Professional Documents

Culture Documents

B Axis

Uploaded by

Arvinder Singh0 ratings0% found this document useful (0 votes)

15 views17 pagesB axis control

Original Title

B axis

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentB axis control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views17 pagesB Axis

Uploaded by

Arvinder SinghB axis control

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

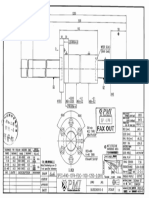

BND-S PRO 0-TC 90/8

B axis operation command code

a

| Command code | Outline

; 400 Positioning (rapid feed)

| con | Vinear interpolation (cutting feed)

| coe | vet

; 628 ae point return

| ci! Spot dritting cycle |

| 82 | Counter boring cycle |

! T type |

He cos Deep Drilling cycle only i

684. | Tapping cycle |

j | Borang epee |

| | Boring cycle |

Feed per minute

| eed per revolution

| Tool position offset

(ote 1) Instruct @ block of "GIOI" "6102" "C103" "G100" only be independent

block.

(ote 2) When operation is registered in the data memory, operation command

instructed before is canceled and new operation instruction is regis~

tered. In addition, when there is an alar@ in the operative instruc-

tion desired to be registered, the data memory is initialized and a

condition where there is no registration appears,

~153—

[2] Operation start command

Execution start of operation command of B axis registered in the

previous paragraph is commanded. When start command is nade, commanded

operation is executed independently from normal NC operation (X, Z

axis).

Execution is made by auxiliary function (M140)

041234 +

Mi40: ~ - B axis operation start command

. * By M140 command, B axis operation program and X and

H Z axis in next block of M140 are concurrently

i executed.

M30 + * M140 (M141 or M142)

= 16—

BND-S PRO 0-7C 90/8

BND-S PRO 0-7¢ 90/8

9-3 Detail of Operation Instruction

‘The contents of G code, M code, and T code becomes as follows so that they

can be used between "G101"("G102" or "G103") ~ "6100".

1. GOO .........4.4. Positioning (rapid feed)

G00 899.9

Movement is made from current position to the position commanded by B

or by transfer amount with rapid feed.

In case of mm input : -9999,999nm ~\ 49999..999nm

In case of INCH input : -999.9999inch *v +999.9999inch

2, GOL sssessssesees Linear interporation (cutting feed)

Feed per minute (G98) 0 to 393.33 in/min

Se (1 te 10000 mn/nin)

Feed per revolution (G99) .000001 to 9.999999

in/rev (0.0001 to 50,0900 mm/rev)

Movement is made from current position to the position or by transfer

amount commanded by B with commanded speed.

3. GO4 seeeeeeeeeeee Dwell

G04_U9999.999 (P9999)

Transfer to nest block is delayed by time conmanded by U or P.

(For U, decimal input'is possible end for P, minimum setting unit is

input)

4, 628 . ++ Reference point retura

28 ;

Automatic return to the reference point is made.

Since there is no processing of intermediate point as normal G28, pay

attention.

The following instruction can not be made.

628 B___; (Example of no instruction)

Drilling fixed cycle (Refer to the separate sheet for

5. 680 ~ G86 ..

detail.) (Mainly used for T type)

Gs B9999 R9999 99999 P9999 F9999

Among drilling fixed cycle which can be performed by FANUC OM-MODEL B,

cycle operations corresponding G80 G86 can be made.

Instruction methods of each data are the same as OM-MODEL B except for

the following.

= ALL operates initial level return mode.

+ Number of repetition (K) cannot be designated.

+ Since decimal point input of address cannot be made, instruction is

made by the minimum setting unit.

(0.001 mm during millimeter input and 0.0001 inch during inch input.)

« During fixed cycle mode, reference point return is always necessary.

(When there is no setting, an alarm of P/S 505 occurs.)

Setting (4) of cutting start point at G83 (deep drilling cycle) is set

at Wo. 9005, of parameter,

G98 ..seseseeeees Feed per minute

G99 s.eeeseeseees Food per revolution

In this device model initial value of start of operation instruction

registration during (Gi01, G102, 6103) ané G110 is set at G99 (feed per

revolution).

In the case of C99 (feed per revolution) mode, feed speed E is obtained

by calculating from actual spindle rotation speed at the time of start

of each cutting feed block.

