Professional Documents

Culture Documents

ProductData Lugs

Uploaded by

Gustavo Rivera0 ratings0% found this document useful (0 votes)

10 views6 pagesP

Original Title

ProductData_Lugs

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views6 pagesProductData Lugs

Uploaded by

Gustavo RiveraP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Product Data

¥

Scotchlok®

Aluminum Compression

tugs OE

1. Product Description 2. Applications 3. Data

SCOTCHLOK Aluminum

Compression Lugs consist of a series

of terminal lugs from No. 6 AWG

through 1000 komil (MCM) designed

for terminating aluminum and/or

‘copper conductors. Each lug has a

bronze underplating and a tin

outerplating to resist corrosion and

can be installed with standard industry

tooling. Chamtered ends ensure

simplicity and ease of insertion.

—To terminate aluminum and/or

copper conductors from No. 6 AWG

through 1000 kemil (MCM);

— Indoor and outdoor;

— Low voltage and high voltage (up to

35 KV);

— For maximum secureness

requirements, two-hole lugs are

available in larger sizes.

‘The SCOTCHLOK lugs consist of a

series of one-hole lugs from No. 6

‘AWG through 1000 kernil (MCM) and

two-hole lugs from 1/0 through 1000

kemil (MGM),

The lug features are:

— Simple application using readily

available tools:

— Chamiered ends for ease of

‘conductor insertion;

—Tinned outerplating and ALSTAN®

process bronze underpiating insure

maximum corrosion protection.

— Color coded end caps for lug

identification and ease of removal

{no tools required).

— Hole size and spacing to NEMA

specifications.

ULL listed, CSA certified

— Contact aid is compatible with all

solid insulations.

[ALSTAN ipa registered vademark of MAT

‘Chemical incorporated

Physical and Electrical

‘The Scotchlok 40,000 series

aluminum/copper lugs, crimped with

approved die sets, can be used on

cables with a rated operating

temperature of 90°C and an

‘emergency overload rating of 130°C.

‘The lugs pass the requirements of UL

486B, Underwriters’ Laboratories’

standard for safety (see Section 5,

Performance Tests). The current rating

of these lugs meets or exceeds the

current rating of the conductor size for

which its intended,

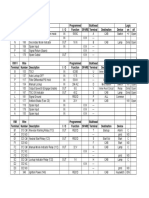

A. Dimensions

(See Table 1)

B. Crimping Tool-Die

Recommendations

(See Tabie I!)

A. Dimensions

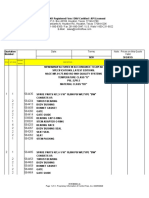

TABLE 1

Dimensions in Inches and (Millimeters)

Wire

Scotchiok | Size 8 P w | oc c |

L Stud | Color

we fAyo] 1% | OP | Ree | ceetn | wth | teath | seagate | S| Se

cM |

[-aoors | 6 | 200¢5.1) | .344(8.8) | 1.000(25.4) | .080.22,9)| 550 (14.0)| 2.900 (58.4) | 440(112)| Grey

[aoaza | « [2656.71 469 10) 000254) |. 000(5.)] 690(17.8)| 2300 684) | 440.2] — Green

[anne [2 | 077.9) 531 (3.8) L000 5.4) | 120(28.5)} 910 @06)| 2500-95) | a40(nt2)| —— Pink

[aos [2 | sore.) | 591 (108) 1000 25.4 sro (206)] 2500 695) | 440(112)| Pik

[40028 | 1 | 3508.9) | 534(13.5)] 940 (23,9) 750 (19,1) | 2:560 (65,0) | .440 (11,2) = Gold

40029 | 1 | .350(8.9) | 591 (13.5) 23.9) 750 (19,1) | 2.560 (65,0) = ia” | Gold

-4o032_| 1/0 | .414(10,5)] 640(16.3)| 1.250 (91.8) | 1.250(31,8)| 080 (22,4)| 3.190 (81.0) | .620(05.)| |W” | Tan

40083 _| v0 | 414 (10.5)] 640 16.3) 1.250 (31,8) |1.250(31.8)| 880 (22.4)| 3.190 (8,0) | 620 (16. Tan

40132 | wo | 4( 03} 640(163) 150 (3.1) [3.280(62.6) 00 22)| 5 za (104)| 620(1501] 780 648)| Y4™ | Tan

40037 | 2/0 | 439 (11,2) -687 (17.5) 1.380 (35.1) | 1.250(91.8)| 940 (23.9)| 3.190 (61.0) | -620(5.)/ — — | 4" | Ole |

