Professional Documents

Culture Documents

Filmtec™ Sw30Hrle-400 Element: Product Data Sheet

Filmtec™ Sw30Hrle-400 Element: Product Data Sheet

Uploaded by

mahdi rasoulianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filmtec™ Sw30Hrle-400 Element: Product Data Sheet

Filmtec™ Sw30Hrle-400 Element: Product Data Sheet

Uploaded by

mahdi rasoulianCopyright:

Available Formats

Product Data Sheet

FilmTec™ SW30HRLE-400 Element

Seawater Reverse Osmosis Element

Description DuPont Water Solutions offers various premium seawater reverse osmosis (RO)

elements designed to reduce capital and operation cost of seawater RO systems.

FilmTec™ Elements combine premium membrane performance with automated

precision fabrication which takes system performance to exceptional levels.

FilmTec™ SW30HRLE-400 Elements offer a combination of high rejection and low

energy requirements to allow lower total costs with medium- and high-salinity feedwater.

Benefits of the FilmTec™ SW30HRLE-400 Element include:

l Helps systems to be designed and operated to optimize operating cost through

lower energy consumption or to optimize capital cost through higher productivity

at lower operating fluxes.

l High NaCl and boron rejection to help meet World Health Organization (WHO)

and other drinking water standards.

l Effective use in permeate staged seawater desalination systems without

impairing the performance of the downstream stage.

l High performance over the operating lifetime without the use of oxidative

posttreatments. This is one reason FilmTec™ Elements are more durable and

may be cleaned more effectively over a wider pH range (1 – 13) than other RO

elements.

l Automated, precision fabrication with a greater number of shorter membrane

leaves reducing the effect of overall fouling and maximizing element efficiency,

helping to lower your cost of operation.

Product Type Spiral-wound element with polyamide thin-film composite membrane

Typical Properties

Stabilized

Active Area Permeate Flowrate

Feed Spacer Thickness Boron Stabilized Salt

FilmTec™ Element (ft 2) (m2) (mil) (gpd) (m3/d) Rejection (%) Rejection (%)

SW30HRLE-400 400 37 28 7,500 28 92 99.80

1. The above values are normalized to the following conditions: 32,000 ppm NaCl, 5 ppm boron, 800 psi

(5.5 MPa), 77°F (25°C), pH 8, 8% recovery.

2. Permeate flows for individual elements may vary ± 15%.

3. Minimum Salt Rejection is 99.65%.

4. Stabilized salt rejection is generally achieved within 24 – 48 hours of continuous use, depending upon

feedwater characteristics and operating conditions.

5. Product specifications may vary slightly as improvements are implemented.

6. Active area guaranteed ± 5%. Active area as stated by DuPont Water Solutions is not comparable to the

nominal membrane area figure often stated by some element suppliers.

Page 1 of 3 Form No. 45-D00967-en, Rev. 3

January 2020

Element

Dimensions

Dimensions – inches (mm) 1 inch = 25.4 mm

A B C

FilmTec™ Element (in) (mm) (in) (mm) (in) (mm)

SW30HRLE-400 40.0 1,016 1.125 ID 29 ID 7.9 201

1. Refer to FilmTec™ Design Guidelines for multiple-element systems of 8-inch elements

(Form No. 45-D01695-en).

2. Element to fit nominal 8-inch (203-mm) I.D. pressure vessel.

Operating and Maximum Operating Temperature a, b 113°F (45°C)

Maximum Operating Pressure b 1,200 psig (83 bar)

Cleaning Limits

Maximum Element Pressure Drop 15 psig (1.0 bar)

pH Range

Continuous Operation a 2 – 11

Short-term Cleaning (30 min) c 1 – 13

Maximum Feed Silt Density Index (SDI) SDI 5

Free Chlorine Tolerance d < 0.1 ppm

a. Maximum temperature for continuous operation above pH 10 is 95°F (35°C).

b. Consult your DuPont representative for advice on applications above 95°F (35°C). Refer to FilmTec™

Elements Operating Limits (Form No. 45-D00691) for warranty-voiding conditions and additional

information.

c. Refer to guidelines in Cleaning Guidelines (Form No. 45-D01696-en) for more information.

d. Under certain conditions, the presence of free chlorine and other oxidizing agents will cause premature

membrane failure. Since oxidation damage is not covered under warranty, DuPont Water Solutions

recommends removing residual free chlorine by pretreatment prior to membrane exposure. Please refer to

technical bulletin Dechlorinating Feedwater (Form No. 45-D01569-en) for more information.