Pay attention since during movement of cutting feed block feed speed

does not change by changing spindle rotation speed.

(Note)

‘Spindle rotation speed cannot be changed between G10] (6102s

6103) to 6100.

Exenple

G110 GOL B....FO.2 ; sseseeeee-002 am/rev

Since a model initial value is G99, operation ia made by feed per

revolution.

6110 G98 GO1_B....F200 ...,.. 200 mm/MIN

Since a model initial value is G99, G98 must be always designaved

after G110 (G101, 6102, 6103) when G98 (Feed per minute) is used.

‘The relationship of feed per revolution and feed per minute is as

follows

Inch Feed per minute (inch/MIN)= Spindle rotation speed (RPM) x feed per

revolution (inch/rev).

Metric Feed per minute (mm/MIN)= Spindle rotation speed (RPM) x feed per

revolution (mi/rev).

7, T Code

Refer to tool position offset of the following paragraph.

8. Auxiliary Function (M Function)

* For $ type, the following M codes can be used between "G1OI" (6102,

6103) ~ "C100".

N03 -- Spindle Forward (Counter-clockvise) _¥176 -- Sub sir blow No.4 oN (For sub

Hoe == Spindle Reverse (Clockeise) Spindie) (ope sonal>

15. =. Spinaie Stop W277 «= Sup'ais Siw Noss OM (Optional)

Taz 7: bar seeding 179 22 Sab eis blow stop (Opeional)

Ta? 7- Hain chuck open Yao => Waieing commend

Tae 77 Hain chuck Close Tist -- Sub encoder of

IG <2 Migh Peesture Cootans ow coptionat) 208 “7 Main and sub spingle forward

M25 2- migh treorsure coolant OFF COpetona?) Shacheonous ‘raeaeion

ISS 22 babe catcher Focwscd (Opeions!) aos -- Hale and sub spindie coverse

Hoe <> Pare catcher Backeara (Opetona!) Synchronous cobstion

fms © cee Gu raedee gece” oretaaaly vans -- HE ad ei epindie sycheonooe

aa 77 Block Delete OFF Reset. (Gpesonal) 0

Milos ~~ Subspinile Forward Rotation gos -- Syathronous operation release

HES: -- Subepincle Reverse Rotation

Mies =- Subepinaie atop

Hay 22 Subepincie chuck, open

Mii8 => Subspindle chuck, close

es

‘BND-8 PRO 0-TC 90/8

BND-S PRO 0-70 90/8

9, Symchrnous Operation (Waiting Command) M190

Normally, although fundamental NC program and operation of B axis are

quite independent, by combining auxiliary function for B axis control

and auxiliary function with fundamental NC program, synchronization

can be obtained.

(Fundamental NC operation) (B exis operation)

@ Mido: Q 600 B-50.0

GOL X20.0 FO.1 5 G01 B-60.0 FO.15 ;

00 250.0 ; 00 850.0 5

M190 5; M190 5

G00 X10.0 ; G00 B-59.0

When command of fundamental "M190" with ladder of PMC and "M190" with B

axis operation is received, both FIN signals are output.

of fundamental NC operation and @ of B axis operation are started at

the same time,

(ote)

In B axis operation program, M code and T code cannot be commanded

in the same block,

9-4 Offset (Mainly used for T type)

1, Instruction Code

With automatic operation mode, they sre effective between "G1O1 (6102,

6103) "G10".

However, instruct as an independent block.

By instruction of

170 «179 5

‘a termination position of movement instruction of B-axis can be shifted

by @ value set is the AUX screen to "+" or "=" side.

By utilizing this function, compensation can be made without changing

‘the program by setting shift between a value of tool position assumed

when programming is made and a tool position of tool which is used for

actual working.

2. Command of offset amount

B axis moves by offset amount set in offset number by T code command.

In addition, this auxiliary function number is displayed on "AUX

screen" and setting of offset amount is made here.

A range of value which can be set as offset amount is as follows +

mm input | inch input

T

|

Offset anount | 10#9999,999 | 02999.9999

(Unit is minimum setting unit.)

~167—

In this device, the offset amount can be set by separating into "WEAR" and

"GEOMETRY".

