Professional Documents

Culture Documents

Image006 PDF

Image006 PDF

Uploaded by

Vinay K0 ratings0% found this document useful (0 votes)

18 views1 pageOriginal Title

image006.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageImage006 PDF

Image006 PDF

Uploaded by

Vinay KCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

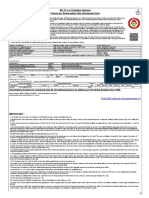

swe va 4as-2011

elements or parallel surfaces, each of which as

associated with a directly toleranced dimension.

3.2.1 Flked Umit Gage

{five limit gage: a device of defined form and

size used fo assess the conformance of a feature(s) of a

‘workplace toa dimenstonal specification, Also referred

to asa “Uumut page.”

3.22 Fieure

(flsture:a device used to hold pants securely in the correct

[position in.a too! or gage during manufscturing, assem-

bly, or inspection.

3.2.3 Functional Foture

{fiorcimalfixture-a device having integral gage elements

that make physical contact with pare datum features.

Ik typically holds pans as they would be held when

assembled. The fixture and its page elements

simulated datum features from the part and are ident

fled on drawings using techniques found in

ASME YI45.

3.2.4 Functional Gage

Jfionctional gage: a fed limut gage used to verify virwal

‘condition boundanies (MMC concept) generated by the

collective effect ofthe feature's MMC and the applicable

‘geometric tolerance at the MMIC size

3.2.15 Gage Hement

gage clement: a physical feature of the gage used in the

‘ventfication of workpiace compliance to the associated

tolerance requirement. These physical features represent

datum feature simulators, vietual condition, or datum

material boundaries.

3.2.16 GO Gage

GO gage: fixed limit gage that checks a feature of size

for acceptance within MMC perfect form boundary

3.2.17 Least Material Boundary (LMB)

(ASME ¥14.5-2009)

{east meteia! bouradary (LIVE): the Himut defined by a toles-

ance or combination of tolerances that existson or inside

the material of a feature).

3.2.48 Least Material Condition (LMC)

{east aaterial condition (LMC): the condition in which a

feature of size contains the least amount of matertal

‘within the stated limits of size (eg, maximum hole

diameter, munimum shaft diameter).

3.2.19 Maximum Material Boundary (MMB)

(ASME ¥14.5-2009)

‘marci mantria! boundary (MMB! the limit defined by

2 tolerance or combination of tolerances that exists on

‘or outside the material of a feats)

NOTE: “Toealeulnte the approprite MAMI fr datum featur sm

slnen,sco ASME VIS 3008, ig 4 Iéand par. 11 Sand 4116,

Licensed to vinayksk041.

3

3.2.20 Maximum Material Condition (MMO,

maximum material condition (MMC): the condition i

‘which a feature of size contains the maximusn amount

of material within the stated limits of size (e.g, mini-

‘mum hole diameter, maximum shaft diameter)

32.21 NOGO Gage

NOGO gage: a fixed Umut gage that checks a feature of

size for Violation of the LMC actual local size. This gage

fs also roferrad to as a "NOT GO gage”

3.2.22 Regardless of Feature Size (RFS)

‘regardless of feature sive (RFS): indicates that 2 geometric

tolerance applies at any increment of size of the actual

‘mating envelope of the feature of siza,

3.2.23 Regardless of Material Boundary (RMB)

(ASME Y14.5-2009)

repordless of materia! toundary (RMB}: indicates that a

datum feature stimulator progresses from MMB toward

(LM until it makes maxianum contact with the extremi-

ties of a feature(s)

32.24 Resuttant Condition

3.2.24.1 Resultant Condition (ASME ¥14.5-2005)

resultant condition: the single worst-casel ‘gener

ated by the collective effects of a feature of sizes speci-

fied MMC or LMC, the tolerance for that

‘material condition, thestze tolerance, and the additional

‘geometric tolerance derived from the feature’sdoparture

from ls specified material condition.

3.2:24.2 Resultant Condition

Y20,5M-1994)

resultant condition: the variable boundary generated by

the collective effects of a stze Features § MMC

‘or LMC, the geometsc tolerance for that material cond!

tion, the size tolerance, and the additional

tolerance derived from the feature’s departure from is

specified material condition.

32.25 Separate Gaging Requirement

separate gaging requiem: the condition in which faa-

tures of pattems of features that are located from a

common datum reference frame do not need to be

inspected together (this does nat affect the within-

allem requirement). If simultaneous gaging is not

required, the abbreviation “SEP REQ” ts placed under

the feature control frame. See simultancous gaging

reyatrement,

32.26 Simultaneous Gaging Requirement

simultaneous gaging requirement: the condition ta which

all ofthe features or pattems of features that are located

from a common datum reference frame are inspected

together as a single pattem relative to that common

(ASME

Last opened 4/30/20. Single user icense-only. Copying and networking prohibited

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lottery of BirthDocument1 pageLottery of BirthVinay KNo ratings yet

- University of GreenwichDocument9 pagesUniversity of GreenwichVinay KNo ratings yet

- Provence Alpes Côte D'azurDocument12 pagesProvence Alpes Côte D'azurVinay KNo ratings yet

- Eiffel Tower NewDocument24 pagesEiffel Tower NewVinay KNo ratings yet

- Chrysler BuildingDocument35 pagesChrysler BuildingVinay KNo ratings yet

- Shiva Aparadha Kshamapana StotramDocument3 pagesShiva Aparadha Kshamapana StotramVinay KNo ratings yet

- Data ExchangeDocument218 pagesData ExchangeVinay KNo ratings yet

- Art, Commonly Known As Cooper UnionDocument18 pagesArt, Commonly Known As Cooper UnionVinay KNo ratings yet

- Job Description: We Are An Equal Opportunities EmployerDocument1 pageJob Description: We Are An Equal Opportunities EmployerVinay KNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Vinay KNo ratings yet