Professional Documents

Culture Documents

Sop Cryogens

Uploaded by

Sandeep ShettyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop Cryogens

Uploaded by

Sandeep ShettyCopyright:

Available Formats

Standard Operating Procedure for Laboratory

Processes

A Standard Operating Procedure (SOP) is a written set of instructions that document how to safely

perform work involving hazardous materials or hazardous operations. An SOP should be written for all

procedures that pose an identified potential risk to the health and safety of the laboratory personnel.

Print out the completed form and keep a readily accessible hard copy in the lab (also keeping an

electronic copy is highly recommended).

NOTE: For all procedures utilizing energetic, highly hazardous or toxic, pyrophoric, air/water

reactive, or novel research materials or methods, multiple sources must be consulted and noted

for information about potential hazards/toxicity other than the SDS and published procedures.

Examples: Bretherick’s , ToxNet’s Hazardous Substance Data Bank, etc.

Chemical Name or Process: Handling of liquid nitrogen

Cryogenic fluids are liquids that exist at a very low temperature (below −150 °C). Common examples of cryogenic

liquids are liquid nitrogen and helium. These fluids are used as coolants for various instruments and experiments.

Purpose: This standard operating procedure (SOP) is intended to provide general guidance on how to safely

work with liquid nitrogen.

Potential Hazards/Toxicity:

Nitrogen and Helium are not toxic, but are simple asphyxiates.

Cryogenic fluids are materials with extremely low boiling points (i.e., less than – 150 °F). At these temperatures,

tissue burns may be sustained after contact with the fluids, surfaces cooled by the fluids, or by evolving gases.

The hazard is comparable to that of handling boiling water.

One special property of cryogenic liquids is that they undergo substantial volume expansion when converted to a

gas phase, which can potentially lead to an oxygen deficient atmosphere where ventilation is limited.

Engineering Controls:

Use cryogenic fluids only in well-ventilated areas. Unconsciousness occurs without warning in an oxygen

deficient atmosphere.

Neither nitrogen nor helium gas is toxic, but if too much oxygen is displaced by these gases, the danger of

asphyxiation is very real! These gases expand their volumes by a factor of ~700 when they are evaporated and

allowed to warm up to room temperature.

California Polytechnic University, San Luis Obispo, CA 1

Personal Protective Equipment (PPE)-

Hand Protection:

Wear thermally protective gloves when working with cryogenic liquids. Gloves must be inspected prior to use.

NOTE: Consult with your preferred glove manufacturer, the (M)SDS and other sources to ensure that the gloves

you plan on using are compatible with chemical(s) being used.

Refer to glove selection chart from the links below:

http://www.ansellpro.com/download/Ansell_8thEditionChemicalResistanceGuide.pdf

OR

http://www.allsafetyproducts.biz/page/74172

OR

http://www.showabestglove.com/site/default.aspx

OR

http://www.mapaglove.com/

Eye Protection :

Safety glasses or chemical splash goggles, as directed by advisor/P.I. Goggles are required whenever there is a

potential for a hazardous liquid splash, as per the Chemical Hygiene Plan Sec 3.1.b

Skin and Body Protection:

Long pants, lab coat, and closed toed shoes should be worn when working with cryogenic fluids. Never allow any

unprotected part of the body to touch non insulated pipes or vessels which contain cryogenic fluids. The

extremely cold metal will cause the flesh to stick fast and tear when one attempts to withdraw from it. Frostbite is

likely to occur.

Hygiene Measures:

Wash hands after working with the hazardous substances and when leaving the lab/shop.

Respirators may be required under any of the following circumstances:

• As a last line of defense (i.e., after engineering and administrative controls have been exhausted).

• When Permissible Exposure Limit (PEL) will or may be exceeded, or the airborne concentration is

unknown.

• Regulations require the use of a respirator.

• There is potential for harmful exposure due to an atmospheric contaminant (in the absence of PEL)

• As PPE in the event of a chemical spill clean-up process

Prior to obtaining a respirator, an exposure assessment of the process or procedure must be conducted. If

respiratory protection is required, then lab personnel must obtain respiratory protection training, a medical

evaluation, and a respirator fit test through EH&S. This is a regulatory requirement.

First Aid Procedures for Chemical Exposures

If inhaled:

Persons suffering from lack of oxygen should be moved to fresh air. If victim is not breathing, administer artificial

respiration. If breathing is difficult, administer oxygen. Get medical attention immediately.

California Polytechnic University, San Luis Obispo, CA 2

In case of skin contact:

Remove any clothing that may restrict circulation to frozen area. Do not rub frozen parts as tissue damage may

result. As soon as practical, place the affected area in a warm water bath which has a temperature not to exceed

105°F (40°C). Never use dry heat. Call a physician as soon as possible

In case of eye contact:

Flush the eyes with cool or warm water for fifteen minutes (do not use hot or cold water). Get medical attention

immediately.

