Professional Documents

Culture Documents

KIOTI tractor manual overview

Uploaded by

Natsumi KawaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KIOTI tractor manual overview

Uploaded by

Natsumi KawaiCopyright:

Available Formats

FOREWORD

Congratulations,and welcome to the fabulous world of KIOTI DK451/501/551 ownership,where serious work is

made fun again!

This versatile tractor is a culmination of the entire tractor and diesel knowledge gained by the DAEDONG

INDUSTRIAL CO.,LTD over the years since 1947 and has been designed with the finest materials and under

rigid quality control standards set forth by the DAEDONG ENGINEERING DEPARTMENT.

Knowledge of tractor operation is essential for many years of dependable service and reliability.to help new

owners familiarize themselves with the KIOTI DK451/501/551, it is the policy of KIOTI tractor to provide an

owners manual which includes helpful information about tractor safety,operation and maintenance. If the infor-

mation you seek is not found in this manual, your KIOTI tractor dealer will be happy to help you.please feel free

to contact DAEDONG INDUSTRIAL CO.,LTD with your questions/concerns. Throughout this manual you will

see text in bold type, preceded by the worlds DANGER, WARNING, CAUTION or IMPORTANT.

Such text has the following significance.

Signs Description

This mark indicates hazardous situation which, if not observed, may result in death or

DANGER fatal injury.

This mark should be indicated for most dangerous situations only.

This mark indicates potentially hazardous situation which, if not observed, may result in

WARNING death or moderate injury.

This mark indicates potentially hazardous situation which, if not observed, may result in

CAUTION minor or moderate injury. And this mark can be used as a warning against unsafe activities.

This mark indicates emphasis on notable characteristics in working procedures or infor-

IMPORTANT mation on working procedures and technology for convenient use.

Downloaded from www.Manualslib.com manuals search engine

ABBREVIATION LIST

Abbreviations Definitions

4WD Four Wheel Drive

API American Petroleum Institute

ASAE American Society of Agricultural Engineers, USA

ASTM American Society of Testing and Materials, USA

fpm Feet Per Minute

Hi-Lo High Speed-Low Speed

HST Hydrostatic Transmission

m/s Meters Per Second

P.T.O Power Take Off

RH/LH Right-hand and Left-hand sides are determined by

facing in the direction of forward travel

ROPS Roll-Over Protective Structures

m-1 (rpm) Revolutions Per Minute

S -1 (r/s) Revolutions Per Second

SAE Society of Automotive Engineers, USA

SMV Slow Moving Vehicle

Downloaded from www.Manualslib.com manuals search engine

UNIVERSAL SYMBOLS

Various universal symbols have been used on the instruments and controls of your KIOTI tractor. Below is a list of the universal

symbols and their meanings.

Safety Alert Symbol Hazard Warning Lights

Fuel-Level Headlight-Low Beam

Engine Coolant-Temperature Headlight-High Beam

Parking Brake Four-Wheel Drive-ON

Battery Charging Condition Fast

Engine Oil-Pressure Slow

Turn Signal High Range

Power Take-OFF Clutch Control- Middle Range

OFF Position

Low Range

Power Take-OFF Clutch Control-

Neutral Position

ON Position

Coolant

Differential Lock

Preheat

Position Control-Lowered

Position

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

PRE-DELIVERY SERVICE

CHECK AND ADJUST AS REQUIRED

INOPERATIVE SERVICE CHECKS 11. Upper link, draw-bar and pin 20. Air cleaner element and hose

in position .............................. connections ...........................

1. Tire pressure and condition ......

12. Wheel-to-rim clamp bolts and 21. Seat mounting and adjust-

2. Lift-rod leveling crank for ment ........................................

lock nuts for tightness ...........

proper operation ......................

22. All electrical cables, termi-

13. Wheel disc-to-hub nuts for

3. Radiator coolant level and . spe- nals and wires .......................

tightness ................................

cific gravity .............................

(1.071 ~ 1.083 at 16°C (60°F)) 14. Front end weight clamp bolts SAFETY ITEMS CHECKS

for tightness ..........................

4. Pulley V belt ............................ 1. Safety decals installed ........

15. Front axle support bolts for

5. Engine oil level ....................... 2. Neutral start switches

tightness ................................

operative ................................

6. Transmission / rear axle oil

16. Fuel level ...............................

level ......................................... 3. Parking brake operation .....

17. Sheet metal and paint

7. Front axle differential oil level ... 4. Flashing lights/tail lights

condition ................................ operation ...............................

8. Front axle oil level .................

18. Drain diesel fuel filter and 5. Owner’s manual supplied ...

9. Brake adjustment and pedal water separator ...................

6. PTO guard installed .............

equalization ............................

19. Lubricate all grease fittings ....

7. SMV emblem installed .........

10. Hand brake adjustment .........

(where applicable)

Downloaded from www.Manualslib.com manuals search engine

OPERATIVE SERVICE CHECKS • Draft control for tension

and compression loads .....

All operative checks are to be

• Auxiliary services control

performed with the tractor at nor-

and remote control valves(If

mal operating temperature.

installed) .............................

1. Lights and instruments for

proper operation ................... PERFORMANCE SERVICE

2. Fluid and oil leaks ................ CHECKS:

3. Maximum no-load speed and 1. Engine operation including thro

idle speed adjustments and ttle and governor operation ......

fuel shut-off ........................... 2. Transmission ...........................

4. PTO operation ...................... 3. Steering control .......................

5. Hydraulic system: 4. Differential lock engagement

and disengagement .................

Select levers for draft and

5. Brake action .............................

position control operation .....

6. All optional equipment and Tractor Model No.

Flow control operation ......

accessories ..............................

Tractor serial No.

Downloaded from www.Manualslib.com manuals search engine

CONTENTS

1. SAFETY PRECAUTIONS ...................................................

2. SERVICING OF TRACTOR ................................................

3. SPECIFICATIONS ...............................................................

4. DESCRIPTION OF OPERATING SYSTEM ......................

5. OPERATING .........................................................................

6. MAINTENANCE ...................................................................

7. STORAGE .............................................................................

8. TROUBLESHOOTING ........................................................

9. INDEX ....................................................................................

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

BEFORE OPERATING THE TRACTOR

OPERATING THE TRACTOR

1

DRIVING THE TRACTOR

PARKING THE TRACTOR

OPERATING THE P.T.O

SAFETY PRECAUTIONS USING 3-POINT HITCH

SERVICING THE TRACTOR

TRACTOR SAFETY LABELS

Downloaded from www.Manualslib.com manuals search engine

1-2 DK451/501/551

BEFORE OPERATING THE

TRACTOR

A careful operator is the best operator.

Most accidents can be avoided by ob-

serving certain precautions. To help pre-

vent accidents, use these safety

precautions, and pay attention to the job

at hand. If you can prevent an accident,

your time will have been well spent.

A12O101A A12O102A

1. It is recommended that you read and 6. When getting on and off the tractor,

understand this entire manual before handholds and step plates should al-

operation of your new tractor. Failure ways be used. This will help to pre-

to do so could result in accidents or vent accidental slips trips and falls.

injury. 7. Be sure to scrape off mud or soil from

2. Only persons who are properly trained your shoes before mounting the tractor.

should be allowed to operate the 8. Watch where you are going at all times

tractor. so that you are able to avoid obstacles

3. Read and follow all warning labels and that can cause injury or damage to

decals affixed to the tractor. your tractor.

4. Replace any missing or damaged de- 9. When starting the tractor make sure

cals as soon as it is practical. A list of your path is clear of people to avoid ac-

decals is shown on page1-14~16 cidents caused by sudden movements.

5. Keep safety decals clean of dirt and 10. Before making reverse movements

debris. with your tractor, you should always

check to see that the path is clear.

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-3

A12O103A A12O104A A12O105A

11. Never operate this tractor or any other 14. Never start the engine while standing 16. All persons using the tractor should

agricultural equipment while under the on the ground. have knowledge of its proper opera-

influence of alcohol, drugs or while 15. Only the operator should ride on the tion and should read this manual

fatigued. tractor unless a passenger seat is carefully.

12. While working in cooperation with installed. Keep bystanders away from 17.Never get off the tractor without set-

other tractors always communicate the tractor while in operation. ting the parking brake, lowering the

your intentions. implement to the ground and shutting

13. Do not start your tractor by shorting of the tractor.

across the starter. 18.No alterations should be made to your

KIOTI tractor without first consulting

your KIOTI dealer.

Downloaded from www.Manualslib.com manuals search engine

1-4 DK451/501/551

20. For your safety ROPS with a seat belt

is recommended for most applications.

NOTE

Always use seat belt when the tractor

is equipped with a ROPS and CABIN.

