Professional Documents

Culture Documents

11-23-18, 4:10 PM Office Lens PDF

11-23-18, 4:10 PM Office Lens PDF

Uploaded by

Ana Gabriela Zelaya Guzman0 ratings0% found this document useful (0 votes)

14 views10 pagesOriginal Title

11-23-18, 4:10 PM Office Lens.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views10 pages11-23-18, 4:10 PM Office Lens PDF

11-23-18, 4:10 PM Office Lens PDF

Uploaded by

Ana Gabriela Zelaya GuzmanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

Pre-inst

‘omic Absorbtion Spectrophotometer

AAS00F/AA500G/AA500FG

At

aD OOOROHOPPOPMOOMDONOAOOPPPINNOHEOHEHEEESEEES

oa) Cb Ty TS HEE] CGR) YE i el ert omy —f = |

ec Requirements

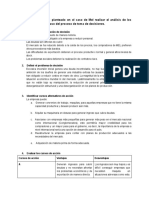

Pre-Installation Requirements

Laboratory environment con:

The instal

ne Sa eavitonment should be carefully selected. The location should from be away

lear to.

situated retest field, strong radiation or strong light. The laboratory should not be

luipment or a workshop that generates strong vibrations. It should also be

Kept away from direct sunshine dust

a smoke, dust, dity air current and vapor. The AAS laboratory

inoue B® Separated tom any chemical teatnent oon soe nat against acid erosion or

= rence. The intemal environment of the laboratory should be kept clean with an

Poropriate temperature (15-30°C) and humidity (below 70% relative humidity).

ions

Equipment requirements for the laboratory

The laboratory bench should be large enough to instal the AASOO instrument, graphite power

GipPly. accessories etc, at a recommended height of 0.75 meters; it should be’stable and solid

with a flat surface.

Around the bench, a sj

0 pace at least half a meter should be left to facilitate the operation and

maintenance.

The bench and instrument should be positioned out of direct sunlight, close to electricity and

gas connections.

Size and Weights of Instruments and Accessorie:

AASOOFIGIGF 100mm 535mm 540mm 430Kg

erase 700mm 535mm 840mm 100Kg

Air Compressor 310mm 310mm 550mm 18kg

Water Re-

Circulating Sump | 250mm 245mm 700mm 45Kg

Universal Auto

Aa 420mm 380mm 460mm 43kg

Efficient fume extraction should be installed in the laboratory to remove any fumes generated by

the instrument.

Note: Without adequate extraction, potentially toxic vapor could build up in the

2

Pinscuments

_——— << Te.

Pre-Installation Requirements

laboratory. Always use an efficient fume extraction system when operating the

instrument.

Installation of ventilation equipment

Laboratory Power Distribution Requirements

The instrument and its accessories use a 220Vac (+/-10%) power supply with standard mains

plugs, so a standard switchboard arrangement can be used.

‘The main unit is rated at 5A and should be free from noise. If the ‘supply is outside the

requirements, a stabilized power supply unit can be used but must be rated higher than 1.5KW.

The graphite power supply should be wired to a separate single phase 220Vac (+/- 10%) rated

at 40A.and a type C over-current trip should be used for protection. If the supply is outside of

the requirements, a stabilized power supply unit can be used but must be rated higher than

10KW.

The air compressor and all other accessories should be connected directly to the standard

mains supply.

Please note: The main unit of the AAS, air compressor, accessories and the power

‘Supply of the graphite furnace should all be connected to the same electrical pha:

Gas source requirements

itis the responsibility of the user to ensure that the gas installation conforms to the local safety

regulations.

An air compressor or bottled air can be used to ‘supply the instrument at a constant Pressure. If

an air compressor is used it should have a tank of at least 9Lt.

The Acetylene gas used should have a purity of no less than 99.9% and the pressure from the

cylinder should be set using a gas regulator. A special gas cylinder storage room is needed and

@ gas on-off valve in the laboratory should be installed, a

Note: Due to the dangers of Acetylene gas, caution should be taken. The pipe work

PYinswuments

SASOSOSOSEFSOSS FESO E HOME BMATTAMHMTOTTODIDG

a ee a

owes

wwe

Pre-Installation Requirements

‘should be checked for leaks and a flash arrestor should be installed.

The Argon gas, when configured with the graphite furnace system or hydride accessory, should

have a punty of 99.99%. The supply pressure should be set using a gas regulator. A special gas

cylinder storage room is needed and a gas on-off valve in the laboratory should be installed.

A special gas (Nitrous Oxide) may be required with the flame instrument. If required, it should

have a purty of no less than 99.9% and the pressure from the cylinder should be set using a

928 regulator. A special gas cylinder storage room is needed and a gas on-off valve in the

laboratory should be installed

If the Propane is required to be configured with the flame instrument, the pressure from the

ylinder should be set using a gas reguiator. The cylinder should be stored in a gas storage

foom and a gas on-off valve in the laboratory should be installed.