Special Handling and Storage Requirements

Liquid nitrogen is under pressure. Store and transport cryogenic fluids only in Dewars or cryogenic liquid

cylinders designed for that particular cryogen. Cryogenic liquid dewars are to be stored in well-ventilated areas

with the pressure relief valve in the opened position. Dispense of cryogenics in a well-ventilated area.

Spill and Accident Procedure

Chemical Spill Dial 911 and 756-6661

Spill – Assess the extent of danger. Evacuate the spill area. Help contaminated or injured persons. . Avoid

breathing vapors. If safe, confine the spill to a small area. Keep others from entering contaminated area (e.g.,

use caution tape, barriers, etc.).

Small (<1 L) – If you have training, you may assist in the clean-up effort. Small amounts of liquid nitrogen will

evaporate quickly. Open doors, windows and let fresh air into the room. Use appropriate personal protective

equipment and wait for complete evaporation.

Large (>1 L) – Evacuate spill area. Dial 911 and EH&S at 756-6661 for assistance. Remain available in a safe,

nearby location for emergency personnel.

Medical Emergency Dial 911 or 756-6661

Life Threatening Emergency, After Hours, Weekends And Holidays – Dial 911

Note: All serious injuries must be reported to Supervisor/PI within 8 hours. Note: Any and all loss of consciousness

requires a 911 call

Non-Life Threatening Emergency –

• Students: Seek medical attention at the campus Health Center M, T, Thu, Fr 8:00 am – 4:30 pm and W

9:00 am – 4:30 pm

• Emergency Medical services in the community are available at any time at hospital emergency rooms and

some emergency care facilities.

California Polytechnic University, San Luis Obispo, CA 3

All injuries must be reported to PI/Supervisor immediately and follow campus injury reporting. Follow

procedures for reporting of student, visitor injury on the EH&S website at:

http://afd.calpoly.edu/riskmgmt/incidentreporting.asp

• Paid staff, students, faculty: seek initial medical attention for all non-life threatening injuries at:

MED STOP, 283 Madonna Road, Suite B (next to See's Candy in Madonna Plaza)

(805) 549-8880 Hours: M-F 8a - 8p; Sat/Sun 8a - 4p

After MED Stop Hours: Sierra Vista Hospital Emergency Room

1010 Murray Avenue (805) 546-7651, Open 24 hours

All injuries must be reported to PI/Supervisor immediately and follow campus injury reporting for

employee injuries (Workmen’s Comp.). Follow procedures on the EH&S website at:

http://afd.calpoly.edu/riskmgmt/incidentreporting.asp

Decontamination/Waste Disposal Procedure

For contact and inhalation exposure, see First Aid Measures above. Return container and unused product to

supplier. Do not attempt to dispose of unused product.

Safety Data Sheet (SDS) Location

Online SDS can be accessed at: http://siri.org/msds/index.php

or MSDSOnline at: http://hq.msdsonline.com/csuedusl/Search/Default.aspx

Protocol/Procedure:

1. Dispensing liquid nitrogen from 160 liter tank or big tank into individual dewars.

a. Dispense in an area with adequate ventilation.

b. Fill hose and diffuser must be connected to the port labeled “liquid” on the big tank. Do not connect to the

port labeled “vent”.

c. Place receiving dewar in a secure location.

d. Open valve for the liquid port on big tank. Wear thermal gloves while holding the fill hose to direct liquid

into dewar.

e. Contents of the big tank are under pressure. Open valve slowing at first while holding the fill hose.

f. Close valve on the big tank completely when small dewar is full.

g. Use only a loose fitting lid to cover the small dewar otherwise pressure will build inside the container.

2. Dispensing liquid nitrogen from big tank into smaller pressurized dewars.

a. Open the door to the loading dock to provide adequate ventilation.

b. Vent all pressure from the small dewar by opening the pressure vent valve and/or opening the dispensing

valve on the dewar’s top assembly.

c. Pressure gauge will read zero when all pressure is relieved.

d. With the leash still secured, turn the bar counter clockwise to releases the top assembly from the dewar.

California Polytechnic University, San Luis Obispo, CA 4

e. Once the top assembly is disengaged from the top of the dewar, the leash can be removed.

f. Set top assembly aside. Top assembly may be cold. Use thermal glove if necessary.

g. Fill hose and diffuser must be connected to the port labeled “liquid” on the big tank. Do not connect to the

port labeled “vent”.

h. Place receiving dewar in a secure location.

i. Open valve for the liquid port on big tank. Wear thermal gloves while holding the fill hose to direct liquid

into dewar.

j. Contents of the big tank are under pressure. Open valve slowing at first while holding the fill hose.

k. Close valve on the big tank completely when small dewar is full.

l. Place top assembly in dewar and secure the leash before proceeding.

m. Hold the top assembly securely in place while turning the bar in clockwise direction.

n. Be sure top assembly is secure. Reposition and retighten if necessary.

o. Close pressure vent valve and/or dispensing valve.

p. It will take 20 to 30 minutes for the pressure to build up enough for the small dewar to dispense.

Top Assembly of Small Pressurized Dewar

Dispensing Valve

Fill Hose

Pressure Vent Valve

Pressure Gauge

Bar Leash

Dewar

3. Handling of cryogenic liquids in dewars for use in laboratory procedure

a. Always use only dewars designed to hold cryogenic liquids in the laboratory

b. Do not cap or cover the dewar tightly

c. Caution must be used when transporting dewars in the lab, wear thermal gloves and avoid spilling

d. Do not leave openings to cold dewars wide open to the atmosphere for any longer than is absolutely

necessary for the manipulations required for transferring liquids. The temperature of liquid nitrogen at

atmospheric pressure is -196°C and of liquid helium is -269°C. Air (and its contents) will condense into

the dewar and can cause blockages that are potentially dangerous and that will almost certainly interfere

with some aspect of the liquid transfer or with the operation of the instrument in the long run. The

freezing point of liquid oxygen is -183°C, i.e., above that of these cryogenic fluids. The collection of liquid

oxygen into these colder liquids is an explosion hazard!

e. Do not attempt to dispose of remaining cryogenic liquid. Return unused liquid in a dewar to the

stockroom.

California Polytechnic University, San Luis Obispo, CA 5

Large 160 lb Nitrogen Dewar

Vent Valve

Fill Hose

Diffuser

NOTE:

Any deviation from this SOP requires approval from PI.

Date: P.I. or Supervisor:

California Polytechnic University, San Luis Obispo, CA 6

Documentation of Training (signature of all users is required)

• The Principal Investigator must ensure that his/her laboratory personnel have attended appropriate

laboratory safety training or refresher training within the last one year.

• Training must be administered by PI or Lab Manager to all personnel in lab prior to start

of work with particularly hazardous substance or newly synthetic chemical listed in the

SOP.

• Refresher training will need to be provided when there is a change to the work

procedure, an accident occurs, or repeat non-compliance.

I have read and understand the content, requirements, and responsibilities of this SOP:

Name Signature Date

California Polytechnic University, San Luis Obispo, CA 7

California Polytechnic University, San Luis Obispo, CA 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Atsc Final Cheat Sheet PDFDocument2 pagesAtsc Final Cheat Sheet PDFManan Shah100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Astm D5084 PDFDocument24 pagesAstm D5084 PDFTatiana ChitivaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SOP Medicine 06v3 Liquid NitrogenDocument5 pagesSOP Medicine 06v3 Liquid NitrogenSandeep ShettyNo ratings yet

- Liq Nitro Sop ChemDocument3 pagesLiq Nitro Sop ChemSandeep ShettyNo ratings yet

- SOP LNFillStationDocument7 pagesSOP LNFillStationSandeep ShettyNo ratings yet

- SOP19 Safe Handling of Liquid NitrogenDocument10 pagesSOP19 Safe Handling of Liquid NitrogenSandeep ShettyNo ratings yet

- Cryogenic Liquids SOPDocument3 pagesCryogenic Liquids SOPSandeep ShettyNo ratings yet

- Liquid Nitrogen ProcedureDocument3 pagesLiquid Nitrogen ProcedureSandeep ShettyNo ratings yet

- SOP-Handling Cryogenic FluidsDocument4 pagesSOP-Handling Cryogenic FluidsSandeep ShettyNo ratings yet

- SOP-51 Safe Handling of LPGDocument3 pagesSOP-51 Safe Handling of LPGSandeep ShettyNo ratings yet

- General Use SOP For Cryogenic LiquidsDocument2 pagesGeneral Use SOP For Cryogenic LiquidsSandeep ShettyNo ratings yet

- Liquid Nitrogen SopDocument3 pagesLiquid Nitrogen SopSandeep ShettyNo ratings yet

- Safe Operating Procedure: (Revised 7/09) Liquified Petroleum Gas (LPG) Portable CylindersDocument2 pagesSafe Operating Procedure: (Revised 7/09) Liquified Petroleum Gas (LPG) Portable CylindersSandeep ShettyNo ratings yet

- SC-01 Safety Code On Storage, Handling & Use of Gas CylindersDocument8 pagesSC-01 Safety Code On Storage, Handling & Use of Gas CylindersSandeep ShettyNo ratings yet

- Protocol Posters SC CHCDocument16 pagesProtocol Posters SC CHCSandeep ShettyNo ratings yet

- Thought Channelizing During COVID PosterDocument1 pageThought Channelizing During COVID PosterSandeep ShettyNo ratings yet