Never use the seat belt when tractor

is not equipped with a ROPS and

CABIN.

The ROPS and Cabin should never be

A12O106A modified by welding, grinding or cutting, A12O107A

as this can weaken the structure. If any

components is damaged, it must be (1) Tread

replaced.

19.Before starting your tractor you If the ROPS unit is removed or loosened 21. Extra caution should be taken when

should depress the clutch and make for any reason, the parts should be fitted driving tractors with narrow tread

sure that all shift levers are in the back to their original positions and all bolts widths. For added stability you should

neutral position. should be properly torqued. adjust your rear wheel tread width, see

page 8-3.

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-5

OPERATING THE TRACTOR

A12O108A A12O109A A12O110A

1. Avoid accidental contact with gear shift 2. Do not park your tractor on a steep 3. Do not operate your tractor in an en-

levers while the engine is running. Un- incline, and remember to shut off the closed building without the proper

expected tractor movements can result engine and P.T.O before dismounting ventilation. Exhaust fumes can cause

in bodily injury. the tractor. serious injury or death.

Downloaded from www.Manualslib.com manuals search engine

1-6 DK451/501/551

A12O111A A12O112A A12O113A

(1) Drawbar

4. Make sure that all pressure lines are 6. If The front of the tractor tends to rise 7. Do not leave equipment in the raised

tight before starting the tractor. up when heavy implements are at- position when the vehicle is stopped

5. Pull only from the drawbar. Never hitch tached to the three point hitch, the or unattended.

anything to the axle housing or any weights should be installed on the 8. When using implements or attach-

other point except the drawbar. tractor. Do not operate the tractor with ments with your tractor you should first

Pulling from any other location only in- a light front end. read their respective owner’s manual.

crease the risk of serious personal You should always keep their safe op-

injury or death. eration procedures in mind.

9. You should be familiar with your equip-

ment and its limitations.

10. Always use the proper ballast weight

on your tractor when using rear

implements.

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-7

11. Driving forward out of a ditch or steep

inclines can cause the tractor to tip

over backwards. To avoid this you

should back out of these positions.

Four wheel drive tractors can give you

a false sense of security in the trac-

tors ability to maneuver out of these

positions, so extra caution should be

taken.

12.Watch front and rear for and avoid

obstacles at row ends, near trees

and around other obstructions.

A12O114A A12O115A

13. If abused or used incorrectly your trac- 14. Never try to get on or off a moving

tor can become dangerous to you and tractor.

bystanders. Overloading your tractor 15. When working in groups, always let

or using unsafe equipment can also the others know what you are going

be dangerous and should be avoided. to do before you do it.

Refer to the “Specifications of Imple-

16. Never “freewheel”. Disengaging the

ment Limitation”, which outlines the

clutch or shifting into neutral while

maximum load for safe tractor

descending a slope as this could lead

operation.

to a loss of control.

17. Do not operate near ditches, holes,

embankments, or other terrain fea-

tures which may collapse under the

tractor’s weight. The risk of tractor

upset is even higher when the ground

is loose or wet.

Downloaded from www.Manualslib.com manuals search engine

1-8 DK451/501/551

DRIVING THE TRACTOR

A12O116A A12O117A A12O118A

(1) Brake Pedal (L) (2) Brake Pedal (R) (1) SMV Emblem (USA, AU)

(3) Brake Pedal Lock (2) Number plate (EU)

1. Lock the brake pedals together when 2. Always slow the tractor before 3. Make sure that the Slow Moving Ve-

traveling at road speeds. Brake both turning. Turning at high speed may tip hicle (SMV) sign is clean and visible.

wheels simultaneously when making the tractor over. Use hazard lights as required.

an emergency stop. Uneven braking at

road speeds could cause the tractor to

tip over.

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-9

PARKING THE TRACTOR

4. Observe all local traffic and safety

regulations.

5. Turn the headlights on. Dim them when

meeting another vehicle.

6. Drive at speeds that allow you to main-

tain control at all times.

7. Do not apply the differential lock while

traveling at road speeds. As the trac-

tor may run out of control.

8. Avoid sudden movements of the

steering wheel as this can cause a

loss of control of the tractor. This risk A12O119A

is especially great when traveling at

road speeds.

9. Do not operate an implement while the

tractor is on the road. Lock the three

point hitch in the raised position. 1. Disengage the P.T.O, lower all

implements, place all control levers in

10. When towing other equipment, use a the neutral position, set the parking

safety chain and place an SMV em- brake, stop the engine and remove the

blem on it as well. key.

Downloaded from www.Manualslib.com manuals search engine

1-10 DK451/501/551

OPERATING THE P.T.O USING 3-POINT HITCH

A12O120A A12O121A A12O122A

(1) P.T.O Shaft Cover (2) P.T.O Shaft Cap (1) 3-point hitch lowering speed knob

(A) “LOCK”

1. Make sure the tractor is completely 3. Before installing or using P.T.O driven

1. Use the 3-point hitch only with equip-

stopped, gears are in neutral and all equipment, read the maunfacturer’s

ment designed for 3-point hitch usage.

moving components have completely manual and review the safety labels

stopped before connecting, attached to the equipment. 2. When using a 3-point hitch mounted

disconnecting, adjusting, cleaning or implement, be sure to install the proper

4. When operating stationary P.T.O

servicing any P.T.O driven equipment. counterbalance weight on the front of

driven equipment, always apply the

the tractor.

2. Keep the P.T.O shaft cover in place at tractor parking brake and place chocks

all times. Replace the P.T.O shaft cap behind and in front of the rear wheels. 3. When transporting on the road, set the

when the shaft is not in use. Stay clear of all rotating parts. implement lowering control in the

“LOCK” position to hold the implement

in the raised position.

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-11

SERVICING THE TRACTOR

A12O123A A12O124A A12O125A

In order to service your tractor you must

park it on a flat level surface, set the park-

ing brake, place the gear shift lever in

4. Before jump starting a dead battery, 6. Do not remove the radiator cap while

neutral and stop the engine.

read and follow all of the instructions. the coolant is hot. When cool, slowly

1. Allow the tractor time to cool off before rotate the cap to the first stop and al-

5. Keep a first aid kit and fire extinguisher

servicing any part that may have become low sufficient time for excess pressure

handy at all times.

hot while the tractor was running. to escape. After all the pressure is re-

2. You must always stop the engine be- leased remove the cap completely. If

fore refueling the tractor. Avoid over- your tractor is equipped with a coolant

filling the tractor or spilling the fuel. recovery tank, add coolant there

3. Do not smoke while working around the rather than to the radiator.

battery or when refueling your tractor.

Keep all sparks and flames away for the

battery and fuel tank. The battery pre-

sents an explosive hazard because it

gives off hydrogen and oxygen… espe-

cially when recharging.

Downloaded from www.Manualslib.com manuals search engine

1-12 DK451/501/551

A12O126A A12O127A A12O128A

(1) Cardboard (3) Magnifying Glass

(2) Hydraulic Line

7. When working with your tractors elec- 9. Tire mounting should be done by quali- 11. Securely support the tractor when

trical components you must first dis- fied professionals, with the proper changing wheels or the wheel tread

connect the battery cables. equipment. width.

12. Make sure that wheel bolts have been

8. To ensure that there are no accidents 10.Maintaining correct tire pressure is

tightened to the specified torque.

from sparks you must first disconnect important for the life of your tire.

13. Escaping hydraulic fluid under pres-

the negative battery cable. Do not inflate the tires above the rec- sure has sufficient force to penetrate

ommended pressure specified in the skin, causing serious personal injury.

owner’s manual. Be sure to release all residual

pressure. Before disconnecting hy-

draulic lines.

Before adding pressure to the hy-

draulic system, make sure that all

connections are tight and that all line,

pipes and hoses are free of damage.

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-13

A12O129A A12O130A

14. Fluid escaping from pinholes may be 15. Keep the environmental pollution in

invisible. Do not use hands to search mind. When replacing cooling water

for suspected leaks; or oil, disuse it to the right way.

Use a piece of cardbord or wood, Be sure to observe the relevant regu-

instead. Use of safety goggles or lations when you dispose of the en-

other eye protection is also highly gine oil, transmission oil, fuel,

recommended. If injured by escaping coolant, filter and battery.

fluid, see a medical doctor at once.

This fluid can produce gangrene and/

or severe allergic reaction.

