Professional Documents

Culture Documents

Digital Multifunctional Digital

Digital Multifunctional Digital

Uploaded by

pedro barbano0 ratings0% found this document useful (0 votes)

6 views14 pagesOriginal Title

digital multifunctional digital

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views14 pagesDigital Multifunctional Digital

Digital Multifunctional Digital

Uploaded by

pedro barbanoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

Hich Tectt Live

MR - Digital multifunctional relays

Contents \

1. Introduction

2. Features and characteristics

3. Technology of the MR-relays

3.1 Input circuits

3.2 Dola communication

3.3 Indication and operation clements

3.3.1 Front plate

3.3.2. Display

3.3.3 LEDs

4, Operation and setting

4.1 Pushbuttons

4.2 Code jumpers

4.2.1. Function ofthe output ioloys

W.2.2 Rosot }

4.3 Relay soting principle

4.3.1 Solting of slondard parameters

4.4 Password

4.4.1 Password programing

4.A.2 Using the password

4.5 Indicaion of moasuting values and

foult dota

4.5.1 Indication of measuring values

4.5.2 Indication of fault dota

4.6 Display of software version and tes tip

5. Relay case

S. Relay testing and commissioning

7. General technical datas

7.1 Power supply

7.2 Output relays

7.3 System data ond test specifications

7.4 Dimensional drowings

2 THe 11.94 E

,\ ta

) Introduction

The application of powerlul microprocessors opens a

now chapler for power system protective reloying. Be-

cause of their copabiliies lo process the measuring

valves digitlly ond to perform arithmetical and logical

‘operations he digital protecive relays are superior fo the

traditional analog sttic protective relays. Besides, the

ligital protective reloys offer somo addliional advan

tages such as very small power consumption, adopto

bility, possibilities for sellsupervsion, fault diagnosis by

‘means of faull data recording, flexible conskuction and

selection of olay characteristics etc

The dovelopment of microprocessorbased prolectve re-

lays and thei introduction info the market ore stimulated

by the trend nowadays io roplace the analog withthe

digital protocive equipments. Owing to this end a new

SEG protective relay family - HIGH TECH UNE MR - wos

developed. The protective rlay family MR consists of a

great deol of protective relays which satsly the needs of

various protective functions. As on example the MRNT,

‘an universially used mains decoupling relay for power

‘generating systems in mains parole! operation with on

‘exceptionally good price/ performance ratio becouse of

inlegration of three protection functions.

The superiorly of digiol protective sysioms lo the trod

ional protecive relays is embodied by the relay family

‘MR wil he following feotes

* tegration of mony protective functions in only one

compact case

‘© High accuracy owing lo digital processing

+ Digial relay seting with very wide seting range

cond fine sting tops

* Comlodable usertiendly menudriven parameter

selings

+ Moasrng vlve ond faut doi inden by menns

of alphanumerical display

‘* Data exchange with station control center by means

of seta interface

+ Opeatioa reliobiliy by means of continuous set

supervision

A silos, but simplified version the PRORESSONAL INE

wilh limited functions is also available.

TOMR 11.94€

Se

2. Features and characteristics

+ Complete digital processing ofthe sompled mea

suing values

+ Exromely wide seting ranges and fine stops for

measuring value and lime setings

* Seting authorization through password against

Uunauhorized seting actions

+ Password defined by he wer himsell

+ Continyous selsupenvsion for softwore ond hard:

wore

+ Serial data communication focilties via RS485

+ Wide voliage range for DC or AC aurliary power

supply

‘+ High precision components and overialing

guaraniee:

= precision

= reliability

long service lle

3. Technology of the MR-relays

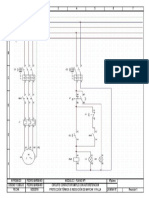

3.1 Input circuits

‘Anolog input signals ore eleckicaly isolated by the

input ronsloxmers ofthe relay, then filered analog

cond processed fo the analog/digial converers. External

wing of he measuring cccuis 0s well as the ouxtiory

‘voltage are shown on the connection diagrams in the

specilic technical descripions

3.2. Data communication

For dota communication with a centtal conitol system oll

‘MR relays can oplionaly be provided with @ serio! inier-

face RS 485. All dota oblainable can be found inthe

specilic lechnical descriptions named RS485-PRO.

3.3. Indication and operation elements

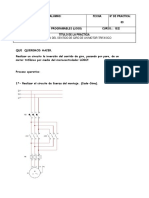

3.3.1 Front plate

The front plate of MRprotection relays comprises the fob

lowing operation and indication elements:

+ Alphonumerical display (4 Digits)

+ Pushbultons for seting and othor operations

+ LEDs for measured value indicaion and seting

Example of a front plate (MAI)

or -

SS

{EDs com on whan cach mecaed

volo lal dso

DISPLAY

Apher ED dpoy

Les Kap rig tgs

een

=} | ops sts

Chon leon eed ay et ———

{EDs como on dig seing wei,

fel lesen

ca

® ®

3.3.2. Display 3.3.3 LEDs

The measured and sel volues, the 1ecoxded fault dota as The LEDs are used for indicating parameters or measur

‘well os the system reply are shown on the alphanumet- ing data on the display.

col display. With the holp of the optical indication of The function of he individual LED is shown on the front

the LEDs on the front plate, the meaning of the dis plate.

ployed value can be identified very easily

a TONR 11.946

4. Operation and setting

4.1. Pushbuttons

Pushbultons oe used for calling up the parameters fo be

processed, for selection of measuting parameters lo be

indicated and for changing ond storing the parameters.

