Professional Documents

Culture Documents

UPVC Pipes and Fittings PDF

Uploaded by

alfreddieick10 ratings0% found this document useful (0 votes)

32 views40 pagesOriginal Title

UPVC Pipes and Fittings.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views40 pagesUPVC Pipes and Fittings PDF

Uploaded by

alfreddieick1Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 40

SAPPCO DAMMAM FACTORY plett) gS lw nee

Branch of Saudi Plastic Products Co. Ltd. Bagbands Da pmead thee dat Gilpin AS pit ood

C.R. 2050050912 VeOe sO ANY io yhet lus

UPVC PIPES AND FITTINGS

SAPPCO THE LEADING NATIONAL FACTORY FOR UPVC PIPES

Pottcaton 3, is

hao -2012

CERTIFICATE TuVNORD

Management system as per

EN ISO 9001 : 2008

In accordance with "DV NORD CEAT procedures, tis heraby eertfied that

SAPPCO DAMMAM FACTORY

(Branch of Saudi Plastic Product Co, Ltd.) Se

08th Street, Dammam First industrial City

(31412 Dammam ase

Saudi Arabia

‘saptian # management system in ive weh the above standard for tha following senpe

Manufacture & Sale of uPVC Pipe and Fabricated Fi

Polythylene Pipes and cPVC Pipes

CContiicate Registration No.0 100 960620 Ved une 2016-02-07

‘Auoit Report No. 2509 6453 nial certification 1996

C.,Briantig om ee

a

ar TOW NORD CERT GroH

“This ceniication was conducte In accordance wit the TOV NORD CERT auditing and certification procedures and is

Subject to raguler survetance audits,

TOVNORD CERT Gmbh: Langemarckstrasee 2 25141 Essen wor lusenord-oset.com

Contents.

Story of Making UPVC Pipes at SAPPCO DAMMAM Factory in Pictures

Foreword, SAPPCO Dammam, SAPPCO Technical Backing

Introduction, Customer Satisfaction

Material Properties

Material Classification

Manufacturing Standards, Chemical Resistance

SAPPCO UPVC Pipe Dimensions

Pipes for Potable Water Supply

Effect of elevated temperature, Comparison of Pipe Classification

Pipes for Soil, Waste and Vent Inside Buildings

Soe arsvaalaln &

Pipes for Underground Drainage and Sewer Systems

3

Hot Water Drainage

Electrical and Telecommunication Cable Conduit

nos

SAPPCO PVC Duct for Telecommunication and Electrical Power System

s

SAPPCO UPVC Pipes to British Standard

Pipe Lengths, Joints, Couplings for Pipe

>

Handling and Storage

a

Site Work Instructions.

a

Solvent Weld Joints, Jointing Procedure

a

Ring Seal Joints, Jointing Clamps

Above Ground Installation

6

Below Ground Installation

Hydraulic Testing of Pipeline

Water Hammer Consideration, Effect of UV Light

Ordering details, Abbreviations and Symbols:

Fabricated drawn radius bends (Solvent Weid joints)

Fabricated drawn radius bends (Rubber Seal ring joints)

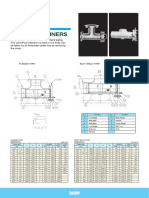

Fabricated Couplings

Solvent Cement, Cleaner, Rubber Seal Rings, Lubricant

Major Project used SAPPCO UPVC Pipes

Quallty Management System, Customer Satisfaction

Location Map, Contacts, Key Facts about SAPPCO Pips

Eseseeeee gis

The story of making UPVC pipes at SAPPCO DAMMAM

{The conversion of polymer to pipe)

1, UPVC PalyeBanin Frey SABIC salve in Ble rr where

‘motels conveyed Yo tha sorege Silos evsomaticlly.

2, From the mia, he cry bland tenerad othe acrusion Ine . Qur wll equieped Qualty Cento bemtory operates around the

The picure shows ihe-auremaic cnwying, mairg and dicribuion corse lack eraure that ell produc nina 'e SAS, IN end ISO standards

3. Each ef he exriion line vecaiven PVC Dry Bleed autaraically

‘orn the Dry Bland Sten, The Dy-Sierd power i eanveyed in ©

dosed eer rom hot Exide.

