Professional Documents

Culture Documents

8474L 000 JSD 2000 001 0

Uploaded by

Kumar sssss0 ratings0% found this document useful (0 votes)

39 views22 pagesregerg

Original Title

8474L-000-JSD-2000-001-0

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentregerg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views22 pages8474L 000 JSD 2000 001 0

Uploaded by

Kumar sssssregerg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

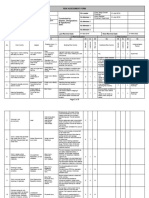

Technip PCG th Projectn’-Unt Doc. type Mat code Setaln® Rav. Page

8474. 000 JSD 2000 001 0 1/2

VIETNAM OIL AND GAS CORPORATION ( PETROVIETNAM )

DUNG QUAT REFINERY (DQR) PROJECT

ae BUILDINGS SPECIFICATION

JOB SPECIFICATION FOR DESIGN

BUILDINGS SPECIFICATION

Document Class: Z"

Pages modified under this revision:

Note: This Document is identical to FEED document 6960-8300-SP.0018 REV D5

bgt BL

a REISSUED FOR DESIGN ie cian cata WY] Aer soirsie0

t

A ISSUED FOR DESIGN 1. CHAN, CALAU C1 sort

DOCUMENT REVISIONS.

‘Sections changed in at revision are denied by 9 verte nein he main

Techni — Proectat-Unt Doe. ype Mal cade Salat Rev. Page

Technip AEH th 8474L.000 JSD 2000 001 0 2/2

VIETNAM OIL AND GAS CORPORATION ( PETROVIETNAM )

DUNG QUAT REFINERY (DQR) PROJECT

BUILDINGS SPECIFICATION

ATTACHMENT 1

DOCUMENT 6960-8300-

SP-0018 REV DS “BUILDINGS SPECIFICATION”

Technip TOG

6960-8300-SP-0018

BUILDINGS FOSTER WHEELER PAGE: 1 OF 20

SPECIFICATION ENGINEERING SPECIFICATION REV: DS,

Revision ot 2 03 on be D3 ot bs

SATE 27 ApalG9 18 June G9 AugustS8 October 99 10 Dec89 Jun 2000 Aug504 Aug.Z6 04

RIGBY Blumenthal Blumenthal Blumenthal Blumenthal Jethwa Blumental Spengler Spengler

PREY Jehwa —Jelhwa —Jethwa _Jethwa _Jethwa Jethwa Singh Singh >

a a ne

- For FDC Issue For

STATUS

Review FOC

Pages modified under revision D4: 2, 4. 11, 14, 15

Page smodified under revision D5: 14

Contract: 7303N

Client's Name: VIETNAMESE OIL AND GAS CORPORATION

(PETROVIETNAM)

Project Title DUNG QUAT REFINERY PROJECT

FEED DEVELOPMENT CONTRACT

Project Location UNG QUAT, VIETNAM

CONTENTS

SECTION SUBJECT

10 GENERAL

20 REFERENCES

30 SCOPE OF WORK

40 BUILDINGS

50 BUILDINGS, AIR-CONDITIONING AND MECHANICAL

VENTILATION (ACMV)

~

6960-8300-SP-0018

Techn REG

ENGINEERING SPECIFICATION _ SPECIFICATION

REVISION STAT!

REVISION PAGES.

ot

2

0s

o1

D2

D3

D4

ALL

ALL

ALL

ALL

34,6,

7,9, 12,

15, 16,17,

18.19

ALL

All

24,19,14.15

FOSTER WHEELER BUILDINGS

REASON FOR REVISION

Preliminary Issue for Comment

Prolminary Issue for Comment

Issued AFD

Comments incorporated and re-issued AFD

Issued for Approval for Project Specification

Comments incorporated and re-issued AFD, Document

tile revised

FEED development and final issue

Exhibit Vil requirements incorporated

Update of building list

Technip Et

16960-8300-SP-0018

GULDINGS FOSTER WHEELER fe oe

SPECIFICATION ENGINEERING SPECIFICATION oe

10 GENERAL

14 This specification describes the minimum requirements for the design

and construction of the various buildings required.

12 This Standard shall be read in conjunction with Vietnamese mandatory

standards, codes and regulations that also apply. In the event of any

conflict Contractor shall seck clarification from VietRoss before

proceeding. Generally the most stringent requirements shall apply.

2.0 REFERENCE!

The design of the buildings shall be in accordance with the latest

revisions of the attached Standards, Specifications and Contract

Documents. The design of the buildings shail incorporate the

requirements of the Project Technical Specification 6960-8820-AVB.

30 SCOPE OF WORK

34 General Design Considerations

The design of the buildings shall be carefully considered and developed

to establish a site aesthetic. Panicular areas for consideration shall

include uniformity and commonality of external finishes, colours, te

construction types, features and proposed final spectfication of

materials, components and workmanship.

