Professional Documents

Culture Documents

21-Stainless Steel Aisi 304 (A2) PDF

Uploaded by

Itx Minhas0 ratings0% found this document useful (0 votes)

40 views1 pageThis document provides specifications for AISI 304 (A2) stainless steel, including its chemical composition, mechanical properties, and dimensions for various bolt sizes. Some key points:

- AISI 304 stainless steel contains 18-20% chromium, 8-10.5% nickel, and a maximum of 0.07% carbon.

- It lists the stress area, proof stress, tensile strength, and elongation for AISI 304 in two classes (70 and 80) across bolt sizes from M6 to M72.

- Mechanical properties like proof load, torque, and tensile strength are provided for each bolt size.

- Dimensional information and markings for AISI 304

Original Description:

Original Title

21-STAINLESS STEEL AISI 304(A2).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for AISI 304 (A2) stainless steel, including its chemical composition, mechanical properties, and dimensions for various bolt sizes. Some key points:

- AISI 304 stainless steel contains 18-20% chromium, 8-10.5% nickel, and a maximum of 0.07% carbon.

- It lists the stress area, proof stress, tensile strength, and elongation for AISI 304 in two classes (70 and 80) across bolt sizes from M6 to M72.

- Mechanical properties like proof load, torque, and tensile strength are provided for each bolt size.

- Dimensional information and markings for AISI 304

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views1 page21-Stainless Steel Aisi 304 (A2) PDF

Uploaded by

Itx MinhasThis document provides specifications for AISI 304 (A2) stainless steel, including its chemical composition, mechanical properties, and dimensions for various bolt sizes. Some key points:

- AISI 304 stainless steel contains 18-20% chromium, 8-10.5% nickel, and a maximum of 0.07% carbon.

- It lists the stress area, proof stress, tensile strength, and elongation for AISI 304 in two classes (70 and 80) across bolt sizes from M6 to M72.

- Mechanical properties like proof load, torque, and tensile strength are provided for each bolt size.

- Dimensional information and markings for AISI 304

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

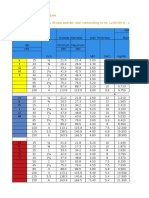

PROPERTIES OF STAINLESS STEEL

AISI 304 (A2)

