Professional Documents

Culture Documents

DOC

Uploaded by

ravigurajapu0 ratings0% found this document useful (0 votes)

21 views21 pagesCSWIP

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCSWIP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views21 pagesDOC

Uploaded by

ravigurajapuCSWIP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 21

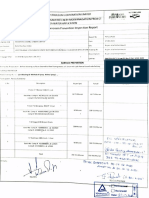

Ras Laffan Liquefied Natural Gas Company Limited (3)

RasGas Onshore Expansion Project Phase 2 (Train 6&7 BPC)

Revision Description (Form - 2)

‘the followang summarizes revisions co Document Number, RG5-S-00-1360-063,

Changes from fev. 1 to Rev. 2

r ~) PRC | PAA | SIR 1

fem | - a | 2 | ss Remarks |

| Para. | Added the word “Fabricated type", since this a jos |na |

3.7 (4) | paragraph is requirement for fabricated type 45deg | |

lateral branch fitings. |

‘Added the requirement for fll size branch. a joie | NA |

|

‘Attach | Updated as per latest design ja joie | NA

ment-t | |

| |

‘Attach | Updated as per latest design a joe | NA |

ment3

| |

‘Attach | Added the dimensions of pad for fully encircled type | a cig NA | |

| ments | and 4deg branch ype

Justification or Impact if not adopted:

Legend

“1: PRC (Primary Reason for Change) +2: PAA (Primary Affected Area)

a. Design development incl. correction P Process

of wording and typographical eror Ul. ——_Ulityrste

b. IndustryVendor standard including non conformance oP Offplot

©. SafetylOperabilty/Maintainabity CIG. —_Common/General

4. EnvonmentalMeath

S COMPANY’s spect request “3: STR ( Subject to Risk Assessment)

f Vaweongnestes YES : Risk Assessment is required.

9. Constructability

Schedule

i Others

Fos”

Date TST TBE |

TO WS: [pee Dori

r

TECHNICAL SPECIFICATION FOR WROUGHT STAINLESS STEEL FITTINGS

FOR CONSTRUCTION

a4 =

2__| Issue for Construction Kvew>| w, iyo waar | Ju-07-06

1_ | Issue for Construction Kuen | mNakamoto | /arai | May-20-06

0 __| Issue for Construction Kuen | MNakamoto | Mari | Jan.2%-

E__| Issue for Approval KUeno | mNakamoto | ¥-Yoda | Sep.02-05

MARK DESCRIPTION BY CHKD | APVD | DATE

REVISIONS

CLIENT Ras Laffan Liquefied Natural Gas Company Limited (3)

PROJECT : RasGas Onshore Expansion Project Phase 2 (Train 6&7 EPC)

JOB NO.

DOCNO._:_RG6-S-00-1360-063

TECHNICAL SPECIFICATION FOR

WROUGHT STAINLESS STEEL

FITTINGS. Page 2 of 5

1360-063

1.0

2.0

3.0

4.0

5.0

6.0

CONTENTS

Scope...

Applicable Codes, Standards and Specifications.......

General Requirements

Tests and Inspections ..

Material Certification / Marking

Others

Attachment-1_ > Design Conditions for Fittings Larger than 48”

Attachment-2: Dimensional Drawing for Fittings Larger than 48” (Elbow, Tees & Reducers)

Attachment-3 : Design Conditions for Reducers up to 48"(Not Covered by ASME B16.9)

Attachment-4 : Dimensional Drawing for Reducers up to 48” (Not Covered by ASME B16.9)

Attachment-5 : Dimensional Drawing for PAD

Page

TECHNICAL SPECIFICATION FOR RG6-S-00-1360-063

WROUGHT STAINLESS STEEL

FITTINGS. Page 3 of 5

2.0

3.0

34

‘SCOPE

This specification applies to the manufacturing of Wrought Stainless Stee! Fittings to be used for

RasGas Onshore Expansion Project Phase 2 (Train 687 EPC).

Fittings shall be supplied in accordance with the material description in ER(Engineering

Requisition). The latest applicable codes, standards and specifications listed in Para. 2.0 and the

additional requirements of this specification shall also be applied

APPLICABLE CODES, STANDARDS AND SPECIFICATIONS

The latest edition as of Sep.-2005 of the codes and standards shall be applied.

(1) ASME

B169 Factory-Made Wrought Stee! Butt welding Fittings

816.25 Butt welding Ends

831.3 Process Piping (Including Addenda)

@) ASTM Fes”

‘A403, detail per Engineering Requisition (Purchase Order)

(3) Project Specification

RG6-S-00-1360-006 - _ Piping - Color Coding for Material Identification

RG6-S-00-1520-005 - —_ Pressure Containing Equipment - Welding and Weld

Inspection

RG6-S-00-1520-007 - _ Positive Materials Identification

RG6-S-00-1520-009 - —_ Certification and Marking of Materials,

Dimensional Dwg for Fittings Larger than 48" (Elbow, Tees

& Reducers)

RG6-SD-00-1360-100

GENERAL REQUIREMENTS

Dimensions

(1) Dimensions shall conform to ASME B16.9. End to End dimensions not covered by ASME

B16.9 (larger than 48°) shall be in accordance with Attachment-2 of this specification.