In addition, the offset amount moves by the total of both "WEAR" and

"GEOMETRY" to be set. Incidentally, since the offset input of this function

in only absolute input both for "WEAR" and "GEOMETRY"

Cancel of tool position offset

170 : Tool position offset cancel number

171 to 179 : Tool position offset number (9 kinds)

Movement of offset amount

For this machine, in the block of T code, offset amount is added to

axis movenent amount in next axis movement block only by output of

MF and M codes.

=168-

BND-S PRO 0-70 90/8

BND-S PRO 0-TC 90/8

5. AUX screen

OFFSET (8-AXTS)

No. (WEAR) |

7 0.000 |

Fr 0.000 |

Cursor/ 73 0.000 |

% 0.000 |

5 0.000 |

76 0.000 0.000 i

i 7 0.000 0,000 |

78 0,000 0.000

i 79 0.000 0.000

i

CE OMe |

|

i

Example) B axis shall start from the original point and returns to the

original point after completion of machining.

B axis original point “7

Ne B axis program original point

(temporary)

Et)

A value of "a" is input to the tool number and corresponding

offset (shape).

"In above figure of exanple a "cursor" is moved to the shape of

‘TN_by_pressing [g] [a] (cursor).

+ TanboEy ie Tact

# A value of a is the distance from B axis original point to B

axis program original point.

Above program of operation: Explanation of operation:

101 (1) TTL is read but B axis does not move.

() THs (2) Moved to the position of T71 + 1.0 by

(2) G00 81.0 ; rapid feed.

(3) G01 B ~20.0 F__; (T/L + 1,0'= ~100.0 + 1.0 =-99.0)

(4) 170 5 (3) Moved to the position of 171 -20.0 by

(5) G00 BO ; (OR, 6283) F feed.

G100 ; (171 ~ 20.0 = -100.0 -20.0 = -120.0)

(4) 170 offset cancel.

(5) Returns to the original point by rapid

feed,

('BO" under the offset cancel condition

is the original point.)

169

Normally, the following subturrets and used:

Subturret No.1

No.2

No.3

TI

12

173

Subturret,

-170-

No.4

No.5

No.6

174

17

176

BND-S PRO 0-T¢ 90/8

BND-S PRO 0-70 90/8

95

Independent Movenent and JOG Operation of B axis

1, Independent movement of B axis

A) By registerating movenent command in the data menory and commanding

operation start, independent movenent of B axis can be performed.

| Normal program

N10 G1O1 ; (Or 6102, 6103)

N11 GOO B-50.0 ;

N12 G81 B-100,0'R-60.0 FO.2

N13. M190

N14 G100

N15 M140 ; (M141 or M142)

N16 M190 ;

1

'

| Normal program

t

As shown in above-mentioned program, by utilizing M190 (Waiting

command), independent operation of B axis 1s possible.

(1) NC operation is executed to N9 along program.

(2) N10 to N14 are registered in the data memory but not

executed.

(3) Operation command of B axis operation registered in

the data memory is performed by N15, M140 conmand.

(4) Although main side becomes stop condition by N16 M190

conmand, at subside, after operation of B axis has

been completed, main side proceeds to next block by

N13 M190 command.

(5) Subsequently, NC is executed along program of

fundaental control axis (X, Z axis).

Explanation :

B) Different from the method where operation of B-axis is started by

registering before mentioned No.1 ~ No.3 program (GI01 ~ G103), the

operation of one motion can be instructed and executed,

GUO ......444 3 (Operation instruction)

By instructing GI10 block, the operation of one motion of B-axis can be

instructed and executed,

G110 GOB... F .., 3 Independent movement of B-axis block.

-n=

Caution)

1, The operation instructed by G110 must be the operation of one motion.

CLIO COO B

C110 G28 +

sleseruceion possible

Although the operation by G110 is one motion, by instructing

continuously C110 as mentioned above, continuous operation is

possible,

by 6110 can not be made.

2. Under MDT mode, instruction of B-ax:

3, Operation instruction of plural motions such as instructions of fixed

cycle with C110 (681 ~ 686) cannot be made.

(P/S alarm 506 occurs.)

C110 G81 B__ F__ + An alerm 506 occurs.

4. When GII0 is used, tool offset cannot be used.

5. During the tool nose radius compensation mode, two or more G110 blocks

can not be commanded continuously.