40137 | 210 | -439(1%,2)) 687 (17.5) 1.500 (38,1) | 3.250(62.6)| 940 (23.8) | 5.500 (199,7)| 620 (15.8) | 1.750(44.5) | Y4" | ive |

aout | a0 | 4(r23))760(799) 150 29,1) | +910(293)] 060 (| 344074) | oe0Uts)| —— [| Ray

‘aoiat | 3/0 | 484 (12,3) .760(19,3)] 1.500 (38,1) | 3.250 (82.6)| 1.060 (26.9) | 5 500 (199.7)| 620 (15.6) | 1.750 (44.5)| 2" | Ruby

4004s | avo | 547 (13.9) 675 (22,2) 1 500 (8-1) [1.310 (68.3)|1.190 20.2)/ 3560 904) |620(158)| — | 4" | White

‘40046 | 4/0 | 547 (13,9)| 675 (22.2)| 1.500 (38,1) | 1.310 33.2)|1.190 (30.2)| 3.560 (90.4) | .620,(15.8) | Sa | white |

40145 | 4/0 | 547(13,9)| .875,22,2)| 1.750 (44,5) [3.380 (85.9) 1.190 (30.2) | 6.940 620 (15,8) | 1.750 (44.5)| Ye" | White

Faooea | 260 | -594(98,1) 906 (25.0) 1.600 4.1) | 1.310(93.3] 1.250 (1.8) | 3.620.01.9) | 620 (08 ed

594 (151)| 906 (2.0)| 1.620 (41,1) | 1.310 (33.3) 1.250 (31,8) | 3.620 (91.9) | 620(15.8)[ _ —

i 1750 (445) | 3.360(850) 1.250 (31.8) | 6000 (1524) 620 (1.8) | 1.750 445)

1 5) 2.250 (57.2) | 1.310 33,3) 1.380 (35,1) | 4.000 (101.6)| .620 (15.8) |

650 16.5). 2.250 (67.2) | 3.560 (90.4)|1.310 (33,3) | 6.560 (166.6)| 620

720118.) 1) 2.260 (67.2) | 1.810 33.3) 1.500 (38,1) | 4.250 (108.0) | 620 (15.8)

(183) 250 (57.2) | 1.310 (33.3)|1 500 (38.1) -620,(15.8) ~

2.250(87,2) | 3.560 (90.4) | 1500 (38.1) 620 (15.8) | 1.750 (445) |

3.5) | 1560(904 1620 (a1.2)1 6880 (174.8) 620015.) |1.750(445)| V4" | Green

500 (38,1)|1.750 (48.5) 5.440 (138.2) 620(15.8) |__| 84” | Pink

843 (24.4) 1.320 (3 2) [3.560 (90,4) 1.750 (44.5) | 7.310 (185,7)| 620 (15.8) |1.750 (44.5) |

523 (28.4) 430 (86) 3.000 (76.2) | 3620 02.0) | 1.750 (44.5) | 7.500 (1908) 6201

4.510 (9,3), 3380 (85,9) | 1.870 47.5) 1.750 (44.5) | 6.500 (165.1)

1.040 (26.4 151098. 3360 (5.9) |3.620(92.00|1 750 44.5) | is" | elon

40079 | 1000 | 1.193 (30.3) 1.843 (46.8) 4.620 (117.4) 1.670 47,5) |2.560, | 5a" | White

40178 | 1000 {1.199 (30.2) 1.04 (46,8)| 4620 (117.4) 3.620 (9.0)|2.560 (65.0) | 9.620 (244.4)| 620 15.) | 1.750 (84.5)| 4" | White

1.105 (28.1)

:2)|

o160__| 400 | -760(19.3)

843 (21.4) 1320 83.5)

34” | Yellow

B. Crimping/Tool Recommendations

TABLE It

imping Tool - Die Sets (No. of Crimps)

cor ‘Tt [Keay

oct Bundy Thomas 8 Bets slacks | Nat

Sze orpration "orporaton burn Co | OW

| seottiok| ANG | ug

tet |u| 8 | wos vou ewe | roms cose_|rvee0]

amr [8 [Sie] wisN ‘RECA = | aw Brig) | 43)

-490@0 [4 |S!" 16248) ‘AaCABCT) | UACABTIN) (Greeny [Greene] — | a7 Ci) said) | PI)

voz [2 |” [ wis) aecaatt) [uecastCn) nat) | pw) | — | 42) Brea) | Yee

ones [2 [iy [wie [ azcaa | aca =| aan, 72303) [ Ya)

ooze [1 | 5 | wi) AAR =| aswy area) | Yaa)