(2) End to End dimensions of Reducers not covered by ASME B16.9 (up to 48°) shall be in

accordance with Attachment-4 of this specification

(3) When “WIREINF (PAD TH'K=*** MM)’ is described in the material description, the reinforcing

ad dimension shall be in accordance with Attachment-5 of this specification and the pad

thickness shall be in accordance with “PAD TH'K=*** MM" in the material description.

(4) When “RUN ID=****.*MM" is described in the material description, the internal diameter of fitting

(in case of tee or lateral, run pipe ID) shalll be fixed in accordance with “RUN ID=**** "MIM" in

TECHNICAL SPECIFICATION FOR RG6-S-00-1360-063

WROUGHT STAINLESS STEEL

FITTINGS Page 4 of 5

3.2

33

34

35

36

37

the material description,

Tolerance

Tolerance shall be in accordance with ASME B16.9, except the tolerance of wall thickness for 8”

and larger diameter shall not be more than 0.3mm under the nominal thickness. Wall thickness of

these ( 8 and larger) shall be measured in accordance Section 4.-(3) of this specification.

End Preparation

Bevel ends as per ASME B16,25 Fig. 2(a) or Fig. 3(a). Hos

Material Requirements

Impact test requirements shall be in accordance with each applicable ASTM standard and section

323 of ASME B31.3.

For welded fittings (A403-WP304LWX) with longitudinal seam, the acceptance criteria of production

weld impact tests shall be minimum lateral expansion of 15 mils (0.38mm) at -196°C on the weld

deposit. Absorbed energy shall also be reported for information purpose. The sampling frequency

of impact test specimens shall be at least one per each heat/ot of finished products unless

otherwise specified by CONTRACTOR.

Positive Materials Identifications

Positive materials identifications shall be performed in accordance with RG6-S-00-1520-007

"Positive Materials Identification’,

Ferrite Content

Filler metals for austenitic stainless steel welds shall be selected to produce weld deposits that fall

within the ferrite ranges and numbers given in the Spec. RG8-S-00-1520-005 para. 5.3.1 and 5.3.2

Design of Fittings

(1) For fitings up to 48° (not covered by ASME B16.9), Vendor shall supply these fitings which

supported by strength calculation or proof testing per Section 2.2 of ASME B16.9. Strength

calculation shall be performed in accordance with the design conditions in Attachment-3, and

submitted for purchaser's review.

(2) For fitings larger than 48° (not covered by ASME B16.9), Vendor shall supply these fitings

which supported by strength calculation or proof testing per Section 2.2 of ASME B16.

‘Strength calculation shall be performed in accordance with the design conditions in Attachment-

1, and submitted for purchaser's review.

(3) Fabricated type tee for full size branch shall be made with reinforcement pad. The

reinforcement pad for full size branch shall be full encirclement type and the minimum wall

thickness shalll be the nominal pipe thickness specified in material description if no required on

branch calculation by manufacturer.

AY -45deq lateral branch fitings shall be made with reinforcement pad. fH

When “WFULL

ENCIRCLED-TP PAD" is described in material description, the reinforcement pad shall be full

38

40

5.0

6.0

TECHNICAL SPECIFICATION FOR RG6-S-00-1360-063,

WROUGHT STAINLESS STEEL

FITTINGS

Page 5 of 5

encirclement type. The minimum wall thickness of pad shall be the nominal pipe thickness

‘specified in material description if no required on branch calculation by manufacturer.

Welding Requirements

(1) FCAW (Flux Cored Arc Welding) process shall not be used for austenitic steel fittings.

(2) Vendor shail submit a welding seam position of all welded fitings at bidding stage for

Purchaser's review.

(3) Welding and weld inspection shall be performed in accordance with RGS-S-00-1520-005

“Pressure Containing Equipment — Welding and Weld Inspection’.

TESTS AND INSPECTIONS

Manufacturer shall conduct tests and / or inspections in accordance with the most recent revision of

the relevant codes and standards listed in Para, 2.0 and the additional requirements of this,

Specification together with the following:

(1) Manufacturer shall perform tests and / or inspections under Manufacturer's own quality

control and shall provide sound quality products.

(2) Manufacturer has the responsibilty of providing CONTRACTOR's inspector with all specified

information, and the inspector shall have free access to witness or audit Manufacturer's

quality control at Manufacturer's facilities throughout the time while work on the products is

being executed, as deemed necessary,

(3) _ For fitings larger than 6”, wall thickness shall be measured to verify that the tolerance shall

‘ot be more than 0.3mm under the nominal wall thickness,

MATERIAL CERTIFICATION / MARKING tos

(1) Certificate

Type "6" certificate shall be required in accordance with Spec. RG6-S-00-1520-009

“Certification and Marking of Materials".