Downloaded from www.Manualslib.com manuals search engine

1-14 DK451/501/551

TRACTOR SAFETY LABELS

DK451

A12O131A

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-15

DK451C

A12O132A

Downloaded from www.Manualslib.com manuals search engine

1-16 DK451/501/551

DK501/DK551

A12O133A

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-17

DK501C/DK551C

A12O132A

Downloaded from www.Manualslib.com manuals search engine

1-18 DK451/501/551

1. T4689-52191 3. T4837-52121 5. T2325-50743

2. T4837-51181 4. T4818-52142 6. T4625-52351 7. T4625-52361

Downloaded from www.Manualslib.com manuals search engine

SAFETY PRECAUTIONS 1-19

8. T4625-53191 10. T2445-50724 11. T4837-51093

9. T2241-50702

13. T4818-52132 14. T2615-55112

Downloaded from www.Manualslib.com manuals search engine

1-20 DK451/501/551

12. T2615-54112 16. T2615-53561

15. T4817-52201

Downloaded from www.Manualslib.com manuals search engine

2 SERVICING OF TRACTOR

SERVICING

Downloaded from www.Manualslib.com manuals search engine

2-2 SERVICING

SERVICING

A12O201A A12O202A

(1) Manufacture Plate (1) Engine Serial Number Identification No.

(2) Transmission Serial Number

Your dealer is interested in your new trac- The tractor serial number is located on the

tor and has the desire to help you get the transmission housing on the left side of the Engine Serial No.

most value from it. After reading this manual tractor. The engine serial number is located

thoroughly, you will find that you can do on the right side of the engine crankcase.

some of the regular maintenance yourself. Locate the serial numbers now and record Transmission Serial No.

However, when in need of parts or major them in the space provided.

service, be sure to see your KIOTI dealer. Before using implements not sold by KIOTI

For service, contact the KIOTI dealership DISTRIBUTOR, contact your nearest

Date of Purchase

from which you purchased your tractor or dealer, regarding safety in its application.

your local authorized KIOTI dealer.

When in need of parts, be prepared to give To be filled in by purchaser

your dealer both the tractor and engine se-

rial numbers.

Downloaded from www.Manualslib.com manuals search engine

3 SPECIFICATIONS

SPECIFICATIONS

TRAVELING SPEED

Downloaded from www.Manualslib.com manuals search engine

SPECIFICATIONS

MODEL DK451 DK501 DK551

Engine Power Gross HP(kW)/rpm 45(33.6)/2600 49(36.5)/2600 54(40.3)/2600

Model 4A220LXB 4A200TLXB 4A220TLXB

Indirect injection, vertical, water- Indirect injection, vertical, water-cooled,

Type

cooled, 4-cycle diesel engine turbocharged 4-cycle diesel engine

Number of Cylinder 4

Bore and stroke mm(in.) 87x92.4(3.43x3.63) 83x92.4(3.27x3.63) 87x92.4(3.43x3.63)

Total displacement cc(cu.in.) 2,197(134.1) 2,000(122.1) 2,197(134.1)

Engine

Rated revolution rpm 2,600rpm

Injection timing BTDC 18° BTDC 12°

Injection order 1-3-4-2

Compression ratio 22:1 20:1 20:1

Lubricating system Forced lubrication by trochoid pump

Cooling system Pressurized radiator, Forced circulation with water pump

Alternator 12V, 50A

Fuel tank (U.S.gal.) 58(15.3) 68(18.0)

Engine crankcase (U.S.gal.) 8.0(2.1) 9.7(2.6)

Capacities

Engine coolant (U.S.gal.) 8.6(2.27) 8.7(2.3) 8.5(2.25)

Transmission case (U.S.gal.) 38(10.0)

Front axle case (U.S.gal.) 8.2(2.2)

NOTE: EU-only Europe, AU-Australia, New zealand

Downloaded from www.Manualslib.com manuals search engine

SPECIFICATIONS

MODEL DK451 DK501 DK551

Overall length (without 3p) mm(in.) 3,120(122.8) 3,171 (124.8) 3,202 (126.1)

Dimensions (with Std.tires)

Overall length (with 3p&front weight) mm(in.) 3,630(142.9) 3,663 (144.2) 3,663 (144.2)

Overall width (minimum tread) mm(in.) 1,540 (60.6) 1,645 (64.8) 1,735 (68.3)

Overall height (Top of ROPS) mm(in.) 2,589 (101.9) 2,685 (105.7) 2,716 (106.9)

Overall height (Top of CABIN) mm(in.) 2,333 (91.8) 2,449 (96.4) 2,480 (97.6)

Wheel base mm(in.) 1,880 (74.0) 1,920 (75.6)

Min. ground clearance mm(in.) 415 (16.3) 439 (17.3) 470 (18.5)

Tread Front mm(in.) 1,300 (51.2) 1,365 (53.7) 1,440 (56.7)

Rear mm(in.) 1,210 (47.6) 1,362 (53.6) 1,352 (53.2)

Tire size Front EU: 9.5-16 PR / AU: 9.5-18 PR 9.5-18 PR 9.5-20 PR

(Std. tires) Rear EU: 13.6-26 PR / AU: 13.6-28 PR 13.6-28 PR 14.9-28 PR

Traveling System

Clutch Dry type single plate-single stage

Steering Hydraulic power steering

Transmission Synchronized shuttle and transmission

(12 forward and 12 reverse speeds)

Traveling Wet disc type

Brake

Parking Connected with the traveling brake

Differential Bevel gear

Hydraulic lift control system Position, Draft and Mixed control

Pump Capacity /min (U.S.gal.) Main pump : 37.4 /min(1.32ft3/min)

Hyd.

Power steering pump16.4 /min(0.58ft3/min)

Three point hitch EU: Category AU: Category

Downloaded from www.Manualslib.com manuals search engine

MODEL DK451 DK501 DK551

Maximum lifting capacity kg(lbs) 1,204 (2,654)

Hyd.

No. of standard remote valves Remote control valve 2ea, port 4ea

(Option : Joy-stick valve)

PTO Shaft SAE 1-3/8, 6 splines

Revolution 1st (rpm)

PTO

(independent PTO) 2nd (rpm)

3rd (rpm)

Min. Turning Radius (without brake) mm(in) 2,730(107.5) 2,780(109.4) 2,820(111.0)

Traction System

Weight(ROPS) kg(lbs) 1,890 (4167) 2,058 (4,537) 2,092 (4,612)

Weight(Cabin) kg(lbs) 2,075 (4575) 2,290 (5,049) 2,360 (5,203)

Forward 0.38 ~ 25.51 0.40 ~ 26.62 0.42 ~ 27.90

Traveling Speed

km/h(mile/h) (0.236 ~ 15.851) (0.249 ~ 16.541) (0.261 ~ 17.336)

(at rated engine

Reverse 0.31 ~ 21.11 0.33 ~ 22.03 0.35 ~ 23.09

speed with Std. tires) km/h(mile/h) (0.192 ~ 13.117) (0.205 ~ 13.689) (0.217 ~ 14.347)

NOTE: The specifications are subject to change for the purpose of improvement without any notice.

Downloaded from www.Manualslib.com manuals search engine

SPECIFICATIONS

TRAVELING SPEED

* At rated engine speed(2,600rpm) with Std. tires.

[Forward] Km/h(mile/h)

Operating the lever Model

Shuttle Hi-Low Mian DK451 DK501 DK551

1 0.4(0.24) 0.4(0.25) 0.42(0.26)

2 0.5(0.34) 0.6(0.37) 0.59(0.37)

Low

3 0.8(0.50) 0.8(0.50) 0.87(0.54)

4 1.3(0.80) 1.3(0.81) 1.39(0.86)

1 1.8(1.13) 1.9(1.18) 1.95(1.21)

2 2.6(1.60) 2.7(0.68) 2.77(1.72)

Forward Middle

3 3.8(2.36) 3.9(1.68) 4.08(2.54)

4 6.0(3.78) 6.3(3.91) 6.53(4.06)

1 7.7(4.81) 8.0(4.97) 8.31(5.16)

2 10.9(6.84) 11.3(7.02) 11.81 (7.34)

High

3 16.0(10.06) 16.6(10.31) 17.37(10.79)

4 25.5(15.85) 26.6(16.53) 27.90(17.37)

Downloaded from www.Manualslib.com manuals search engine

[Reverse] Km/h(mile/h)

Operating the lever Model

Shuttle Hi-Low Main DK451 DK501 DK551

1 0.3(0.20) 0.3(0.19) 0.3 (0.21)

2 0.5(0.31) 0.5(0.31) 0.5 (0.30)

Low

3 0.7(0.43) 0.7(0.43) 0.7 (0.45)

4 1.1(0.68) 1.1(0.68) 1.2 (0.71)

1 1.5(0.93) 1.5(0.93) 1.6 (0.72)

Reverse

2 2.1(1.30) 2.2(1.37) 2.3 (1.42)

Middle

3 2.1(1.93) 3.2(1.99) 3.4 (2.09)