Gas Pressure:

Air 2.5bar / 32PSI

Acetylene 0.75bar / 9PSI

‘Argon 6bar /70PS|

Nitrous Oxide bar / 35PS|

Propane O.6bar /7PSI

Water source requirements

Cooling water is required when the A500 instrument is configured with a graphite furnace

system, The flow rate should be at least 1.5L/min and a re-circulating water system is

fecommended for constant flow and temperature. De-ionized water should be used to keep the

cooling system clean and free from growth. A small amount of additive can be added to the

water to stop bacteria developing.

Solution requirements

D1 water should always be used when running the AASOO system. Standard solutions of

1000ppm for each element can be obtained and used to make operational standards to

calibrate the system for analysis.

Note: acid concentration of the samples should be kept to a minimum (<6%) If high acid

concentrations cannot be avoided then some parts will need to be upgraded. For

information please contact your local agent.

Operation Instruction Manual

Atomic Absorption S| ectrophotometer

AA500

§

c

od

5

g

a

&

AAMMDVMMMOA MPRA RENAN DANE EDOODAD .

PIII IRE EI GUO

A500 Operation Instruction Manual _ oe 2

™ Cautions and Warning labels

Daily operation cautions:

1. Asuitable exhaust system should be installed above the burner to remove any fumes

r potentially combustible gas,

2. Do not smoke or use any open fire near the instrument.

3. Always extinguish the flame before leaving the laboratory.

4. For HF analysis, do not .use the standard glass nebulizer.

Warning labels:

Note: There are a number of warning labels attached to the instrument. Please take

notice of them.

™ Precautions of using gas

The user should strictly observe the following safety operating precautions, please read

before using the instrument.

The installation of the cylinders:

Cylinders should be installed outside of the laboratory where they are not exposed to

sunlight directly.

© Cylinder temperature should be less than 40C and do not allow any flame within 2

meters.

© Locate the cylinder in a vertical position; do not locate the cylinder horizontal.

Acetylene gas:

@ Always use the correct regulator valve for the acetylene gas. Do not use pipes

made from copper, silver, mercury or their alloys in order to prevent the formation of

metal-acetylides, which could break down the pipe under the pressure.

@ The acetylene gas cylinder contains dissolvable substance such as acetone. If the

primary pressure falls below 70Opsi, it should be replaced with a new cylinder in

order to prevent the diffuseness of the dissolvable substance.

Nitrous Oxide:

© Nitrous oxide is a colorless and sweet-tasting gas which is used to support the

acetylene flame. It is stable at normal atmospheric temperature and can be

dissolved with water, alcohol and high concentration Sulphuric Acid. Always use

adequate ventilation due of the anesthesia effect of the gas.

2

BQinstruments

‘AAS00 Operation Instruction Manual

Liquefied petroleum gas:

‘© The main components of LPG are propane and butane. The gas is combustible so

please make sure there is adequate ventitation

Oxyge

© Oxygen should never be used.

Air:

© This should be dry and free from oil. A moisture or oil trap on the exit tube can be

installed

After using:

© Always tum off the gasses after using the gas instrument

Regulator valve:

© Periodically inspect the pressure gauges for leaks or problems

Pressure adjustmen

‘© Before installing the regulator valve, always make sure that the gas cylinder exit

tube and valve are clean and free from dirt or grease.

© The leaking of gas at the cylinder may be caused by incorrectly fitting of the

Fegulator valve. Do not try to install by force, replace with a new cylinder if this

situation is occurs.

Turn on and Turn off the cylinder:

‘© Before turning on the cylinder, make sure that the regulator valve is turned off.

Open the cylinder using the correct tool only. Do not knock the main valve with a

hammer if it tight.

© Check the connection of the regulator valve and cylinder for gas leak using soap

solution. If a leak is found, please tum off cylinder.

‘© Rotate the main valve of the cylinder for acetylene gas by 1 or 1.5 tums only to

prevent leakage.

PQinstruments

CQeececeeececee SCCIETLLLLL Lele

aaee,

eo

e000

0000000066

‘AAS00 Operation Instruction Manual =

™ Security management of cylinder

Acetylene cylinder:

This instrument uses flammable high purity acetylene for the flame system, please pay

attention to the storage and usage safely.

© Locate the gas cylinder in a correct place with good ventilation where it is not

exposed to direct sunlight. Do not place the acetylene cylinder and instrument in

the same room.

© The temperature of the cylinder must be less than 40C and do not allow any flame

within 3 meters.

‘© The cylinder must be fixed securely and keep in a vertical position.

© Use a special regulator valve for the acetylene gas. Do not use pipes made from

copper, silver, mercury or their alloys in order to prevent the formation of

‘metal-acetylides, which would be break down the pipe under the pressure.

‘© Tum off the main valve after using the gas.

© Periodically inspect the pressure gauge to maintain its normal function.

Before installing the regulator valve, always make sure that the gas cylinder exit

tube and vaive is clean and free from dirt or grease.

© Before opening the cylinder, make sure that the valve is closed. Adjust the pressure

valve fully to the left, and open the cylinder using the correct tool. Apply soapy

water to the connection of the pressure regulator to check that no gas leak is

generated.

