Professional Documents

Culture Documents

Roshan Bhagat - Improvements FY201920 Rev.01 PDF

Uploaded by

unknown unexplainedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roshan Bhagat - Improvements FY201920 Rev.01 PDF

Uploaded by

unknown unexplainedCopyright:

Available Formats

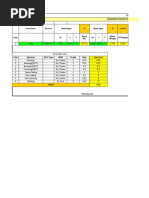

IMPROVEMENTS & SUGGESTIONS FY2019-2020

Name: - Roshan F. Bhagat

Sr. No. Present Problem/ Suggestion Changes Made Benefits in PQCDSM

Existing Stores was not enough to store 1) Got a New stores 1) Productivity

1 all the necessary material. This was built and shifted all improved as

causing delay in finding stuff also hard consumables and misc maintaining stock

to maintain inventory level. Hence, in it. became easy

suggested for new stores area for 2)Sorted all items. 2) Cost saving as waste

consumables and misc item. 3)Critical material will is easily identified &

be stored in existing prevented

stores

Earlier we did not separate Scrap (MS 1)Segregation of Scrap 1) Cost: - We get a

2 & SS) , Thus Suggested to separate before Selling significant amount of

Scrap before selling as both material money by selling

have different rate and we can get segregated

more money. scrap(MS/SS)

Earlier there was proper place to store Got a Scrap Storage Productivity by saving

3 Scrap. also, to help Helpers easily Shed Built & helped in scrap segregation time

segregate scrap got a Scrap Storage the layout and map

Shed built

No effective track on PPEs, this was a 1) Inputs on PPE Card 1) Safety

4 major safety issue. Also, 2) Implementation of 2) Morale

unaccountability increased and more PPE Card 3) Cost (Saving due to

PPEs were being used by some accountability and

workers. monitoring)

Suggested for New Fire Extinguisher Contacted HRD and the 1) Safety

5 near Oxygen Tank new Fire Extinguisher

will be installed soon

We had to prepare Label for Gave Inputs on Label. 1) Productivity

6 Identification of China Powders Got the Labels

prepared

Oil Separation in proper location, Helped in Sorting of 1) Productivity

7 maintaining stock and control in ERP Location, identified 2) Cost

also location and now all

activities have been

streamlined

There was no PPE and proper place for 1) Ordered necessary 1) Safety

8 keeping PPEs near Acid Bath this was PPEs

major safety issue 2)Got a PPE Box

prepared

BHEL Patterns to be stored properly as Identified location and Productivity

9 they are very costly (Valve Cone, Ext) stored patterns

properly

IMPROVEMENTS & SUGGESTIONS FY2019-2020

Storage of Essential Motors All motors identified Productivity

10 and kept in proper

location

Difficulty in preparing Stock Statement Suggested to prepare Productivity

11 Monthly Stock Cost

Statement in ERP

Earlier we needed to add all Instrument Suggested to link Productivity as it saves

12 details while preparing Delivery Challan Instrument master with a lot of time

for Instruments DC for Instruments

Earlier we didn’t have indent report Suggested to prepare Productivity

13 indent report it gives a

lot of insights

Earlier it was difficult to trace Implemented Productivity

14 consumption of LPT Material suggestion as informed Cost

by Vivek sir

You might also like

- Welders Work Log PDFDocument1 pageWelders Work Log PDFunknown unexplainedNo ratings yet

- TUV India Training Academy Online Training Schedule PDFDocument5 pagesTUV India Training Academy Online Training Schedule PDFunknown unexplainedNo ratings yet

- Manufacturing Instructions SN 200-7/ A1: Corrosion ProtectionDocument2 pagesManufacturing Instructions SN 200-7/ A1: Corrosion Protectionunknown unexplainedNo ratings yet

- Manufacturing Instructions SN 200-7/ A1: Corrosion ProtectionDocument2 pagesManufacturing Instructions SN 200-7/ A1: Corrosion Protectionunknown unexplainedNo ratings yet