“ona [| 347 | wren) | tawern | ArcAn(H) — | asi) even) | (9)

‘eos | 10 | 34 [wean] vo cy | azsancny [us = so 7250) [84-10

400s [10 [1 [weanra)| won| A2sancn) Tan(2) = [sa 72549) | 4-119]

wean | WO) (1 Tanta) | Tan | — [som | 5y25(3) | vial

2m) atvet2) | over | — | sate) [2 ay8100) [4-19

ivet2) [over] — [satay |) 8y3101)

ubya) Jaub(an? — | 90 | a =

uzrantie) | (1) | Aub | Raby) | Yoo =

sania) [witty] — avasoa)

tesani2y wit | [180 ayes

manna) [itn | [510 Byascia)

oat) = [ane | ey = [=

sane, =| =| ray ae = {=

ueaanriay | cy | — | — | roma) | 70H) ==

usoanriay [oy | =| =| rome) TE

usoanra) | | = | = | rene)

ussannia |_| — | —_| 87m) — =

= fussamriay [wy [=| [ara | arr = |=]

= Justa, Toy | — | — | ara [army | =

= fuseantian [nf — =| saves) | savy = f=

0067 [500 [34° | — = = juseanren [a [= [=] reeena [ 06a = [=

woes | 500 | 14" | — = = justanreay Fa [=| =| sonia) | to) =|

‘oir oo tf — | — | — usar [a [= [ — | — [sna =

woors [oso [of — vusaama | | — | — | — [ene ==

some [750 [ie [= = = lussanriay [om [= = _| 12566) = [=

‘oor frooo [34 | — [= a |= =| tua =

ware [wo [sf — | — | — [swan [oo [ — | — [ — [one =

+745 an 4 accel Y95 es ("U" series), For YAS use PTS adapter For Y4B use PUADP adapter

~ Anderson VO6-3, VOB, NOBC and Burndy Y1000 require node se

4. Specifications

Product

Lugs must be constructed of seamless

aluminum and must be underplated

with 30 milionth-inch minimum

thickness of bronze and tin plated with

‘a minimum thickness of 3ten-

thousandths inches. They must be

availabe in one-hole sizes trom No. 8

‘AWG through 1000 Kemil (MCM) and

two-hole sizes from 1/0 through 1000

omit {MCM}. The lugs when crimped

with the approved die sets must have a

current-carrying capacity equal othe

‘conductors for which they are rated

Engineering/Architectural

Lugs shall be crimped with one of the

approved die sets according to the

engineering information supplied with

the connectors. (See Crimping Too!

and Die Set Table.) All terminations of

aluminum and/or copper stranded

wires in sizes No. 6 AWG through 1000

kemil (MCM) shall be made electrically

‘and mechanically secure with

SCOTCHLOK Aluminum

Compression Lugs. The lugs must

have a current-carrying capacity equal

to the conductors they are rated for

and must also meet the requirements

4 listed in U.L. 4868 test standards.

5. Performance Tests

A. Physical and

Electrical Properties

Material — Lug: 1100t Aluminum

Plating: Outerplating:

Bright tin — minimum

thickness 3 ten-

thousandths. Underplating:

ALSTAN" process bronze

undorplating minimum

thickness — 30 millionths

inches.

Voltage Rating — Low and high

voltage (up to 35 KV)

Current Rating — Same as each

‘conductor for which

lug is rated

Aluminum Association

8. UL. 486B

SCOTCHLOK lugs crimped with the

approved die sets pass the following

series of tests as found in ULL. 4868

Underwriters’ Laboratories’ standard

for safety.

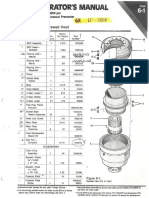

ic Sequence Test

a) Secureness Test

(See Figure A)

‘The test was set up as shown in Figure:

‘A. The values of the height H, diameter

Of the bushing hole, and weight W_

were selected from Table Ii in

accordance with the size of the wire to

which the weight was attached. The lug

was secured rigidly to simulate actual

service conditions. The bushing

‘oscillates about the lugin a

predescribed circle at a rate of 9 rpm

for 30 minutes. At the end of this

period the lug/wire connection must

be secure,

Results: All ugs passed.