BOTL/NUT BOTL/NUT

AISI 304 CLASS 70 AISI 304 CLASS 80

OR EN 1.4301 OR EN 1.4301

STRESS PROOF PROOF TOUR- TENSILE ELONGA- PROOF PROOF TOUR- TENSILE ELO-

BOLT AREA STRESS LOAD QUE* STRESS TION# STRESS LOAD QUE* STRESS GATIO

SIZE PITCH MM2 N/MM2 KN N-m N/MM2 % N/MM2 KN N-m N/MM2 on#

M6 1 20.1 450 9.0 7.3 700.0 45.0 600 12.1 9.7 800.0 45.0

M8 1.25 36.6 450 16.5 17.7 700.0 45.0 600 22.0 23.6 800.0 45.0

M10 1.5 58.8 450 26.5 35.5 700.0 45.0 600 35.3 47.4 800.0 45.0

M12 1.75 84.3 450 37.9 61.1 700.0 45.0 600 50.6 81.5 800.0 45.0

M14 2.0 115.0 450 51.8 97.3 700.0 45.0 600 69.0 129.7 800.0 45.0

M16 2.0 157.0 450 70.7 151.8 700.0 45.0 600 94.2 202.3 800.0 45.0

M18 2.5 192.0 450 86.4 208.8 700.0 45.0 600 115.2 278.4 800.0 45.0

M20 2.5 245.0 450 110.3 296.0 700.0 45.0 600 147.0 394.7 800.0 45.0

M22 2.5 303.0 450 136.4 402.7 700.0 45.0 600 181.8 536.9 800.0 45.0

M24 3.0 353.0 450 158.9 511.8 700.0 45.0 600 211.8 682.4 800.0 45.0

M27 3.0 459.0 450 206.6 748.7 700.0 45.0 600 275.4 998.3 800.0 45.0

M30 3.5 561.0 450 252.5 1,017 700.0 45.0 600 336.6 1,356 800.0 45.0

M33 3.5 694.0 450 312.3 1,384 700.0 45.0 600 416.4 1,845 800.0 45.0

M36 4.0 817.0 450 367.7 1,777 700.0 45.0 600 490.2 2,369 800.0 45.0

M39 4.0 976.0 450 439.2 2,300 700.0 45.0 600 585.6 3,066 800.0 45.0

M42 4.5 1,120.0

M45 4.5 1,310.0

M48 5.0 1,470.0

M52 5.0 1,760.0

M56 5.5 2,030.0

M60 5.5 2,360.0

M64 6.0 2,680.0

M68 6.0 3.060.0

M72 6.0 3,460.0

DIMENSIONS NORMAL HEX NORMAL HEX

MARKINGS ‘RS‘ ‘A2-70‘ ‘RS‘ ‘A2-80‘

CARBON -0.07 -0.07

MANAGENESE -2.0 -2.0

SULPHUR -0.03 -0.03

SILICON -1.0 -1.0

CHROMIUM 18.0-20.0 18.0-20.0

MOLYDENUM - -

NICKLE 8.0-10.5 8.0-10.5

VANADIUM

BORON

PHOSPHOROUS -0.045 -0.045

MATERIAL AISI 304 AISI 304

NOTES: *If carbon is < 0.03 SS304L *If carbon is < 0.03 SS304L

Left hand side of ‘-’ is minimum value

Right hand side of ‘-’ is maximum value

Eg. 0.5 - 0.7 min. is 0.5 and max is 0.7

Eg. -0.8 max is 0.8 no minimum value

Eg. 2.0- min. is 2.0 no maximum value * Torque value based on 75% of proof load and finish as recieved steel

While every care has been taken in preparation of the information,the company accepts no liability for any loss or damage either direct or consequential. Please refer Original standards for details.

You might also like

- Operations Research by H.A TAHA Solution Manual (8th Edition)Document475 pagesOperations Research by H.A TAHA Solution Manual (8th Edition)Gwen Tennyson84% (180)

- Microstructure Lab ReportDocument13 pagesMicrostructure Lab ReportUdani Wijekoon100% (1)

- Free Audiobook VersionDocument1 pageFree Audiobook Versioncigevoyani0% (1)

- Engineering Materials PDFDocument24 pagesEngineering Materials PDFPradeepkumarKatgiNo ratings yet

- 4 Steel Pipe Sans 719Document1 page4 Steel Pipe Sans 719Roddy TeeNo ratings yet

- 01 Bs 3692 Grade 88 Bolt Nut CompressDocument1 page01 Bs 3692 Grade 88 Bolt Nut Compresssssaiyed786yahoo.com ShoebNo ratings yet

- Hex Bolts: Tensile / Yield / Shear Strength Tightening TorqueDocument1 pageHex Bolts: Tensile / Yield / Shear Strength Tightening TorqueVivekNo ratings yet

- Bolt Torque Cl4.6-Tight-TorqDocument1 pageBolt Torque Cl4.6-Tight-TorqMir AsifNo ratings yet

- Bolt Pro PDFDocument4 pagesBolt Pro PDFWaqar FaziNo ratings yet

- Hex Bolts - Minimum Tensile StressDocument4 pagesHex Bolts - Minimum Tensile StressWaqar FaziNo ratings yet

- Threaded Rod M33 (3.5) 10.9Document4 pagesThreaded Rod M33 (3.5) 10.9Konstantinos SynodinosNo ratings yet

- Eurocode Axial DesignDocument10 pagesEurocode Axial Designamanpreet_ahuja100% (1)

- Upvc PipesDocument1 pageUpvc PipesMuneer mahammadNo ratings yet

- Impact Wrenches: Optimal Torque of BoltDocument6 pagesImpact Wrenches: Optimal Torque of BoltFarjad KhanNo ratings yet

- HTD HXB cl10.9 Tight TorqDocument1 pageHTD HXB cl10.9 Tight Torqaegean227No ratings yet

- Screw DimensionDocument2 pagesScrew DimensionAbhijeet SinghNo ratings yet

- Specifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Document3 pagesSpecifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Manish StauffenbergNo ratings yet

- Catalog Bich 3Document2 pagesCatalog Bich 3Ngọc TùngNo ratings yet

- HTD Ss HXB Tight TorqDocument1 pageHTD Ss HXB Tight TorqTony CefaiNo ratings yet

- Trip CurrentDocument49 pagesTrip CurrenthareeshksomanNo ratings yet

- Mechanical Engineering: 1.plain Washers, Black: Metric SeriesDocument7 pagesMechanical Engineering: 1.plain Washers, Black: Metric SeriesRathnakrajaNo ratings yet

- Dimensões Das TubulaçõesDocument2 pagesDimensões Das TubulaçõesAlice Boll AltieriNo ratings yet

