Professional Documents

Culture Documents

ISO 5173 Destructive Tests in Welds in Metallic Maetrials Bend Tests PDF

Uploaded by

ss0 ratings0% found this document useful (0 votes)

462 views28 pagesOriginal Title

345619238-106735679-ISO-5173-Destructive-Tests-in-Welds-in-Metallic-Maetrials-Bend-Tests-pdf.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

462 views28 pagesISO 5173 Destructive Tests in Welds in Metallic Maetrials Bend Tests PDF

Uploaded by

ssCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 28

INTERNATIONAL Iso

STANDARD 5173

‘Second edition

2000-12-15

Destructive tests on_welds in metallic

materials — Bend tests.

Essais destructifs des soudures sur matériaux métalliques — Essais de

plage

Reference number

180 5173:2000(E)

@180 2000

1SO 5173:2000(E)

PDF disclaimer

‘Tis POF file may contain embedded typefaces. In accordance with Adobe's icensing policy, ths file may be printed or viewed but shall rot

‘be edited unless the typetaces which are embedded are licensed to and installed on the computer performing the editing In downloading this

file, partes accept therein the responsibilty of no iniinging Adobe's licensing policy. The ISO Central Secretariat accepts no labity this

area.

‘Adobe is a trademark of Adobe Systems Incorporated.

Doiails ofthe software products used to create this POF file can be found in the Genera nto relative tothe fle; the POF-creation parameters

‘were optimized for printing. Every care has been taken to ensure thatthe file is sultable for use by ISO member bodies. In the unfxely event

that a problem relating tit is found, please inform the Cental Secretariat atthe address given below.

© 1802000

All rights reserved, Unless otherwise specified, no pat ofthis publication may be reproduced or utlized in any form or by any means, electronic

fr mechanical including photocopying and microfim, without permission in writing from either ISO at the adress below or ISO's member body

in the country of the requester.

180 copyright office

Case postale 58 « CH-1211 Geneva 20

Tel +41 22 7490111

Fax +41 2274909 47

E-mail copyright@lso.ch

Web vaeiso.ch

Printed in Switeecand

© 1S0 2000 ~ Al rights reserved

ISO 5173:2000(E)

Contents Page

4

.2 Abbreviations.

3 Figures corresponding to the abbreviations

5 Preparation of test specimens...

51 Gener

5.3 Marking.

5.4 Heat treatment andior agein

5.5 Extraction

56 8

6

61 15

62

6.3 Diameter of former and rolle!

64 Distance between rollers

(© 180 2000 ~ All rights reserved ii

1SO 5173:2000(E)

Foreword

'SO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing Intemational Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

‘Commission (IEC) on all matters of electrotechnical standardization,

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting,

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

Patent rights. ISO shall not be held responsible for identiying any or all such patent rights.

Intemational Standard ISO 5173 was prepared by Technical Committee ISO/TC 44, Welding and allied processes,

Subcommittee SC 5, Testing and inspection of welds.

This second edition cancels and replaces the first edition (ISO 5173:1981), which has been technically revised.

iv © 180 2000 - All rights reserved

INTERNATIONAL STANDARD ISO 5173:2000(E)

ese See SESE SEE erate eee

Destructive tests on welds in metallic materials — Bend tests

1 Scope

This Intemational Standard specifies a method for making transverse root, face and side bend tests on test

specimens taken from butt welds, butt welds with cladding (subdivided into welds in clad plates and clad welds)

and cladding without butt welds in order to assess ductility and/or absence of imperfections on or near to the

Surface of the joint. It also gives the dimensions of the test specimen,

'n addition this Intemational Standard specifies a method for making longitudinal root and face bend tests to be

used instead of transverse bend tests for heterogeneous assemblies when base materials and/or filer metal have a

significant difference in their physical and mechanical properties in relation to bending,

This International Standard applies to metallic materials in all forms of product with welded joints made by any

fusion arc welding process, Side bend tests may be carried out when the wall thickness is greater than 12 mm.

2 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

24

face bend test specimen for a butt weld, FBB

Specimen for which the surface in tension is the side which contains the greater width of the weld or the side from

which the welding arc was first applied, applicable to both transverse and longitudinal butt weld specimens

See Figures 1 and 3.