6. Tonite sola delvary texters

SAPPCO UPVC, with Rubber Seal Joint

SAPPCO DAMMAM

FACTORY

‘There has been a tremendous growth in the industrial, commercial,

‘and housing sectors and in all types of public amenities in Saudi

Arabia. For this grawth, pipelines are needed to convay water and

sewage, and to protect telecommunication and electrical cables. To

fulfil this: need, Saudi Plastic Products Co. Lid. was formed with the

‘aim of produoing, in Saudi Arabia, a full rango of unplasticised

polyvinyl chloride (UPVC) pipes and fittings to internationally

recognised standards and Saudi Arablan Standards.

SAPPCO DAMMAM FACTORY also manufacture:

- CPVC pipes for Hot water distribution systems

= Polyethylene (PE100/PE80) pipes for various services

applications

= Polyethylene sub-ductminiduct for Fibre Optic

Cabla/Tatscom.

- PVC pipes to American Standards for Various Application

‘Qur modal factory in Dammam industrial Estate is equipped with the

most advanced extrusion systeme available today and we are abie to

Supply complete UPVC, GPVG and HDPE pipalinas at relatively short

Notice for either new projects or additions to, or replacement of,

sedating pipe lines.

Wo are confident that pipe of our manufacture is especially suited to

the needs and environment of Saudi Arabia and the surrounding

Countries and are proud that SAPPCO by producing pipes locally is

‘contributing to the industrialisation of Saudi Arabia,

SAPPCO DAMMAM FACTORY was formed with manufacturing

‘capacity of 14000 Tons of pips products,

‘Our affliated company APLAGO In Riyadh manufactures UPVC and

CPC pipe fillings designed to standards for use with SAPPCO

pipes. The Comprehensive range of fittings is available fom our

factory stores.

Introduction

This Is a technical handbook for the engineers who designs and

Installs water and sewage pipelines and It contains tha most

up-to-date information now available, based on world wide know how

‘and technical knowledge,

‘The period of pioneering the use of UPVC pipes for the distribution of

water and sewerage is past and UPVC is widely established

throughout the world because of i's many advantages over other

materials.

High quality pipes are manufactured within a EN ISG 9001-2008

certified quality management system,

In addition to the Riyadh Plant SAPPCO have built a model factory in

[Dammam and equipped il with the most modem machinery available,

‘using many automated techniques a produce UPVC pipes to

exacting standards.

The socumulated knowledge of our Technical Advisors is freely

‘offered to engineers and our Technical Service Department is

available al all times to offer guidance and advice on the use of

‘SAPPCO UPVC pipes.

‘Consultants and Engineers are welcome to visit our offices, factory

‘and laboratory at the Dammam Industrial Estate, Dammam-Alkhobar,

Highway, for full discussions and to assure themselves that our

Production and testing facilities are of the highest order.

‘We also cater for the Telecommunication and Electrical Engineer with

‘the supply of UPVC conduits and Ducts, For any information please

‘contact our Technical Sales Engineers,

PROPERTIES

MATERIAL. : Unplasticised Polyvinyl Chloride (UPVC)

TABLE 1 : All values at 23°C unless otherwise specified

General Properties:

Density 1.42

Water absorption (boilingwater x 24h) <4

Poisson's Ratio 0.35 - 0.38

Friction Co-etficient, Hazzen William 150

Mechanical Properties:

Tensile strength ullimais >52

Modulus of Elasticity in tension 3180

Compressive strength 655

Floxural strangth 93

lzod Impact strangih 55-60

Hardness (Rockwell) 119

(Durometer) >7023

Thermal Properties:

Deflection temperature > 78

Vicat softening temperature >80

Co-efficient of linear Th-Expansion 0.08

Specific Heat 0.23

Thermal conductivity 0.15

Flammability Properties:

Flammatility (extinguishing) ‘Self extinguishing

Flammability (UL-94 rating) vo

Rate of buming 10

Extend of buming 315

Electrical Properties:

Dielectric Constant 4.00

Dielectric Strength 1100

Volume resistivity > 10%

manufacturer. It should be used as a general recommendation only and not as. guaranteo of

Note: 1.11; This data is based on information obtained from samples tested or provided by material

performance or longevity,

SAPPCO pipe is made from unplasticized Polyviny! Chioride UPVC

Materlal ‘Compound ‘uly mesting the requirements of the manulacwring

Classification ‘standards. SAPPCO UPVC Campound consist substantially UPVC resin

and to which only those additives are added which facilitate the

production of sound, durable and high quelity pipes fully conforming to

‘the requirements of all relevant manutacturing Standards.

EN ISO 12162 CLASSIFICATION PVC-U 250

EN ISO 12162 MIN, REQUIRED STRENGTH MRS, 25 MPa

‘ASTMD 1784 CELL CLASS 12454

PRI- USA DESIGNATION PVC'1120 (HDS 2000 psi)

Manufacturing SAPPCO manufacture UPVC pinos to ISO 161-1 Matric Sertes spocitios

Standards ‘the nominal outside diameters for conveyance of fluids in pressure and

ronpressure . It also species nominal pressure rating,

MAS and overall service (design) Coefficions for thermoplastic pipes far

pressure application. Table 3 describe the manufacturing standards,

SASO SAUDI ARABIA SSA 14, 15, 255

=a DIN 8062, 16873, 18875

E N EUROPIANS DIN EN 1328-41, 1401-1

BSEN 1320-4, 1401-1, 1482 (mperial)

Iso: INTERNATIONAL 's0 161-4,9693, 4495

SAPPCO PVC Pipe satisty the

requirements of DIN 8061 supp. 1

and ISO/TR 7473. Our pipe has

excellent chemical resistance to

strong acids and bases.

APPCO L

UPVC

sions

TABLE 4 : SAPPCO UPVC Pipe dimensions based on SSA 14, DIN 8062 and ISO 161-1

Norisal PN4 PNG PN 10 PN 16

outsioa

siameter | Nominal | Nominal | Nominal | Nominal | Nominal | Nominal | Nominal | Nominal

a ‘Wal | Weight | Wall | Weight | Wall | Weight | Wal | Weight

mm Kgim mim Kgim mm Kgim mm Kgim

16 12 0.090,

2 15 0.137

a 15 0.174 1.8 0212

32 18 0.264 ad 0.342

40 18 0.334 19 0.350" 30 0.525

# 18 ose | 24 | ose | 37 | 0.800

3 19 0.582 30 0.854 a7 1.29

aid 18 0.642 22 0.782 38 1.22 56 1.82

cy 18 o774 27 1.13 43 1.75 67 261

no 22 116 32 1.64 63 261 B82 3.00

125 25 148 a7 243 60 3.34 93 5.01

140 28 1.84 44 2.65 87 41a | 104 6.27

160 32 241 47 a4 WT ‘5.47 8 8.17

200 40 3.70 59 537 98 B51 149 128

45 4.70 66 67 | 108 tos | 187 16.41

49 5.65 73 ast nga 13.2 188 19.9

55 All 82 10.4 134 16.6 208 249

a5 62 8.02 a2 134 150 | 209 | 234 35

355 70 4 10.4 16.7 169 265 283 30.9

400 Ta 145 WT at m1 B7 237 50.8

450 aa 188 w2 | 2a | 215 | 427 : :

‘500 38 224 14.6 ne 23.9 526 - -

560 1.0 28.1 164 aA 26.7 5B x ies

620 4 | 357 wea | 322 | 300 | o92 : :

710 14.0 453 20.7 66.1 - > - -

Notes : 4.1 : Nominal pressure (PN) in BAR, Nominal outside diameter and nominal wall thickness are

based on overall service (design) Coefficient of C 2.5

4.2 : Shaded sizes are only manufactured on special request.

43:1 BAR = 0,1 MPa = 0,1Nimm? = 100 kPa = 14.5 psi = 1,02 kg/om? = 0,987 alm = 10 meterhead water

44:1 metor.m= 39:97 in = 3.281 ft = 100 6m = 1000 mm = 1.094 yd = 0.001 km

4,5: Colour : Grey

Pressure SAPPCO'DAMMAM UPVC pipe is produced from specific pipe grade suspension

PVC homopolymer and only recommenced additives are added ta give optimize

Pipes for Potable processing and generate desirable physical charateriaieain the pipe.

Water Supply

‘Table 5 shows the range of UPVC pipes of two different pressure ratings 10 Bar

‘and 18 Bar Jor potable waler supply, iigalion or for any ather under-pressure

sgyatam. The pressure ratings indicated are the cantinuaus working pressures at

20°C temperature for portable water,

Nominal

Outside 10 | 20 | 25 | s2 | 40 | 50 | 03 | 75 | oo | 110] 140 | 100 | 225 | 200 | 315

Diameter, re

Class 4 (10 Bar)

Norainal wall - | - | 15] 1e] 19} 26] a0] a6 as | ss] a7 | rr | to8| 134 | 150

‘Thickness, men

Claas 5 (16.80)

Norninal Wail 12) 15 | 18) 24) 30) 57) 47) 56) 7 | B2 | 104) 18 | 167 | 208 | 234

‘Thickness, mm

\Notes ; 5.1 ; Nominal Pressure and wall thickness are based on Cefficient °C" 2.5

5.2; Colour : Grey

5.2 : Specify joint, Rubber seal or solvent weld whan ordering.

EFFECT OF UPVC pipe is culate for water application upia 80°C (140°F) and relationship between recommended

ELEVATED ‘magnum working pressures and verious temperatures for plpes to ISO and DIN Standerda ks given in

TEMPERATURE Table 6.

SSA 4 Giese 2 3 4 5

DIN 8062 ‘Saries: 2 3 4 5

so | nee Saries 20 107 10 as

EN 1452 ‘Sores: - 167 10 a3

SDR CLASSIFICATION ‘SDR 51 ‘SDR 34 ‘SDR 2 SDR 135

(Notes : 7-1 : Classification is according to diferent standards based on metic aystems dimensions

72 : Comparisons in rotation to design Coefficient of C = 2.5

7-2 : Standard Dimension Ratio “SDR = Outside dia / wall thickness

Pipes for Soil, Table 8 shows the range of UPVC pipes intwo types.- Type Band Type BD for soll,

Waste discharge ‘waste discharge inside the buildings; Type BD Is particularly sued for maximum

in buildi service ite with inteminsnt domestic hat and cold water discharge tor inside

with ing buildings and buried within the building structure

1320-1 Identical to BS EN 1829-1 and DIN EN 1329-1

1928-1 replaces DIN 19631, BS 4514

‘Type "3" used for inside building

‘Type "BD" used for inside builing and buried in ground within building siwature

DNWOD : nominal size to outside ameter related,

our Grey

Pipe for Table § shows the range of UPVC pipes for below graund drainage and sewerage.

underground ‘SDR 34 (GN 8) being suiled for maximum service lf fr the area. under and within

‘one meter irom the building where pipes and fitings are butied in ground and are

Drainage and connected tn the soil and waste discharge systom and SOR 41 (SN 4)4or the area

Sewerage more than one meter away ftom the bulldhng.

DN OD wma | 125 | 140 | 160 | zon | 250 | 315 | s55 | 400 | asa | 500 | goo | 710

‘SDR 41 (SN 4)

‘Nominal Wl sz |a2|35 | 40 | 49 | 2 | 77 | 87 | 98 | 110 | 125 | 154 | 178

‘Nominal Wall a2 |ar |4i | a7 | 69 | 79 | 92 | 104) 17 | 192] 140/184] -

Notes : 8.1 : EN 1401-1 identical to BS EN 1401-1 and DIN EN 1401-1

replaces DIN 19597, BS 4960, BS S481

N, ring setness of pipes expressed in KN”

‘8.4: Sims groator than 400 mm aro only manufactured on special raquest

19.5 : DN/OD nominal size wo qulside diametor relat,

ie 18.6 : Golour, Grey or Golden Brown. Picase spocty colour when orcering.

Hot water

Surface Temperature due

to discharge of hot water

‘Theoretically pipes and fitings made irom UPVC are unsuitable for use

with very hol water and this is true for continuous flow al full bore.

Hovaver, planeoring work carried out in Groat Britain astablishad dosign

crteria that became adopted into thelr national standards. From tis

acceptance of UPVC:drainage system, the Market grew unt itnow has far

‘greater sales and use than any other above ground system and is

rapidly following the same trend with below ground drains and sewers.

