Professional Documents

Culture Documents

Nha Type

Nha Type

Uploaded by

chemical5090 ratings0% found this document useful (0 votes)

4 views6 pagesOriginal Title

NHA-TYPE

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views6 pagesNha Type

Nha Type

Uploaded by

chemical509Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

WATER [=D

Tuse [J

For HEAVY OIL or GAS BURNING “NHA

HIGH-PERFORMANCE BOILER

FOR HOSPITALS,

BUILDINGS ano INDUSTRIES

(FEATURES of tree NNHIA)

THIGH EFFICIENCY OF 86-88%.

Complete combustion can be achieved without heat loss by buming fuel in the spacious combustion chamber

covered with water-tube walls. Accordingly high boiler efficiency of 86-88% can be maintained

2WIDE COMBUSTION RANGE.

‘Adjustable range of boiler capacity by burner control is 20 to 120%. Within this range, complete combustion

‘and long continuous operation can be realized

SOUTER WALL TEMPERATURE OF BOILER EQUIVALENT TO ROOM TEMPERATURE.—————

Wholly double casing censtruction provides perfect heat insulation, making radiant heat of outer walls nil

@ MINIMUM NOISE. —

Forced-draft fan is so silent that it is virtually noiseless.

SEASY CLEANING OF THE INSIDE. AND OUTSIDE $$ Ra

Tube inside is completely cleaned by tube cleaner. Outer walls of tube bank are readily cleaned by 2 mechanical

‘soot blower even during operation, All water tubes can be perfectly removed of soot at the time of performance

test.

EASY HANDLING AND ABSOLUTELY SAFE OPERATION

Simple construction makes handling easy. Safety is insured by safety devices. Double safety devices each

different in type are used for burner cut-off at low water level.

LOW RUNNING AND MAINTENANCE COST, ——___—_—_—

Annual running and maintenance cost including power and boiler clearing expenses are far lower than those

required by other types.

‘SDURABILITY.— — 6

Simple construction, easy inspection end no parts subjected to corrosion and buming guarantee exceptionally long

durability.

‘SMINIMUM WEIGHT. ——-

Fin panel construction eliminates the needs for brick walls and make boiler weight lighter.

WSMALL FOUNDATION AREA — a

Both boiler and its accessaries are assembled on the minimum area with the height shorter than ever.

TIMEASURES TO BE TAKEN TO REDUCE NOx EMISSION, HHH

Multiplied effect obtained by the combination of Low NOx Burner with recuced load in a combustion chamber

can Keep NOx emission less than regulated figures.

UNIQUE ano EPOCH-

EN Tee Se Ue Tt]

ano COMBUSTION

HUG

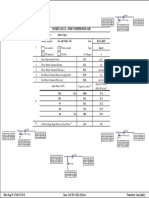

SPECIFICATION of Tyre INIHA

TPE Namen

Enuvalent Stam | Rating K/h

Evaporated Output | Normal ——_‘a/h

Healing Siface Nornal a

{Sioa quaint Bret Racivan

Fuel Consumption | Hamy Ol ig/h

Noxmat Goa nt

Main Steam valve er

Food Water Vavo om da

Bow-0M Vato wm da

Height Fear w Top of Baler

Dimon Four Center of um (AP

sions | wan (Over mee)

Longin (Gvera) mid

Net weight "9

Weigh wih Full Weer "9

1,200

2,882

1,950

1,684

4,008

6,40

7.040

200 | 2.500

240 | 3,000

200 | 2,600

ne) 2,100

wz.7 | 159.6

m2 | m4

% 100

5 a

ae | 268

nao | a0

178 1,08

4a are

7.130 770

seo | 9,510

300 | 3500

aieco | 4,200

3000 | 3.500

zsco | 2.900

ts | ans

aaa | 461.7

10 100

5 a

a a

ams | 318

230 | 2300

2.051 2.061

40 | 520

sien | 10,410

ie |:

3. Fuel consumption is calculated on a basis of caloric value par BOK eal/kg of Hoavy OF and 4, 500K

calfNi of Gas. both In lower evel

4.Eiter Hoavy Ol or Gat a Fue!

be used.

