & Copper Pipe.

Baan at 12

WAN es.

naar ony approved drovings and nate are used for Raabe

‘Mark the pipe reuting onthe soit ef sb or as requred, duly cordnatd wth oer serves and

3s per approved layout drags.

Intl angers and supports wih approved materi

‘The epacng of the supprts fr the vertical ad oczntalplpes shall be in scorénce with the

pproved det ravings and standards as appicable.

“The pes shal be installed at designate levels as per the coordinated layout,

“The pes ae otto required length, anal sharp edpes and burs shal be removed

Al safety measies tobe taken for fusion weting of PPR.

Use proper se of ison weld bushes fr ining of PPR pipes and tings while ong

Ensure manufetce's recommended timing fer heating and hand pressing

‘A vaes shale instal in an easly accuse cation and adequate space shal be aval for

rmaintenonce.

Ensure that Air ents Intaled on al high pols required fr effient operation and venting of

system whether ested onthe drawings

Rvs wil be installed as per manufacturer’ instructions at leations approved on approved shop

traigs

Isolating valves shal be insted tal pols

"ake sure that woter homme arrestor isan allopen cet water sytem, It must be select

as per approved shop cravings.

Moke sure thet the water meter ietalled as per manufacturer recommendation and as per

approved shop cranings.

Ensure ta the Backfiw preventers installed in horizontal or vertical posten as per approved shop

rownas.

Alpe ons sha be let exposed unl stfectry completion of hycrosto pressure testing,

‘The pipe work, voNes etc, shal be Wentiied as per speciatins and_ manufacturer

recommen.

‘Aer Intaltionidentcation label to be done fer CS & HWS.

‘Alt water reer pipes and tings shal be copper and as per approved meter submit

Hydrostatic Test.

zen completion of alton, the open ended ppes shal stably be pope or banked.

Al the joints shal be et uncovered unt satisfactory completion of testing.

Connect calibrate pressure gauge tothe pipe werk ata sutable lca

‘Check and ensie al dain valves ar close and inne ales ae ope,

Falthe section of ppe work under test wth Gan water.

Subject the Cold & Hat Water pping to hyo tet for 24 hours of 1.5 times ofthe working

pressure,

Tee Th ST

Sass mmace

WAN | 22... ses=: |...

15s

152

‘Mer pressuring te pipe work to The requred pressure, a hoking Une of 2 hours shall be

alow

Inspect alos, valves, tings ec for leaks, thre isa drop n pressure.

Repat leaks and detects, any, wth new mater a= required and retest the pipe work unt

satstacor results ae obtained.

Cconaant/Consutant shall be ntfid at least 24 hours in advance Wo witness the test by

submission of week inspection request.

(Only clbratd pressure gauge shall be used fr pressure testing

‘Water Supply Pipe insulation Works.

Approved materials to be used forte instalation,

‘Al insulates pipework installed on rot, th in plat room and wherever epesed to view shal be

19s per seats.

Cold water services pipe werk instaled on ref level shall be thermally irsusted were exposed

Srfaces shale cad protected against u-v degradation as per approved material submit

Insulton tides wl be as per the attached water supp pipe insulation schedule

PPR Pipe Cadding.

‘Al insulate pipe work insted on oot within plant com and wherever exposed to vw shal be

‘added wh approved mater

PEK Pipes & Fittings Installation Procedure

Ensue only approve drawings and materi reused fr instalation

Before marking starts, ste engineer shall ensure thatthe route of Pex pipe is corned with

other series ae applicable,

oc wal shall be marked by Foreman 2s per the approved shop drawing wth reference to wal or

(ri ine ad it shal be the eovenint locaton of supply requirements for santary tings.

‘Chase te wall vertically Gorm with X Sm depth forint the corrugated sleeves

‘Wherever the plastic boes tobe installed, Sutable size of Styrofoam shal be fed on wal before

plastering.

Pat box shal be fed fr female elbow inside the wal by cement at the velo sanitary fitures

and i shal aon to dry.

‘Actual length of pipes tobe installed shal be messwed fom the ste and shall be ct aczoringy

by Pex pipe cater.

‘Burs fom Isde and ouside sta be removed by emery paper.

Pex ppe shal be installed inside the wall trough corugated sleeves anc female ebow shall be

‘ennetted othe Pex pie

ale adeptor shale Instala othe domestic water supply ean Yo Pepi.