4 5.0(3.11) 5.2(3.23) 5.4 (3.36)

1 6.4(3.98) 6.6(4.10) 6.9 (4.28)

2 9.0(5.59) 9.4(5.84) 9.8 (6.07)

High

3 13.3(8.26) 13.8(8.57) 14.4 (8.94)

4 21.1(13.12) 22.0(13.67) 23.1 (14.35)

Downloaded from www.Manualslib.com manuals search engine

4 DESCRIPTION OF

OPERATING SYSTEM

EXTERIOR VIEW AND APPELLATION

INSTRUMENTS PANEL AND SWITCHES

OPERATING THE CONTROLS

DESCRIPTION OF CAB OPERATING SYSTEM

Downloaded from www.Manualslib.com manuals search engine

4-2 DK451/501/551

EXTERIOR VIEW AND APPELLATION

DK451

A12O401A

(1) Head Light (6) Turn Signal Lamp (11) Telescopic Sway bar

(2) Hood (7) Top Link (12) Lower Link

(3) Side Cover (8) Transmission Oil Gauge (13) Draw Bar

(4) Step(LH) (9) PTO Shield Cover (14) Work Lamp

(5) Steering Wheel (10) Crank Lifting Rod

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-3

DK451C

A12O402A

(1) Working Lamp (6) Front Grill (11) Side Cover

(2) Rear View Mirror (7) Turn Signal Lamp (12) Top Link

(3) Wiper (8) Door Grip (13) Lift Rod

(4) Hood (9) Muffler (14) Lower Link

(5) Head Lamp (10) Step (15) Draw Bar

Downloaded from www.Manualslib.com manuals search engine

4-4 DK451/501/551

DK501 / DK551

A12O403A

(1) Head Light (5) Steering Wheel (9) PTO Shield Cover

(2) Hood (6) Turn Signal Lamp (10) Crank Lifting Rod

(3) Side Cover (7) Top Link (11) Lower Link

(4) Step(LH) (8) Draw Bar

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-5

DK501C / DK551C

A12O404A

(1) Working Lamp (6) Front Grill (11) Side Cover

(2) Rear View Mirror (7) Turn Signal Lamp (12) Top Link

(3) Wiper (8) Door Grip (13) Lift Rod

(4) Hood (9) Air Cleaner (14) Lower Link

(5) Head Lamp (10) Step (15) Draw Bar

Downloaded from www.Manualslib.com manuals search engine

4-6 DK451/501/551

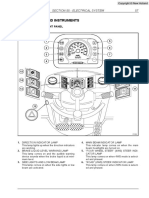

INSTRUMENTS PANEL AND SWITCHES

(1) Panel

(2) Turn Signal Light Switch

(3) Head Light Switch

(4) Hazard Lamp Switch

(5) Horn Switch

(6) PTO Change Switch

(7) Key Switch

(8) Tachometer

(9) Temperature Gauge

(10) Fuel Gauge

(11) Differential Lock Indicator

(12) PTO ON Indicator

(13) Hydraulic System Warning Lamp

(14) Engine Oil Pressure Warning Lamp

(15) Battery Charge Warning Lamp

(16) Glow Plug Indicator

(17) Parking Brake Indicator

(18) High Beam Indicator

(19) 4WD Operation Indicator

(20) Turning Signal Indicator

(21) Hour Meter

A12O405A

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-7

KEY SWITCH TURN SIGNAL/ HEAD LIGHT SWITCH

OFF

A key position for stopping the engine.

ACC

A key position for operating accessory

function.

ON

A key position at which the engine is

running.

Heat

A key position for preheating the inside

of the combustion chamber.

A12O406A A12O407A

Start

(1) Key Switch (A) Start (B) Heat (1) Turn Signal Light Switch

A key position for operating the motor. (2) Head Light Switch

(C) On (D) Acc (E) Off

(A) Right (B) N (C) Left

Inserting the key and turning it one click Turning the light switch one click to C.W.

CAUTION

to the right, closes the electrical circuit illuminates the low beam headlights and

and lights up the engine oil pressure lamp Because of the safety device, the taillights.

(RED). Depress the clutch pedal to dis- engine may not be started except Next, turning it one more click illuminates

engage the clutch. Next, turning the key when the clutch is depressed. the high beam headlights.

right activates the glow plug, preceding

to preheat the combustion chamber. Af- OFF

ter the glow plug lamp has turned red Headlight is turned OFF

and that the engine has been preheated

completely, turn the key switch right and

the cell starter will start to rotate and the Low beam headlight is turned ON

engine should start. Release the key

switch and it will return to the ON position. Upper beam headlight is turned ON

Direction indication lamp is turned ON

Downloaded from www.Manualslib.com manuals search engine

4-8 DK451/501/551

PTO CHANGE SWITCH HAZARD LAMP SWITCH

(MT/AT)

A12O408A A12O409A

(1) PTO Change Switch (N) Neutral (1) Hazard Lamp Switch

(A) Auto (B) Manual (A) Hazard Lights OFF (B) Hazard Lights ON

The PTO change switch must be placed When a hazard lamp switch is pulled to

to the “neutral” position before starting on position, the hazard lamps blink.

the engine. Otherwise, the engine will not

start. When turning PTO change switch CAUTION

to Automatic, the PTO operates only when When it is used for a long time, a

the implement is in the lowered position. lot of electricity will be used.

For example, if you lift the implement while Therefore, it must be used only

working, the PTO will stop. If the PTO

in case of emergency.

change switch is in the Manual position,

the PTO will operate continuously.

IMPORTANT

Always turn the starter switch key

to the “OFF” position. Damage

may occur to the electrical sys-

tem if the engine is running with

the starter switch off.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-9

TACHOMETER/HOUR METER COOLANT TEMPERATURE GAUGE FUEL GAUGE

A12O411A A12O412A A12O413A

(1) Hour Meter (1) Coolant temperature Gauge (1) Fuel Gauge

(2) Engine Revolution Meter

This meter shows the number of hours Wait until Engine is warm enough. Do not Fuel gauge indicates the amount of fuel.

the tractor has been operated at rated operate tractor before Temp. meter indi- Be careful to refill the fuel tank before it

engine rpm. The last digit (white cates the proper temperature. Be care- becomes empty. Once the fuel tank be-

background) indicates 1/10 of an hour. ful not to overheat the engine by exceed- comes empty, it will be necessary to

The time in minutes will be shown by mul- ing the normal operating of the cooling bleed the fuel system before the engine

tiplying by six to last digit on white water (red section on temperature gauge start.

background. indicates overheating). Before operating

Example 0 1 7 0 1 …. 170 hours 6 min- tractor, always check the amount of cool-

utes used. Moving hand indicates the ing water in the radiator.

revolution per minute of the engine

Downloaded from www.Manualslib.com manuals search engine

4-10 DK451/501/551

DIFFERENTIAL LOCK INDICATOR PTO ON INDICATOR COOLANT LEVEL WARNING LAMP

A12O414A A12O415A A12O416A

The light will illuminate when the differ- This lamp lights up red while operating Light will illuminate when the engine cool-

ential lock pedal is engaged. PTO. ant is not enough to operate the tractor.

As soon as the light illuminate, stop the

CAUTION

engine and investigate the cause.(If the

It is not possible to start the en- coolant is low level, put the coolant into

gine if this lamp lights up. the surge tank.)

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-11

HYDRAULIC SYSTEM WARNING LAMP ENGINE OIL PRESSURE WARNING BATTERY CHARGE WARNING LAMP

LAMP

A12O417A A12O418A A12O419A

This lamp lights up yellow when certain The oil pressure lamp will glow red when The battery charge lamp will glow red

problems occur in hydraulic system. the key switch is turned on. This indi- when the main switch is turned on and

This lamp lights up when the pressure in cates the light and electrical wiring are should go out as engine starts. If the lamp

hydraulic system drops down below a functioning properly. The light should go continues to glow above idle speeds, the

specified value due to high oil tempera- out after engine starts. If light remains battery is being discharged, indicating the

ture (approx. 60 + 5°C) or blocked oil fil- on, stop engine and inspect cause. electrical system should be checked.

ter carefully check the hydraulic system.

Downloaded from www.Manualslib.com manuals search engine

4-12 DK451/501/551

GLOW PLUG INDICATOR PARKING BRAKE INDICATOR HIGH-BEAM INDICATOR

A12O420A A12O421A A12O422A

When the key switch is turned to the This lamp lights up red when locking the This indicator lights up blue when the

right, the glow plug indicator becomes parking brake while depressing the brake headlamp switch is in high-beam position.

amber. This shows the condition of pre- pedal. Make sure to drive the machine

heating in the combustion chamber. with parking brake unlocked.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-13

4WD OPEATION INDICATOR

A12O423A

This lamp lights up yellow when 4WD

switch is in “4WD” position. At this time,

the machine drives with 4 wheel drive

mode.