- DIN 433 SpecDocument4 pagesDIN 433 SpecChris StefanouNo ratings yet

- Orrcon Steel Chequer PlateDocument1 pageOrrcon Steel Chequer PlateOliver HermosaNo ratings yet

- Slip On Flanges - ANSI B16.5: Class 150 LBDocument5 pagesSlip On Flanges - ANSI B16.5: Class 150 LBJosé A. RamírezNo ratings yet

- ASME B16.5-Flanges Class 150Document1 pageASME B16.5-Flanges Class 150radziNo ratings yet

- Section 10 Useful Information: Iso General Purpose Metric ScrewthreadsDocument1 pageSection 10 Useful Information: Iso General Purpose Metric ScrewthreadsRicardo_CHES1986No ratings yet

- Anchor Industries Products Stud Link Chain and Ships AnchorsDocument6 pagesAnchor Industries Products Stud Link Chain and Ships Anchorsanto3harrish3fdoNo ratings yet

- Iso Metric Thread Sizes Bs.3643: Nominal Diameter Pitch Tolerance Class Major Diameter Pitch Diameter Minor DiameterDocument1 pageIso Metric Thread Sizes Bs.3643: Nominal Diameter Pitch Tolerance Class Major Diameter Pitch Diameter Minor DiametervvvvvvNo ratings yet

- Jis g3444-1 PDFDocument1 pageJis g3444-1 PDFbkprodhNo ratings yet

- Jis g3444-1 PDFDocument1 pageJis g3444-1 PDFRokhmatuSivaNo ratings yet

- WN 300Document7 pagesWN 300ANANDAN NNo ratings yet

- Wideflange PDFDocument4 pagesWideflange PDFandNo ratings yet

- Segments ImmobilierDocument1 pageSegments ImmobilierABDELAZIZ HAYOUNNo ratings yet

- Monel 400Document16 pagesMonel 400amr kouranyNo ratings yet

- Elbow Centre To FaceDocument2 pagesElbow Centre To FaceRNo ratings yet

- HSFG Part I Bolt & NutDocument1 pageHSFG Part I Bolt & NutvpjagannaathNo ratings yet

- Stainless Steel Tubing Sizes ChartDocument6 pagesStainless Steel Tubing Sizes ChartGonzalo MazaNo ratings yet

- Blind Flanges ANSI B16.5 600lbsDocument1 pageBlind Flanges ANSI B16.5 600lbsvinonaguNo ratings yet

- HTD Shcs 12.9 T TorqueDocument1 pageHTD Shcs 12.9 T TorqueChandru Vel100% (1)

- JIS G3444 Tube For General StructureDocument1 pageJIS G3444 Tube For General StructurelukmanNo ratings yet

- Cmpl-Bolt and Torque Specifications UsDocument3 pagesCmpl-Bolt and Torque Specifications UsYanina CamonesNo ratings yet

- Iso 965 2 1998Document8 pagesIso 965 2 1998Gerald CelisNo ratings yet

- WDS Torque ChartDocument9 pagesWDS Torque ChartThaharNo ratings yet

- Calculation For 450Mm Pipe Culvert Capacity: Velocity, V Capacity, QDocument11 pagesCalculation For 450Mm Pipe Culvert Capacity: Velocity, V Capacity, QAnonymous O404LiV4CNo ratings yet

- W F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485072082.xlsx Page 1 Sur 21Document21 pagesW F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485072082.xlsx Page 1 Sur 21dsd sdsdNo ratings yet

- W F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485067870.xlsx Page 1 Sur 19Document19 pagesW F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485067870.xlsx Page 1 Sur 19dsd sdsdNo ratings yet

- Gi Pipe Size Is 1239Document4 pagesGi Pipe Size Is 1239sshnvlNo ratings yet

- W F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485065812.xlsx Page 1 Sur 17Document17 pagesW F y Z T 2 4 4 4: Le 07/26/2020 Profilés Profiles Du 485065812.xlsx Page 1 Sur 17Maheshwari TradersNo ratings yet

- Giddings & Lewis Zappendix ADocument9 pagesGiddings & Lewis Zappendix AAngel AdautaNo ratings yet

- Slip On Flanges ANSI B16.5 300lbsDocument1 pageSlip On Flanges ANSI B16.5 300lbskannu19802550No ratings yet

- Horizontal Tank Chart 2Document4 pagesHorizontal Tank Chart 2גרבר פליקסNo ratings yet

