Professional Documents

Culture Documents

Processing Belts E-5EXCT-S1: Wood Surfacing, Leather Inspection/control Belt, Scanning Belt Low Reflection Surface

Uploaded by

agusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Processing Belts E-5EXCT-S1: Wood Surfacing, Leather Inspection/control Belt, Scanning Belt Low Reflection Surface

Uploaded by

agusCopyright:

Available Formats

Processing Belts

E-5EXCT-S1

Main industry segments

Wood surfacing, Leather

Applications

Inspection/control belt, Scanning belt

Special features

Low reflection surface

Product Construction / Design

Conveying side material Thermoplastic polyurethane (TPU)

Conveying side surface Super matt finish

Conveying side property Medium-adhesive

Conveying side color Cobalt blue

Traction layer (material) Polyester (PET)

Number of Fabrics 2

Pulley side material Polyester (PET)

Pulley side surface Impregnated fabric

Pulley side property Non-adhesive

Pulley side color White

Product characteristics

Antistatically equipped Yes

Adhesive free joining method Yes

Flammability No specific flammability prevention property

Food suitability, FDA conformance Yes - acc. to 21CFR parts 170 - 199. Details/restrictions see

Habasit food compliance declaration.

Food suitability, EU conformance Yes - acc. to Regulation (EC) No. 1935/2004 as well as

Regulation (EU) No. 10/2011 and/or other relevant food contact

legislation. Details/restrictions see Habasit food compliance

declaration.

Product Data Sheet (Released) 24.08.2018

Processing Belts

E-5EXCT-S1

Technical data

Thickness of belt 1.45 mm 0.06 inch

Mass of belt (belt weight) 1.6 kg/m² 0.328 lb/sqft

Tensile force for 1% elongation (k1% static) per unit of width 9.0 N/mm 51 lbf/in

(Habasit standard SOP3-155)

Tensile force for 1% elongation after relaxation (k1% relaxed) 6.5 N/mm 37 lbf/in

per unit of width (Habasit Standard SOP3-155 / EN ISO 21181)

Min. operating temperature admissible (continuous) -30 °C -22 °F

Max. operating temperature admissible (continuous) 80 °C 176 °F

Coefficient of friction (running side / steel driving pulley) 0.15 -

Coefficient of friction (running side / driving pulley with friction 0.35 -

cover)

Coefficient of friction (running side / pickled steel slider bed) 0.20 -

Coefficient of friction (running side / phenolic resin slider bed) 0.20 -

Coefficient of friction (running side / stainless steel slider bed) 0.20 -

Seamless manufacturing width 4000 mm 157 inch

Joining related properties

Joining method

Flexproof 20 x 80 Master joining method for standard applications

Flexproof 10 x 80 Master joining method for nosebar / high stress applications

Thermofix Optional joining method

Link to JDS:

Joining method Flexproof Flexproof Thermofix

20 x 80 10 x 80

Nosebar radius (minimum) mm 4

inch 0.157

Pulley diameter (minimum) mm 15 15

inch 0.59 0.59

Pulley diameter minimum with mm 25 25

counter flection inch 0.98 0.98

Admissible tensile force per unit N/mm 13 15

of width lbf/in 74 86

Admissible tensile force per unit N/mm 5.5 8.0

of width at max. operating lbf/in 31 46

temperature

Slider bed suitable Yes Yes Yes

Carrying rollers suitable Yes Yes Yes

Troughed installation suitable No No No

Power turns / curved installations No No No

Nosebar suitable No Yes

Low noise applications No No No

Metal detector suitable Yes Yes Yes

All data are approximate values under standard climatic conditions: 23°C/73°F, 50% relative humidity (DIN 50005/ISO 554).

Product Data Sheet (Released) 24.08.2018

Processing Belts

E-5EXCT-S1

Chemical resistance

Link to 'Chemical resistance information': http://www.habasit.com/en/chemical-resistance.htm

Mode of use or conveyance

Horizontal, Inclined

Calculations

For most applications calculation is not required. Should you still need a calculation: please ask Habasit.

Recommendation

Do not go below initial elongation (epsilon) ~ 0.3%, Install the slack belt and tension until running perfectly under

the full belt load

For details consult 'Storage and handling requirements for belts and machine tapes' or contact Habasit, Protect

belts from sunlight/UV-radiation/dust and dirt. Store spare belts in a cool and dry place and if possible in their

original packaging.

