Professional Documents

Culture Documents

Astm D4285-83 PDF

Astm D4285-83 PDF

Uploaded by

Jose Luis Lopez0 ratings0% found this document useful (0 votes)

56 views1 pageOriginal Title

ASTM_D4285-83.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views1 pageAstm D4285-83 PDF

Astm D4285-83 PDF

Uploaded by

Jose Luis LopezCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

i iy Designation: D 4285 - 83 (Reapproved 1999)" *

NO.DE TEL : 4256532,

~UA: SAEZIO CAhloS

Standard Test Method for

29 MAY. 2002 05:19" PL

(en) FAX: GOB OT

Indicating Oil or Water in Compressed Air’ .

“Tig andar sive under the fod deipation D 4285; the number metal oie the deeaton cae the year of

ginal adaption orn he eu fe, the ear oft revison number paces nizates te year of strapped A

‘recip spoon) incatn 4a etan change nce the ast revision ot reappoval.

‘Reeds were aed elias Tau 198

1. Scope

1.1 This test method is used to determine the presence of |

cil or water in compressed air used for abrasive blast

cleining, air blast cleaning, and coating application gpera-

tions,

1.2 This standard does not purport to address all of the

safety problems, if any, associated with its use, It 18 the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

Dility of regulatory limitations prior 10 use. For specific

hazard statements, see Section 4,

2, Significance and Use

2.4 Clean compressed air is required to prevent contami-

nation of coating materials and surfaces being prepared for

coating. This test method is # visual examination technique

for determining oil or water in Compressed ai. Other types of

contamination may require additional analytical techniques

for detection.

3. Apparatus and Matertals

3.1 Absorbent Collector, such as white absorbent paper oF

loth and rigid backing for mounting absorbent collector, or

3.2 Nonabsorbent Collector, such 2s rigid ‘transparent

plastic, gpproxitmately % in. thick.

4. Cautions

4,1 To avoid false indications prior to testing

4.1.1 Allow compressed air system to reach operating

conditions, and

"Talent nthe eunder the jusucton of ASTM Comuitee DAS on

‘Proantve Coming snd Linne Work for Ponte Genet Fults 200 is tht

‘eet eporatty of Sobcometee D333 on Suice Peron

‘Gunest eon appreved Sept. 30,1983, Puied Dees 1983,

4.1.2 Allow air to discharge at operating conditions to

remove accumulated condensation in the system.

4.2 Fasten the collector material to the rigid backing.

Precantion: Avoid personal contact with the air stream.

8. Sampling

5. Conduct the test on discharzing air as close to the use

point as possible and after the inline oil and water separators,

6. Procedure

6.1 Use either the absorbent or nonabsorbent collector,

6.2 Position the collector within 24 in, ofthe airdischarge

point, centered in the air stream,

6.3 Adjust air discharge so that the collector’ remains

intact during the test. Allow air to discharge onto the

collector for a minimum of 1 min

64 Visually examine the collector for the presence or

absence of oil or water, or both.

7. taterpretation of Results

7.1, Any indication of oil discoloration on the collector

shall be cause for rejection of the compressed air for use in

abrasive blast cleaning, air blast cleaning, and coating

application operations.

7.2. Any indications of water contamination oa the cok

lector shall be eause for rejection of the compressed aie for

use in those applications where water is detrimental, such &

abrasive blast cleaning, air blast cleaning, and coating

application operations.

8. Procision and Bins

8.1. No piecision or bins statement has been established

for this test method.

9. Keywords

‘9.1 compressed air; oil and water in compressed air

‘The American Seat or Tasting and Meza takes Pe potion eepctng th vaio ary patent int exerted in connactn

wh any hm rondo esa. Una Eanoar re expressly aod nat cera he vay Fay Sue

Ptr Pres, and te 94 of rogue exc ro, ar ery he cwn rps,

‘ne etandard auto to een oy tng byt responsi lachoea conmtee ad rust bw rnd oy tv yer end

rctrened, tor roopevovd owt, YOu comms are ed ea fr ison ON stands fr agbon sandhds

fd should be apcresed o ASTM Hac, Your comments wil cave carey eonederagon ate Meng of ha rexponse

tehacal commitea, which yoo my aon you ext Pa your commas have rat recived a Tar ea7g yOu shed ake

ewe kn tate AsTa Comes an Seantares, 078 Race St, Pinsetona, Pk TOS.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Control Electronico HyundaiDocument34 pagesControl Electronico HyundaiJose Luis LopezNo ratings yet

- Transmisión AutomáticaDocument28 pagesTransmisión AutomáticaJose Luis Lopez100% (1)

- Practicas de Electronica AnalogicaDocument40 pagesPracticas de Electronica AnalogicaJose Luis LopezNo ratings yet

- Catalogo Jimny 20x20 Oct03Document16 pagesCatalogo Jimny 20x20 Oct03Jose Luis LopezNo ratings yet

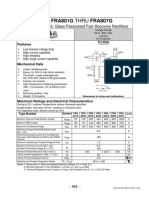

- Fra801G Thru Fra807G: 8.0 AMPS. Glass Passivated Fast Recovery RectifiersDocument2 pagesFra801G Thru Fra807G: 8.0 AMPS. Glass Passivated Fast Recovery RectifiersJose Luis LopezNo ratings yet

- Api 5LX-52 PDFDocument9 pagesApi 5LX-52 PDFJose Luis LopezNo ratings yet

- Astm A106 PDFDocument13 pagesAstm A106 PDFJose Luis LopezNo ratings yet

- Astm A106 PDFDocument13 pagesAstm A106 PDFJose Luis LopezNo ratings yet