- SN200-1 2016-05 e PDFDocument5 pagesSN200-1 2016-05 e PDF30410929No ratings yet

- DMAIC Part 1 of 5 Define PDFDocument7 pagesDMAIC Part 1 of 5 Define PDFunknown unexplainedNo ratings yet

- 5S Part 1 SORT PDFDocument7 pages5S Part 1 SORT PDFunknown unexplainedNo ratings yet

- Manufacturing Instructions SN 200-6: Assembly and DisassemblyDocument6 pagesManufacturing Instructions SN 200-6: Assembly and DisassemblyVirtual BoxNo ratings yet

- Quality Clinic Process Overview: L.A. SiteDocument15 pagesQuality Clinic Process Overview: L.A. SiteKristof MCNo ratings yet

- Work Permit FlowDocument1 pageWork Permit Flowunknown unexplainedNo ratings yet

- Ashok Resume PDFDocument3 pagesAshok Resume PDFunknown unexplainedNo ratings yet

- BS OHSAS 18001 Implementation GuideDocument12 pagesBS OHSAS 18001 Implementation GuideAditya BagrolaNo ratings yet

- Alloy Key Features: Information SourceDocument1 pageAlloy Key Features: Information Sourceunknown unexplainedNo ratings yet

- Tech Spec Diffuser725Document15 pagesTech Spec Diffuser725unknown unexplainedNo ratings yet

- Emergency Stop Valve-V5i352 PDFDocument4 pagesEmergency Stop Valve-V5i352 PDFmahesh waliNo ratings yet

- The Effects of Alloying Elements On SteelsDocument36 pagesThe Effects of Alloying Elements On SteelsRahul PandeyNo ratings yet

- Buttress Thread Measurement PDFDocument1 pageButtress Thread Measurement PDFunknown unexplainedNo ratings yet

- G0807014650 PDFDocument5 pagesG0807014650 PDFunknown unexplainedNo ratings yet

- Surface RoughnessDocument9 pagesSurface RoughnessKarthick DuraiNo ratings yet

- Vda BrochureDocument8 pagesVda BrochureSaul Serrano CahuantziNo ratings yet

- The Effects of Alloying Elements On SteelsDocument36 pagesThe Effects of Alloying Elements On SteelsRahul PandeyNo ratings yet

- Utblock Model PDFDocument1 pageUtblock Model PDFunknown unexplainedNo ratings yet

- MetcoDocument1 pageMetcounknown unexplainedNo ratings yet

- Guidelines For The Use of Personal Protective Equipment (PPE) in Thermal SprayingDocument33 pagesGuidelines For The Use of Personal Protective Equipment (PPE) in Thermal SprayingDANIEL F. HERNANDEZNo ratings yet

- Liquid Penetrant Testing (LPT)Document2 pagesLiquid Penetrant Testing (LPT)unknown unexplainedNo ratings yet

- Liquid Penetrant Testing (LPT)Document2 pagesLiquid Penetrant Testing (LPT)unknown unexplainedNo ratings yet

- CNC Programming Handbook 2nd Edition by Peter Smid PDFDocument529 pagesCNC Programming Handbook 2nd Edition by Peter Smid PDFunknown unexplainedNo ratings yet

- Dichtol WFT Standard 1532 en 1Document2 pagesDichtol WFT Standard 1532 en 1unknown unexplainedNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 3 Axis CNC Router 60x60x5Document13 pages3 Axis CNC Router 60x60x5Bien Morfe100% (1)

- Electric Arc Furnace PDFDocument18 pagesElectric Arc Furnace PDFUlises Quintana CarhuanchoNo ratings yet

- Disposal ProcessDocument2 pagesDisposal ProcessRey Regaspi TuyayNo ratings yet

- PH3 30 Iron SteelDocument142 pagesPH3 30 Iron SteelMouna GuruNo ratings yet

- Pug Mills MixersDocument6 pagesPug Mills MixersStefan Van CleemputNo ratings yet