If High Frequency (HF) system is used check belt heating, Not suitable for wet operations combined with increased

temperatures and with extreme greasy and oily conditions, This product has not been tested according to ATEX

standards (atmospheres with explosion risk - ATEX 95 regulation or EU directive 2014/34/EU) and therefore is

subject to user’s analysis in the respective environment, Use cleaning agent as prescribed by the machine or

cleaning agent manufacturer

Group Various Special Belts

Sub-Group -

Item number H800007971

Disclaimer

Product Application Disclaimer (valid for ALL Habasit products and mentioned on all PDS)

This disclaimer is made by and on behalf of Habasit and its affiliated companies, directors, employees, agents and contractors (hereinafter

collectively "HABASIT") with respect to the products referred to herein (the "Products"). SAFETY WARNINGS SHOULD BE READ CAREFULLY AND

ANY RECOMMENDED SAFETY PRECAUTIONS BE FOLLOWED STRICTLY! Please refer to the Safety Warnings herein, in the Habasit catalogue

as well as installation and operating manuals. All indications / information as to the application, use and performance of the Products are

recommendations provided with due diligence and care, but no representations or warranties of any kind are made as to their completeness,

accuracy or suitability for a particular purpose. The data provided herein are based on laboratory application with small-scale test equipment,

running at standard conditions, and do not necessarily match product performance in industrial use. New knowledge and experience may lead to

re-assessments and modifications within a short period of time and without prior notice.

EXCEPT AS EXPLICITLY WARRANTED BY HABASIT, WHICH WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, THE PRODUCTS ARE PROVIDED "AS IS". HABASIT DISCLAIMS ALL OTHER WARRANTIES, EITHER EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

NON-INFRINGEMENT, OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE, ALL OF WHICH ARE HEREBY EXCLUDED

TO THE EXTENT ALLOWED BY APPLICABLE LAW. BECAUSE CONDITIONS OF USE IN INDUSTRIAL APPLICATION ARE OUTSIDE OF

HABASIT'S CONTROL, HABASIT DOES NOT ASSUME ANY LIABILITY CONCERNING THE SUITABILITY AND PROCESS ABILITY OF THE

PRODUCTS, INCLUDING INDICATIONS ON PROCESS RESULTS AND OUTPUT.

Product Data Sheet (Released) 24.08.2018

You might also like

- Evergreen Review Number 13 - What Is PataphysicsDocument198 pagesEvergreen Review Number 13 - What Is Pataphysicsthomas.patteson6837100% (2)

- LAB 1-Projectile MotionDocument4 pagesLAB 1-Projectile MotionNilay Mehta100% (2)

- Applied Management Science Lawrence 2Nd Edition SolutionsDocument3 pagesApplied Management Science Lawrence 2Nd Edition Solutionsptanoy8No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

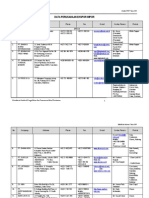

- 01 Data Perusahaan Ekspor ImporDocument47 pages01 Data Perusahaan Ekspor ImporEhridx_Machiavel_22496% (25)

- Bandas ModularesDocument3 pagesBandas ModularesRuben MartinezNo ratings yet

- Light Conveyor Belts SAG-8E 07: Main Industry Segments Applications Special FeaturesDocument3 pagesLight Conveyor Belts SAG-8E 07: Main Industry Segments Applications Special FeaturesMuchamad Fajar NugrohoNo ratings yet

- Light Conveyor Belts H-4Emdt: Main Industry Segments Applications Special FeaturesDocument3 pagesLight Conveyor Belts H-4Emdt: Main Industry Segments Applications Special FeaturesizhharkamaluddinNo ratings yet

- Food Belts CNW-5E-A1: Main Industry SegmentsDocument3 pagesFood Belts CNW-5E-A1: Main Industry SegmentsagusNo ratings yet

- PB 2461Document3 pagesPB 2461M Aamir AsgharNo ratings yet

- Food Belts F-5EXWT 05: Main Industry SegmentsDocument3 pagesFood Belts F-5EXWT 05: Main Industry SegmentsSlobodan VidovichNo ratings yet