Additional Before use or storage, review these additional resources for important information:

Important l Usage Guidelines for FilmTec™ 8” Elements (Form No. 45-D01706-en)

l Start-Up Sequence (Form No. 45-D01609-en)

Information

l Storage and Shipping of New FilmTec™ Elements (Form No. 45-D01633-en)

Product DuPont has a fundamental concern for all who make, distribute, and use its products, and

Stewardship for the environment in which we live. This concern is the basis for our product stewardship

philosophy by which we assess the safety, health, and environmental information on our

products and then take appropriate steps to protect employee and public health and our

environment. The success of our product stewardship program rests with each and every

individual involved with DuPont products—from the initial concept and research, to

manufacture, use, sale, disposal, and recycle of each product.

Page 2 of 3 Form No. 45-D00967-en, Rev. 3

January 2020

Customer Notice DuPont strongly encourages its customers to review both their manufacturing processes

and their applications of DuPont products from the standpoint of human health and

environmental quality to ensure that DuPont products are not used in ways for which they

are not intended or tested. DuPont personnel are available to answer your questions and to

provide reasonable technical support. DuPont product literature, including safety data

sheets, should be consulted prior to use of DuPont products. Current safety data sheets are

available from DuPont.

Please be aware of the following:

l The use of this product in and of itself does not necessarily guarantee the removal

of cysts and pathogens from water. Effective cyst and pathogen reduction is

dependent on the complete system design and on the operation and maintenance

of the system.

l Permeate obtained from the first hour of operation should be discarded.

Regulatory Note This product may be subject to drinking water application restrictions in some countries;

please check the application status before use and sale.

Have a question? Contact us at: All information set forth herein is for informational purposes only. This information is general information and may differ from that based

on actual conditions. Customer is responsible for determining whether products and the information in this document are appropriate for

www.dupont.com/water/contact-us

Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other

government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where

DuPont is represented. The claims made may not have been approved for use in all countries. Please note that physical properties may

vary depending on certain conditions and while operating conditions stated in this document are intended to lengthen product lifespan

and/or improve product performance, it will ultimately depend on actual circumstances and is in no event a guarantee of achieving any

specific results. DuPont assumes no obligation or liability for the information in this document. References to “DuPont” or the “Company”

mean the DuPont legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. No

freedom from infringement of any patent or trademark owned by DuPont or others is to be inferred.

DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned by affiliates of DuPont de

Nemours Inc. unless otherwise noted. © 2020 DuPont.

Page 3 of 3 Form No. 45-D00967-en, Rev. 3

January 2020

You might also like

- Allies and AdversariesDocument146 pagesAllies and AdversariesBálint Vincze100% (4)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Installation and Set Up of Hamster Scalping Ea For Mt4Document7 pagesInstallation and Set Up of Hamster Scalping Ea For Mt4jin onNo ratings yet

- Techno - Funda Society - by Nishant Arora PDFDocument241 pagesTechno - Funda Society - by Nishant Arora PDFUtkarsh Shah100% (3)

- Filmtec™ Bw30Xfrle-400/34 Element: Product Data SheetDocument3 pagesFilmtec™ Bw30Xfrle-400/34 Element: Product Data SheetElajmi RostomNo ratings yet

- Filmtec™ Nf90-400/34I Element: Product Data SheetDocument3 pagesFilmtec™ Nf90-400/34I Element: Product Data SheetReyna OrihuelaNo ratings yet

- Filmtec™ Bw30-400/34 Element: Product Data SheetDocument3 pagesFilmtec™ Bw30-400/34 Element: Product Data SheetPraveen Kumar100% (1)

- DOW FILMTEC™ SW30HR-380 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HR-380 Element: DescriptionAnonymous zUsOCUNo ratings yet

- Filmtec™ Bw30Xfr-400/34I Element: Product Data SheetDocument3 pagesFilmtec™ Bw30Xfr-400/34I Element: Product Data SheettorrecillaNo ratings yet