Occupied buildings shall be designed to be energy efficient with

insulated construction, solar/double glazing, sunscreens, recessed

external openings, etc. as necessary. All buildings shall be designed to

reflect the local Vietnamese environmental/climatic constraints and

conditions.

Al roof drainage shall be externally routed to the site stormwater

drainage system.

32 Schedule of Buildings

Refinery Service Facilities

= Administration Building

Entrance/Reception/Security Building: 1

- Entranee/Reception/Security Building: 2

Technip At

6960-8300-SP-0018

PAGE: 4 FOSTER WHEELER BUILDINGS

REV: D5 ENGINEERING SPECIFICATION _ SPECIFICATION |

Fire Station )

- Gas Rescue Station) Combined

- Cafeteria/Shop/Laundry

- First Aid Centre

- Maintenance Shop: Mechanical

- Maintenance Shop: Electrical/Instrumentation/Communications

+ Maintenance Warehouse

Garage Facilities/Motor Pool Building

- Laboratory

- Chemical)

Catalyst Store ) Combined

322 Pover Generation Facilities

= Electrical Substations

3.23 Product Tank Farm

~ Gatehouse/Truck Loading Control Building

= Pump Shelters

Drivers’ Facilites Building

Fire Station

! + Satelite Control Complex (SCC)

324 Control Facilities

i‘ - Main Control Building (or CCC: Central Control Complex)

Process Interface Buildings

- - Marshalling Rack Rooms

325 Jetty Facilities

| Jetty Control Complex (JCC)

Jetty Substation

Jetty Workshop/Marine Equipment Store

40 BUILDINGS.

44 Administration Building

‘The Administration Building shall be a three storey fully air-conditioned

facility including all necessary fresh and exhaust air systems, containing

the main reception area, administration, management and executive

offices; tollet and washroom facilities; computer room suite; storage

areas and telecommunicationlemergency communication facilities, and

a conference hall,

cons Qt

Technie AAA

6960-8300-SP-0018

BUILDINGS FOSTER WHEELER PAGE: &

SPECIFICATION ENGINEERING SPECIFICATION fee

Construction shall be reinforced in-situ concrete structural frame, floors

and insulated roofs with painted, rendered infil masonry walls and

pattitions, and glazed anodised aluminium framed windows and painted

external steel doors.

Internally, all finishes shall be suitable for the functions to be carried out

within the respective areas. Generally, floors shall be ceramic

tilediterrazzo finished with non-slip ceramic tiling to all potentially wet

areas. Walls shall be painted render with ceramic tiling to toile wash

areas. Ceilings shall be proprietary, suspended tiled type with painted

plasterboard/render to storage and ancillary spaces. The main

reception area and executive offices shall be provided with a higher level

of quality finish. The computer room suite shall be provided with a

proprietary, anti-static raised access flooring system.

42 Cafeteria/Kit

‘The Cafeteria/Kitchen shall be a single storey fully air-conditioned

structure, including all necessary fresh and exhaust air systems,

containing the main dining facility for all refinery managerial,

administrative and operative staff and visitors with associated fully

‘equipped kitchen, Food storage, preparation, servery and washing

facilities together with administration offices, lockers, toilets and

washrooms shall cater for various religiousethnic requirements.

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infill walls and partitions,

glazed anodised aluminium framed windows and painted external steel

door

Internally all finishes shall be suitable for the functions to be carried out

within the respective areas. Generally, flor shall be ceramic/terrazzo

tiled with non-slip ceramic tiling to wet areas. Walls shall be painted

render with ceramic tiling to wet areas, Ceilings shall be proprietary,

suspended tiled type with moisture resistant tiles to wet areas, and

painted plasterboardirender to storage/ancillary areas,

43 Laundry

‘The Laundry shail be a single storey fully air-conditioned facility,

including all necessary fresh and exhaust air systems, sized and

equipped to accommodate the requirements of the whole refinery with

reception, washing/drying areas, administrative offices, storage and

lockersftolletshwashing areas.

Construction shall be reinforced in-situ concrete frame, floor and

installed roof with painted, rendered masonry infil walls and partitions,

glazed anodised aluminium framed windows and painted external steel

doors.

Techn EAA

a 6960-8300-SP-0018

PAGE: 6

REV: D5

44

48

FOSTER WHEELER BUILDINGS

ENGINEERING SPECIFICATION _ SPECIFICATION

Internally, finishes shall be hardwearing and easily maintained with non-

slip ceramic tiled floors, painted rendered walls and ceiling sofits,

staff

The Shop shall be a single storey air-conditioned facility, inctuding all

necessary fresh and exhaust air systems, sized to service the

requirements of all the refinery operatives/administration staff, with

associated storage, office and toiletiwashing areas.