‘The individual seting ond meosuiing values car) be

selected ono offer another by pressing pushbutlon

UECT/RESET>. This pushbution is also used for

‘osoting the display by pressing approx. 3s.

As [or an individual case [relay version D) the pushbutton

can also be operated when the front cover of the relay

is,losed ond sealed with lead

Puchbulions <#> <> are used for in-/decrementing of

the parameter indicoted on he display. They can be

pressed slap by-lep or continuously

‘Alter ho selected porameter is et by the <+> <> pushe

button it moy bo siored using the pushbuton,

Through the pushbutlon the set volue indicated

(on the display will be ansfered fo the internal por-

‘ameter memory. An uninented or unauthorized change

of he solected parameter is avoided by means of a pass

word identification (see 4.4.2}

Sse

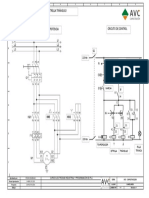

4.2 Code jumpers

Behind the front plate of the MRrelays there are three

code jumpers lo pres the following functions

+ Password progeamming

‘© Ouiput relay functions

The following figure shows the position and designation

of the code jumpers:

Front plate eee

000

(Code “Jumper

The pushbutton is used lo lest the ouput relay cir

«ails both for tipping and signaling. During normal oper

lion i is also interlocked by means of the password Cob timpatON = |

idonification

Céde-Jumper OFF =

Coding possibilities

‘Code [Function [Code (Operation mode

Jumper jumper Posi

yy [Password OFF | Normal postion

| ‘ON Password selection

jp [Norm rcloys OFF [Alarm relays will be activated at pickup

ON [Alarm relay will be activated at tipping

33 [Reet |__OFF | Output reloys will be reset oulomatical

: ON [Ouiput relays will be reset manual external/vi solwore

TMB 11.94 E 5

4.2.1. Function of the output relays

The folowing functions of MR output relays ean be

preset:

+ Alaim relay activation ot pickup or alte tipping

ofthe wolay

‘= Reset of the oulput relays

the alarm relays are activated according o the prose

fing:

Code jumper J2 OFF:

tho alam selays pickup diccly wih enoxgizing of he

oxexponding meosuting cieuit, Thus, an ola signal

-an be given before the teloy tips.

ic jumper J2 ON

ihe alam relays pickup only ofl relay hp. Tha! means:

ho tip relay and the conesponding alarm relay pickyp

11 hie saine time alter the time delay elapsed

‘ode jumper J3 OFF:

All output clays wal be resel automatically aftr the faut

v0 been recilied, (e.g. when the fault curren is inter

uptod})

Code jumper J3 ON:

Al oulput relays remains activated and must be reset

aller foul cleorenes.

+ Manually: By pressing pushbution

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Circuito Nº1-Contactor Simple Con Autoretención-Indicadores de Marcha y FallaDocument1 pageCircuito Nº1-Contactor Simple Con Autoretención-Indicadores de Marcha y Fallapedro barbanoNo ratings yet

- Circuito Nº3 - Inversor de Marcha Con Fines de CarreraDocument2 pagesCircuito Nº3 - Inversor de Marcha Con Fines de Carrerapedro barbanoNo ratings yet

- Logo - Inversion Del Sentido de GiroDocument2 pagesLogo - Inversion Del Sentido de Giropedro barbano0% (1)

- TMD-T4 TMD-T4s IM303-E v2.8Document10 pagesTMD-T4 TMD-T4s IM303-E v2.8pedro barbano100% (2)

- Llave Estrella Triangulo - 2019Document1 pageLlave Estrella Triangulo - 2019pedro barbanoNo ratings yet

- SELTIR - Control de Nivel de Depósitos Con ElectrodosDocument2 pagesSELTIR - Control de Nivel de Depósitos Con Electrodospedro barbanoNo ratings yet

- Como Hacer Una Instalacion Electrica Domiciliaria - AÑO - 2018Document9 pagesComo Hacer Una Instalacion Electrica Domiciliaria - AÑO - 2018pedro barbanoNo ratings yet

- Arranque Directo - 2019Document1 pageArranque Directo - 2019pedro barbanoNo ratings yet

- 1241 CCT-04 PDFDocument4 pages1241 CCT-04 PDFpedro barbanoNo ratings yet

- Introducción A ElectricidadDocument16 pagesIntroducción A Electricidadpedro barbanoNo ratings yet