Downloaded from www.Manualslib.com manuals search engine

4-14 DK451/501/551

OPERATING THE CONTROLS

DK451(ONLY AU)

(1) Hi-Lo Shift Lever

(2) Main Gear-Shift Lever

(3) Seat Reclining Lever

(4) PTO Shift Lever

(5) Clutch Pedal

(6) Brake Pedal (L)

(7) Brake Pedal (R)

(8) Parking Brake Lever

(9) Draft Control Lever

(10) Position Control Lever

(11) Double Acting Lever (A, B)

(12) Double Acting Lever (C, D)

(13) Foot Throttle

(14) Shuttle Shift Lever

(15) Tilting Steering Lever

(16) Hand Throttle Lever

(17) Joy-stick Lever(Option)

(18) PTO Safety Switch

(19) Front Wheel Drive Switch

A12O424A

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-15

DK501 / DK551(ONLY AU)

(1) Front Wheel Drive Switch

(2) Hi-Lo Shift Lever

(3) PTO Change Lever

(4) Seat Adjusting Lever

(5) Clutch Pedal

(6) Steering Wheel Tilt Lever

(7) Parking Brake Lever

(8) Brake Pedal (L)

(9) Brake Pedal (R)

(10) Foot Throttle

(11) Joystick Lever (Option)

(12) Main Shift Lever

(13) Shuttle Shift Lever

(14) Hand Throttle

(15) Double Acting Lever

(16) Position Control Lever

(17) Draft Control Lever

(18) PTO Safety Switch

A12O425A

Downloaded from www.Manualslib.com manuals search engine

4-16 DK451/501/551

DK451(ONLY EU)

(1) Hi-Lo Shift Lever

(2) Main Gear-Shift Lever

(3) Front Wheel Drive Switch

(4) PTO Shift Lever

(5) Clutch Pedal

(6) Brake Pedal (L)

(7) Brake Pedal (R)

(8) Parking Brake Lever

(9) Draft Control Lever

(10) Position Control Lever

(11) Double Acting Lever (A, B)

(12) Double Acting Lever (C, D)

(13) Foot Throttle

(14) Shuttle Shift Lever

(15) Tilting Steering Lever

(16) Hand Throttle Lever

(17) Joy-stick Lever(Option)

(18) PTO Safety Switch

A12O459A

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-17

DK501 / DK551(ONLY EU)

(1) Front Wheel Drive Switch

(2) Hi-Lo Shift Lever

(3) PTO Change Lever

(4) PTO Safety Switch

(5) Clutch Pedal

(6) Steering Wheel Tilt Lever

(7) Parking Brake Lever

(8) Brake Pedal (L)

(9) Brake Pedal (R)

(10) Foot Throttle

(11) Joystick Lever (Option)

(12) Main Shift Lever

(13) Shuttle Shift Lever

(14) Hand Throttle

(15) Double Acting Lever

(16) Position Control Lever

(17) Draft Control Lever

A12O460A

Downloaded from www.Manualslib.com manuals search engine

4-18 DK451/501/551

MAIN / HI-LOW SHIFT LEVER

DK451 DK501/551

A12O426B

(1) Main Shift Lever (2) Hi-Low Shift Lever

The main shift lever pattern is in the form

CAUTION

of an “H”. The range lever is used to se-

lect three stage, “High”, “Middle” and To change speed, press the clut-

“Low”. By combination and use of the ch pedal completely down before

main shift lever and the range lever, it is attempting to proceed with speed

possible to obtain four speeds forward change.

and reverse in “High” range, four speeds

forward and reverse in “Middle” range

and four speeds forward and reverse in

“Low” range, or a total of twelve speeds

forward; and twelve speeds reverse,

High, Middle and Low.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-19

SHUTTLE SHIFT LEVER PTO SWITCH(ON/OFF) PTO CHANGE LEVER

DK451 DK501/551 EU

AU

A12O427A A12O428A A12O429B

(1) Shuttle Shift Lever (1) PTO Switch (1) 540rpm (3) 1000rpm

(A) Forward (B) reverse (A) - OFF (B) - ON (2) 750rpm (4) PTO Change Lever

The tractor’s driven forward or in The PTO switch must be placed to the Shift

reverse, without the steps of main or “OFF” positions before starting the 1st 2nd 3rd

Model

secondary shift by pushing it forward or engine. Otherwise, the engine will not

DK451

pulling it backward. start.

DK501 540 750 1000

CAUTION IMPORTANT DK551

The shuttle shift lever maybe be Always turn the starter switch key CAUTION

shifted while the tractor is mov- to the “OFF” position. Damage

ing slowly and the clutch is may occur to the electrical sys- To avoid personal injury:

depressed. tem if the engine is running with Disengage PTO, stop engine, and

Sudden gear shift may cause the starter switch off. allow all rotating components to

transmission damage. come to a complete stop before

connecting, disconnecting, ad-

justing, or cleaning any PTO dri-

ven equipment.

Downloaded from www.Manualslib.com manuals search engine

4-20 DK451/501/551

FRONT WHEEL DRIVE SWITCH CLUTCH PEDAL BRAKE PEDAL(RIGHT AND LEFT)

A12O430A A12O431A A12O432A

(1) Front Wheel Drive Switch (1) Clutch Pedal (1) Brake Pedal (R) (3) Brake Lock

(2) Brake Pedal (L)

- ENGAGE - DIS ENGAGE When the clutch pedal is fully depressed,

the clutch is disengaged. Shift the main

Push the switch to engage the front 1. Before operating the tractor on a road,

shift lever to the desired speed and

wheel drive mechanism. be sure to interlock the right and left

gradually release the clutch pedal, then

The front wheel drive mechanism is very the clutch will become engaged. pedals as illustrated below. It will be

effective on the following jobs. very dangerous to use only one brake.

The clutch should be disengaged by step-

1. On slopes and in wet fields, or when ping on the pedal quickly, and engaged 2. Use individual brake to assist in mak-

connected to the Trailer or the Front- by slow releasing the foot from the pedal ing sharp turns. Disengage the brake

End-Loader where great traction is so as not to damage the clutch plate. lock and depress only one brake pedal

required. with direction that you are turning.

IMPORTANT

2. On sandy land.

The clutch pedal must be quick- 3. When operating the tractor on roads,

3. To prevent the tractor being thrust for- always be sure to interlock the left

ward during rotary tilling hard soil. ly disengaged and be slowly en-

gaged. and the right brake pedals. Do not

4. Entering a job location or going over a Never operate the tractor with forget to observe this precaution, oth-

high bank. erwise, stepping on only one brake

your foot resting on the clutch

Under normal operating conditions, keep pedal. Doing so may contribute to while operating on roads would cause

the lever up to leave the mechanism premature clutch wear. unforeseen accidents.

disengaged.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-21

STEERING WHEEL ADJUSTMENT PARKING BRAKE LEVER

DK451 DK501/551 AU EU

A12O433A A12O434A A12O435A

(1) Tilting Steering Lever (1) Tilte Lever (A) Pull (1) Parking Brake Lever

AU

Steering Wheel tilt lever is a ratchet type It is possible to adjust the steering wheel 1. To set the parking brake:

of lever. Push lever in and turn clock- into two stages according to operator’s Interlock the brake pedals.

wise to release steering wheel and turn physical condition. Adjust it for the proper

Depress the brake pedals.

counterclockwise to tighten steering operating position by stepping slightly on

wheel once in required position. the tilt lever. Latch the brake pedals with the park-

ing brake lever

WARNING WARNING 2. To release the parking brake, depress

Once the steering wheel is in the Do not adjust it surely while the brake pedals again.

desired position, and has been driving. EU

tightened using the lever, it the

1. To set the parking brake, pull the brake

important to check that it is tight

lever.

before moving off.

Do not adjust steering wheel while 2. To release the parking brake, push the

in motion. button and pull down parking lever.

