Professional Documents

Culture Documents

R05323 M 106 X014 0166

R05323 M 106 X014 0166

Uploaded by

ATALAY0 ratings0% found this document useful (0 votes)

27 views4 pagesOriginal Title

R05323-M-106-X014-0166

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views4 pagesR05323 M 106 X014 0166

R05323 M 106 X014 0166

Uploaded by

ATALAYCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

‘A Sesacase COMPANY

Operation & Maintenance

_Manual

MINERA CHINALCO TOROMOCHO

clo Aker Solutions Inc.

Rail Yard Lime Silo Package

400-LM-001/002/003

Document No: PD-1025-2-A-801-1

‘Stanco Job No: $10-1025

fm sve

91-05-27 [tales TOR #1 ie

DESCRIPTION CHK

Plerse wad iT CeeTIPIeD OTe

(IPLAC

Ble|

SIANGG-

‘The information in this manual, including technical data and copies of drawings, embodies

information proprietary to Stanco Projects. ‘This manual is provided to the user of equipment

purchased from Stanco Projecs for use only In operation of maintenance of such equipment.

‘Such information inthis manual isnot fo be used, disclosed, copied, o reproduced in whole oF

in part for any use other than that indicated above, or for any other purpose detrimental to the

interests of Sanco Projects, "

1.2 Lime Silo Safety

1.3. Lime Silo Bin Vent Fiter Safety.

4.4 Lime Silo Bin Activator Safety.

1.5 Lime Silo Actuated Isolation Knife Gate Safety

1.8 Lime Silo Rotary Airlock Safety.

1.7 Lime Silo Truck Loading Downspout Safety

1.8 Lime Silo Truck Loading Displaced Air Blower Safety

1.9 Lime Silo Rallcar Unloading Compressor Safety

Description

21 OVERVIEW. .

22 MAJOR MECHANICAL EQUIPMENT

2.2.1 400-BN-005/008/007 Lime Silo,

2.2.2 400-AT-005/006/007 Lime Silo Bin Activator.

2.2.3 400-DC-005/006/007/008/008/010 Lime Silo Bin Vent Fite.

2.2.4 400-AL-005/008/007 Lime Silo Rotary Aitock.

2.2.5 400-2M.006/006/007 Lime Silo Truck Loading Downspout.

2.2.6 400-GC-005/008/007 Lime Silo Ralicar Unloading Compressor

2.2:7 Lime Silo Truck Loading Ae Blower.

2.3. Miscellaneous Equipment

2.4 INSTRUMENTATION.

25 CONTROLS.

26 Lime Silo Truck Loading Contro! Panel.

2.7 Lime Sito Raiicar Unloading Control Pane

‘System Startup and Operation

3.4 Lime Silo Filing

3.2 Pre-Start Check.

8.2.1 Dry Test Run.

3.2.2 Startup Procedure,

3.2.3 Automatic Sequential Shutdown.

4

12

12

12

12

12

12

24

24

22

22

22

22

23

23

25

25

25

26

26

26

26

34

3

A

ges

STIANGG:

3224 Automatic Ervetgency ShubTown 3a

3.3 Troubleshooting. 36

3.3.1 Buk Chemical Delivery 36

3.32 Flow Promotion 36

3.33 Alarms, a7

4 Maintenance. so AM3

4.1 Lime Silo Bin Vent Fiter(400-0¢-005/00610071008/009/010) A13

4.2 Lime Sto Bin Activator (400-AT-008/006007) 413

43 Lime Silo Truck Loading Downspout (400-2M-005/006/007) so

44 Lime Silo Rotary Airock (400-AL-006/008/007) Ans

45 Lime Silo Raiicar Unloading Compressor (400-GC-005/0061007). a3

LUBRICATION SCHEDULE cS

‘STORAGE AND PRESERVATION REQUIREMENTS. cy

APPENDIX. 7A

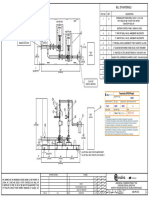

7.1. FOUNDATION LOAD DIAGRAM os 72

72 SILO CALCULATIONS, os 73

7.3 GENERAL ARRANGEMENT DRAWING. 74

7.4 CONTROL NARRATIVE, os 78

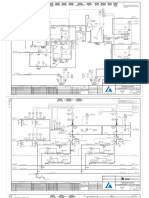

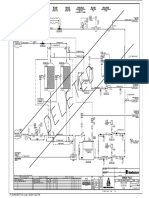

7.5 PROCESS & INSTRUMENTATION DIAGRAMS. 76

78 ELECTRICAL DRAWINGS, 1

7.7 PLC PROGRAM. 78

8 EQUIPMENT... 89

8.1 MECHANICAL EQUIPMENT LIST 810

82 MOTOR LOAD UIST. eat

83. ELECTRICAL EQUIPMENT LIST 212

84 INSTRUMENT INDEX 13

85 VALVELIST. o cary

86 SPARE PARTS.IST. a4

9 MANUALS FOR MECHANICAL EQUIPMENT. son 4

10 MANUALS FOR INSTRUMENTATION & CONTROLS. ns 102

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Toromocho EPCM Project: Albert J. YeeDocument1 pageToromocho EPCM Project: Albert J. YeeATALAYNo ratings yet

- Minera Chinalco Toromocho C/O Aker Solutions Inc. Lime Offload & Storage SystemDocument409 pagesMinera Chinalco Toromocho C/O Aker Solutions Inc. Lime Offload & Storage SystemATALAYNo ratings yet

- REM54 Tob 752429 ESgDocument74 pagesREM54 Tob 752429 ESgATALAYNo ratings yet

- Project C560 Document List: Client: Minera Chinalco Peru S.A. Page 791 of 1966Document23 pagesProject C560 Document List: Client: Minera Chinalco Peru S.A. Page 791 of 1966ATALAYNo ratings yet

- Pid Area 293Document6 pagesPid Area 293ATALAYNo ratings yet

- Pid Area 282Document15 pagesPid Area 282ATALAYNo ratings yet

- 7000 Troubleshooting - Es P PDFDocument110 pages7000 Troubleshooting - Es P PDFATALAYNo ratings yet

- Pid Area 284Document10 pagesPid Area 284ATALAYNo ratings yet

- 240-TB-001 240-PP-102 240-PP-002 240-PP-004 240-PP-104 240-TK-001 240-TM-001 240-TK-002 240-PP-014 240-Sa-001Document2 pages240-TB-001 240-PP-102 240-PP-002 240-PP-004 240-PP-104 240-TK-001 240-TM-001 240-TK-002 240-PP-014 240-Sa-001ATALAYNo ratings yet

- Pid Area 280Document21 pagesPid Area 280ATALAYNo ratings yet

- Lista de Actos y Condiciones SubestándarDocument1 pageLista de Actos y Condiciones SubestándarATALAYNo ratings yet

- PRECOM AREA 400 - Fuel Oil Transfer PackageDocument11 pagesPRECOM AREA 400 - Fuel Oil Transfer PackageATALAYNo ratings yet

- 5-Microscopia de MineralesDocument7 pages5-Microscopia de MineralesATALAYNo ratings yet