Professional Documents

Culture Documents

!!!!pa - A194 2H

Uploaded by

J.Guerhard0 ratings0% found this document useful (0 votes)

17 views8 pagesPESQUISAS SOBRE JUNTA APARAFUSADAS

Original Title

!!!!PA_A194 2H

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPESQUISAS SOBRE JUNTA APARAFUSADAS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views8 pages!!!!pa - A194 2H

Uploaded by

J.GuerhardPESQUISAS SOBRE JUNTA APARAFUSADAS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

wos ‘eu aie else ler Cana Ba all ar ASME Prien angen Tee

@ Hex Technology

The Stud Guide: B7s,

Bl6s, and Other

Common Bolt

Materials found in

ASME Pressure

Vessels and Piping

lay

‘sunucmne ‘eu aie else er cana Ba all ar ASME Preteen anges Tecrlgy

AL frst glance, the names of fasteners used in bolting for ASME pressure vescele and piping ean gound like something out

of the old-school board game “Battleship.”

87, 86, 2H, A193. dangit, you ust sunk my destroyer.

Each of these labels are meaningful, and can indicate the use of diferent materials (such as alloy steel or stainless steel)

with alifferent mechanical properties. —

oetaececrabanzomichascabgic! oe

ran SME rs Ve nd igh shay

The names also indicate which will perform better in certain environments, such as high-temperature and high-pressure

applications.

In this article, wel discuss several different relevant aspects of these fasteners, including

+ tensile strength

+ stainless steal (grade B8) vs. carton steel (grade 87 & B16)

+ heavy hex nuts (2H nuts, or Grade 4 & 7 nuts)

ut well start with an overview of the standards governing the use of nuts and bolt in industrial applications

Summary of Standards for Common Fasteners

Industrial fasteners can be called stud bolts or — of course — just plain of bolts. They are governed by three main

Industry standards:

+ ASTM A193: “This specication covers alloy steel and stainless steel bolting material for pressure vessels, valves,

flanges, and fitings for high temperature or high-pressure service, or other special-purpose applications. Ferric

steels shall be properly heat treated as best suits the high-temperature characteristics of each grade.

+ ASTM A320: This specification covers ally steel bolting materials and bolting components for pressure vessels,

valves, flanges, and iting for low-temperature service

+ ASTMAI94: “Ths specication covers a variety of carbon, alloy, and martensitic and austenitic stainless steel

ruts. These nuts are intended for high-pressure or high-temperature service, or both”

NOTE: Items that we will nt cover in this article include: coating practices such as zinc plated, PTFE or Xylan(R) coating,

hhex bolts, or hex cap screws or machine screw nuts and coupling nuts found in ASME 18.2.2, a5 these have nothing to

0 with industrial Botting.

Stud and Nut Combinations

B7 Studs and 2H Nuts

oetaececrabanzomichascabgic!

ran SME rs Ve nd igh shay

[ASTM A193 Grade B7 bolts are made of chromium-molybdenum steel. The bolts are quenched and tempered (a.k.a heat

treated) to develop the desired tensile strength (mechanical properties)

(Grade 87 Stud Bolts are used in pressure vessels that do not need corrosion resistance, aren't susceptible to stress

Corrosion cracking, and for temperatures typically less than 750F. However, these bolts can have many different types of

finishes, including

+ lain finish for standard applications

+ hot-dip galvanized process

+ zine plated andor have a PTFE or Xylan coating for corrosion resistance

NOTE: Typical a coated stud will have a lower temperature rating than plain finish stud bolts. (See our article “PTFE

Coated Studs: Do They Work?" for more.)

Size and strength:

+ ASTM A193 B7 stud bolts with a diameter of 25 inches or less will have a yield strength of 105,000 PSI.

