0% found this document useful (0 votes)

58 views4 pagesEnhancing Insulating Oil Test Methods

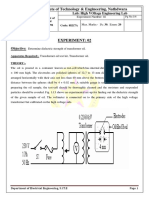

This document discusses improvements to the standard test method for measuring the breakdown voltage of insulating oils. It notes that current standard methods can result in high variability in test results, with coefficients of variation up to 30% or higher. This variability makes it difficult to accurately assess oil quality. The document suggests that using a larger oil volume and a coaxial cylinder electrode arrangement rather than flat electrodes could help reduce variability by minimizing the effect of localized contaminants on test outcomes. It also advocates modifying test procedures to incorporate more breakdown measurements per test to provide a more representative assessment of overall oil quality.

Uploaded by

Juan Manuel Ríos FrancoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

58 views4 pagesEnhancing Insulating Oil Test Methods

This document discusses improvements to the standard test method for measuring the breakdown voltage of insulating oils. It notes that current standard methods can result in high variability in test results, with coefficients of variation up to 30% or higher. This variability makes it difficult to accurately assess oil quality. The document suggests that using a larger oil volume and a coaxial cylinder electrode arrangement rather than flat electrodes could help reduce variability by minimizing the effect of localized contaminants on test outcomes. It also advocates modifying test procedures to incorporate more breakdown measurements per test to provide a more representative assessment of overall oil quality.

Uploaded by

Juan Manuel Ríos FrancoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd