Professional Documents

Culture Documents

162JGS

162JGS

Uploaded by

Héctor Gabriel Castillo0 ratings0% found this document useful (0 votes)

4 views45 pagesmanual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmanual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views45 pages162JGS

162JGS

Uploaded by

Héctor Gabriel Castillomanual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 45

MODEL: 162 JGS

INTEGRAL ENGINE/COMPRESSOR

ARIEL CORPORATION

35 BLACKJACK ROAD, MOUNT VERNON, OHIO 43050

TELEPHONE: 740-397-0311 FAX: 740-397-3856

VISIT OUR WEB SITE: www.arielcorp.com

DATE February 2, 1987 REV INTRODUCTION

INDEX. . pnbapocroasodoooban ee lad

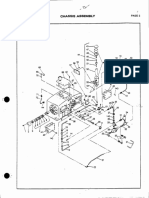

CROSS SECTION, TOP VIEW.....--.0eeee0e eee ee

INTRODUCTION. . oe eld

SIZE, RATINGS, LIMITS......-00ee000+ ee ie

PRIMARY COMPONENTS......+++000+ eee ee 18)

ANCILLARIES.... + 1-6

Te2 JGS INTEGRAL

ENGINE/COMPRESSOR

SECTION I INDEX

1-1

ARTEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHTO 43050

Date: February 2, 1987 Re’

The JGS Integral is basically a single throw Ariel

Compressor. It runs 1400 RPM and utilizes Ariel's line of

3-1/2 inch stroke cylinders including the tandem ones.

It has one engine cylinder on the right side of its

crankcase opposite one compressor cylinder on the left side.

The engine cylinder provides power through a common crankshaft

to run the compressor cylinder and cooling fan load.

In applications where compression up to 2000 PSI discharge

pressure is required, and where 25 HP is adequate, the JGS

Integral offers several advantages over coupled, engine-driven,

compressors.

Its skid can be smaller because only one crankcase

needs to be mounted.

There are no shaft flexible couplings to align or

maintain.

At turnaround, overhaul is simpler and Tess

expensive because there are fewer parts and

unbolting from the skid is unnecessary.

Fuel rate is attractive because of the four-stroke

cycle design and low friction resulting from a

minimized parts count.

Ariel quality is built into both the compressor and

engine.

162 JGS_INTEGRAL

ENGINE/CONPRESSOR

INTRODUCTION

{OT is

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050,

Date: February 2, 1987 __Rev:

Number of Power Cylinders...... seesesl (4-stroke Cycle)

1-7/8 Inches

Strokes ee ee -6 Inches

Operating Speed Range... ++-800 to 1400 RPM

Rated Horsepower... -25 at 1400 RPM

Fuel Rate at Rated Load........ -226 Ft3/Hr. (Natural Gas)

Fan Drive..ssesssereeeeeeees -Stub Shaft, Flywheel End

Heat Rejected to Radiator at

Rated Load (from coolant)... + 62,000 BTU/HR

Number of Compressor ThrowS....+sssseseeeeeeees

Compressor Stroke... -3-1/2 Inches

.-l or 2 (Tandem Cylinders

furnished for Multi-

Stage Compression)

Number of Compression StageS....sseeeesseeeee

Haximum Discharge Pressure....sseeeeeeeseeeeeeee +2000 PST

++4,500 Ibs. Tension

5,000 Ibs. Compression

Rated Rod Load..

Maximum Tension + Compression........+++++seee++++9s000 Tbs.

seeeeseesesseeesses++1700 to 1900 Ibs. (depending

Assembled Unit Weight.

on Compressor Cylinder)

56 inches

292 inches

30 inches

Length.

Width...

Height.

O41 Sump. se eeeeeeeeeeeeeeee3.0 Gallons,

Water Jacket Capacity.....-seseeeeeereeeeeeeeeee +30 Gallons

162 JGS_ INTEGRAL

ENGINE/COMPRESSOR

SIZE, RATINGS AND

1-4

=

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

Date: February 2, 1987 Rev: INTRODUCTION

Crankcase, Cylinders, Head, Crosshead Guide......Class 30 Gray Iron

Crosshead.......seseeseeeeaeeesseseeesereeeeesessClass 40 Gray Iron

Power Cylinder Head... -Class 36 Gray Iron

Power Piston.. seeseseeeeess€lass 40 Gray Iron

Power Cylinder Liner......sssseseseeeeeseeeeeeessAlloy Iron, Hardened Bore

Crankshaft.....csessesseeeeueeceeeeseeeeeeeseeessDuctile Iron

Camshaft. . seteteeeeeeeeeeseeeeeteeeereeesATToy Tron, Hardened Lobes

Power Connecting Rod. «Steel Forging

+ Ductile Iron

Compressor Connecting Rod....++.+ssese000

Compressor Piston Rod. seesesesessees]+1/8" Diameter Steel

Main Bearings (4)......seseseeseeeeeneeeeesereees3-1/4" Diameter x 2" Steel

Backed Tri-Metal (F-5)

Connecting Rod Bearings (3).......s++sesseeeeee++3" Diameter x 1-11/16" Steel

Backed Tri-Metal (F-112)

Camshaft Bearings (4).....+sseeeeseeseeeeeeeese+ 25/16" x 1" SAE 64 Bronze

Flywheel... seeeee-Ductile Iron

162 JGS INTEGRAL

ENGINE/COMPRESSOR

PRIMARY COMPONENTS

1-5

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

Date: February 2, 1987

Lube Oi1 Pump....... -Gear Driven 5-1/2 GPM

Water PUND....ssseseceeeseeeeeseeeseeseeeeeeeessGear Driven-15 to 25 GPM

Lube Oil Filter. -Spin On

Lube O11 Cooler......csscseeeseeeseeessseesseeesaMounted on Engine (Shell and

Tube)

Governor. . -Ariel (Mechanical)

Carburetor....seeseseeeeee ceeeeseeeeeeImpeo 200

Ignition.. -Solid State, Fairbanks Morse

Altronic I

Air Filter. ceeeseeeeesesseeeessOm Engine-Dry Element (Ariel)

+12 Volt Electric or Gas Motor

Staten ee ee

Compressor Cylinder Lubricator.......csee+ee0+++eMega

Cylinder Lubricator Distribution Block...........Lincoln St. Louis

-+Kenco

Cylinder Lubricator no Flow Switch...

Exhaust Silencer.....ssseeeeeeee +-One Engine Mounted

162 JGS INTEGRAL

ANCILLARIES

1-6

‘ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

Date: February 2, 1987 Rev: APPLICATION

INTEGRAL ENGINE OUTLINE P-CLASS CYLINDERS ..............5 2-2

INTEGRAL ENGINE OUTLINE M-CLASS CYLINDERS ............005 2-3

ENGTHE|COOLAN TAs cee ee eee 2-6

RADVATORV HEAT UOAD 2 tee eee 2-7

COOLING SYSTEM SCHEMATIC DIAGRAM ..........seseeeeeeeenee 2-8

COOVANT (PIPINGs (PRESSURIZATION eects ce eee 2-9

PANS SHAT ORIVED cee ee eee ee

LUBRICATING OIL/CRANKCASE HEATER

FUEL SYSTEM SCHEMATIC DIAGRAM .....esceeeeeeeeeeereeeenee

CONT ROS et ee

ALTRONIC MAGNETO/CONTROL MODULE

AVATUASLE HORSEPOWER eects se eee rae en

BUMPINGRCARACKING (eee eee eet ee eee

GUY OUT RT DWG qooesooeanopondn speenodbonecudosdoodoans

MANIFOLD PRESSURE VS. HORSEPOWER ..

ELECTRIC STARTER .

SCARE le

POW-R-QUIK STARTER ceeeeesesececceeeecteereestereseeeenes 2-22

SPECIAL TOOLS (2 sheets) ....-.ceeeeeeeeeeeeeeeeeeeeeeeee 2-23,24

162 JGS INTEGRAL

ENGINE/ COMPRESSOR

SECTION 2 INDEX

ee | ee

ARTEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

[960-0 | srs women 7

sor z91 HI

3NI1LNO_3NIONS

‘0 "NONB_ Tye

NOILVUO.

“a

“ worse ena / Se

tes

DATE August 14, 1981 REY 2 March 7, 1983 APPLICATION

Do not use untreated water for coolant.

Untreated water is usually "hard", which means it contains

calcium and magnesium. Calcium and. magnesium are sources of

"scale" which deposits on liner and cylinder head cooling

Surfaces. Scale reduces the rate of heat removal and can make

heads and liners run hot enough to de damaged by cracking or lack

of lubrication.

er that has been softened by removing calcium and

magnesium is suitable for coolant. However, it must be treated

further with a corrosion inhibitor to prevent rust on the wetted

liner and head surfaces.

Cleaned softened water with a corrosion inhibitor added

Should have a pH between 8.5 and 10.

In temperatures where freezing is expected, anti-freeze

should be mixed with clean soft water according to the supplier's

instructions. Most commercial anti-freezes contain their own

rust inhibitor. Do not add anti-freeze to a cooling water

Solution that already contains some other type of rust inhibitor.

Do not select anti-freeze that contains sealer additives,

Periodic replacement of the coolant {ts advisable. Anti-

freeze does not lose its ability to prevent freezing. but i¢ does

Gradually lose its ability to prevent rust.

Ariel recommends that treatment of the engine coolant be

gone according to the advice of a reputaole manufacturer of that

type of product. Before making a selection, considers

If the coolant requires a radiator larger than one

for simple treated water,

If there fs an an anti-foaming agent.

If the coolant will harm gaskets, seals, hoses, etc,

If there is danger to human eyes or skin.

Laws and regulations regarding disposal of used

coolant.

96S INTEGRAL

43050

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OH:9

© THOUSANDS >

BTU/HOUR

HEAT CARRIED TO RADIATOR

BY POWER CYLINDER COOLANT

T qT iaeeeel se

DATA COLLECTED USING 182F THERMOSTAT

| MULTIPLY HEAT LOAD OF INTEREST

| BY 1.15 FOR RADIATOR SELECTION

i l {| i |

10 15 28 25 38 35

BRAKE HORSEPOWER

62 JGS INTEGRAL

ENGINE/ COMPRESSOR

RADIATOR

HEAT LOAD

Lez

DATE: August 14, 1987 Rev: 7 January 4, 1984 APPLICATION

—vecewo—

xxx wax

RADIATOR WITH 22x oe .

PRESSURE CAP x venones SH

=== Funniswen By oruens

FURNISHED BY ARIEL

‘cusTower

SL cOnMEC TIONS

I-

=

TAN way BE ORIEN FROM OR MED 81

SuatShabh OF renee ens oF tact

yee on.

eeu

UGS INTEGRAL

JENGINE/ COMPRESSOR

COOLING SYSTEM

SCHEMATIC DIAGRAM

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

m.

DATE August 14, 1981 REV. APPLICATION

PRESSURE CAP

q

VENT PLUG

Q

To avoid trapping air, arrange piping so there is continual

upward slope in the direction of the coolant flow.

To avoid excessive pressure loss due to flowing friction,

use piping with at least 1 1/4" inside diameter.

When filling cooling system, always vent trapped air using

brass plug on water discharge manifold,

PRESSURIZATION

Positive pressure maintained by 2 pressure cap or

standpipe is advisable to prevent air entrainment and

consequential damage to the coolant additives. Air can be drawn

in thru the engine driven coolant pump shaft seal if pressure

at the pump suction becomes negative. If such occurs

continuously, the anti-corrosion agent in the SES INTEGRAL

coolant will be consumed rapidly. ENGINE/ COMPRESSOR

COOLANT PIPING,

PRESSURIZATION

a

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

DATE January 7, 1983 REV_1_March 7, 1983 APPLICATION

March 7.1985

FIGURE 1 FIGURE 2

Al1_0GS flywheels are furnished with a pilot and tapped

hole circle for mounting a power take-off shaft. Details are

shown on the main outline drawing.

Figures 1 and 2 show two optional fan drive shafts that can

be supplied by Ariel. Each is capable of transmitting full

engine torque. The shaft in Figure | is intended for a flexible

Coupling drive or V-belt drive. It has flats milled in two

places to enable rotating the crankshaft for inspection or

maintenance.

V-belt side loads should not exceed 50 pounds force.

Figure 2 shows a shaft _for driving a fan mounted directly

on the shaft outboard end. This shaft is long enough that the

fan will be positioned about twelve inches from the flywheel.

Total "side and top" discharge area of the cooling air path

Thoald be at least as great as the crossectional area of the fan

There are four holes in the shaft to enable rotating the

crankshaft for inspection and maintenance.

A mounted fan should not weigh more than 26 pounds.

The INTEGRAL ENGINE OUTLINE (s) at the beginning of this

section show dimensions that can be used for

GS INTEGRAL

skid design.

ENGINE/ COMPRESSOR

FAN DRIVE SHAFT

—2-10_

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

DATE Avaust 14, 1981 REV. March 7, 1983

APPLICATION

(— PRESSURE swITCH

Ser sss!

FALLING

—pisTRIBUTION

i= ye

/ (J. ~esessure

nes

roa my

TO BEARINGS: Aiwa, TP

_ of

ag SUCTION

COMPRESSOR —T— sr

Sa ae

mae genonve BE

DENOTES iN Luge om pump—!

FURNISHED BY OTHERS

—ruaniseD By ARIEL

DGS INTEGRAL

ENGINE / COMPRESSOR

LUBRICATING OTL

SCHEMATIC DIAGRAM

2-11

ARIEL CORPORATION, INDUSTRIAL PARK, MOU

NT VERNON, OHIO 43050

Date: February 2, 1987 Rev: APPLICATION,

SAE 30 weight lubricating of1 is recommended for most applications.

Brands found suitable for other four-stroke heavy duty gas engines are

appropriate. Ashless or low ash oils are preferred.

When selecting a brand of oi1, consideration should include the

facts that the lubricating system serves both power and compressor

cylinders and that the engine cylinders are four-stroke cycle and

natural gas fueled.

It should be kept in mind that lube ofl is taken continuously from

the crankcase by the force feed lubricator pump to lubricate the compressor

cylinder(s) and packing. That of] is not returned to the crankcase. There-

fore, residence time in the JGS is somewhat less than in “non-integral”

engines and consideration of a less expensive lube of1 may be appropriate.

Ariel recommends consultation with a lubricant specialist before

changing to a “cheap" brand.

See CYLINDER LUBRICATION SHEET to determine of1 rate of the compressor

side.

162 JGS INTEGRAL

LUBRICATING OIL,

CRANKCASE HEATER

2-12

ENGINE/COMPRESSOR

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OH 43050

DATE: August 14, 1981 REV 5 March 7, 1986

APPLICATION

mM fr val

won 110.3 INCHES oF

i WATER POSITIVE

" PRESSURE AT

I

|

I

tow CARBURETOR FUEL

I IWLET,

!

I

@

lauick actins eee!

ICever Vatve |

:

' ot |

I \ —

RE pkg t (oti,

PF SECONDARY \BOTTLE” |

a REGULATOR (OPTIONAL) |

npr equIRED) TL \

a

TOA CLEAN FUEL Gas souRce-fkJ-—fepX. ——_J

SHUT-OFF pRiMaRy

7 VALVE, REGULATOR

(OPTIONALD

—Leceno—

‘ ——— FURNISHED BY

OTHERS

FURNISHED BY

Arie

The diagram above is appropriate for ordinary natural gas

whose composition is mostly methane and ethane, C, and C,.

If the fuel contains a large percentage of propane, C,, @

vaporizer will be required. A schematic diagram, instructfons,

and a parts list for using propane are available upon request.

Butane or heavier, C,+, in percentages of 12 or higher, may

detonate. Low compressiod pistons are required for fuel with a

substantial butane content.

Fuels with a high heat value below 700 BTU/FT° require

engine modification to achieve rated horsepower.

Ariel will be pleased to help in cases where fuel is

special.

162 JGS_ INTEGRAL

ENGINE /COMPRESSOR

FUEL SYSTEM

SCHEMATIC DIAGRAM

2:13

Date: August 14, 1987 Rev. 5 January 9, 1984 ‘APPLICATION

eae

Ariel provides standard:

Speed control governor.

Force feed lubricator (for compressor cylinder (s) with

distribution block and no-flow switch connected and

adjusted for break-in.

Thermostatic valve that maintains coolant within an

acceptable temperature range.

Switch/gage in coolant discharge manifold to detect

excessive coolant temperature.

Switch/gage in main crankcase header to detect loss of

lubricating of1 pressure.

Threaded locations to detect:

_RPM by magnetic pick-up from ring gear (152 teeth).

Coolant pressure.

Lube of] temperature.

Intake manifold pressure and temperature.

Power cylinder exhaust gas temperature. (2)

Compressor cylinder discharge temperature.

Overspeed. protection device:

Furnished by others.

JGS_INTEGRAL

ENGINE /COMPRESSOR

CONTROLS

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

BRAKE HORSEPOWER

8

y

a

POWER AVAILABLE FOR SIMULTANEOUS

COMPRESSION AND COOLING FAN LOAQS

NATURAL GAS FUEL

28.5 IN MERCURY BAROMETER

a 9 18 nn 12 13 14

RPM = HUNDREDS >

62 JGS INTEGRAL

ENGINE/ COMPRESSOR

AVATLABLE

HORSEPOWER

2-16

Date:

March 30, 1987 Rev: 0

MILLIONS OF STANDARD CUBIC FEET PER DAY, MMSCFO.

RATED PUMPING CAPACITY (S) AT 1420 RPM

T T — T T T T

300 408 saa

208

r NATURAL GAS

! ! | . . ‘ :

a 3B 108 158 208 258 308 350

SUCTION PRESSURE, PSIG

THRUPUT CAN BE REDUCED TO 57% OF ABOVE VALUES BY SLOWING UNIT

TO 820 RPM, MANUALLY OR AUTOMATICALLY.

FURTHER TURNDOWN IS POSSIBLE

USING VARIABLE CLEARANCE VOLUME

OR FIXED SPACERS IN VALVE POCKETS.

Tea JGS INTEGRAL

ENGINE/ COMPRESSOR

PUMPING CAPACITY

2-17

Date: January 6, 1986 Rev: APPLICATION

BATTERY POWERED

CRANKING MOTOR CHARACTERISTICS

T T T T T r T

1@ PINION TEETH

35+ 152 RING GEAR TEETH 4

FT-LBS

Dc voLTS

8 9 18 it 12 13 14

Fae lad hh) ¢ HUNDREDS >

UGS INTEGRAL

ENGINE/ COMPRESSOR.

ELECTRIC STARTING

MOTOR

2-20

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

Date: January 6, 1986 Rev: APPLICATION

INGERSOLL-RAND GAS STARTING MOTOR CHARACTERISTICS

ta

1a PINION TeETH

152 RING GEAR TEETH

= 16

g 208 T 15a Ps1G, WAX INLET PRESSURE 428 PS

G

Zz

2 isab a PsiG |

12a | 7

saboror oto tort tot te tot tp ta J

25- !

gal oS J

1 PINION.

So, TON -ToRaUE 12a psig |

al Nee RECOMMENDED Psig

ee pe a

4

6a 78 er] 38 wa Bs

CRANKSHAFT RPM

‘TGS INTEGRAL

T.R. STARTING

MOTOR

ENGINE/ COMPRESSOR

2-21

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

Date: January 6, 1986 Rev: APPLICATION

POW-R-QUIK GAS STARTING MOTOR CHARACTERISTICS

It

18 PINION TEETH

_ 152 RING GEAR TEETH 516

F200 ea rata, wax incr PRESSURE ,

G

4g

&

15a + psis 4

10a | i

saber or orotor ttt tt te te ea d

2p ir cic

g aot PINION TORQUE i

a

: '

z ;

a psic 4

2 | NMINIMUM RECOMMENDED

|

6a 78 8B 98 188 1a

CRANKSHAFT RPM

128

‘UGS INTEGRAL

ENGINE/ COMPRESSOR

SFr fig Abron

2-22

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON,

OHIO 43050

APPLICATION

INTAKE VALVE SEAT

REMOVAL TOOL COLLET

VALVE SEAT

REMOVAL TOOL SLIDE HANMER

ExXH. VALVE SEAT INSTALLATION TOOL

EXH, VALVE SEAT

REMOVAL TOOL COLLET

VALVE GUIDE

DRIVER STOP SLEEVE

VALVE GUIDE DRIVER DRIFT

CYLINDER LINER

PULLER & INSTALLATION BRIDGE

CYLINDER

LINER PULLER &

INSTALLATION

PLATE. CamsHarT

BEARING

& REMOVAL

CONE

UGS INTEGRAL

ENGINE /COMPRESSOR

SPECIAL TOOLS

Sheet_1 of 2

PT 2s J

SHIELDED SPARK PLUG LEAD NUT “TOOL HEX ADAPTER

APPLICATION

ae ee

TOOL DESCRIPTION

[ee [eee Pree [ [en ae error oF]

INTAKE VALVE SEAT INSTALLATION TOOL 2

JExXH. VALVE SEAT REMOVAL TOOL COLLET

[een a ae ee |

[nie ee ner vr wane |

[— |

acrsice | __[evcinoan cinen puaen 4 IngTALLaTiON ATE y

732-8 [CAMSHAFT BEARING INSTALLATION & REMOVAL SEGMENT” BAR|

ecrooe | __ [oven rule wa Tonouine wer AOTER =

[= _|estecocn ora ro tan vat Too

* Upon request, Ariel will provide detail drawings

for building this tool. It is also available via

direct purchase.

jGS_ INTEGRAL

ENGINE/COMPRESSOR

‘SPECIAL TOOLS

Sheet 2 of 2

a

CONPONENT

Date: January 10, 1987 _ Rev. DESCRIPTION & ADJUSTHENTS

weeB

LUBE OIL PUMP, LUBE OIL PRESSURE. boone ppacG 32

THERNOSTATE, COOLANT. ....+.2sseeeeeeeeeeeeeeee see

CARBURETOR. . seeet eee teen eee eee BS

FORCE FEED LUBRICATOR.......... eo veel

RUPTURE DISC, SIGHT GLASS, FORCE FEED OIL SUPPLY, PRIMING. 3-12

DISTRIBUTION BLOCK. . . seteeeeeseeeeeee B13,

CYCLE INDICATOR.

NO FLOW SWITCH.

MAGNETO ASSEMBLY, ALTRONIC. .

MAGNETO AND TIMING, ALTRONIC. .

162 JGS INTEGRAL

NE/COIL

SECTION 3 INDEX

Sasssaassaaae

31

T

WOCKNUTT ADJUSTMENT BOLT

[ fimuRNcw to:

INCREASE PRESS) |

/ - CAP SHOWN

é / REMOVED

ssc _

La PUMP '

tant by

041 pump discharge pressure is held nearly coi

d. Lube

a spring loaded regulating valve within the pump

system pressure can be raised or lowered by adjusting this

valve. (See {1lustration above.)

|

|

i

Normal pressure on the discharge (engine) side of the |

lube of] filter is about 55 PSI when crankshaft speed is 900

RPM or more. If of] pressure drops below 45 PSI, the reason |

should be found. |

!

!

Possible causes are:

Dirty lube of1 filter element.

Plugged lube of1 suction strainer.

Major leak.

Defective lube o11 pump.

Engine RPM below 700.

i

Continued operation with lube of pressure below 35 PSI I

can cause serious bearing and crankshaft damage.

OIL PUMP,

LUBE OIL PRESSURE |

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

DATE: August 14, 1981 REV_1 12/2/82 COMPONENT DESCRIPTIONS & ADJUSTMENTS

THERMOSTATIC ELEMENT

a WATER DISC

MEE Scounce

ep

1

Tro cuge on

COOLER

The thermostat maintains engine coolant temperature to the radiator

at about 180 degrees F. Coolant returning from the radiator passes

through the lube oil cooler before going to the cylinder heads and

cylinders; thus lube of] temperature, as well as coolant temperature, is

controlled by this one thermostatic valve.

‘The temperature at which this valve operates is not adjustable.

Temperature rating is stamped on the device. The thermostat will

“crack” open about 5 degrees F below the stamped value and be full open

about 5 degrees F above the stamped value.

Unlike automotive thermostats, this one does not have a leak path

to the radiator. It should not be replaced with an automotive substitutes

‘the coolant may not warm up in cold weather.

JGS_INTEGRAL

ENGINE/COMPRESSOR

‘THERMOSTAT,

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

DATE REV.

LRH

AIF RATIO ADJUSTMENT NUT

CARBURETOR VIEWED FROM INTAKE MANIFOLD

The carburetor is an Impco Model 200. With {t, the JGS

will run satisfactorily on most ordinary gaseous fuels. Liquid

fuels can not be used with this carburetor.

Gas pressure at the carburetor fuel inlet connection should

be maintained between land 3 inches-of-water pressure.

When the engine is running, the carburetor senses intake

atr rate and admits fuel in a proportion that promotes good

combustion in the power cylinders. When the engine is stopped

and the carburetor senses air rate to be "O", it shuts off the

fuel tight.

The ability of the carburetor to shut off fuel when th

sogiog te" ttnpos opped Tene aE tute fora Separate fuel shut-

oft valye.

The ratio of air to.fuel (A/F) 1s adjustable to accomodate

use of various fuel compositions. To change the A/F ratio,

rotate the adjusting nut shown above. Turning the pointer toward

“leans the mixture and turning toward "R' soo

makes the mixture richer. Cee eRe

Fuel consumption rate will be lowest when i

the A/F ratio 1s as lean as can adjusted

without misfiring or groping off rapidly in

RPM. (Pointer toward “L*.

COMPONENT

Date: February 2, 1987 DESCRIPTIONS & ADJUSTMENTS

Maximum horsepower can be pulled when the mixture is as rich as

can be without misfiring. (Pointer toward "R")

Carburetor adjustments should be made after the unit has warmed

up and the Toad has stabilized.

162 JGS INTEGRAL

ENGINE /COMPRESSOR

CARBURETOR

DATE August 14, 1981 REV COMPONENT DESCRIPTIONS & ADJUSTMENTS

Instruction Plate

Pump Qutlet

9 Dist. Block

Pump Inlet

Adjustment Locknut Plunger STroke Adjustment

Force Feed Lubricators used on the JGS are identical to those used on

all other Ariel Compressors. They can pump lubricant in quantities from "0"

to more than 16 pints per day at pressures from "0" up to several thousand

PSI. Their purpose is toperiodically inject drops of lubricating oi] into

compressor cylinders and packing glands that cannot be lubricated by other

methods .

The pump is a positive displacement, cam actuated, plunger type and,

as such, delivers a constant quantity per stroke regardless of pressure

in the cavity into which it is discharging. Thus it lubricates high pressure

cylinders, low pressure cylinders, or packing, with consistent accuracy. The

plunger drive cam is on the low speed side of a worm/gear speed reducer,

making the pump cycle at about 40 strokes per minute. Lubricant rate from

the pump is adjustable by changing the plunger stroke. Lowering the priming

stem reduces stroke and delivery rate: conversely, raising the priming stem

increases delivery Chant ump stroke is the only way to change the

rate at which oi] is delivered to the compressor cylinder’

See the Cylinder Lubrication Sheet. Ariel's nominal cylinder and

packing lube re¥es-are-0-3 pints per day per inch of cylinder bore and

0.6 pints per day per inch of packing diameter. (Ariel recommends doubling

these quantities for breakin.)

UGS INTEGRAL

ENGINE /COMPRESSOR

FORCE FEED

The instruction plate (above) shows total lube rate

for the machine on which it is mounted. If cylinders are

changed, this plate should be corrected.

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

DATE August 14, 19817 REV. COMPONENT DESCRIPTIONS & ADJUSTMENTS

RUPTURE DISC

Except for special applications, each force feed assembly

is fitted with a rupture disc that ruptures if pump discharge

pressure exceeds 2950 PSI due to a fault such as a blocked lube

oi] passage. When the disc ruptures, oil from the pump escapes

past the disc rather than following a proper path through the

“no-flow" switch. When that happens, the "no-flow” switch closes;

and, with proper control circuitry, it secures all connected

machinery,

SIGHT GLASS

Before operating, the force ed lubricator case must be

filled about halfway up the sight glass to lubricate the worm,

gear, cam, and bearings. Use the same lube of] as in the main

Crankease. During operation, enough oi] leaks past the pump

plunger to maintain the oi1 level to the sight glass. There is

an overflow drain that prevents overfilling.

FORCE FEED OIL SUPPLY

O11 inside the case of the Force Feed Lubricator has nothing

to do with ofl being pumped to the distribution block and

cylinders-that oi] enters the pump through the fitting marked

“Pump Inlet". See illustration

PRIMING

Since the Force Feed Lubricator Pump takes its ofl from the

main lube oi] header, force feed Tines cannot be primed by

manually actuating the cam driven pump.

In order to fill or prime the Force Feed Lube System, it 4

necessary to remove the brass plug provided and connect a

“priming” gun to the fitting. See OPERATION

UGS INTEGRAL

ENGINE/ COMPRESSOR,

Rup DISC, S. GLASS,

FF, OIL SUP 7

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OH:0 43050

DATE August 14, 1981 REV 3 2/18/83 COMPONENT DESCRIPTIONS & ADJUSTMENTS

Connection from Force Feed

Lubricator Pump

CYCLE PIR-

The number stamped

on each valve

assembly indicates

volume in

thousandth's of a

cubic inch that is

discharged from that

valve at each stroke

of the cycle pin

Connections to

lube points

(out either

or both sides)

By selecting appropriate divider valves and assembling them on a

common base plate, distribution blocks can be made to proportion large

amounts of of] to large cylinders, small amounts to small cylinders, etc.

Each Ariel machine has its own custom assembled distribution block that

“matches” the compressor cylinders on that machine. Ariel's formulas

for proportioning of1 and selecting divider valves are shown on the

CYLINDER LUBRICATION SHEET.

A completed copy of a CYLINDER LUBRICATION SHEET is shipped with

each unit in each of the instruction books for that unit. Those copies

show the original divider valves that were put on at the factory, and

how they were arranged and tubed.

The distribution block can only divide up and distribute the of!

that it receives from the force feed lubricator pump. It cannot control

the total quantity being pumped; that must be done by changing the stroke

length of the force feed lubricator pump.

Each distribution block has a CYCLE PIN. The cycle pin, along with

a watch, is used to verify the quantity of of] being passed thru the

assembly and onto the lubrication points. Oil delivery rate is correct

when you count or adjust the number of cycle pin cycles-per-minute and

find them to be about equal to that recommended by the plate on top of

the Force Feed Lubrication Pump. Be sure the unit is running at rated

RPM when you perform this count.

The CYCLE PIN is driven by one of the divider valves in the distri-

bution block assembly. It is important to realize that each and every

divider block cycles once each time the cycle pin cycles once. A “cycle”

is ‘in’ to ‘out’ to ‘in’. GS INTEGRAL

ENGINE/COMPRESSOR.

Always replace the cycle pin cover after testing is

completed.

DISTRIBUTION BLOCK

a eS

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

Date: February

1987

COMPONENT

DESCRIPTIONS & ADJUSTHENTS

The table below lists divider blocks that are available. The

letter after the number indicates whether the block has one or two

outlets; i.e. S for a single port and T for twin ports.

SINGLE PORT DISCHARGE | TWIN PORT DISCHARGE

‘CONFIGURATION PER CYCLE | CONFIGURATION PER CYCLE

PER PORT

6s 012 cu. in. 6T 006 cu. in,

9s -018 cu. in, 9T -009 cu. in.

#12 S -024 cu. in, 127 -012 cu. in.

*18'S -036 cu. in. 18 T +018 cu. in.

*24S -048 cu. in. 247 +24 cu. in.

* Can use cycle indicator.

If compressor cylinders are exchanged in the field for ones of

different size, divider valves should be changed accordingly. It is

advisable to record these changes. The CYLINDER LUBRICATION SHEET is

a good place. If assistance is needed for selecting new divider valves,

the people at Ariel will be pleased to help.

3GS_ INTEGRAL

ENGINE/COMPRESSOR

DISTRIBUTION BLOCK

314

DATE:

CONPOHENT DESCRIPTIONS

BLOCK

O'RING

INDICATOR PIN

O'RING

PISTON

BEARING

RETAINER

As described in section 3-13 a CYCLE INDICATOR PIN is used to

determine the rate at which lubricating of] is being pumped

by the force feed lubricator pump and being delivered to the

compressor cylinders and packing.

The VALVE, VALVE STEM, INDICATOR PIN and BUSHINGS, are not

furnished individually for repairs. Complete valve assemblies

with the cycle pin in place are available. Always replace the

Old assembly with one having identical delivery

characteristics. f.e a 6S for a 6S, a 12T for a 12T, etc

See section 3-14,

UGS INTEGRAL

a ce

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

DATE August 14, 1987 REV_Y 2/1/83 COMPONENT DESCRIPTIONS § ADJUSTMENTS

Stud and terminal

Contact assembly

Contact insulator

During normal operation, all lube oi] pumped by the force

feed lubricator passes thru the no-flow switch. If flow stops

for an extended period, the piston is forced slowly upward by

the spring until the switch contacts close.

When the switch closes, the connector (stud and terminal)

“goes to ground". This signal is generally used to secure

operating machinery when lubrication is lost.

The piston is made to move slowly by the viscous force of

oi] trapped between the piston and bore. Since viscosity of

lube oil varies with temperature, it is advisable to test the

no-flow device frequentiy-especially in the spring and fall.

Contacts should close within one to three minutes after

the unit is shutdown. Check closure (from stud to case) with

a continuity checker.

Switch closure time can be reduced by tightening the

spring and vice versa.

Reconnect all wiring after testing.

ARTEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

INDEX. .

CLEARANCES AND FITS...

CRITICAL ASSEMBLY TORQUES........

VALVE CENTER BOLT TORQUES. .

PISTON/CYLINDER CLEARANCES. ....-.0seeeeeeeeeees

PISTON RING END GAPS/P, M CYLINDERS...

PISTON RING END GAPS/JG CYLINDERS.

BALANCE CHART/12000 POUND ROD LOAD. .

sevens e 69

162 JGS INTEGRAL

ENGINE /COMPRESSOR

SECTION 6 INDEX

[es]

1

Date:

Rev:

February 2, 1987

PART DESCRIPTION

Main Bearing to Crankshaft...

Rod Bearing to Crankshaft...

Rod Bushing to Conn-Rod (Engine)

Rod Bushing to Conn-Rod (Compr).

Crosshead Pin to Conn-Rod.........+

Piston Rod to Conn-Rod (Engine)...

Crosshead Pin to Crosshead.........++

Piston Pin to Piston (Engine).

Crosshead to Crosshead Guide. .

Top Ring Side.

Top Ring End Gap.

Intermediate Ring Side.....ssseeeeseeeeeeeeee

Intermediate Ring End Gap.

041 Control Ring Side..

Oi1 Control Ring End Gap.

Piston to Liner, Skirt (Engine)............+5

Valve Guide to Stem (In & Ex).

Valve Guide to Head (In & Ex)...

Valve Seat to Head...

Crankshaft End Thrust..

Camshaft End Thrust......-.

Camshaft Bearing to Camshaft........+++

STANDARD CLEARANCE

-0025

0014

-0055

0039

-0015

+0005

+0015

-0002

-008

+003

-030

-003

+025

002

-018

-005

-0018

+005 - .010

004 - .010

002 - .006

TABLES.

INTERFERENCE

+0005 - .0015

+ 0015 = 0025

+0004 -

0025 -

0022

-0045

162 JGS INTEGRAL

ENGINE/C(

CLEARANCES AND FITS

Date: February 2, 1987 Rev: TABLES

PART DESCRIPTION STANDARD CLEARANCE INTERFERENCE

Rocker Arms to Rocker Shaft......sseseseeeee+ «0005 - 0025

Rocker Arm Bushing to Rocker: teetstescesseeneceeess 0025 ~ .0035

Rocker Shaft to ROcker BOX......sssseeeeeeeeenee = 0003 - .0009

Valve Tappet, Exhaust. + 018 = .022

Valve Tappet, Intake......sssseeseeeeeeeeeeee 013. = .017

Spark Plug Electrode Gap....ssseseeseeeeseeee 024 = .026

Conn-Rod Side Clear, Engine..........eesee24 005 = 010

Conn-Rod Side Clear, Compressor. 010 = .015

162 JGS INTEGRAL

ENGINE/ COMPRESSOR

CLEARANCES AND FITS

i 6-3}

Date:

oe

February 2, 1987 Rev: TABLES.