1 be l0ug/em® opto BOhg/em? tre obtainable on applica:

5.The maker reserves the right te alter, witout notice, dimensions, designs and componerts of the ent

CONSTRUCTION OF YOSHIMINE BOILER TYPE NHA.

Boilers installed 2s a heat source in the industrial mills or various including hospitals are generally

required to maintain 24-hour continuous operation without any trouble and also they must hold re~

‘sponsible for durability and safety enough to withstand buming damage caused by heat and corro-

ssion by water quality.

Yoshimine NHA type boiler can satisty not only these conditions but also pollution regulations per-

forming high efficiency by employing the following construction.

NHA type boiler has a simple construction which consists of convection zone of the vertically con-

nected tubes to spacious upper and lower drums and a combustion chamber coverd with shape

bent tubes installed at the side of this zon

Zigzag arrangement of the tubes is employed at convection zone to obtain best heat absorption |

ting gas pass in a single passage method. The tubes at convection zone can be easily inspected

by removing them temporarily for the wall separating convection zone from furnace is made of de~

mountable fire bricks inserted between water tubes.

‘The tubes forming a combustion chamber side walls are bent on such a large radius that tube

‘cleaners can easily pass through the tubes. Tubes outside cleaning can be conducted by scot

blower even during boiler operation and when stopping water washing can be also conducted.

{In addition to these merits this type of boiler as also a suitable construction for pressurized burning

for fin tubes are employed for the front.rear and side walls.around which double casings are instal-

led to prevent gas leakage.

That the associated equipment except feed water tank and water softening equipment are all shop

‘assembled makes boiler operation very easy.

Gas fuels such as LNG,LPG and City gas are all available for this type of boiler by selection of

each suitable burner.

Your good understanding and favourable response leading to order for Yoshimine packaged boiler

of this type taking full advantage of the merits of water tube boller should be highly appreciated.

a0 | soo | 700 | [1200 | 1600 | coo

ao | a0 | aan |

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lecture 5 - General 3D Stress, Elastic and Thermal StrainDocument13 pagesLecture 5 - General 3D Stress, Elastic and Thermal Strainchemical509No ratings yet

- Brochure - Duct BurnerDocument1 pageBrochure - Duct Burnerchemical509No ratings yet

- Coil HE-1Document13 pagesCoil HE-1chemical509No ratings yet

- Steam Liquid Ex With Steam Flow of 0.224 KgpersecDocument5 pagesSteam Liquid Ex With Steam Flow of 0.224 Kgpersecchemical509No ratings yet

- CAGI Air Compressor SimulationDocument1 pageCAGI Air Compressor Simulationchemical509No ratings yet

- Fired Heater Cause and Effects Table ChartDocument1 pageFired Heater Cause and Effects Table Chartchemical509No ratings yet

- Fired Heater CO Emission Study ReportDocument15 pagesFired Heater CO Emission Study Reportchemical509No ratings yet

- Fired Heater Safety ReviewDocument8 pagesFired Heater Safety Reviewchemical509No ratings yet

- US ExamplesDocument95 pagesUS Exampleschemical509No ratings yet

- Metric ExamplesDocument98 pagesMetric Exampleschemical509No ratings yet

- Egypt Gas: AL-SHOUHADA P&I Diagram Guideline For BiddersDocument1 pageEgypt Gas: AL-SHOUHADA P&I Diagram Guideline For Bidderschemical509No ratings yet

- Fired Heater Simulation Study ReportDocument6 pagesFired Heater Simulation Study Reportchemical509No ratings yet

- Above Ground Fuel Storage TanksDocument7 pagesAbove Ground Fuel Storage Tankschemical509No ratings yet

- Do Not Use This Area: Rectangular FinsDocument20 pagesDo Not Use This Area: Rectangular Finschemical509No ratings yet

- A A A D N L A: Company DateDocument6 pagesA A A D N L A: Company Datechemical509No ratings yet

- Max-Allowable-Pressure-of-Pipes-and-Pipellines-CER-04022013-1 (V. S. Kumar-Unprotected)Document74 pagesMax-Allowable-Pressure-of-Pipes-and-Pipellines-CER-04022013-1 (V. S. Kumar-Unprotected)chemical509No ratings yet