- Training Resources For Covid 19 Management: Ory - HTTPS://WWW - Mohfw.Gov - In/Pdf/5Covidflw Trainingplan27March - PDFPDFDocument4 pagesTraining Resources For Covid 19 Management: Ory - HTTPS://WWW - Mohfw.Gov - In/Pdf/5Covidflw Trainingplan27March - PDFPDFSandeep ShettyNo ratings yet

- Government of Karnataka: Department of Health and Family Welfare Office, District Surveillance UnitDocument1 pageGovernment of Karnataka: Department of Health and Family Welfare Office, District Surveillance UnitSandeep ShettyNo ratings yet

- Notes Science Form 1Document12 pagesNotes Science Form 1Aimi Nadia YusofNo ratings yet

- Phosphorene As A Superior Gas Sensor DFT Coupled With NEGF StudyDocument21 pagesPhosphorene As A Superior Gas Sensor DFT Coupled With NEGF Study王孟謙No ratings yet

- I. Choose The Best Answer To The Following Questions!Document8 pagesI. Choose The Best Answer To The Following Questions!Rudi Hendra GunawanNo ratings yet

- Revision Notes - Unit 2 AQA Physics A-LevelDocument12 pagesRevision Notes - Unit 2 AQA Physics A-LevelElliot ThomasNo ratings yet

- Rocks & Energy Chapter 1 & 2 Environmental Management 0680 Geography GCSE IGCSE O-LevelsDocument108 pagesRocks & Energy Chapter 1 & 2 Environmental Management 0680 Geography GCSE IGCSE O-LevelsIGCSE Physics & Chemistry100% (1)

- Kurva Tegangan Dan Regangan: Strain (%)Document8 pagesKurva Tegangan Dan Regangan: Strain (%)Anna DestNo ratings yet

- Concept: Subject-General ScienceDocument2 pagesConcept: Subject-General SciencetrevorNo ratings yet

- Combustion: Luminous Gas Flame Flame Front Luminous Non-LuminousDocument18 pagesCombustion: Luminous Gas Flame Flame Front Luminous Non-LuminousMd. Ahsanur RahmanNo ratings yet

- Biogeography & EvolutionDocument11 pagesBiogeography & EvolutionDaniel Berry100% (1)

- MCQ On Smart GridDocument4 pagesMCQ On Smart GridJoshi RohitNo ratings yet

- WeCommunities - BrochureDocument6 pagesWeCommunities - BrochurejayanthfunucationNo ratings yet

- 1500 Words EssayDocument5 pages1500 Words EssayVaishnavi ShandilyaNo ratings yet

- Protok Realnog Fluida-3Document34 pagesProtok Realnog Fluida-3konticvNo ratings yet

- Lecture Note On Photon Interection An Cross SectionDocument21 pagesLecture Note On Photon Interection An Cross SectionpankajNo ratings yet

- E8. SBT HK2 (HS) PDFDocument82 pagesE8. SBT HK2 (HS) PDFBùi Thị Doan HằngNo ratings yet

- Competency 10Document20 pagesCompetency 10Charis RebanalNo ratings yet

- The Shepherd of Banbury's Rules To Judge of The Changes of The Weather, Grounded On Forty Years' Experience by Claridge, JohnDocument30 pagesThe Shepherd of Banbury's Rules To Judge of The Changes of The Weather, Grounded On Forty Years' Experience by Claridge, JohnGutenberg.org100% (1)

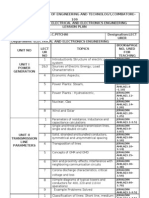

- Ee2303 Newlp ADocument3 pagesEe2303 Newlp ARavi KannappanNo ratings yet

- Mold Advance Course BookDocument121 pagesMold Advance Course Bookshahzad afzal100% (6)

- Chapter 5 Thermodynamic First LawDocument37 pagesChapter 5 Thermodynamic First LawAfiq ZikriNo ratings yet

- Steam Circuit Diagram PDFDocument1 pageSteam Circuit Diagram PDFAgeng Firstyan BagaskoroNo ratings yet

- Photovoltaic CellsDocument8 pagesPhotovoltaic CellsridNo ratings yet

- Variable Speed DrivesDocument9 pagesVariable Speed DrivesEmmanuelNo ratings yet

- IAS Mains Geology Papers 1997: ExamraceDocument3 pagesIAS Mains Geology Papers 1997: ExamraceD DNo ratings yet

- Standard Spreadsheet For Batch ColumnDocument14 pagesStandard Spreadsheet For Batch ColumnBagadi AvinashNo ratings yet

- Engineering Geology: Katsuo Sasahara, Naoki SakaiDocument9 pagesEngineering Geology: Katsuo Sasahara, Naoki SakaiRehan HakroNo ratings yet

- R134a TableDocument5 pagesR134a TableAhmed Mahmoud AbouzaidNo ratings yet