2, JOG-operation and reference point return of B axis

JOG operation and manual reference point return can be performed in the

same manner as fundamental control axis (X, 2 axis). Movement by manual

pulse generator (handle) is also possible

BND-S2 PRO 0-7¢ 92/7

9-6 Data Memory

The data memory in which operation command is registered counts movenent,

dwell, auxiliary function, ete. as one block and has menory of total of

200 blocks. Even in case of drilling fixed cycle of G81, etc.,

registration is made by dividing into movement, dvell, etc.

In addition, since all data memory are backed up by battery, operation

command is not cleared when power source of the system is made OFF,

Example

Gio1 ;

G00 B-10,0 ; —————_______—. One block

G04 P1500 ; ———____________________. One block

(81 B-50.0 R-30.0 FO.15 ; ———--—————-—— Three blocks

Goo ag; ———_"______________ one block

6100 ;

Total six blocks

-173-

oT

Alara

Since a check method of each conmand data is the sane as normal NC

program, normal P/S alarm such as excess of digit number, address which

cannot be used, ete. is output. Here, an alarm peculiar to this machine

is explained... An alarm with this function is output as P/S alarm fron

500 to 599.

Mar with B axis control function

Aare Explanation

Nunber

2/8501 | Registration start command (G101, G102, 6103) is not made and

end command (G100) was commanded.

7/5502 | During registration comand, registration start command (6101,

C102, G103) was conmanded again.

7/8503 | During execution of B axis operation, new operation command was

tried to be registered.

P/S505 | During fixed cycle mode, there is no setting of address R,

[77ss06 | wunber of registerated Block exceeded 200 blocks. i

| pyssor | For cutting feed, feed speed is not commanded. |

p/8508 | For G83 (Deep drilling cycle), there is no designation of

cutting amount (Q). Or, 0 is designated.

P/SS81 | More than 6 of operation start command M codes are

connanded .

P/S582 | Wot registered program was tried to start.

During synchronous control, command was tried to make

for Braxis.

During operation of Beaxis, synchronous control was

tried ‘to make.

1

BND-S PRA Ame anro

BND-S PRO 0-7¢ 90/8

9-8 Caution and Others

1, Addresses vhich are usable for operation command are nine kinds of G,

B,R, Q, P, F, M, Tand U, In addition, for address G, command of G

code'of ten kinds other than GOO is possible.

When other addresses (X, Z, .....) and G code are comanded, an error

does not occur and they are negiected.

2, At the time of registration start of operation command (6101), modal

data is as follows 3

G function ...... G00 (Positioning)

G80 (Fixed cycle cancel)

699 (Feed per revolution)

Fe P OQ cecccceeeeeeeeee O

3. Single block can be used for B axis too,

a. Display of "cycle start lamp" of B axis is only turned on during its

operation and turned off after completion of operation. (B axis, etc.

operate.)

b. Display of “cycle start lamp" when both main (X, Z axes) and B axis

operate is turned on when either axis operates and only turned off

when all axes stop.

¢. Single block cannot be released during operration of B axis.

When single block is used and single block is released (OFF) during

operation of B axis, B axis stops at the position after completing

the operating program.

Since B axis stops at the position of completed block and only X axis

and Z axis implenent continuously when this action is taken when B

axis operates together with I+ and Z-axes, there is a possibility of

interference.

Never make "single block’

" OFF during operation of B axis.

4, Pay attention since the following operation can not be performed by

this function, (Only Baxis)

a. MDI operation

Incidentally, above-mentioned matter applies only the B-axis, and it is

possible for’ the fundamental axis (X-, Z-axis)

5, The following item are slightly different from the fundamental axis (X-

| Z-axis) which can be operated by this function.

a. Feed per revolution

Feed per revolution of this function differs from fundamental axes

(&, Z-axis) feed speed F is obtained by calculating from spindle

rotation at the time of start of each cutting block.

For this reason, if spindle rotation speed is changed during

movement of cutting feed block, feed speed of the block does not

change.

When spindle rotation is changed or a spindle is started from zero

speed.

Sometime require for the timer (G04) before operation instruction of

Beaxis is made.

Example) When the spindle is started from spindle speed zero.