22

root bend test specimen for a butt weld, RBB

specimen for which the sufface in tension is the side opposite to that of the face butt weld bend test specimen,

applicable to both transverse and longitudinal butt weld specimens

See Figures 1 and 3.

23

transverse side bend test specimen for a butt weld, SBB

specimen for which the surface in tension is a cross-section of the weld

See Figure 2.

24

face bend test specimen for cladding without a butt weld, FC

Specimen for which the cladding is in tension, applicable to both transverse and longitudinal specimens

See Figure 4.

(© 180 2000 ~ All rights reserved 1

ISO 5173:2000(E)

25

side bend test specimen for cladding without a butt weld, SBC

Specimen for which the cross-section of the cladding overlay is in tension, applicable to both transverse and

longitudinal specimens

See Figure 5.

26

face or side bend test specimen for cladding with a butt weld, FBCB or SBCB

‘specimen for which the cladding is in tension ot for which the cross-section of the cladding overlay is in tension and

Which contains a butt weld

See Figures 6 and 7.

3 Principle

Submitting a test specimen, taken transversely or longitudinally from a welded joint, to plastic deformation by

bending it, without reversing the bending direction, in such a way that one of the surfaces or cross-sections of the

Welded joint is in tension

Unless otherwise specified, the test shall be carried out at ambient temperature (23 + 5) °C.

The test shall be made in accordance with one of the methods described in clause 6.

2 G1SO 2000 ~All ights reserved

480 6173:2000(E)

4 Symbols and abbreviations

4.1 Symbols

See Table 1 and Figures 1 to 17,

Table 1 — Symbols and designations

[_Symbor Designation Unit

| Wiath of the test specimen mm

61 __| Width of outside fusion tine mm

L a Diameter of the former mm

D___| Outside diameter of the pipe @ mim

7 Distance between the rollers mm

1 | initial aistance between contact ofthe roller and the centre line of the weld | mm

Zo ___| Original gauge length im

1,__| Maximum width of the wold after machining mm

Z,___| Total ength of the test specimen mm

| Radius of the test specimen edges mn

R___| Radius of the roliers mm

1 | Thickness ofthe tost pioce mm

‘ ___| Thickness of the cladding mm

‘5 __ | Thickness ofthe test specimen mm

fw __| Thickness of the welded joint or base material under cladding mm

@__ | Bending angie °

E The term pipe’, alone or in combination, is used to mean ‘pipe’, “tube” or “hollow section (without rectangular

ross section)".

4.2. Abbreviations

FBB Face bend test specimen for a butt weld

RBB Root bend test specimen for a butt weld

SBB Transverse side bend test specimen for a butt weld

FBC Face bend test specimen for cladding without a butt weld

SBC Side bend test specimen for cladding without a butt weld

FBCB Face bend test specimen for cladding with a butt weld

SBCB ‘Side bend test specimen for cladding with a butt weld

© 1SO 2000 — All rights reserved 7

180 5173:2000(E)

4.3 Figures corresponding to the abbreviations

Figures 1 to 7 represent bend test specimens for butt welds and cladding.

The edges shall be rounded to a radius, r, on the side where the surface is in tension.

by

Figure 1 — Transverse root and face bend test specimen for a butt weld (RBB and FBB)

Ly

L4

- 5

:

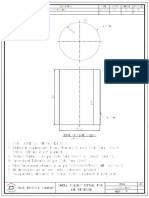

Figure 2 — Transverse side bend test specimen for a butt weld (SBB)

4 © 180 2000 ~ Al rights reserves

ISO 8173:2000(E)

Figure 3 — Longitudinal bend test specimen for a butt weld (RBB and FBB)

uy b

Figure 4 — Face bend test specimen for cladding without a butt weld (FBC)

(© 180 2000 ~ All rights reserved 5

1S 5173:2000(E)

J

Figure 5 — Side bend test specimen for cladding without a butt weld (SBC)

: Za

Figure 6 — Face bend test specimen for cladding with a butt weld (FBCB)

© 1SO 2000 All rights reserved

ie é

$0 5173:2000(E)

Figure 7 — Side bend test specimen for cladding with a butt weld (SBCB)

5 Preparation of test specimens

5.1 General

‘Specimens shall be prepared in such a manner that the preparation does not affect either the base material or the

weld metal,

5.2 Location

For transverse bend testing of butt welds the test specimen shall be taken transversely from the welded joint of the

manufactured product or from the welded test piece in such a way that after machining the weld axis will remain in

the centre of the test specimen or at a suitable position for testing,

For longitudinal bend testing of butt welds the test specimen shall be taken longitudinally from the welded joint of

the manufactured product or from the welded test piece.