Downloaded from www.Manualslib.com manuals search engine

4-22 DK451/501/551

FOOT THROTTLE HAND THROTTLE LEVER DIFFERENTIAL LOCK PEDAL

DK451

A12O436A DK501/551 A12O437A A12O438A

(1) Foot Throttle (1) Hand Throttle Lever (1) Differential Lock Pedal

(A) Decrease (A) Press to “ENGAGE”

(B) Increase (B) Release to “DISENGAGE”

The foot throttle is interlocked with the Differential lock is applied only in cases

hand throttle. Depressing the foot throttle where: the wheels are likely to slip, or

increases engine speed. Full engine only one of the rear wheel slips. Lightly

speed control can be obtained with the stepping on the differential lock pedal with

foot throttle if the hand throttle is in full the heel makes the rear wheels run at

rearward position. The foot throttle may equal speed. To unlock, just release the

also be used to temporarily increase en- pedal.

gine speed above the hand throttle While the Diff. Lock pedal is engaged,

setting. the warning lamp in instrument panel will

light up in the instrument panel.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-23

POSITION CONTROL LEVERS EXTERNAL POSITION CONTROL LEVER

WARNING DK501/551

To prevent loss of control of trac-

tor, never use the differential lock

at speeds above 8 km/h (5 MPH).

Never use the differential lock

when turning the tractor. When

engaged, the differential lock will

prevent the tractor from turning.

IMPORTANT

If a rear wheel spins at speed,

A12O440A A12O441A

reduce engine speed before en-

gaging the differential lock, to (1) Position Control Lever (1) External Position Control Lever

avoid shock loads to the trans- (2) Draft Control Lever

mission. (3) Stop Bolt

Operating the hydraulic control lever ac- The tractor is equipped with an external

tuates the hydraulic lift arm, which con- position control lever. Use this lever

trols implement height or working depth. when connecting implements to the three-

To lower implement, push the lever point hitch.

forward; to raise it, pull the lever back.

WARNING

HOW TO USE THE STOP BOLT

When external position control le-

1. Determine a desired working position, ver is adjusted, the transmission

using the control lever. lever and PTO transmission lever

2. Fix the stop bolt in the desired position. must be located in neutral

3. Once the stop bolt is set, simply move position. Pull the parking break.

the relevant hydraulic lever forward The engine must be operated in

until it reaches the stop bolt. idle state. Draft control lever push

to the front side, and maintain in

floating range.

Downloaded from www.Manualslib.com manuals search engine

4-24 DK451/501/551

JOY STICK LEVER(OPTION)

A12O442A

Joystick valve/lever is installed by stan-

dard to be used as outer hydraulic oil

pressure valve for only loader. Joystick

lever operates along the way in form of

cross. When joystick moves toward front

& rear side in a straight line, hydraulic oil

pressure applies into H & G port and it

moves toward right & left side in a straight

line, hydraulic oil pressure applies into E

& F port. Also when joystick moves

diagonally, hydraulic oil pressure applies

into the related port. Hydraulic oil pres-

sure applies into H & F port when the

joystick moves as the up figure shown.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-25

DESCRIPTION OF CAB OPERATING SYSTEM

INTERNAL ADJUSTMENT SYSTEM

DK451

A12O443A

(1) Air conditioner Switch (6) Air Outlet(Cool) (11) Cigar Jack

(2) Heater Switch (7) Room Lamp (12) Ashtray

(3) Working Light(Front) Switch (8) Air Outlet(Hot) (13) Speaker

(4) Working Light(Rear) Switch (9) Cassette Tape Recorder (14) Hanger

(5) Front Wiper Operating Switch (10) Sunroof Handle

Downloaded from www.Manualslib.com manuals search engine

4-26 DK451/501/551

DK501/551

A12O444A

(1) Air conditioner Switch (6) Air Outlet(Cool) (11) Cigar Jack

(2) Heater Switch (7) Room Lamp (12) Ashtray

(3) Working Light(Front) Switch (8) Air Outlet(Hot) (13) Speaker

(4) Working Light(Rear) Switch (9) Cassette Tape Recorder (14) Rear Wiper Operating Switch

(5) Front Wiper Operating Switch (10) Sunroof Handle

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-27

EXTERNAL NAME OF THE CABIN REAR WINDOW ENTRANCE ON EITHER SIDE

A12O445A A12O446A A12O447A

(1) Working Lamp(Front) (3) Rear View Mirror (1) Handle Of Rear Window (1) Handle Of Entrance

(2) Working Lamp(Rear) (4) Wiper (2) Button (2) Button

1. The cabin is designed for comfort and If you lightly push rear window while Pressing the button of the handle will

convenience and is made of steel frame. depressing the button on the handle, the open the door, and then it will be fixed

2. It always provides you wide-angle rear window will automatically open. after opening to some extent.

view by using very wide window, exter- The cabin can be locked and unlocked

nal rear view mirror on the left and right WARNING by inserting the key into the lock and

side, and window-shield wiper in case Sometimes, it is impossible for turning.

of rain. you to open and close the window

3. It is possible for you to work slowly because of the detachment, please

and conveniently using air conditioning make sure of the position of the

and heating system. attachment when opening and

closing it.

4. With doors on both sides, entry on ei-

Do not drive the tractor at full

ther side is possible.

speed or on the road with sharp

curves with the window open.

Downloaded from www.Manualslib.com manuals search engine

4-28 DK451/501/551

WORKING LIGHT (FRONT/REAR)

To turn on, position the switch marked

DK451

(front) to “ON” the position.

To turn on, position the switch marked

(rear) to “ON” the position.

WARNING

Do not drive with the working

light (rear) turned on when you

are on the road at night. It is dan-

gerous because it affects the

driver’s view behind you.

In this case, use the hazard lamp.

A12O448A

(1) Door Hanger(LH,RH) DK501/551

When operating the tractor with the doors

open, use the extendable door stopper.

Do not leave the doors fully open while

driving the tractor.

A12O449A

(1) Working Light (Front) Switch

(2) Working Light (Rear) Switch

(3) Working Lamp

A12OG06A

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-29

WIPER HEATER

1. To turn on, position the switch marked

DK451

(wiper) to the “ON” position.

2. When you press the ON direction of

the switch, wash fluid will spray from

the nozzle connected to the wind-

shield wiper.

3. The tank for the washer fluid is

equipped on the left side behind the

seat.

WARNING

You may use general tap water as

A12O451A

the washing fluid. But it is better

DK501/551 to use the washer fluid for auto- (1) Heater Switch

mobile if possible. You have to

use it especially in winter.

If you operate the windshield HEATER SWITCH

wiper without the washer fluid, it Turning the switch to “LOW” or “HIGH”

will damage the motor. Therefore, operates it.

you should check the washing

fluid before operation. WARNING

Do not wash the windshield with

After driving with warm air, place

the wiper if it is covered by mud.

the heater switch at “LOW”

Please spray the washing fluid

position. Wipe off the indoor win-

during the operation of the wiper.

dow if it becomes blurred.

A12O450A And if you operate the wiper with

Make sure that nothing will block

the window frozen in winter, the

(1) Wiper Operating Switch (Front) the entrance of the heater grill. It

internal fuse will may short

(2) Wiper Operating Switch (Rear) is the cause of fault.

(3) Wiper Front circuit. Please operate the wiper

after raising the temperature in

this case.

Downloaded from www.Manualslib.com manuals search engine

4-30 DK451/501/551

AIR CONDITIONER

ADJUSTMENT OF THE DIRECTION OF DK451

DK451 THE WIND

The direction of the warm wind can be

adjusted forward, backward, left and

right.

FOR HEATER USE

1. Please use antifreezing solution suit-

able for the external temperature in

winter.

2. Check the heater hose before using.

DK501/551

DK501/551

A12O453A

(1) Wind Volume Adjusting Switch

(2) Temp. Adjusting Knob (3) Cold Air Outlet

You can adjust wind volume three stages

as “LOW”, “MEDIUM”, “HIGH”. If you turn

the right switch clockwise, you can ad-

A12O452A

just the room temperature.

(1) Warm Air Outlet

Adjustment of the Direction of the Air

You can freely adjust the direction of the

air by turning the grill.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-31

CASSETTE TAPE RECORDER

FOR AIR CONDITIONER USE

1. The air conditioning system uses the Therefore, compressor oil should always

new refrigerant HFC-134a. Therefore, be changed or refilled with prescribed

if you put old refrigerant CFC-12 by amount as the refrigerant.

mistake, it will cause the fault similar

In case that the refrigerant or oil is

to the compressor leakage. So make

leaking from the system.

sure that you are using the correct

refrigerant before refilling the refri- In case that the refrigerant is sud-

gerant. denly released from the system.

2. If some moisture enters the inside of In case that the system parts are

the air conditioning circuit, it can changed.

cause a failure of the air conditioner As you work in the cabin for a long

and damage to the parts of the comp- time with the air conditioner turned

ressor. on, the air in the cabin becomes foul.

A12O454A

3. If the amount of the oil in the air condi- So you should let fresh air in perio-

dically. (1) Cassette

tioning circuit is not correct, it will

cause the following troubles:

Oil shortage - lubricating function is * PRESCRIBED AMOUNT

POWER SUPPLY

not enough. Leakage of the compre-

New refrigerant Compressor oil Turning the handle clockwise makes the

ssor.