TABLE tll

Secureness Test Valves

— Conductor [Diameter Wi

‘Scotchilok ‘Size of Bush- ® Weight in Pound

Log AWGo | ing ole } Height in [Aluminum | Copper

No "MM | ininches | "inehes’ | conduct | Conductor

006. Te 11% 0 8

[0020 [ Va 11% 8 30

“024, 40025 | [he We | 15 30

gna ‘40028, 40029] ot 5h 132 | 5

Eee 40022, 40035,

4013 w|i ii | 25 | 69 |

40037, 40137 20 Ba 14h, 26 50

| 40041, aors1 [30 Me 14h | |

eomove1or— x 40045, 40086,

40145; ee 14 30 sa.

40049, 40050

| 40149) 250 % | 16 20 9 __|

r | (40083, 40159) 300 a is | 40 | to

susnaa ce 48 40056, 40057,

mee OS 40156 so | 4 | 4 _

[40160 ee 1 40

| 40067, 40166 500 0% 50

[aor 00 | 18h 50

4007s, 40172 | 750~*(| 1% ig [56 | 110

FIGURE A 40079, 40178 | 1000 te | ae | 58 110

b) Pullout Tests

After the heating tests, the lugs were

subjected to a direct pull of the value

given in Column 6 of Table 1V. The

values shown in the table are listed in

ULL. 4868.

Results: All lugs passed. The pullout

forces required to separate the

conductors from the lugs are much

greater than those which are listed.

©) Static Heating

The lugs carried a continuous A.C.

current in accordance with the values

in column § of Table IV with a

temperature rise no greater than 50°C

above ambient. Lug temperatures

were considered to be stable when 3

readings, taken not less than 10

minutes apart showed a variance of

no more than 2°C between any 2

readings.

Results: all lugs passed.

B2. Heat Cycling Test

Lugs were subjected to currents and

cycle times having values in

accordance with those in columns 3

and 4 of Table IV. The lugs were on

test for 500 cycles without exceeding

the maximum allowable temperature

rise or stability factor as specified in

the U.L. 4868 standard.

Results: All lugs passed.

TABLE IV

ounn 3 ee Gon S| columns

Heal

vat | Ge | Static | Minimum Aowable

yee | oyeing | Heating [ulate in Pounds

(Amperes) | Times | (Amperes) Al cu

AeT"Gu_| cious) | 1} Gu_| Conductor | conic

wef f 2 | 78 | 95 “00

[#0030 a fo 175, joo” | 425 140

024. wi05 | 2 | 190-| 240 5 | [a0 | 10

[aes 020° | 195} 100 | 200

| 10 roo | 250 | 125_| 250

[ao woTa7_| 20 aro | 285

aoe 40141 | a 240 | 310

05, 046 |

Hon | go 20 | 260

40085, 4050,

ao | 495

eS is

4056, 40057

40158 250 50s,

as

&

~ oat

0073, 0172 | 705

07, «0178 | 1000 ‘on |

6. Installation Techniques

Make connections for SCOTCHLOK

‘compression lugs with the approved

Crimping tool and die sets as listed in

Table Il. When preparing cable, wire

brush conductor end and immediately

insert into lug end. Make sure end is

pushed tight against end of lug barrel

When crimping lugs, if more than one

crimp per end is required, make initial

Ccrimps closest to the pad of the lug

and subsequent crimps should

progress outward. If any flash or sharp

points exist on lugs atter crimping,

they should be removed or smoothed

out

IW the lugs are to be used on insulated

cable (above 600 V), all indents should

be filled and the lugs should be

“rounded out" with SCOTCH Brand 13

‘Semiconducting Tape.

7. Availability

SCOTCHLOK Aluminum

Compression Lugs are available in the

tollowing quantities and can be

‘ordered trom your electrical

distributor:

Complete product and use

Specifications are available through

the Electro-Products Division/3M.

TABLE V

Seotchiok Conductor

Lug Size Packaging

No. AWG or MM Carton

40016 6 50

40020 4 50

4024 2 25

0025 2 25

40028 1 10

40029 4 10

40032 10 10

40033 0 ‘0

aorg2 0 10

40037 210 10

40137 210 10

40084 30 10

404i 30 10

40045 410 10

40046 40 10

40145, 40 0

40049 250 10

40050 250 10

404g 250 10

10053, 300 10

40153 300 40

40056 350 10

40057 350 10

40156 350 10

40160 400 10

40067 500 10

ani88, 500 10

40170 600 6

40073 730 6

40172 750 6

40079 +1000 6

40178 4000 6

eMTOAL-AC1 #34 998

IMPORTANT NOTICE:

Al statements, technical information and

recommendations contained herein are

based on tests we believe o be reliable,

but ine accuracy or sampletoness thereot

‘snot guaranteed, and the following is

‘made in lou ofall warranties. express or

implied: Seller's and manufacturer's only

‘obiigation shall be to replace such quantity

Of the product proved to be defective.