+ Grade 87 fasteners with a stud diameter of 2-5/8" to 4" ciameter have a lower yield strength of 95,000 PSI

+ "107" inch stud bolts have an even lower yield strength of 75,000 PSI

The nut material for Grade B7 bolts is typically ASTM A194 heavy hex nuts (2H nuts).

oetaececrabanzomichascabgic! oo

This is supposed to be a stack of 87s on aj site, Can you fin

A194 Grade 2H Nuts

2H nuts workin eo

ia Ould see failure o

7 Studs and are stronger than the

his does not include over tapping of the nut fo strength ofthe nut

Grade B7M Studs and Nuts

ran SME rs Ve nd igh shay

[ASTM A193 Grade B7M studs are identical in chemistry to Grade B7, as they are quenched and tempered carbon steel to.

achieve a lower hardness. However, they have a lower tensile strength than B7 studs.

\We typically see Grace B7M bolts in hydrogen stress corrosion cracking (SCC) applications such as hydrofluoric acid or in

Floating Head Heat Exchangers.

[ASTM A194 GRADE 2HM are similar to 2H nuts, except this grade is re

envionment.

ynended for use in stress corrosion cracking

Grade B16 Studs

ASTM A193 B16 stud bolts are used primarily fr high temperature applications. They are manufactured from a chromium=

molybdenum-vanadium alloy steel,

Although £193 Grade B16 bolts and studs have similar strength requirements as Grade 87, the fasteners retain strength

Under high temperatures, and also experience less relaxation at those high temperatures.

‘There are two nut combinations you can use for B16 stud bolts. They are:

+ ASTM A194 GRADE7: These are also heat-treated chrome-molybdenum steel nuts that are also sultabe for sub

zero service conditions and have minimum Charpy impact values in accordance with ASTM specifications

+ ASTM A194 GRADE 4: Those were taken out of ASTM AT94 in 2017, but were heat treated molyodenum steel nuts.

Itis imperative that you use Grade 7 (or 4) nuts with 816 studs, because thoy have similar propertles. 2H Nuts, on the

‘other hand, wil relax more. Sof you have high temperature and 24 nuts you will se increased relaxation, or loss of bolt

toad, (Not sure how to handle bot relaxation? Contact us. We can help.)

B8 Studs Class 1 and Class 2: What's the Difference?

ASTM A193 B8 studs are commonly used in high temperature applications (roughly 7S0F to 1100F) . However, you have to

be cautious because there isa aference between 88 Class 1 and B8 Class 2 studs.

oetaececrabanzomichascabgic! eo

ran SME rs Ve nd igh shay

Grade 88 stud bolts are made of AISI 304 stainless steel, These type of fasteners are made with austenitic stainless steel

‘and require carbide solution treatment

‘The carbide solution treatment, also known as solution annealing, isthe process in which fasteners are heated and then

water-quenched to assure maximum corrosion resistance.

Clase 1 stud bolts are not

rain-hardened, and have a yield strength of 30 KSI, or 30,000 PSI. However, Class 2 stud

bolts are strain-hardened and have a 95,000 PSI or 95 KSI yield strength,

How can you tella Class 2 versus a Class 1 bolt? The B8 symbol on @ Clase 2 will have a line underneath it

will not have an underine, Please look forthe line on 2 B8 class 2.

while a Class

ASTM Al94 GRADE @ Stainless stee! nuts requied for these fasteners

BBM Studs

ASTM A193 Grade BBM fasteners are manufactured the same way as 88 fasteners. The difference isn the materials that

they are made of

BBM fasteners are manufactured from AISI 316 stainless steel as opposed to AIS! 304 stainless steel. The 316 form of

stainless steels better for corrosion resistance because it has more molybdenum,

ASTM A193 Grade BBM Class 1 fasteners require a carbide solution treatmer

additional strain hardening ust lke 88 fasteners.

while Class 2 fasteners require an

ASTM A194 GRADE @M Stainless stee! nuts are required for these fasteners.

ASTM A320, GRADE L7 and Grade L7M

ASTM A320 Grade L7 and L7M fasteners are recommended for use in low temperature environments typically found to be

-S0F to -150F, These fasteners also require Grade 4 or Grade 7 nuts

oetaececrabanzomichascabgic! te

RELATED:

ran SME rs Ve nd igh shay

Beyond ASME PCC~1: What Today's Boltng Professionals Need to Know

‘The Myth About Bolt Yield

‘Guide to Bott Lubricant and Torque

Learn the best practices in bolting when you enral in our ontne training. I's 100% free.