‘The design criteria was verfied and tested by development of a Hot &

Cold Cycie Test and iis principles have been adopted by many other

National Standards Organisations, ISO, Goverimant and Private Test

Establishments,

‘The work camiad out on UPVC drainage pipe work producsd the Yolowing

design crftorta:

1. UPVC has natural insulating properties.

2. Each increment of wall thhokness has is own insulating value thus the

thicker the pipe the less transfer of heat through the wallthickness, So

‘constant water flawing at 90°C will only produce a surface temperature

1f €0°C an the outside suriace of a pipe with wall thickness 3.2 mm

(Soa Fig. 2).

&. A discharge of short period for about 20-30 minutes will be neceszary

{or the above ranster at heat to ocour.

4, Tho sattening point af UPVG plays an important role in the above

situation.

Although the temperature ol the Inside wall of the pipe has exceeded the

softening point, the extemal surteos tamporature Is weil bolow. Thus the

pipe and fitings remain rigid and able to resist loadings imposed by

‘expansion, contraction and soll pressures in the case of buried drains.

‘Aiso, normal discharges, {rom the most powerful washing machines and

domestic appliances will not harm UPVC Drainage Systems.

‘Simitar tests have been devised for below ground applications, but using &

lower discharge temperature to ensure that below ground drainage also

mots the samo service life expectancy,

Fig2

‘The Combination of ganarous wal thcknaas

snd igh eoflaing peintprevides cafe Binite

{or mazcmum sere Ie,

‘Enema Surtees,

Aeriporatare not

‘exceeding 80°C.

Electrical and ‘Table. 10 shows the UPVC pipes of different gauges - medium and

Telecommunication heavy gauge for use es electrical and telecommunication condults,

For consideration of pipes of other cimensions our Technical Sales

Cable Condult Department may bs consulted.

NOTES ; 10.1 : S8A256 Spectios mogium gaupe pipes upto 32mm

10.2: Nominal outsida ciamater 38 mm is customers spoctiog

10.3 : Colour; Groy or black, othor colors on request

104; Spoaty clase tice MG or HG of Condit wrile ordering

Cable duct pipes for Table 11 shows the range of UPVC pipes for use as underground electrical and

Telecommunications telecommunication cable ducts inciuding those passing underneath the

roads-direct buried (DB) or encasement buried (EB). For consideration of pipes of

and Electrical Power ier danensions ou Teivical Sales Departnent ay be coneuted.

NOTES: 11.1 :*Pipa contorm to SEC specification 23 - SMS -1

‘and Swu

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Process Control Manifolds PDFDocument189 pagesProcess Control Manifolds PDFalfreddieick1No ratings yet

- Statiflo Brochure - EN-GBDocument12 pagesStatiflo Brochure - EN-GBalfreddieick1No ratings yet

- Temporary Strainers - DaidoDocument1 pageTemporary Strainers - Daidoalfreddieick1No ratings yet

- Protek Flange Protection 211108Document2 pagesProtek Flange Protection 211108alfreddieick1No ratings yet

- GreenDrain - Spec SheetDocument2 pagesGreenDrain - Spec Sheetalfreddieick1No ratings yet

- Tee Type StrainersDocument2 pagesTee Type StrainersFederico De MartiniNo ratings yet

- Techlok Product Range A4 V003 2014Document4 pagesTechlok Product Range A4 V003 2014alfreddieick1No ratings yet

- Aluminum-n-Stainless Steel Gauge ChartDocument1 pageAluminum-n-Stainless Steel Gauge Chartalfreddieick1No ratings yet

- Heavy Hex Nuts Dimensions Weight Imperial - MetricDocument2 pagesHeavy Hex Nuts Dimensions Weight Imperial - MetricAkshay PoddarNo ratings yet

- Polyisocyanurate InsulationDocument2 pagesPolyisocyanurate Insulationalfreddieick1No ratings yet

- 9 Stang Catalog Deluge PDFDocument2 pages9 Stang Catalog Deluge PDFalfreddieick1No ratings yet

- Cesmm Rev 9Document209 pagesCesmm Rev 9antscarNo ratings yet

- Bumpers Pipe SupportsDocument1 pageBumpers Pipe Supportsalfreddieick1No ratings yet

- Pipe Bending (BillP)Document5 pagesPipe Bending (BillP)ehsnakaliaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)