© Be sure to rotate the main valve of the cylinder for acetylene by 1-1.5 turns.

© Adjust the pressure at the second valve clockwise to 0.1MPa. Do not exceed

0.12MPa as acetylene is not stable at high pressure.

© The acetylene gas cylinder contains dissolvable substance such as acetone. If the

Primary pressure falls below 0.5Mpa, it should be replaced with a new cylinder in

order to prevent the diffuseness of the dissolvable substance.

BDDDIDD\9\o'w\e\a\a\n\a\a\a\'a es

¢

vos

.

Nitrous oxide cylinde:

© Turn on the main valve, adjust the second valve to the correct, pressure. Carry out a

leak check periodically before ignition. Do not ignite flame if there is a gas leak.

@ Pay attention to the cylinder pressure when using nitrous oxide, it should be

replaced if the pressure is lower than 100psi.

©. The exit pressure is 35psi.

DANA ANG EGU

Liquefied petroleum gas cylinder:

© When replacing the cylinder, check the seal washer, then install the regulator valve,

check the tube and connect.

PQjnstruments

‘AAS00 Operation Instruction Manual

© Carry out a leak check periodically before ignition. Do not ignite flame if there is a

gas leak.

© The regulator valve model is JYT-0.6, the output pressure is 2.840.5KPa; the

output pressure for the other model is SKPa.

Argon cylinder:

© Carry out a leak check periodically before ignition. Do not use if there is a gas leak

© Pay attention to the cylinder pressure when using argon, Replace the cylinder if the

Pressure is lower than 145psi

™ Operation precautions of instruments

There are many safety features for the instrument, but the user should strictly observe

the operation precautions before operating.

Gas leak alarm:

The gas leak alarm, uses a combustible gas sensor and is located inside of the

instrument near the gas inlet. It will operate when the external power is switched on

(weather the instrument power is on or off). It provides an audible alarm in addition to a

safety chain abnormity protection.

Warning: If the alarm sounds, please turn off the instrument and acetylene

cylinder and check/repair leak before turning the instrument and gas back on.

Pressure monitoring:

The flame will not operate if the pressure of air, nitrous oxide and acetylene is too high

or too low. The graphite furnace atomizer will not work if the pressure of argon is too low

oF too high.

Heat Protection Baffle monitoring

The flame will not ignite if the heat protection baffle is not installed correctly.

Waste liquid level monitoring:

‘The flame will not ignite if the level of the waste trap is to low.

Flame monitoring:

If the flame extinguish abnormally, the instrument will give an alarm.

PQinstruments

‘AA500 Operation Instruction Manual

Emergency switch:

Press the emergency switch and tum off the gas valve in an emergency situation.

Points for attention:

.

The safety system of flame atomizer is effective when using flame work mode. The

flame atomizer will work normally.

The flame will be extinguished safely if there are any abnormalities, and the

oftware will show Waming information.

Please check the instrument carefully before use. Contact technical support or your

local agent if necessary.

Emergency steps:

© Tum off the power supply.

‘© Switch off the main valve of the acetylene, nitrous oxide, LPG and argon.

© Switch off the cooling water.

© Switch off the compressor.

™@ General Precautions:

In order to use the instrument safely, be sure to observe the following precautions.

© Use the correct burner head for different flame mode (Air-Acetylene flame, Air-LPG

flame, Nitrous Oxide-Acetylene flame).

@ Never put your face or hands in the burner compartment. during ignition or with

flame on. Never look directly at the flame above the chamber or put hands over the

‘chamber. Close the flame shield (bumer compartment door and chamber) before

igniting.

Do not ignite flame without bumer head.

Do not ignite flame without nebulizer installed.

‘Do not ignite flame if the water level is too low in the liquid trap.

Do not remove the burner head when flame is on.

Do not touch the burner head until cool.

Do not touch the deuterium lamp when itis lit.

‘Do not put hand in the lamp tower.

‘Do not put hand over the igniter and flame monitor.

Do not put foreign objects into the lamp holder.

Do not remove the heat protection baffle when the AA5OO flame is on.

Please check the setting ofthe flow rate before ignition,

Do not touch the flame shield when flame is on.

6

; PQinstruments

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Practica 2, Termo UPB PDFDocument64 pagesPractica 2, Termo UPB PDFAna Gabriela Zelaya Guzman33% (3)

- Practica 2, Termo UPB PDFDocument64 pagesPractica 2, Termo UPB PDFAna Gabriela Zelaya Guzman33% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Caso IKEA PDFDocument2 pagesCaso IKEA PDFAna Gabriela Zelaya GuzmanNo ratings yet

- Caso VW vs. PorscheDocument1 pageCaso VW vs. PorscheAna Gabriela Zelaya GuzmanNo ratings yet

- Caso TwitterDocument2 pagesCaso TwitterAna Gabriela Zelaya GuzmanNo ratings yet

- Caso MELDocument5 pagesCaso MELAna Gabriela Zelaya GuzmanNo ratings yet