Neither seller nor manufacturer shall be

liable for any injury, loss or damage, direct

fr consequential, arising out of the use of

(oF the inability tose the product. Betore

sing, user shall determine the suitability

(of the produc for his intended use, ana

User assumes all isk and labiliy

whatsoever in connection therewith. No

statement or recommendation not

‘contained herein shall have any force or

effect unless in an agreement signed by

officers of seller and manufacturer

Lito in USA wih 3M ofset pats, im and prooting syst

Electro-Products Division/3M.

225-4 3M Conter

SU Paul, MN'SS144

You might also like

- Instrucciones de ManejoDocument2 pagesInstrucciones de ManejoGustavo RiveraNo ratings yet

- Partes para Bombas Triplex Continental EmscoDocument4 pagesPartes para Bombas Triplex Continental EmscoGustavo RiveraNo ratings yet

- Triple Gardner Denver Pump Parts for PZ ModelsDocument2 pagesTriple Gardner Denver Pump Parts for PZ ModelsGustavo RiveraNo ratings yet

- 3M - ScotchDocument3 pages3M - ScotchGustavo RiveraNo ratings yet

- Iron Roughneck PW163 PDFDocument51 pagesIron Roughneck PW163 PDFGustavo RiveraNo ratings yet

- Pieter Eras Mus: R ErasmDocument1 pagePieter Eras Mus: R ErasmGustavo RiveraNo ratings yet

- EM000039Rev1 PDFDocument1 pageEM000039Rev1 PDFGustavo RiveraNo ratings yet

- Engineering Memorandum: ScopeDocument1 pageEngineering Memorandum: ScopeGustavo RiveraNo ratings yet

- BOMBAS DE LODO CapacidadDocument9 pagesBOMBAS DE LODO CapacidadGustavo RiveraNo ratings yet

- 91000015rev4 PDFDocument1 page91000015rev4 PDFGustavo RiveraNo ratings yet

- Tesco Torque Sheet TDS 250T PDFDocument10 pagesTesco Torque Sheet TDS 250T PDFharsha alapatiNo ratings yet

- Rev 12Document1 pageRev 12Gustavo RiveraNo ratings yet

- System Description - 880025 Rev 2Document18 pagesSystem Description - 880025 Rev 2Gustavo RiveraNo ratings yet

- Manual de Partes Unit 1168 HMI PDFDocument231 pagesManual de Partes Unit 1168 HMI PDFGustavo RiveraNo ratings yet

- System Description - 880025 Rev 2Document18 pagesSystem Description - 880025 Rev 2Gustavo RiveraNo ratings yet

- Installation Guide - 880026 Rev A PDFDocument56 pagesInstallation Guide - 880026 Rev A PDFGustavo RiveraNo ratings yet

- Garden Denver PDFDocument26 pagesGarden Denver PDFGustavo RiveraNo ratings yet

- 881006RevA PDFDocument1 page881006RevA PDFGustavo RiveraNo ratings yet

- Installation Guide - 880026 Rev 3Document62 pagesInstallation Guide - 880026 Rev 3Gustavo RiveraNo ratings yet

- System Description - 880025 Rev 2Document18 pagesSystem Description - 880025 Rev 2Gustavo RiveraNo ratings yet

- Operation Guide PDFDocument86 pagesOperation Guide PDFLuis Eduardo Albarracin RugelesNo ratings yet

- Battery SpecsDocument2 pagesBattery SpecsAbraham SaucedoNo ratings yet

- C BOP Parts List PDFDocument9 pagesC BOP Parts List PDFGustavo RiveraNo ratings yet

- Aceites Codigo JDE Parte Numero SHELL Parte Numero MOBIL UM: Mobilux EP-2Document2 pagesAceites Codigo JDE Parte Numero SHELL Parte Numero MOBIL UM: Mobilux EP-2Gustavo RiveraNo ratings yet

- Copia de Choke - Manifold.SparesDocument4 pagesCopia de Choke - Manifold.SparesGustavo RiveraNo ratings yet

- Brandt Agitators GeneralDocument4 pagesBrandt Agitators GeneralCESAR SEGURANo ratings yet

- GK-11 5M Parts ListDocument1 pageGK-11 5M Parts ListGustavo RiveraNo ratings yet

- EG-3P/EG-6P/EG-10P: Proportional ActuatorsDocument4 pagesEG-3P/EG-6P/EG-10P: Proportional ActuatorsGustavo RiveraNo ratings yet

- P2P Connections General KitDocument9 pagesP2P Connections General KitGustavo RiveraNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)