- Food Belts TT12 Frayless: Main Industry SegmentsDocument3 pagesFood Belts TT12 Frayless: Main Industry SegmentsSlobodan VidovichNo ratings yet

- FAB 5E en UsDocument3 pagesFAB 5E en UsSlobodan VidovichNo ratings yet

- Tobacco Belts for Processing and WeighingDocument3 pagesTobacco Belts for Processing and WeighingagusNo ratings yet

- HAM 5P en UsDocument3 pagesHAM 5P en UscarlosNo ratings yet

- Power Transmission Belts TC-20EF: Main Industry Segments Applications Special FeaturesDocument2 pagesPower Transmission Belts TC-20EF: Main Industry Segments Applications Special Featuresc4128248No ratings yet

- Spindle Tapes TS-55: Main Industry Segments Applications Special FeaturesDocument2 pagesSpindle Tapes TS-55: Main Industry Segments Applications Special FeaturesjavierNo ratings yet

- TF 15Document2 pagesTF 15Raghavendra MurthyNo ratings yet

- S-10 15Document2 pagesS-10 15Raghavendra MurthyNo ratings yet

- TC 20efDocument2 pagesTC 20efVenkat PrasannaNo ratings yet

- Power Transmission Belts XVR-2389: Main Industry Segments Applications Special FeaturesDocument2 pagesPower Transmission Belts XVR-2389: Main Industry Segments Applications Special FeaturesMd Abu Bakkar ChowdhuryNo ratings yet

- Habasit Product Data Sheet NVT-270Document4 pagesHabasit Product Data Sheet NVT-270Salpa AdenugrahaNo ratings yet

- Belt Habasit XVT-2236Document2 pagesBelt Habasit XVT-2236Savio FernandesNo ratings yet

- Folder-Gluer Belts for Cardboard, Paper ProcessingDocument2 pagesFolder-Gluer Belts for Cardboard, Paper ProcessingSavio FernandesNo ratings yet

- Enu 20exbdDocument2 pagesEnu 20exbdM Aamir AsgharNo ratings yet

- HNI-5P Machine Tape for Paper ProcessingDocument2 pagesHNI-5P Machine Tape for Paper ProcessingSolid DesignNo ratings yet

- A200cos BDocument2 pagesA200cos BClaudia LopezNo ratings yet

- S-18 20Document2 pagesS-18 20Raghavendra MurthyNo ratings yet

- Datasheet PVC Flexam EM Ammeraal Beltech ZazDocument2 pagesDatasheet PVC Flexam EM Ammeraal Beltech ZazchristineNo ratings yet

- Conveyor Belt Technical Data Sheet: UF30 - 0/V08P Vcexcon 3R/ 16 W 38 General InformationDocument2 pagesConveyor Belt Technical Data Sheet: UF30 - 0/V08P Vcexcon 3R/ 16 W 38 General InformationDAMIAN QUIMIZNo ratings yet

- M5010 Flat TopDocument2 pagesM5010 Flat TopĐăng Điệp NguyễnNo ratings yet

- KR2DB2403 enDocument1 pageKR2DB2403 enCustomer ServiceNo ratings yet

- KR2WH2004 enDocument1 pageKR2WH2004 enCustomer ServiceNo ratings yet

- FNB 12E Bandes transporteuses-FR-FT-v1Document2 pagesFNB 12E Bandes transporteuses-FR-FT-v1Kamel IfrahNo ratings yet

- KR3PG3804 enDocument1 pageKR3PG3804 enCustomer ServiceNo ratings yet

- Conveyor Belt Joining GuideDocument2 pagesConveyor Belt Joining GuideDaniel GarcíaNo ratings yet

- KR2PG2402 enDocument1 pageKR2PG2402 enCustomer ServiceNo ratings yet

- Datasheet SBRY577950 enDocument2 pagesDatasheet SBRY577950 enKiss JózsefNo ratings yet

- Datasheet SBRY577951 enDocument1 pageDatasheet SBRY577951 enPetr PavlíčekNo ratings yet