The location and orientation of bend test specimens of cladding shall be specified by the application standard or by

agreement between the contracting parties.

5.3 Marking

Each test piece shall be marked to identify its exact location in the manufactured product or in the joint from which it

has been removed,

'" required by the relevant application standard, the direction of working (e.g. roling or extrusion) shall be marked.

Each test specimen shall be marked to identify its exact location in the test piece from which it has been removed.

When removed from the test piece, each test specimen shall be marked,

{© 1SO 2000 ~ All rights reserved 7

ISO 5173:2000(E)

5.4 Heat treatment and/or ageing

No heat treatment shall be applied to the welded joint or to the test specimen unless it is specified or permitted by

the relevant application standard dealing with the welded joint to be tested. Details of any heat treatment shall be

recorded in the test report. If natural ageing of aluminium alloys takes place, the time between welding and testing

shall be recorded.

5.5 Extraction

5.5.1 General

The mechanical or thermal processes used to extract the test specimen shall not change the properties of the test.

‘specimen in any way.

5.5.2 Steel

Shearing shall not be used for thicknesses > 8 mm. If thermal cutting or other cutting methods which could affect

the cut surfaces are used to extract the test specimen from the welded plate, or from the test piece, the cuts shall

be made at a distance > 8 mm from the test specimen but in any case sufficient (depending on the process used)

not to introduce metallurgical effects which could affect the test results.

5.5.3 Other metallic materials

‘Shearing and thermal cutting are not permitted; only machining (e.g. sawing or milling) shall be used.

5.6 Size of specimens

5.6.1. Transverse root and face bend tests of a butt weld (RBB and FBB)

See Figure 8.

For transverse root and face bend tests the test specimen thickness, fs, shall be equal to the thickness of the base.

material adjacent to the welded joint.

When a relevant application standard requires testing of a full thickness > 30 mm, several test specimens may be

taken in order to cover the full thickness of the joint.

In such cases, the location of the test specimen in the welded joint thickness shall be identified.

5.6.2 Transverse side bend tests of a butt weld (SBB)

See Figure 9,

For side bend tests the test specimen width, b, shall be equal to the thickness of the base material of the welded

joint, The specimen shall have a thickness, ‘5, of at least (10+0,5) mm and, in addition, shall be such that

D215 ty.

The ratio between the thickness, 1, and the diameter of the former, d, shall conform to the requirements of the

relevant application standard.

‘When the joint thickness exceeds 40 mm, it is permissible to take several specimens from the welded joint, instead

of one only, provided the width, b, of each test specimen is in the range from 20 mm to 40 mm. In these cases the

location of the test specimen in the welded joint thickness shall be identified.

8 ‘© 1SO 2000 ~ All rights reserved

180.5173:2000(E)

5.6.3 Longitudinal bend tests of a butt weld (RBB and FBB)

See Figure 10.

For longitudinal bend tests the test specimen thickness, /s, shall be equal to the thickness of the base material near

the welded joint. If the test piece thickness, 1, is greater than 12 mm, the test specimen thickness, fg, shall be equal

to (12+ 0,5) mm and the face or root of the weld shall be in tension,

5.6.4 Face bend tests of cladding without a butt weld (FBC)

See Figure 11.

For face bend tests the test specimen thickness, fg, shall be equal to the thickness of the base material plus the

thickness of the cladding up to a maximum of 30 mm.

When the thickness of the base material plus cladding exceeds 30 mm, itis permissible to remove material from

the base material in order to produce a test specimen thickness, f, in accordance with the application standard or

as agreed between the contracting parties,

5.6.5

ide bend tests of cladding without a butt weld (SBC)

See Figure 12.