- Filmtec™ Membranes: Product Data SheetDocument3 pagesFilmtec™ Membranes: Product Data Sheetcello loNo ratings yet

- Membrane SW30XLE-440iDocument3 pagesMembrane SW30XLE-440iecrNo ratings yet

- Data Sheet - BW30-PRO-400Document2 pagesData Sheet - BW30-PRO-400satheesh kumarNo ratings yet

- Bw30xfrle-400 34Document2 pagesBw30xfrle-400 34Alejandro OdioNo ratings yet

- Lenntech: DOW FILMTEC™ BW30XFRLE-400/34 ElementDocument2 pagesLenntech: DOW FILMTEC™ BW30XFRLE-400/34 ElementApatinNo ratings yet

- BW30XFR-400 34Document2 pagesBW30XFR-400 34Alejandro OdioNo ratings yet

- DOW FILMTEC™ SW30HRLE-400 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HRLE-400 Element: Descriptiongvnks90No ratings yet

- Filmtec SW30HRLE-400Document3 pagesFilmtec SW30HRLE-400PT Deltapuro IndonesiaNo ratings yet

- Filmtec™ Bw30Hr-440I Element: Product Data SheetDocument3 pagesFilmtec™ Bw30Hr-440I Element: Product Data SheetcaparedeszNo ratings yet

- Membrana Filmtec Sw30xle-400iDocument3 pagesMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoNo ratings yet

- DOW FILMTEC™ BW30-400/34 Element: DescriptionDocument2 pagesDOW FILMTEC™ BW30-400/34 Element: DescriptionLam NgọcNo ratings yet

- DOW FILMTEC™ BW30-400 Element: DescriptionDocument2 pagesDOW FILMTEC™ BW30-400 Element: DescriptionKamal ChokshiNo ratings yet

- Bw30hrle 440Document2 pagesBw30hrle 440Alejandro OdioNo ratings yet

- Dow Filmtec Eco Pro 440 LDocument2 pagesDow Filmtec Eco Pro 440 LFabiola SanchezNo ratings yet

- Filmtec™ Soar 7000I Element: Product Data SheetDocument3 pagesFilmtec™ Soar 7000I Element: Product Data Sheetali jafNo ratings yet

- BW30-400 34Document2 pagesBW30-400 34Alejandro OdioNo ratings yet

- FilmTec SOAR 5000i PDS 45 D03707 enDocument3 pagesFilmTec SOAR 5000i PDS 45 D03707 enyuansen.wangNo ratings yet

- Ficha Técnica FilmTec BW30XFR 400 34Document3 pagesFicha Técnica FilmTec BW30XFR 400 34Daniel HernándezNo ratings yet

- BW30HR 440Document2 pagesBW30HR 440Alejandro OdioNo ratings yet

- FilmTec BW30 PRO 365 PDS 45 D03747 enDocument2 pagesFilmTec BW30 PRO 365 PDS 45 D03747 enMasoud AmirzadehfardNo ratings yet

- DOW FILMTEC™ ECO Line RO Elements: Product DatasheetDocument2 pagesDOW FILMTEC™ ECO Line RO Elements: Product DatasheetakbarNo ratings yet

- Filmtec Hsro 390 FF Pds 45 d01701 enDocument3 pagesFilmtec Hsro 390 FF Pds 45 d01701 enGunwant VarmaNo ratings yet

- Filmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetDocument4 pagesFilmtec™ Fiberglassed Elements For Light Industrial Systems: Product Data SheetfasihulNo ratings yet

- Membrane 45-D01750-EnDocument4 pagesMembrane 45-D01750-EnkepetrosNo ratings yet

- 10 Dow-Filmtec-Bw30-400-34i-MembraneDocument2 pages10 Dow-Filmtec-Bw30-400-34i-MembraneCHAMOUXNo ratings yet

- Filmtec™ Sanitary Ro Membranes: Product Data SheetDocument3 pagesFilmtec™ Sanitary Ro Membranes: Product Data Sheetali jafNo ratings yet

- DS TW30 4040Document3 pagesDS TW30 4040caparedeszNo ratings yet

- Filmtec SW30-8040Document2 pagesFilmtec SW30-8040PT Deltapuro IndonesiaNo ratings yet