PART DESCRIPTION DIA. - TPT ENGINE COMPR

Connecting Rod Cap... 20.. = 36

Connecting Rod Cap.

Main Bearing Cap........

Cylinder Head to Cylinder...

Flywheel to Crankshaft. .

Cam Gear to Camshaft...

Crosshead Pin Thrubolt..

Rod Packing Bolts.. -1/2

Piston Nut....cceseceesesnessee eres T/B

Crosshead Nut... vol

Guide to Cylinder Bolt.........46+.1/2

Spark Plug to Cyl. Head............14 4M

Valve Cap Bolts 3/8

7/16

ve

5/8

Tabulated values are based upon

clean, smooth, rust free, threads

that have been oiled or greased

directly before torquing.

-170

20... = 55)

16... = 40

2a...

one

ese

oe BB

16 Hex Grade 8...

14 Hex Grade 8 .

13 Hex Grade 8 ...

11 Hex Grade 8

162 JGS INTEGRAL

| ENGINE /COMPRESSOR |

CRITICAL ASSEMBLY

6-4

DATE: March 9, 1987

TABLES.

7 Drake Lock Nut

FASTENER

Valve Center Bott or

Center Stud

Greer Spiraiock

(1 Piece)

SIZE TYPE

1428 UNF ‘Greer

3624 UNF, Spiralock

36-24 UNF. ‘Drake Lock Nut 7

1220 UNF (Bottom Half 7

A 36-18 UNF, 73. Lbs. | 87 ft. Lbs.

T

(2 Piece)

‘31824 UNF Drake Lock Nut_|_6fi.Lbs, | 6 ft. Lbs.

11220 UNF (Top Locking | 20 ft Lbs. | 20 ft. Lbs

56:18 UNF, Half 0 ft. Lbs [40 fe. Lbs.

Halt

FN to wostig

Bottom

Halt

JGS_ INTEGRAL

ENGINE/ COMPRESSOR

VALVE CENTER

BOLT TORQUES

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO 43050

DATE february 21, 1983 REV rH

ylinder bore diameter ametral clearance

PISTON END CLEARANCE

Crank end, of total

Head end of total

ARIEL CORPORATION, INDUSTRIAL PARK, MOUNT VERNON, OHIO

ENGINE COMPRESSOR

PISTON/CYLINDER

CLEARANCE

43050

Date: March 9, 1987 TABLES

hhh

Bronze 1-PC. ‘Teflon 1-PC.

few Wax, New [Wax]

“012.022 088 0307086 ue

012.022 1088 -0381.040 ‘160

0141026 096 0961.44 376,

089/047 188

10421052 ‘208

046,056 204

“049.060 0

0211081 124 .9571.077 308

0231083, ‘382 061.081 324

096.086 “aa 10657085 “340

026.036 fae 088/088 352

0731093 312

071/097 “388

0891.09 436

095/115 480

“012.022 “088 0807036 de

012.022 088 -0897.040 360

014.024 096 096.044 176

“0997087 — 188

0421052 208

0481056 244

i “0491060 240

024.081 324 0871077 ‘308,

023.088 ‘se 061.081 324

0261036 “da 065.085, 340

0281.036 aaa 088.088 352

0731098 312

OTT 087 388

091.109: 436,

095/115 460

Tr —

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Engine Data MiniGuideDocument28 pagesEngine Data MiniGuideMaik AmayaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Manual 3500A3Document1,231 pagesManual 3500A3Maik AmayaNo ratings yet

- E1 Pneumatic ControlDocument90 pagesE1 Pneumatic ControlMaik AmayaNo ratings yet

- 4 236Document82 pages4 236Maik Amaya0% (1)

- 3516B Generator Set ZAR00001-UP (SEBP4058 - 27) - DocumentationDocument21 pages3516B Generator Set ZAR00001-UP (SEBP4058 - 27) - DocumentationMaik AmayaNo ratings yet

- SERP4751 Parts ADEM IIIDocument426 pagesSERP4751 Parts ADEM IIIMaik Amaya100% (1)

- Joy Parts1Document76 pagesJoy Parts1Maik AmayaNo ratings yet

- BarreNaciones RinDocument7 pagesBarreNaciones RinSalvador Crisantos50% (2)

- O&M Old1Document56 pagesO&M Old1Maik Amaya0% (1)

- Bseries Op InstDocument71 pagesBseries Op InstMaik AmayaNo ratings yet

- g-26 O&MDocument52 pagesg-26 O&MMaik AmayaNo ratings yet

- G26 PartsDocument28 pagesG26 PartsMaik AmayaNo ratings yet

- Bseries PartsDocument290 pagesBseries PartsMaik AmayaNo ratings yet

- 212JGSDocument134 pages212JGSMaik AmayaNo ratings yet

- Catalogo Dk-Lok Dklok80pDocument80 pagesCatalogo Dk-Lok Dklok80pMaik AmayaNo ratings yet

- Valvula Check 6000 Lbsv3xDocument6 pagesValvula Check 6000 Lbsv3xMaik AmayaNo ratings yet

- 325JGSDocument107 pages325JGSMaik AmayaNo ratings yet

- Valvulas de AlivioV6XDocument2 pagesValvulas de AlivioV6XMaik AmayaNo ratings yet

- PackingDocument40 pagesPackingMaik Amaya100% (1)

- Catalogo Dk-Lok Dklok80pDocument80 pagesCatalogo Dk-Lok Dklok80pMaik AmayaNo ratings yet