For side bend tests the test specimen width, 4, shall be equal to the thickness of the base material plus the

thickness of the cladding up to a maximum of 30mm. The specimen shall have a thickness, 1, of at least

(10+ 0,5) mm and, in addition, shall be such that b> 1,5 fe

When the thickness of the base material plus cladding exceeds 30 mm, itis permissible to remove material from

the base material to produce a test specimen width, b, in accordance with the application standard or as agreed

between the contracting parties.

5.6.6 Transverse face bend tests of cladding with a butt weld (FBCB)

See Figure 13,

For transverse face bend tests of cladding with a butt weld the test specimen thickness, ‘5, shall be equal to the

thickness of the base material plus the thickness of the cladding

in such a case, the location of the weld shall remain in the middle of the test specimen or at a suitable position for

testing,

When the test concems the complete joint incorporating both the butt joint and the cladding and when the thickness

of the joint exceeds 30 mm, several specimens may be taken as described in 5.6.1 and Figure 1

When the purpose of the test is to examine the cladding only and when the thickness of the specimen, 1g, exceeds

30 mm, no further tests on the base material are required.

Figures 8 to 13 represent the location of bend test specimens for butt welds and cladding.

© 150 2000 ~ All rights reserved 9

ISO 5173:2000(E)

fs M2 mm

te

4

6

te 12mm te 12mm

Position of the test specimen ifthe face is in tension Position ofthe test specimen ifthe root isin tension

Figure 10 — Longitudinal bend test specimens for a butt weld (RBB and FBB)

10 © 180 2000 ~ All rights reserved

_-é—COE

Ld

1 LA

6

Alt

Figure 11 — Face bend test specimens for cladding without a butt weld (FBC)

© 1SO 2000 ~ All ight reserved "

12

ISO 5173:2000(E)

b= 30mm

fe fe» 30mm

Figure 12 — Side bend test specimens for cladding without a butt weld (SBC)

© 180 2000 ~All rights reserved

ISO 5173:2000(E)

t

f= 30 mm

NOTE —Itr+ F¢> 80. mm, see Figure 8.

Figure 13 — Transverse bend test specimens for cladding with a butt weld (FBCB)

5.6.7 Dimensions

7.1 Length

The length £1 of test specimens shall be £;> + 2R and at least be such that the requirements of the appropriate

application standards are fullled

567.2 TI

kness,

For the thickness, tg, see 5.6.1 10 5.6.6.

6.6.7.3 Width

a) Transverse root or face bend tests

1) For plates

~_ for steel, the width 6 of the test specimen shall not be less than 1,5 x ,, with a minimum of 20 mm;

— for aluminium, copper and their alloys, the width b of the test specimen should be not less than 2,

with a minimum of 20 mm,

(© 180 2000 ~ All rights reserved 13

1SO 5173:2000(E)

2) For pipes, the width & of the test specimen shall be a minimum of:

= for pipe diameters < 50 mm: 1+ 0,1 D (with a minimum of 8 mm);

— for pipe diameters > 50 mm: 1+ 0,05 D (with a minimum of 8 mm and a maximum of 40 mm).

NOTE For an outside diameter, D, > 25 x the wall thickness of the pipe, the specimen may be taken as required for the flat

plates.

b) Transverse side bend tests:

The width of the test specimen shall generally be equal to the thickness of the base material near the welded

joint,

‘The width b of the test specimen shall be:

b=L,+2b,

Table 2— Width of longitudinal bend specimen

Dimensions in mitimetres

Material % 6

(see Figure 3)

Steel ‘20 154210

>20 [g+2x 15,

Aluminium, copper and their <20 154215

alloys >20 Lg +2 x25

NOTE The width of the specimen for other metallic materials is by agreement between the

contracting partes,

5.6.7.4 Edges

The edges of the test specimen on the face in tension shall be rounded by mechanical means to a radius r not

exceeding 0,21, to a maximum of 3mm (see Figure 14).

5.6.8 Surface preparation

The final stages of preparation shall be obtained by machining or grinding, suitable precautions being taken to

avoid superficial strain hardening or excessive heating of the material. Within the length 1 (see Figures 14 to 16),

the surface shall be free from scratches or notches transverse to the test specimen direction except for undercut .

which shall not be removed unless required by the relevant application standard and/or by agreement between the

contracting parties.