97 $1000 M3;

G101 5 Since spindle rotation is zero when

600 BL; operation instruction of B-axis is

registered, proper feed speed is not given.

01 B__

100 ;

u

G97 $1000 M3 ; ]

Gio;

coe 00.5 ; Feed speed of B-axis moves at @ proper

G00 B__ f value.

Gor Bo

ido + J

Refer to "ACTF" of the program check screen of B-axis for properness

of feed speed F of Beaxis.

=116—

BND-S PRO 0-TC 90/8

BND-8 PRO 0-76 90/8

10. STANDARD PROGRAM STYLE FOR BND-20S, BND-34S

10-1. Programming of Bar Work

In case of M12 (Bar Push out)

0

NOOI G20 (621)

woo2 GSO S

NOS TOO00;

NOo4 coo xo Z___ TODO ~ Bar stopper

yOOS M12. Bar feed operation

xo06 ay

Nool Tee00 M91; <— Nain encoder ON

Noo2 S__ M03; <-~-- Main spindle nornel rotation start

Nee3 GOO XI Z__' Tesos MB; =--~ Coolant ON

NaoL ~--Nain encoder

Nao2 <-Nain end sub spindle normal

N03 rotation start

Raga i

aos |B axis operation conmand

NAO6 G100 ; a

Nao7 B axis operation start command] Independent

Nas Waiting connand operation

Na09 Sub spindle chuck close command of B axis

xa10 one ee ~ Cutting off

Natt ~ Cut off tool retract

Nal2

Nol a i

NOls 190 |B oxis rearward

Na15 Gi00 ; = 5

Nal6_ Mid ; ~~~ B axis operation start connand] Independent

Nal? M190 ; =-—-Waiting command ‘operation

conmand of B axis

Nvvol ——-T¥V00

Nvv02 Goo X__Z_

Nis X_Mo9

NvvI6 GloL 7 —=--5

NVV17 GOO BO; /B axis zero point return

NYVI8 190°;

NVVI9 G100 ; =

~Subspindle side operation

= Coolant OFF

NVVZ0 M140 ;<-B axis operation start command) Independent. operation

NVV2I M190; +-Waiting command ‘command of B axis

NVv22 M205 ; =--—- Main and’ subspindle stop

NVV2Z3 MBO; End of program

-7-

10-2, Programming without Nose R-comp

|

} See 10-1, Programing of Bar ork

NOIS GOO x.

NOL6

NAOL

N402 G97

When constant cutting speed control

is not used

See 10-1 Programming of Bar Work

~178—

BND-§ PRO 0-7C 90/8

BND-S PRO 0-10 90/8

10-3. Programming with Nose R-Conp

See 10-1. Programming of Bar Work

N06 G41 or G42 GOO X__ z__Ta000;

8007 COL ee gee pee

NOL? G40" Goo

Nols

i See 10-1, Programming of Bar Work

an

You might also like

- R40 10T4 Fdic 1100 1250 0.018Document1 pageR40 10T4 Fdic 1100 1250 0.018Arvinder SinghNo ratings yet

- Batliboi Ballscrew DrawingDocument2 pagesBatliboi Ballscrew DrawingArvinder SinghNo ratings yet

- "AR" Series Variable Displacement Piston PumpsDocument10 pages"AR" Series Variable Displacement Piston PumpsArvinder SinghNo ratings yet

- Abb Cam Switch PDFDocument22 pagesAbb Cam Switch PDFArvinder SinghNo ratings yet

- Position Sensors / Valve Positioners / Control BackupsDocument1 pagePosition Sensors / Valve Positioners / Control BackupsArvinder SinghNo ratings yet

- GSM I/O - Relay Board: User ManualDocument13 pagesGSM I/O - Relay Board: User ManualArvinder SinghNo ratings yet

- Mesa Motion ControllerDocument2 pagesMesa Motion ControllerArvinder SinghNo ratings yet

- Keb DrivesDocument24 pagesKeb DrivesArvinder SinghNo ratings yet

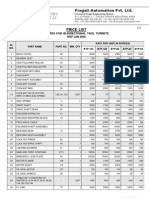

- Price List: Spares For Bi-Directional Tool Turrets WEF JAN 2006Document2 pagesPrice List: Spares For Bi-Directional Tool Turrets WEF JAN 2006Arvinder SinghNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)