WAN | crs

153 HYDROSTATIC TEST:

"+ Upon completion of instalation, the open ended pipes shal stably be plugged or blanked

1+ Alte joints shall be left uncovered ut satstactory completion of testing.

“+ Connect a cabrated pressure gauge othe pipe wok ata sutabl eatin,

“+ Check and ensure al rain valves ae dosed ar intne vals are open.

+ Fillthe section of pipe werk under test ith ean water.

+ Subject the Cold & Hot Water piping to yoko test at for 2 hours of 15 times of the working

pressure, whichever the highest by us @ mechaical hand pump.

+ After pressuring the pve wor to the required pressure, holding tine of 2 hours shall be

alowed.

+ Inspec ol ft, vais, tings et. for leaks, there is 3 drop in pressure

+ Repak leaks and defects, any, with rew materiel as requted and reas the pipe work nt

‘Stsacory results ae tained.

+ Consutant{Conautant shall be noted at least 24 hours In advance to witness the test by

Submision of work inspection request.

+ On) cabrated pressure gauge shal be used for pressure testing,

“+ Aundersrund ping al be tested in accordance wit the manufacturer test pressure, before

tack ling con commence the sme tobe avalabe during the sai ten.

16, COMPLITION OF WORK.

+ ARer completion of work, QUOC Enlner shal check the instalation as per epprove drawings and

spectation,

+ After nspeetion of QAIQC Enlner, IR shal be raised for constant approval,

117, EMERGENCY ARRANGEMENT

+ Any emergency cases sol be reported to HSE department and immediate sper,

‘She shel be evocuted i requte as pr ste evcustion plan

18, ATTACHMENTS

+ Risk Assessment

+ Inspection and Test Pan

‘+ Instaliaton inspection Chectist

+ Gravity Test Record Check ist

EPG eee

CHECK EST FOR:

Pressure Testing of Water Supply Network RueNe

SUBCONTRACTOR CONTRACTOR []|hme stort

‘SECTION OF WORK: Mechanical TOEATION

Lave: win nas

“AREATLOCATION Smem [eae Wate

pps Tat Fess [_—“tetteses —T

Pinna sysTeM Demet Wier Sup Pipe (PPR Copy Fe) Wark

[TEST PRESSURE working ece -

MINIMUM AMBIENT TEMP,

“TEST MEDIUM TEMP,

DATE oF Test

DDuRATION oF TEST MIN 2HOURS,

TESTING FLUIDIGAS ae 2

Tete snd i ran tr pl

Tetra mt ply

FOR CONTRACTOR For Date

‘enoc: Consaea

meeps

Rae Sign | Name

a _

fe Syren nce nt

|

t

Bla lels ony |

‘

By

7

Tlelele viele | sme "a's sores |

me veoronare=ne

7 "es

am) | sa fe] >| See |

= ‘somseon jane maul Pawenar seize sunoy |

wey was] | ommeme

a ‘all [nme | ames

OD) um fail NP) | sun ‘DNA: Poked

rs La ETO Ta aS Bane Fas

- ad

: ee e102 "00 a0

zoowanraasurroason wos | ooronnrn | EOC | ytMOsW | saan stem shinny

377

‘ONLLDYALLNOD ¥ ONTAZRNIONS VHEOS ~ ANGHRIvEBC INBWNOMIANG 9 ALBANS “HEWSH

SISATWNV GUVZVH / LNSWSS3SSV SIE

f TS RTT

{% ea yeast oes

Mel» |e] e| Suamrtuceuosuoe aa ppexs Sudeorsod) 5 | ¢ | ¢ | femen an ve “ns lesa ae

“ sonny pamat geen eas ee

é ayia eh Demat eg

aeteanopeny ase on

Tara

= vo aga eo 9 ae spt

Zl el ele] SSemmemernreymtmmne | 6 |< | © | samy] wera ans coc

; ee ae faa

auinn pane hon cen Bo OS ate

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- BS en 1825-2 2002Document30 pagesBS en 1825-2 2002senthilkumar_5425717100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Water Pipe SizingDocument40 pagesWater Pipe Sizingsenthilkumar_5425717No ratings yet

- Recirculation Pump CalculationDocument4 pagesRecirculation Pump Calculationsenthilkumar_5425717No ratings yet

- Watts Interceptor CalcualationDocument49 pagesWatts Interceptor Calcualationsenthilkumar_5425717No ratings yet

- ASHRAE Table9 Hot Water Demand PDFDocument1 pageASHRAE Table9 Hot Water Demand PDFsenthilkumar_5425717No ratings yet