- E3125.14atex - Pvcexcon 3F24 W74 V14V25 As Ar Fa FR AtexDocument1 pageE3125.14atex - Pvcexcon 3F24 W74 V14V25 As Ar Fa FR AtexCustomer ServiceNo ratings yet

- Datasheet SBRO511512 enDocument1 pageDatasheet SBRO511512 enALEX CHANDYNo ratings yet

- Datasheet SBFL514471 en USDocument2 pagesDatasheet SBFL514471 en USGuang ChenzNo ratings yet

- Datasheet SBNO575230 enDocument1 pageDatasheet SBNO575230 enYenireé MedinaNo ratings yet

- GG E10.40 RRQDocument1 pageGG E10.40 RRQMauro Junior Schlickmann MartinezNo ratings yet

- Datasheet SBRY577190 enDocument1 pageDatasheet SBRY577190 enPetr PavlíčekNo ratings yet

- Siegling Transilon Conveyor Belt Data SheetDocument4 pagesSiegling Transilon Conveyor Belt Data SheetedNo ratings yet

- Datasheet SBPX513804 en USDocument2 pagesDatasheet SBPX513804 en USsuemar jose da costaNo ratings yet

- 2M8 U0-V5 A: Technical Data Sheet Conveyor and Process BeltsDocument2 pages2M8 U0-V5 A: Technical Data Sheet Conveyor and Process Beltsnavneet jainNo ratings yet

- Habasitlink M2480 Flush Grid 1": (1.6") PossibleDocument2 pagesHabasitlink M2480 Flush Grid 1": (1.6") PossiblerizqiNo ratings yet

- Datasheet A480Document2 pagesDatasheet A480Mustafa Lagha100% (1)

- Datasheet A483Document2 pagesDatasheet A483KAKI BELANGNo ratings yet

- EM 10-2 0+07 PVC V Bandas de SecadorDocument1 pageEM 10-2 0+07 PVC V Bandas de SecadorJAVIER MTOLEDONo ratings yet

- Datasheet SFPU000812 enDocument4 pagesDatasheet SFPU000812 enTECHXPERT SOLUTIONNo ratings yet

- 2M8 U0-V-U0: Technical Data Sheet Conveyor and Process BeltsDocument2 pages2M8 U0-V-U0: Technical Data Sheet Conveyor and Process Beltsnavneet jainNo ratings yet

- Conveyor Belt Technical Data SheetDocument1 pageConveyor Belt Technical Data SheetCustomer ServiceNo ratings yet

- KR2PG2005 enDocument1 pageKR2PG2005 enCustomer ServiceNo ratings yet

- Datasheet SBPE510438 en USDocument2 pagesDatasheet SBPE510438 en USmechanical09No ratings yet

- Ropanyl em 6 2 00+02 White As FGDocument1 pageRopanyl em 6 2 00+02 White As FGJonathan LujanNo ratings yet

- E3120.07vratex - Pvcexcon 3F30 PG62 V07V20 As Ar Fa FR AtexDocument1 pageE3120.07vratex - Pvcexcon 3F30 PG62 V07V20 As Ar Fa FR AtexCustomer ServiceNo ratings yet

- DG2/40 HS: Flat Transmission Belts Technical Data SheetDocument2 pagesDG2/40 HS: Flat Transmission Belts Technical Data Sheetdirkz26No ratings yet

- S 5-2 E V03N-0 Black enDocument1 pageS 5-2 E V03N-0 Black enWilliam Enrique Rodriguez PinzonNo ratings yet

- 6XV1830 0PH10 DatasheetDocument3 pages6XV1830 0PH10 DatasheettahirNo ratings yet

- Datasheet FBGG054790 en USDocument1 pageDatasheet FBGG054790 en USsalpa nugrahaNo ratings yet

- Animasi Conveyor BeltDocument1 pageAnimasi Conveyor BeltagusNo ratings yet

- Tobacco Belts for Processing and WeighingDocument3 pagesTobacco Belts for Processing and WeighingagusNo ratings yet

- Animasi Conveyor BeltDocument1 pageAnimasi Conveyor BeltagusNo ratings yet

- Habachain Case Chain 60P (Straight) : DescriptionDocument1 pageHabachain Case Chain 60P (Straight) : DescriptionagusNo ratings yet