- Motorola Six Sigma Conversion TableDocument1 pageMotorola Six Sigma Conversion TableMars HNo ratings yet

- Jadual Transaksi Selangor LPH2021Document33 pagesJadual Transaksi Selangor LPH2021Venice ChenNo ratings yet

- Axial Flow FansDocument3 pagesAxial Flow FansABCDNo ratings yet

- Jadual Transaksi Selangor LPH 2022Document38 pagesJadual Transaksi Selangor LPH 2022Venice ChenNo ratings yet

- Table 8 Commercial Pipe Sizes and Wall ThicknessesDocument1 pageTable 8 Commercial Pipe Sizes and Wall ThicknessesYahia Abou-ShoshaNo ratings yet

- Steam Table 1Document1 pageSteam Table 1Luis Esteban GarzonNo ratings yet

- Changbao Specification For Perforating Gun REV.Document5 pagesChangbao Specification For Perforating Gun REV.PAULNo ratings yet

- Elbows Dimensions ASTM A403Document1 pageElbows Dimensions ASTM A403vasudevanNo ratings yet

- Tendons 4+579Document13 pagesTendons 4+579soujanya rajeshNo ratings yet

- Metric: Torque & Makeup LossDocument18 pagesMetric: Torque & Makeup LossAnsar AkhtarNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Bills of Quantity AtkinsonDocument10 pagesBills of Quantity AtkinsonGalen McbrideNo ratings yet

- 空调剩余工 作 Weekly ScheduleDocument2 pages空调剩余工 作 Weekly ScheduleMinhas ArshadNo ratings yet

- Eset Nod 32 LicensesDocument2 pagesEset Nod 32 LicensesItx MinhasNo ratings yet

- P6 Data-Dictionary PDFDocument90 pagesP6 Data-Dictionary PDFKazim Naqvi100% (1)

- Quality Criteria of Powder Coated HDG STDocument8 pagesQuality Criteria of Powder Coated HDG STItx MinhasNo ratings yet

- S19DsgnGdln PDFDocument23 pagesS19DsgnGdln PDFmohanrajNo ratings yet

- Mechanical, Materials and Manufacturing Engineering: Undergraduate Guide 2017Document13 pagesMechanical, Materials and Manufacturing Engineering: Undergraduate Guide 2017Itx MinhasNo ratings yet

- Pasco CatalogDocument7 pagesPasco CatalogItx MinhasNo ratings yet

- Fe-C Phase DiagramDocument34 pagesFe-C Phase DiagramYoung-long Choi100% (1)

- Complete Physics Notes F.sc. Physics Second Year PDFDocument124 pagesComplete Physics Notes F.sc. Physics Second Year PDFAdnan ShiekhNo ratings yet

- Welded Steel Pipe 10.10.07Document37 pagesWelded Steel Pipe 10.10.07Dadi DahalNo ratings yet

- Material ComparisonDocument10 pagesMaterial ComparisonMardeOpamenNo ratings yet

- Useful Phrases Report PDFDocument1 pageUseful Phrases Report PDFneviaNo ratings yet

- N 1-Where "... " Appears in This Table, There Is No RequirementDocument1 pageN 1-Where "... " Appears in This Table, There Is No RequirementItx MinhasNo ratings yet

- Welded Steel Pipe 10.10.07Document37 pagesWelded Steel Pipe 10.10.07Dadi DahalNo ratings yet

- Useful Phrases Report PDFDocument1 pageUseful Phrases Report PDFneviaNo ratings yet

- N 1-Where "... " Appears in This Table, There Is No RequirementDocument1 pageN 1-Where "... " Appears in This Table, There Is No RequirementItx MinhasNo ratings yet

- Material ComparisonDocument10 pagesMaterial ComparisonMardeOpamenNo ratings yet

- Quality Criteria of Powder Coated HDG STDocument8 pagesQuality Criteria of Powder Coated HDG STItx MinhasNo ratings yet

- Tappi Press: Document Name: Section: TitleDocument16 pagesTappi Press: Document Name: Section: TitleMinhas ArshadNo ratings yet

- Useful Phrases Report PDFDocument1 pageUseful Phrases Report PDFneviaNo ratings yet

- Strut Technical DataDocument15 pagesStrut Technical DataJOFRANo ratings yet

- NES-M2027 - 2021 - (Galvanneal, GI-Hot Dip)Document51 pagesNES-M2027 - 2021 - (Galvanneal, GI-Hot Dip)dpfloresNo ratings yet