The surfaces of the test specimen shall be machined in such a way that, unless otherwise specified in the relevant

application standard andior by agreement between the contracting parties, all excess weld metal is removed,

Unless otherwise specified, the penetration bead may be left intact inside pipes of small diameter on the opposite

side of the former.

14 ‘© 1S0 2000 ~ All rights reserved

ISO 5173:2000(E)

6 Conditions of testing

6.1 Etching

Before starting the bend test, the shape and the position of the fusion zone of fusion line may be established by

lightly macroetching the surface of the test specimen to be tested in tension.

6.2 Testing

6.2.1. Testing with a former

See Figures 14 to 16.

The test shall be carried out by placing the test specimen on two supports consisting of parallel rollers. The weld

shall be at the mid-point between the rollers, except for longitudinal bend tests. The test specimen shall be bent by

loading gradually and continuously in the middle of the span, on the axis of the weld, with a load applied by a

former (three-point bending) perpendicularly to the test specimen surface,

© 150 2000 - Alt ights reserved a

ISO 5173:2000(E)

d4 2

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Material Receiving Report FormDocument2 pagesMaterial Receiving Report FormssNo ratings yet

- 190301SKD S2Document2 pages190301SKD S2ssNo ratings yet

- DRP001 Ouf Pro U 000 001 B4Document58 pagesDRP001 Ouf Pro U 000 001 B4ss50% (2)

- 190301SKD S2Document2 pages190301SKD S2ssNo ratings yet

- DRP001 Ouf Pro U 000 001 B4Document58 pagesDRP001 Ouf Pro U 000 001 B4ss50% (2)

- TWI UT Level IIDocument7 pagesTWI UT Level IIssNo ratings yet

- Noise Measurement Procedures Manual: Second Edition July 2008Document85 pagesNoise Measurement Procedures Manual: Second Edition July 2008barun1977No ratings yet

- LPT ParikshaDocument6 pagesLPT ParikshaKlusnerKlusnerKlusnerNo ratings yet

- MRIR FOrmDocument1 pageMRIR FOrmssNo ratings yet

- Diagram Hydro TestDocument9 pagesDiagram Hydro Testss100% (1)

- Panamax - Rudder Stock - Offset Details - R1 PDFDocument1 pagePanamax - Rudder Stock - Offset Details - R1 PDFssNo ratings yet

- DFG GTRFCDocument38 pagesDFG GTRFCssNo ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuNo ratings yet

- Odc ND RevDocument1 pageOdc ND RevssNo ratings yet

- Aws Preheat Calculations From HardnessDocument6 pagesAws Preheat Calculations From HardnessElias KapaNo ratings yet

- Odc VT RevDocument1 pageOdc VT RevssNo ratings yet

- Odc-Sh-Rev 0Document1 pageOdc-Sh-Rev 0ssNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- 35% Reduction in Welding Costs PDFDocument4 pages35% Reduction in Welding Costs PDFssNo ratings yet

- Visualacuityform PDFDocument1 pageVisualacuityform PDFP BNo ratings yet

- Odc-Vt-Rev 0 - 14.02.19 PDFDocument2 pagesOdc-Vt-Rev 0 - 14.02.19 PDFssNo ratings yet

- Odc-Dd-Rev 0 - 30.12.18 PDFDocument1 pageOdc-Dd-Rev 0 - 30.12.18 PDFssNo ratings yet

- AUdit Schedule 2018Document1 pageAUdit Schedule 2018ssNo ratings yet

- Odc-Sh-Rev 0 - 14.02.19Document1 pageOdc-Sh-Rev 0 - 14.02.19ssNo ratings yet

- Cast Iron Weld RepairDocument1 pageCast Iron Weld RepairssNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- Weld MapDocument1 pageWeld MapssNo ratings yet

- Odc-Vt-Rev 0 - 14.02.19Document2 pagesOdc-Vt-Rev 0 - 14.02.19ssNo ratings yet

- Aws Preheat Calculations From HardnessDocument6 pagesAws Preheat Calculations From HardnessElias KapaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)