(© Copyright 2020 Hex Technology

5, Suite 601

‘ems of Use Privacy Poley

oetaececrabanzomichascabgic! os

You might also like

- 3211 2 Engl 2013 11Document171 pages3211 2 Engl 2013 11Андрей ИнгельбергNo ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document158 pagesOf The Nuclear Safety Standards Commission (KTA)J.GuerhardNo ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document11 pagesOf The Nuclear Safety Standards Commission (KTA)J.GuerhardNo ratings yet

- Integrated Finite Elements Analysis and Design of StructuresDocument50 pagesIntegrated Finite Elements Analysis and Design of StructuresJ.GuerhardNo ratings yet

- Safety StandardsDocument157 pagesSafety Standardssonnu151No ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document125 pagesOf The Nuclear Safety Standards Commission (KTA)J.GuerhardNo ratings yet

- A Limit Analysis Study To Interpret The PDFDocument19 pagesA Limit Analysis Study To Interpret The PDFJ.GuerhardNo ratings yet

- KTA2201.4 - Design Against EarthquakespdfDocument23 pagesKTA2201.4 - Design Against EarthquakespdfJ.GuerhardNo ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document158 pagesOf The Nuclear Safety Standards Commission (KTA)J.GuerhardNo ratings yet

- MSSS TalkDocument148 pagesMSSS TalkTemirlan StabaliyevNo ratings yet

- Bolted Joints Analysis Methods and Evalu PDFDocument9 pagesBolted Joints Analysis Methods and Evalu PDFJ.GuerhardNo ratings yet

- Of The Nuclear Safety Standards Commission (KTA)Document125 pagesOf The Nuclear Safety Standards Commission (KTA)J.GuerhardNo ratings yet

- Iso Tolerances For Metric Fasteners: References NotesDocument2 pagesIso Tolerances For Metric Fasteners: References Notestushk20No ratings yet

- Sa194m 2007Document18 pagesSa194m 2007J.GuerhardNo ratings yet

- Wwelds in CreepDocument24 pagesWwelds in CreepJ.GuerhardNo ratings yet

- Bolted Joints Analysis Methods and Evalu PDFDocument9 pagesBolted Joints Analysis Methods and Evalu PDFJ.GuerhardNo ratings yet

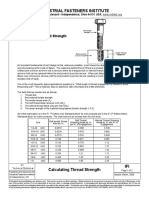

- Engineering Bulletin Calculating Thread PDFDocument2 pagesEngineering Bulletin Calculating Thread PDFJ.GuerhardNo ratings yet

- Pip STF 05501 - 2012Document17 pagesPip STF 05501 - 2012Денис Пекшуев100% (1)

- Studies On Factors Influencing The Behav PDFDocument7 pagesStudies On Factors Influencing The Behav PDFJ.GuerhardNo ratings yet

- JSSW Vessel Design CriteriaDocument38 pagesJSSW Vessel Design CriterialafondejsNo ratings yet

- Effective Process Safety Management For Highly HazDocument5 pagesEffective Process Safety Management For Highly HazJ.GuerhardNo ratings yet

- Greenslade Bsee Astm f16 May 8 Presentation 1Document14 pagesGreenslade Bsee Astm f16 May 8 Presentation 1J.GuerhardNo ratings yet

- Irjet V3i8129 PDFDocument5 pagesIrjet V3i8129 PDFmahakNo ratings yet

- Friction Buffer Stop Design PDFDocument4 pagesFriction Buffer Stop Design PDFJ.GuerhardNo ratings yet

- Educational Bulletin No 1Document2 pagesEducational Bulletin No 1sandeep5No ratings yet

- Nonlinear Soil Abutment Bridge StructureDocument14 pagesNonlinear Soil Abutment Bridge StructureJ.GuerhardNo ratings yet

- The Basic Mechanisms of Bursts and LeakageDocument146 pagesThe Basic Mechanisms of Bursts and LeakageJ.GuerhardNo ratings yet

- Lateral Loads ManualDocument316 pagesLateral Loads ManualJ.GuerhardNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)