- 5 - D. Ungermann, R. Trillmich - Tension Tests On Welded Threaded Studs With A Tensile Strength of 800Nmm2 PDFDocument11 pages5 - D. Ungermann, R. Trillmich - Tension Tests On Welded Threaded Studs With A Tensile Strength of 800Nmm2 PDFJEANNINA BULEJE CASTILLONo ratings yet

- Metal CastingDocument93 pagesMetal CastinghashimtkmceNo ratings yet

- Stainless SteelDocument110 pagesStainless SteelcidaaalvesNo ratings yet

- Nas 254N: (Uns S32053)Document4 pagesNas 254N: (Uns S32053)munif finumNo ratings yet

- Stainless Steel Pipe and Tube Manufacturing Process: Pearlite Steel Stainless Steel Blog Uncategorized No CommentDocument2 pagesStainless Steel Pipe and Tube Manufacturing Process: Pearlite Steel Stainless Steel Blog Uncategorized No CommentpritiNo ratings yet

- IPS d-SIGN 98Document2 pagesIPS d-SIGN 98Toma IoanaNo ratings yet

- Niels Hansen. Metallurgical Transactions 16A (1985) - P. 2167-2190.Document24 pagesNiels Hansen. Metallurgical Transactions 16A (1985) - P. 2167-2190.Bruna OliveiraNo ratings yet

- AWS D1 VR Sir DharmaDocument26 pagesAWS D1 VR Sir DharmaHariPrasathNo ratings yet

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument6 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewskrutikNo ratings yet

- Welding Electrode-Wire SpecificationDocument3 pagesWelding Electrode-Wire SpecificationRajan SteeveNo ratings yet

- Induction Heating Validation of Dieless SPIF of AHSSDocument10 pagesInduction Heating Validation of Dieless SPIF of AHSSrene.mayerNo ratings yet

- ASTM A372-A372M-03 Standard Specification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsDocument5 pagesASTM A372-A372M-03 Standard Specification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsAarón Escorza MistránNo ratings yet

- 1233051969ct 109 Smelter ContractsDocument4 pages1233051969ct 109 Smelter ContractsZVIKOMBORERONo ratings yet

- Piping TCG Caliberation BlockDocument1 pagePiping TCG Caliberation BlockAhmed Abd ElmegeedNo ratings yet

- 1A Study On The Work Hardening and The Effect of Triaxiality On The Fracturebehaviour of Some Cryorolled Aluminium AlloysDocument13 pages1A Study On The Work Hardening and The Effect of Triaxiality On The Fracturebehaviour of Some Cryorolled Aluminium AlloysAnonymous c14ePs5No ratings yet

- Metals: Properties of Metal Solidification of A Substance Modification of Grain SizeDocument15 pagesMetals: Properties of Metal Solidification of A Substance Modification of Grain SizeAlka MoonNo ratings yet

- Ch-5 DrillingDocument41 pagesCh-5 DrillingakshayNo ratings yet

- Phosphor Bronze To Bs 1400: Pb2Document1 pagePhosphor Bronze To Bs 1400: Pb2Suresh NairNo ratings yet

- Arcos 625Document1 pageArcos 625bowotriantoNo ratings yet

- Process and Economic Considerations in Copper MetallurgyDocument53 pagesProcess and Economic Considerations in Copper Metallurgydars23No ratings yet

- Extracting IronDocument5 pagesExtracting IronThunderNo ratings yet

- 03 AbrasivesDocument16 pages03 AbrasivesWeldingSupply.com.auNo ratings yet

- Welding: Krishnanand Prasad 0501213359 (04) Mechanical Engg 8 SemesterDocument21 pagesWelding: Krishnanand Prasad 0501213359 (04) Mechanical Engg 8 SemesterSuphi YükselNo ratings yet

- Stainless Steel 316l (SA240)Document2 pagesStainless Steel 316l (SA240)Sugiarto SaptomoNo ratings yet

- Materials of Pharmaceutical Plant ConstructionDocument2 pagesMaterials of Pharmaceutical Plant Constructionrhittum1802No ratings yet

- Machine Design Examination 11Document4 pagesMachine Design Examination 11SYBRELLE CRUZNo ratings yet

- ASTM B479 19 Standard Specification For Annealed Aluminum and Aluminum Alloy Foil For Flexible Barrier Food Contact and Other ApplicationsDocument7 pagesASTM B479 19 Standard Specification For Annealed Aluminum and Aluminum Alloy Foil For Flexible Barrier Food Contact and Other ApplicationsCheng PengNo ratings yet