(2) Color Coding

Each fitting shall be color coded in accordance with Spec. "RG8-S-00-1360-006"

OTHERS

(1) This specification has priority over the others specified in the applicable documents,

(2) Manufacturer shall submit manufacturing, test, inspection, and welding procedures for

CONTRACTOR’ approval prior to manufacturing,

(3) __Allconficts between the requirements of this specification, related specifications, standards,

codes and CONTRACTOR's requisition shall be referred to CONTRACTOR in writing for

Clarification before proceeding with manufacturer.

ROS

=

VSAYITBYVAN7 WHINE ENGAGE VEGAS

F

aRsaygagaaant:

aAyaaIT]

Bay

(paras

a

0-081 804 =W D3

“TEV NVA W398V T SORITIG WOT SNOLLIONOS WOO

MD st ret rt rote TB

MP9 mo foment eT

| of

ToT

Gistatete |)

P29 9 ON PUT ae

(ee) e-INSWHOVILY

€90-08E1-00-S-85H "ON “90

ae ee)

S2230285

)

LI

a

150 oF

Ben-o8i-090-g04 |9X OU

(Gi) S-INSWHOVLLY

£90-09€1-00-S-954 ON 000

SET TTI Oa WTS

{

4

sso

LBTWN NE-3BY SNOSNIMG

9X9 3

04-0861-00-0-808

zea [oeize|oe'zc[o-|e2[25|+2|20[c0]ex| 26 [rele os|as|as|+»[zs|o» cl oe|>cleclorlee|se(veleclocte at tat

L aba tatgede tent.)

AP PET"O MOTemN Pub eI

Lele] > |e] [rove

RES

tar ane

77

zy

(g72) S-INSWHOWLLV.

€90-09E1-00-S-95Y ON 900

e

secon OXDY

Wetsereet mien eB

PTO MO oN Pi Ce

vzlezlozlafas|n|afor

awe

Tas ronves |

alo

‘S¥BLINTIN NI BAY SNOISNaNO

ES [oa TT

loziza}os Tze oe

Wa RTD

an L

SATIN 3a sHORSHWE

+z ———i_—_

‘SURINTIA Ni Guy ENO

eeetin rent RPB

APIO MON gr HT

TOF TSHITINGA Giaavs BALy

35389 Hu

(8/5) S-INSWHOV.

Lo

ia Foo {ce o3|2zlouLn0 oo valzafoolas] al e[zs|oslav gvleelevlovleclacleslasiert

| atatatiadeteae.]

MOPeT=O MO Ra UE HT

T awe

’ ape

Tad ROWE

(878) S-INSWHOWLLY

£90-09€1-00°S-99u ON 000

8/2) S-INSWHOVLLV:

FOSEL-00-S-30U ON i

re)

Te) SINSWHOVILV

ES-09E1-00-S-95e ‘ON OT

eja}e]s| |e] 2 [rom

aa

erro

——1——F+

V

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Bishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004Document1 pageBishweshwar Lal Steels: Hot Rolled Steel Strip For Welded Tubes and Pipes As Per Is: 10748 - 2004ravigurajapuNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Adobe Scan 30-May-2021Document2 pagesAdobe Scan 30-May-2021ravigurajapuNo ratings yet

- Production ScheduleDocument7 pagesProduction ScheduleravigurajapuNo ratings yet

- Indian Standard: Recommendations For General Pipeline WeldingDocument48 pagesIndian Standard: Recommendations For General Pipeline WeldingravigurajapuNo ratings yet

- DOC000Document34 pagesDOC000ravigurajapuNo ratings yet

- Pipe DataDocument3 pagesPipe DataravigurajapuNo ratings yet

- Reaffirmed 1998Document14 pagesReaffirmed 1998ravigurajapuNo ratings yet

- Piping Engineering4Document18 pagesPiping Engineering4ravigurajapuNo ratings yet

- voter InformationDocument1 pagevoter InformationravigurajapuNo ratings yet

- Visakha Institute of Welding & NDTDocument3 pagesVisakha Institute of Welding & NDTravigurajapuNo ratings yet

- Doc013 PDFDocument1 pageDoc013 PDFravigurajapuNo ratings yet

- Course Details: 4 Weeks (Excluding Sundays)Document1 pageCourse Details: 4 Weeks (Excluding Sundays)ravigurajapuNo ratings yet

- Integral Ei/Gineering: I: 1E I 19AABCV0225G1ZM Date: 27t12t2017Document2 pagesIntegral Ei/Gineering: I: 1E I 19AABCV0225G1ZM Date: 27t12t2017ravigurajapuNo ratings yet

- Future AssignmentDocument1 pageFuture AssignmentravigurajapuNo ratings yet