- FilmTec BW30XHR PRO 440 PDS 45 D03750 enDocument2 pagesFilmTec BW30XHR PRO 440 PDS 45 D03750 enMasoud AmirzadehfardNo ratings yet

- DOW FILMTEC™ SW30ULE-440i Element: DescriptionDocument4 pagesDOW FILMTEC™ SW30ULE-440i Element: DescriptionMaria SilvaNo ratings yet

- FilmTec SW30XHR 440 PDS 45 D00970 enDocument2 pagesFilmTec SW30XHR 440 PDS 45 D00970 enAndri Sanjaya SembiringNo ratings yet

- Dow Filmtec SW30XHR 440iDocument2 pagesDow Filmtec SW30XHR 440ijazaibNo ratings yet

- Filmtec Sw30hrle 440i Pds 45 d00965 enDocument2 pagesFilmtec Sw30hrle 440i Pds 45 d00965 encarlospNo ratings yet

- Data Sheet Sw30hrle-400Document2 pagesData Sheet Sw30hrle-400Alexis Antonio Jara VidalNo ratings yet

- DOW FILMTEC™ Membranes: Product Data SheetDocument3 pagesDOW FILMTEC™ Membranes: Product Data SheetPT Purione MegatamaNo ratings yet

- Filmtec™ Bw60-1812-75 Element: Product Data SheetDocument4 pagesFilmtec™ Bw60-1812-75 Element: Product Data Sheetnagaraj p sNo ratings yet

- Membranas BW30 440ienDocument29 pagesMembranas BW30 440ienMarco GonzálezNo ratings yet

- Dupont Filmtec Xle Pro 4040 LDocument2 pagesDupont Filmtec Xle Pro 4040 Ldavid andres sandi ovaresNo ratings yet

- TapTec TT 3012 600 PDS 45 D03596 enDocument2 pagesTapTec TT 3012 600 PDS 45 D03596 enLam PhiNo ratings yet

- FILMTEC™ MembranesDocument2 pagesFILMTEC™ MembranesSamir BensitouahNo ratings yet

- FILMTEC™ Membranes: Product Data SheetDocument3 pagesFILMTEC™ Membranes: Product Data SheetAshish GulrandheNo ratings yet

- Filmtec™ Membranes: Product Data SheetDocument3 pagesFilmtec™ Membranes: Product Data SheetandresNo ratings yet

- Hsro 4040 FFDocument3 pagesHsro 4040 FFAlejandro OdioNo ratings yet

- Membrana SW30ULE-440Document3 pagesMembrana SW30ULE-440Maria SilvaNo ratings yet

- 10 - Filmtech MembraneDocument2 pages10 - Filmtech MembraneAnonymous XbmoAFtINo ratings yet

- Technical Manual Ultrafiltration: Inge Watertechnologies AGDocument40 pagesTechnical Manual Ultrafiltration: Inge Watertechnologies AGPraveen KhatriNo ratings yet

- Filmtec BW30-400-IGDocument2 pagesFilmtec BW30-400-IGPT Deltapuro IndonesiaNo ratings yet

- Filmtec BW 30-400 PDFDocument2 pagesFilmtec BW 30-400 PDFAnonymous qzPNpf100% (1)

- Ecosafe Ro Membrane CatalogDocument11 pagesEcosafe Ro Membrane CatalogecosafeNo ratings yet

- Filmtec BW30-2540Document3 pagesFilmtec BW30-2540PT Deltapuro IndonesiaNo ratings yet

- Dow Filmtec™ Fortilife™ Cr100: DescriptionDocument3 pagesDow Filmtec™ Fortilife™ Cr100: Descriptionadi khafidh persdaNo ratings yet

- TM700D Series: High-Rejection Brackish Water Reverse Osmosis Membrane Element With Enhanced Chemical ToleranceDocument2 pagesTM700D Series: High-Rejection Brackish Water Reverse Osmosis Membrane Element With Enhanced Chemical ToleranceKeily VilcarromeroNo ratings yet

- Imperite 300: Technical Data SheetDocument4 pagesImperite 300: Technical Data SheetBiju_PottayilNo ratings yet

- Japan Kanjis StudyDocument111 pagesJapan Kanjis StudyMaricela TorresNo ratings yet

- De Cuong Giua Hoc Ki 2 Mon Tieng Anh 6 Sach Ket Noi Tri Thuc PDFDocument5 pagesDe Cuong Giua Hoc Ki 2 Mon Tieng Anh 6 Sach Ket Noi Tri Thuc PDFLê HườngNo ratings yet

- Reflective Essay On Critical ThinkingDocument5 pagesReflective Essay On Critical ThinkingIQBAL NASEEM IQBAL NASEEMNo ratings yet

- GTO Series II: Service ManualDocument33 pagesGTO Series II: Service ManualSkai666No ratings yet

- Notice Regarding Computer Test of Block Epidemiolorist and Bilock Public Health Manager and Block DataDocument5 pagesNotice Regarding Computer Test of Block Epidemiolorist and Bilock Public Health Manager and Block DataRahul DeyNo ratings yet

- Ma2 Mock 3Document10 pagesMa2 Mock 3yashwant ashokNo ratings yet

- ConclusionDocument2 pagesConclusionHannah HermickNo ratings yet

- Afar302 A - ConsignmentDocument5 pagesAfar302 A - ConsignmentNicole Teruel0% (1)

- Consumer Behavior Towards Shopping Malls: A Systematic Narrative ReviewDocument14 pagesConsumer Behavior Towards Shopping Malls: A Systematic Narrative Reviewmanjusri lalNo ratings yet

- Week 3Document2 pagesWeek 3Trần Diệu LinhNo ratings yet

- Dogs at Work British English Student Ver2Document5 pagesDogs at Work British English Student Ver2CRISTINANo ratings yet

- Introduction To IPR - 1Document2 pagesIntroduction To IPR - 1sumit panchalNo ratings yet

- Customer Approval Specification: Digital PDP Division, LG Electronics IncDocument37 pagesCustomer Approval Specification: Digital PDP Division, LG Electronics InccaseysamNo ratings yet

- Part I - Personal Information: Assisted byDocument2 pagesPart I - Personal Information: Assisted byRV GRACE TORNONo ratings yet

- Ashkan Fayyaz - CVDocument1 pageAshkan Fayyaz - CVAshkan FayyazNo ratings yet

- IP Basics and Routing Protocols PDFDocument241 pagesIP Basics and Routing Protocols PDFWubie NegaNo ratings yet

- Scrap MGT - Optimization Solutions PDFDocument25 pagesScrap MGT - Optimization Solutions PDFDibyayan DasNo ratings yet

- !global (Message)Document6 pages!global (Message)llrprojetosgraficosNo ratings yet

- Lil Woodzeez Book Sheep WEBDocument32 pagesLil Woodzeez Book Sheep WEBGaspar SalasNo ratings yet

- Iga - PmppaDocument38 pagesIga - PmppaRapplerNo ratings yet

- 2005 항만 및 어항 설계기준 (목차)Document39 pages2005 항만 및 어항 설계기준 (목차)최광민No ratings yet

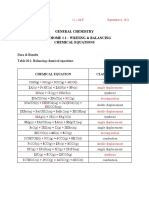

- General Chemistry Lab at Home # 2 - Writing & Balancing Chemical EquationsDocument3 pagesGeneral Chemistry Lab at Home # 2 - Writing & Balancing Chemical EquationsJayphet ChristianNo ratings yet

- Guest Posting Specialist Gig DescriptionDocument3 pagesGuest Posting Specialist Gig DescriptionAzhar RanaNo ratings yet

- Pointillist Journey Analytics Financial Services Use Cases EbookDocument25 pagesPointillist Journey Analytics Financial Services Use Cases EbookSachin MehraNo ratings yet

- Extended Metaphor Lesson PlanDocument7 pagesExtended Metaphor Lesson PlanElmo YuNo ratings yet

- Trust Me Liner NotesDocument4 pagesTrust Me Liner NotesSylvia Cissi Kennedy JacobusNo ratings yet

- Maternal and Child Health Nursing Exam 2Document7 pagesMaternal and Child Health Nursing Exam 2Khryzzl VlsrNo ratings yet