Kinds HFC-134a VCON 488 power ON, and volume is getting louder.

Excessive engine oil - bad cooling. Turning the switch counterclockwise

Injecting 0.95 – 1.0kg 265ml

makes the volume is getting weaker and

amount (2.09 to 2.20 ld) (0.07U.S.gal.) the power OFF.

WARNING WARNING

If you sleep with the air condi- Adjust the volume so that you can

tioner turned on, you are at risk still hear the sounds from outside

of injury or death. Do not sleep in while driving.

cabin.

Downloaded from www.Manualslib.com manuals search engine

4-32 DK451/501/551

INDOOR LAMP SUNROOF

DK451 DK501/551 DK451 DK501/551

A12O455A A12O456A A12O457A

(1) Antenna (1) Indoor Lamp (1) Sunroof

INSERTING A CASSETTE TAPE If you press the symbol , the indoor 1. You can use it, to let the fresh air in

If you turn ON the power source, and lamp will be turned on. If you press it the cap.

insert the cassette tape with the tape side again, it will be turned off. 2. If you want to open it, just press the

to the right, it will play automatically. For button of the handle, then it will

more information, please see the manual smoothly open by the gas cylinder.

for the cassette tape recorder. 3. If you want to close it after letting the

RADIO ANTENNA fresh air in, just pull the handle lightly.

You can move the antenna about 100° in 4. When you open and close it, do not

the forward and backward direction of apply the excessive force.

the tractor.

Downloaded from www.Manualslib.com manuals search engine

DESCRIPTION OF OPERATING SYSTEM 4-33

ACCESSORIES

A12O458A

(1) Cigar Jack (2) Ashtray

(3) Hanger

1. To increase more convenience in the

cabin, the accessories are attached.

2. Cigar jack for vehicle, ash tray, room

mirror, and clothes hanger are

equipped so that it brings you more

comfort.

Downloaded from www.Manualslib.com manuals search engine

4-34 DK451/501/551

Downloaded from www.Manualslib.com manuals search engine

PRE-OPERATION CHECK

OPERATING NEW TRACTOR

5

OPERATING THE ENGINE

OPERATING THE TRACTOR

HYDRAULIC UNIT

OPERATING 3 POINT HITCH

TIRES, WHEELS AND BALLAST

Downloaded from www.Manualslib.com manuals search engine

5-2 DK451/501/551

PRE-OPERATION CHECK OPERATING NEW TRACTOR

DAILY CHECK ITEM

It is a good practice to know the condi- - Walk around inspection. How a new tractor is handled and main-

tion of your tractor before you start it. tained determines the life of the tractor.

- Check the engine oil level

You should do routine check before each

- Check the transmission oil level A new tractor just off the factory pro-

use.

duction line has of course been tested,

- Check the coolant level

but the various parts are not accustomed

CAUTION - Clean the grill and radiator screen. to each other, therefore care should be

To avoid personal injury: - Check the air cleaner and evacuator taken to operate the tractor for the first

Be sure to check and service the valve. 50 hours at a slower speed and avoid

tractor on a level surface with the - Check the brake pedal excessive work or operation until the

engine shut off and the parking various parts become “broken-in.”. The

brake “ENGAGED”. - Check all dash gauges and indicators manner in which the tractor is handled

- Check head lights, tail lights, and all during the “breaking-in.” period greatly

working lights. affects the life of your tractor. Therefore,

- Check accessible wiring harness for to obtain the maximum performance and

any damage. the longest life of the tractor, it is very

important to properly break-in your

- Check the seat belt and ROPS for

tractor.

damage.

- Refuel (See “daily check” in the peri-

odic service section)

- Check all danger and warning labels.

Downloaded from www.Manualslib.com manuals search engine

OPERATING 5-3

CHANGING LUBRICATING OIL FOR

NEW TRACTORS

In handling a new tractor, the following Special attention should be given to new

precautions should be observed. tractors lubrication oil. New parts are not

You Should not operate the your trac- accustomed to each other and are not

tor at full speed for the first fifty hours broken in properly. Small metal grit can

of use. develop in the lubricating system as metal

parts begin to “break in”, and continuous

Avoid sudden starts and stops.

use of the contaminated oil can cause

In cold climates, allow your tractor damage and failure. Therefore you should

plenty of time to warm up. change the tractor’s oil after the break -

Do not run the engine at speeds faster in period.

than necessary. For further details of the oil change and

Use due caution when operating your service schedule, see “maintenance”

tractor on rough roads or terrain. section.

The above precautions are not limited to

new tractors only, but are a good prac-

tice for tractors regardless of their age.

Downloaded from www.Manualslib.com manuals search engine

5-4 DK451/501/551

OPERATING THE ENGINE

STARTING THE ENGINE

WARNING

Carefully read and understand the

instructions in “Safe Operation”

chapter in the owner’s manual

and warning and warning plates

attached to the tractor.

Avoid engine starting in con-

cealed space as much as possible.

It may be fatal. Do so only with

proper ventilation.

When stating the engine, apply the

parking brake after positioning

A12O501A A12O502A

the main shift lever to Neutral

position and turning the PTO (1) Parking Brake Lever (1) PTO Switch

switch to OFF. (A) Lock - ON - OFF

Do not start the engine with un-

seated in driver’s seat since it may 1. MAKE SURE THE PARKING BRAKE IS 2. Place the P.T.O switch to the off position.

cause unwanted accident. SET.

(1) Pull(push) the parking brake lever

while fully depressing the pedal af-

ter connecting the left and the right

of the brake pedal. The “P” lamp in

the instrument panel turns on

when the key is inserted while

brake engaged.

(2) To release the parking brake press

the brake pedals again.

IMPORTANT

Make sure that the parking brake

pedals are fully depressed before

pushing the brake lever up

Downloaded from www.Manualslib.com manuals search engine

OPERATING 5-5

A12O504A A12O505A

(1) Position Control Lever (1) Hand Accelerator Lever

(A) Decrease

(B) Increase

4. Lower the attachment by pushing the 5. Pull the hand accelerator lever

position control lever forward. halfway.

6. Step on the clutch pedal.

WARNING

If you do not step on the clutch

pedal, the safety switch will not

A12O503A operate so that the engine is not

(1) Main Shift Lever (2) P.T.O Change Switch

starting.

3. Place the main shift lever and the P.T.O

change switch in the neutral position.

Downloaded from www.Manualslib.com manuals search engine

5-6 DK451/501/551

HOW TO START IN WINTER STOPPING THE ENGINE

7. Turn the switch key to “Start” position. 1. First, you place the start switch in Reduce engine revolution and apply even

“ON” position, and please wait (about foot pressure on both brake pedals. De-

WARNING 20 seconds) till the indicator light for press the clutch pedal and place main

As starting motor needs a lot of preheating is turned off. Now, you can gear shift lever and PTO switch in neutral.

electric current, please do not use start. If the start is not smoothly per- Lower equipment. Allow engine to idle

it more than 10 seconds contin- formed in spite of the try, repeat the for a short time before turning it off. Stop-

uously. If it is not started within above method. ping a hot engine at high speed may cause

10 seconds, stop doing it more 2. Turn the switch key for start to “Start” internal engine damage.

than 30 seconds, and then repeat position with your foot stepping on the Set parking brake by pulling the rod.

the same operation. If it will not clutch pedal. Turn main switch key counterclockwise

start at all, please do not restart 3. Take your hands off from the key when to the “OFF” position to open electric

before the flywheel stops. the engine is starting. It is automati- circuit.

cally turned ON.

8. Please take your hands off from the 4. Let it run with warm-up at idle speed

key when the engine is starting. It is for about 10 minutes after starting.

automatically turned ON.

9. Operation principle of preheating sys-

tem

If you continue to turn the start

switch more than 8 seconds, the

indicator of preheating plug is

glowing.

WARNING

Please do not turn the key to start

position while the engine is

running.

10.Let it run for heating for about 5 min-

utes after taking your foot off from

the clutch pedal.