- Habachain Case Chain 40P (Straight) : DescriptionDocument1 pageHabachain Case Chain 40P (Straight) : DescriptionagusNo ratings yet

- Aerodynamics of the Airplane: The Drag Polar ChapterDocument88 pagesAerodynamics of the Airplane: The Drag Polar ChapterMuhammad Ishaq KhanNo ratings yet

- A6/a6m A27/a27m A307 A325 A325m A500 A501 A502 A563 A563m A668/a668m A1011/a1011mDocument4 pagesA6/a6m A27/a27m A307 A325 A325m A500 A501 A502 A563 A563m A668/a668m A1011/a1011mRocio AriasNo ratings yet

- Ce 5 Sem Reinforced Cement Concrete (RCC) Structures Jun 2017Document2 pagesCe 5 Sem Reinforced Cement Concrete (RCC) Structures Jun 2017Monika jainNo ratings yet

- Behaviour of Sliding Isolation Bearings - Constantinou Et Al. 2007 - Extract of MCEER ReportDocument150 pagesBehaviour of Sliding Isolation Bearings - Constantinou Et Al. 2007 - Extract of MCEER ReportDavide FerrareseNo ratings yet

- Flame Emission Photometers - Analytical Instrumentation Questions and Answers - SanfoundryDocument6 pagesFlame Emission Photometers - Analytical Instrumentation Questions and Answers - SanfoundryFaisal Shahzad100% (1)

- LGZ Series DatasheetDocument13 pagesLGZ Series DatasheetMIGUEL LOPEZNo ratings yet

- Typical gc6180 ManualDocument33 pagesTypical gc6180 ManualPabloLinuxNo ratings yet

- Chapter 5 - ProbabilityDocument97 pagesChapter 5 - ProbabilityPoison IveeNo ratings yet

- MOSFETs 2015 02 23Document197 pagesMOSFETs 2015 02 23楊易儒No ratings yet

- REPERTORIO Menara Mesiniaga PDFDocument80 pagesREPERTORIO Menara Mesiniaga PDFAnggy GNo ratings yet

- Reluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDocument2 pagesReluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDina GaranNo ratings yet

- Manual de Información Técnica Promass 83A PDFDocument36 pagesManual de Información Técnica Promass 83A PDFFredy BarretoNo ratings yet

- Gage R&R Details of AnalysisDocument6 pagesGage R&R Details of AnalysisNeelesh CharanNo ratings yet

- CVH 99Document294 pagesCVH 99Halil AKSUNo ratings yet

- A Distributed Hydrological Model With Coupled Water and Energy BudgetsDocument18 pagesA Distributed Hydrological Model With Coupled Water and Energy BudgetsFiromsa IbrahimNo ratings yet

- 1 Phase SpaceDocument1 page1 Phase Spaceaaditya3015No ratings yet

- Is 1904 1986Document24 pagesIs 1904 1986mttaibNo ratings yet

- Course NotesDocument253 pagesCourse NotesbuenasmhNo ratings yet

- Sepharial (1920) - Collection of Keys (10 P.)Document10 pagesSepharial (1920) - Collection of Keys (10 P.)brijeshjana7318100% (2)

- Structural and Magnetic Properties of Nizn Ferrites Prepared by Microwave SinteringDocument7 pagesStructural and Magnetic Properties of Nizn Ferrites Prepared by Microwave SinteringRobert LongNo ratings yet

- Ims ManualDocument148 pagesIms ManualAnubhav Srivastav100% (1)

- Centrifugal Compressor SRL 454 - Ge Oil&gasDocument20 pagesCentrifugal Compressor SRL 454 - Ge Oil&gasKamal Buddy50% (2)

- Generation Requirements Shape FunctDocument34 pagesGeneration Requirements Shape FunctyohplalaNo ratings yet

- DNS of Separating, Low Reynolds Number Ow in A Turbine Cascade With Incoming Wakes (2 PRD)Document10 pagesDNS of Separating, Low Reynolds Number Ow in A Turbine Cascade With Incoming Wakes (2 PRD)Mai ZhangNo ratings yet

- HW4 SolutionsDocument7 pagesHW4 SolutionserfanghlmNo ratings yet

- Coherent OscillationsDocument10 pagesCoherent OscillationsAlejandraNo ratings yet