- Myb1 2015 Nicke PDFDocument18 pagesMyb1 2015 Nicke PDFakbar suhadaNo ratings yet

- Improving Ship Design Process To Enhance Ship RecyDocument10 pagesImproving Ship Design Process To Enhance Ship RecyRASHWATH JNo ratings yet

- Steelez 'We Make It Easy' FARA.Document21 pagesSteelez 'We Make It Easy' FARA.Ashish MishraNo ratings yet

- Pak Steel August 2022 Price - ListDocument5 pagesPak Steel August 2022 Price - ListAshraf AliNo ratings yet

- Cost SheetDocument66 pagesCost SheetShivani Kumai100% (1)

- Magenetic Chip Collector New 2Document27 pagesMagenetic Chip Collector New 2Hemasundar Reddy JolluNo ratings yet

- MGT 423Document4 pagesMGT 423Ajmal AftabNo ratings yet

- Life Cycle AssessmentDocument65 pagesLife Cycle AssessmentFarol Raji PaRrNo ratings yet

- Price History: Tables and ChartsDocument16 pagesPrice History: Tables and ChartsbencoolsNo ratings yet

- Radiation Manual 8-27-09Document33 pagesRadiation Manual 8-27-09ericd_flores939No ratings yet

- Ba CFD - RLM - 9 8 10 2018 - en PDFDocument18 pagesBa CFD - RLM - 9 8 10 2018 - en PDFAngga HardiyantomoNo ratings yet

- The Market For Ship DemolitionDocument9 pagesThe Market For Ship Demolitiony4x6kfzhc8No ratings yet

- Julian Allwood Sustainable Materials With Both Eyes Open SoSL12 LowDocument3 pagesJulian Allwood Sustainable Materials With Both Eyes Open SoSL12 LowbeccafabbriNo ratings yet

- Continuous Casting Solutions SERVICE 24/7Document2 pagesContinuous Casting Solutions SERVICE 24/7abramNo ratings yet

- Four Cavity Foil Container Making Machine PDFDocument12 pagesFour Cavity Foil Container Making Machine PDFBijayShahNo ratings yet

- 03 34 11 - MSL Intel - Mughal Initiation - Capitalizing On The Global Base Metal FiestaDocument15 pages03 34 11 - MSL Intel - Mughal Initiation - Capitalizing On The Global Base Metal FiestaMehroz KhanNo ratings yet

- Material Review BoardDocument13 pagesMaterial Review BoardSaurav KumarNo ratings yet

- 3-0 BOF SteelmakingDocument7 pages3-0 BOF SteelmakingTamal Tanu RoyNo ratings yet

- Sap Apo PPDSDocument77 pagesSap Apo PPDSmanish161286% (7)

- Grills, Railings, Fence: Profile No.: 220 NIC Code:24109Document10 pagesGrills, Railings, Fence: Profile No.: 220 NIC Code:24109Sanyam BugateNo ratings yet

- F and Q Project Heera PDFDocument8 pagesF and Q Project Heera PDFSherry HenryNo ratings yet

- Scrap Sales Order Cycle:-: Step 1: Sales Document Type IMG Sales and Distribution Sales Sales DocumentsDocument2 pagesScrap Sales Order Cycle:-: Step 1: Sales Document Type IMG Sales and Distribution Sales Sales DocumentshdrNo ratings yet

- Ib 1500893 EngdDocument480 pagesIb 1500893 Engdjoefendi85No ratings yet

- FS Rkef 02Document123 pagesFS Rkef 02فردوس سليمانNo ratings yet

- SCHAEFFLER PIRACY 20213 Pressrelease - 87902145Document3 pagesSCHAEFFLER PIRACY 20213 Pressrelease - 87902145Gerardo Cabral AlonsoNo ratings yet