Downloaded from www.Manualslib.com manuals search engine

OPERATING 5-7

WARMING UP

WARM-UP AND TRANSMISSION OIL IN

THE LOW TEMPERATURE RANGE

IMPORTANT CAUTION

Hydraulic oil serves as transmission

Remove the key whenever you To avoid personal injury:

fluid. In cold weather, the oil may be cold

leave the tractor. Then you are During warm up of the engine be

with increased viscosity. This can cause

certain the ignition and lights are sure that the parking brake is set.

delayed oil circulation or abnormally low

off. Also, it prevents unauthorized

After starting your tractors engine allow hydraulic pressure for some time after

operators from starting the

a five minute warm up before applying engine start-up. This in turn can result in

tractor.

any load to the tractor. This will allow trouble in the hydraulic system. To pre-

time for oil to reach every part of the vent the above, observe the following

WARNING instructions:

engine. If a load is applied to the tractor

After operating the tractor or en- before it has time to warm up then seri- Warm up the engine at about 50 % of

gine, never touch the muffler or ous damage can occur like, premature rated rpm according to the table below:

the heat shield until it has suffi- wear, breakage, or seizure.

cient time to cool. Ambient Warm-up time

temperature requirement

CAUTION

Above 0 °C

At least 5 minutes

To avoid the damage to the turbo (32 °F)

charger of this engine: 0 ~ -10 °C

Do not accelerate quickly right 5 ~ 10 minutes

(32 ~ 14 °F)

after engine start.

-10 ~ -20 °C

A minute of idling is recom- 10 ~ 15 minutes

(14 ~ -4 °F)

mended before getting into the

work and also before the engine Below -20 °C More than 15

stop. (-4 °F) minutes

IMPORTANT

Do not operate the tractor under

full load condition until it is suffi-

ciently warmed up.

Downloaded from www.Manualslib.com manuals search engine

5-8 DK451/501/551

JUMP STARTING

4. Attach the red clamp to the positive

WARNING

terminal of the dead battery and at-

tach the other end to the positive ter This tractor has a 12 volt nega-

minal of the helper battery. tive ground starting system.

5 . Clamp the black cable to the engine Use only the same voltage for

hook and attach the other end to the jump starting the tractor.

negative cable of the helper battery. Keep all flames, sparks, and ciga-

rettes away from the battery.

6. If the helper battery is in another

If the tractors battery is frozen,

vehicle, do not allow the tractor and

do not jump start the engine.

the other vehicle to touch.start the

The use of a higher voltage sys-

vehicle’s engine after connecting the

tem for jump starting can cause

cables and let it run for a few

severe damage to the tractors

A12O507A moments.Turn off all accessories on

electrical system.

both vehicles. Then start the disabled

(1) Dead Battery Use only a matching voltage

(2) Lay a Damp Rag Over the Vent Caps tractor.

source when “Jump Starting” a

(3) Jumper Cables (4) Helper Battery 7. Disconnect the battery cables in the dead battery.

When jump starting the engine, follow the exact opposite order as they were Do not allow battery fluid to con-

instructions below to safely start the attached. tact your skin, eyes, fabric, or

engine. painted surfaces.

1. Use a battery of the same voltage as After touching a battery, do not

the disabled tractor to jump start the touch or rub your eyes. Thor-

tractor. Locate the good battery in a oughly wash your hands.

safe place where the jumper cables If the acid contacts your body or

will reach. clothing, immediately flush with

water for at least 15 minutes and

2. Set the parking brake and turn the key

you may see a physician, if

switch to off.

necessary.

3. Put on safety goggles and rubber

gloves.

Downloaded from www.Manualslib.com manuals search engine

OPERATING 5-9

OPERATING THE TRACTOR

STARTING THE TARCTOR

WEARING THE SEAT BELT

WARNING

Always wear the seat belt when

cabin or ROPS is installed

In case where cabin or ROPS is

absent or ROPS is folded, do not

wear the seat belt.

When the seat belt is worn at the

waist or belly other than at the

pelvis, it may cause abdominal

injury during collision.

A12O508A A12O509A

(1) Seat (2) Seat Reclining Lever (1) Brake Pedal (RH) (2) Brake Pedal (LH)

(3) Seat Ajuster (3) Brake Lock

1. Adjust the seat and fasten the seat 2. Adjust the steering wheel according 3. Make sure whether the brake pedal of

belt. to the driver’s physique. the left and right side is engaged.

SEAT ADJUSTMENT

WARNING

Adjust the seat to the position for easy

access to the pedal and steering wheel. Do not adjust the steering wheel

while driving. You could lose the

control of your tractor, causing

WARNING

an accident.

Check if the seat is securely

locked after the seat adjustment.

Do not adjust the seat while

driving. The seat may move sud-

denly causing the loss of control

of the tractor.

Downloaded from www.Manualslib.com manuals search engine

5-10 DK451/501/551

A12O510A A12O511A A12O512A

(1) Position Control Lever (1) Hand Accelerator Lever (1) Parking Brake Lever

(A) Decrease (A) Release

(B) Increase

4. Pull the position control lever backward 5. Increase slowly the engine RPM from 7. Release the parking brake.

to raise the detachment idle speed to the middle speed.

6. Step on the clutch to the full.

Downloaded from www.Manualslib.com manuals search engine

OPERATING 5-11

8. Change the main and Hi-Lo shift, and

CAUTION

forward and reverse lever shuttle le-

ver to the position you want. Do not put one of your feet on the

9. The tractor starts to move if you take clutch while driving. If you put it,

away the clutch pedal slowly. the clutch stays in the slip posi-

tion, and as a result it wears quic-

kly.

As for the clutch operation. You

should take away the clutch quic-

kly, and connect it slowly.

Avoid sudden speed change for

the safety.

Before moving the tractor, take

care of the front and back, and

left and right direction. If you are

careless about it, you may have

injury.

When driving on the steep slope,

loading and unloading something

to or from the vehicle, entering

and going out of the job field, driv-

ing over the ridge way, please do

not drive with your hand off from

the main shift lever. If you change

gears halfway, it is dangerous.

Therefore, you should put the

A12O513A gears in the low speed position

in advance.

(1) Main Shift Lever (2) Hi-Lo Shift Lever

Downloaded from www.Manualslib.com manuals search engine

5-12 DK451/501/551

STOPPING THE TRACTOR PARKING

PARKING BRAKE LEVER

IMPORTANT

When you park and stop the

tractor, you should push the park-

ing brake to fix it. As the tractor

is constructed in transmission

that is always engaged, if the Hi-

Lo shift is put in “Low”, the trac-

tor can move even in “Neutral”

position. Such phenomenon can

easily occur easily when:

1. The temperature of the mission

oil is low, and

A12O514A

2. The rotation of the engine is

high. But this phenomenon is

1. Adjust the accelerator to put the en- not abnormal.

gine rotation in the idle speed. Please get out of the tractor after

2. Step on the clutch pedal and brake confirming the tractor is stopped

pedal. while you are parking and stop-

ping it.

3. If it stops completely, put the shift le-

When you park the tractor at the

ver in the neutral position.

steep place, please fix its tire so

4. If some implement is mounted, put PTO A12O515A

that the tractor will not move.

clutch switch and PTO shift lever in Do not park it on the grass or (1) Chocks

the neutral position. straw. (2) Parking Brake Lever

5. Pull the lifting lever forward to lower If they touches the exhausting

the attachment slowly. pipe, a fire can break out.

6. You should surely lock the parking

brake.

7. If you put the start switch in “OFF”

position, the engine will stop.

Downloaded from www.Manualslib.com manuals search engine

OPERATING 5-13

HOW TO TURN HOW TO DRIVE ON A SLOPE

When parking or stopping the tractor, You should turn slowly by lowering the 1. Please drive according to the condi-

secure it by applying the brake pedal. engine rotation if possible. tions of the slope at safe speed so

When applying the parking brake, con- that the engine is not under heavy load

nect the left and the right of the brake WARNING if possible.

pedal, fully depress the brake pedal and If you turn at high speed, the trac- 2. On the uphill slope, change the main

then push (move upwards) the parking tor can turn over. shift lever into a lower gear so that

brake lever. Do not operate the tractor at high the engine will not stop.

In order to release the parking brake, speeds with the differential lock 3. On the downhill slope, drive at the low

depress the brake pedal fully once more. engaged. speed.

Do not attempt to turn with the

differential lock engaged. WARNING

WARNING

Make sure that the coupling de-

Driving without releasing the vice of brake pedal and differen-

parking brake will cause brake tial lock pedal are surely relea-

disc to wear out quickly. sed.

Apply the parking brake and On the slope, do not put the main

place the chocks at the rear shift in neutral position or do not

wheels when parking. cut off the clutch.

When parking the vehicle on a On the downhill slope, apply en-

hill, position the shift lever at low gine brake, and should not step

forward 1st gear for uphill and low on the clutch pedal. If you do not

reverse 1 st gear for downhill. keep this rule, you can be injured.

Do not park on steep hills. The ve-

hicle may roll down and cause

accident.

Downloaded from www.Manualslib.com manuals search engine

5-14 DK451/501/551

THE CAUTIONS WHEN COMING IN

AND OUT OF PAVED ROAD

1. Make sure that the left and right pedal

are connected.

2. If the difference of the height is large

when coming in and out of the culti-