Construction shat be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infill walls and partiions,

glazed anodised aluminium framed windows and painted steel doors

Internally, finishes shall be hardwearing and easily maintained with

ceramicherrazzo tiled floors, painted rendered walls and ceiling softs.

Entrance/Reception/Security Buildings

The Entrance/Reception/Security Buildings at the Refinery shall be

single storey, fully air-conditioned facilities, including all necessary fresh

and exhaust air systems, containing the gatehouse control room;

security office: visitor reception/waiting areas and toilet/washlacker

facil

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infill walls and partitions,

glazed anodised aluminium framed windows and painted steel doors.

Internally, all finishes shall be hardwearing and easily maintained with,

ceramiciterrazzo tiled floors, painted rendered walls and proprietary,

suspended tiled ceilings.

a

BUILDINGS

SPECIFICATION

46

aq

Technip PEAT

6960-8300-SP-0018

PAGE: 7

REV: 05

FOSTER WHEELER

ENGINEERING SPECIFICATION

The Refinery Fire Station shall be combined with the Gas Rescue

Station (Clause 4.8) and shall be a two storey naturally ventilated

building with a fire tender/foam trailer garage, associated equipment

storage, hose drying and battery charging facilities. Ancillary offices,

classrooms, toilets and washvlocker facilities shall be provided with

dedicated air-conditioning units including all necessary fresh and

exhaust air systems,

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infill walls which shall

include areas of ventilation blockwork. The garage shall be provided

with proprietary industrial-type painted steet sliding doors. All other

doors shall be painted steel. Windows shall be glazed anodised

aluminium framed.

Internally, finishes shall be hardwearing and easily maintained with

painted, Sealed concrete floors, painted masonry walls and concrete

soffits to the garaging/storage areas, Terrazzo tiled floors, painted

rendered walls and ceiling soffits to ancillary areas.

‘The Product Tank Farm Fire Station shall generally be simiar fo the

Refinery Fire Station except that provision shall be made for two fire

tenders,

First Aid Centre

‘The First Aid Centro shall be a single storey, fully air-conditioned

building including all necessary fresh and exhaust air systems with fully

‘equipped emergency treatment suite of rooms, doctor's

surgery/consulting room, recovery room, nurses’ room and secure

stores together with toilet, wash and changing facilities and a dentist's

surgery with ancillary facilities

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infill walls, glazed

anodised aluminium framed windows and painted steel doors

Internally, finishes shall be hardwearing, hygienic and easily maintain

with ceramic/terrazzo tiled floors, non-slip to potentially wel areas,

painted rendered walls, with ceramic tiling to wet areas and proprietary

suspended tiled ceilings.

Technip BIE ta

6960-8300-SP-0018

48

49

FOSTER WHEELER BUILDINGS

ENGINEERING SPECIFICATION _ SPECIFICATION

Gas Rescue Station

‘The Gas Rescue Station shall be combined with the Refinery Fire

Station (Clause 4.6) and shall be a two storey naturally ventilated

building with an emergency vehicle garage, associated equipment

storage and breathing air tank maintenanceffiling facilities. Toilet and

wastviocker facilities shall be provided with dedicated air-conditioning

tnits including all necessary fresh and exhaust air systems.

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted rendered masonry infill walls which shall

include areas of ventilation blockwork. The garage shall be provided

with a proprietary industrial-type painted steel sliding door. All other

‘doors shall be painted steel. Windows shall be glazed, anodised

aluminium framed

Internally, all finishes shall be hardwearing and easily maintained with

painted, sealed concrete floors, painted masonry walls and concrete

soffits. Non-slip ceramic tiled floors and ceramic wall tiles to toilevwash

areas.

Garage Facilities/Motor Pool Building

‘The Garage Facilties/Motor Poo! Building shall be a single storey

naturally ventilated building including all necessary dedicated extract

systems with a fully equipped vehicle workshop with associated storage

facilities and covered extemal work areas/parking areas sized to

accommodate the largest site vehicles. Ancillary office. toilets,

washilocker facilities shall be provided with dedicated air-conditioning

Units including all necessary fresh and exhaust air systems. External

covered vehicle wash areas shall be provided.

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted rendered infil masonry walls which shall

include areas of ventilation blackwork. The workshop shall be provided

with proprietary industrial-ype sliding painted steel doors. All other

doors shall be painted steel, Windows shall be glazed, anodised

aluminium framed

Internally, finishes shall be hardwearing and easily maintained with paint 1

sealed concrete floors, painted masonry walls and concrete soffits to }

garaging, workshop/storage areas, Non-slip ceramic tiled floors and

eramic wall ties to toilevwash areas.

BUILDINGS

SPECIFICATION

4.10

Technip PIE ta

6960-8300-SP-0018,

PAGE: 9

REV: 05

FOSTER WHEELER

ENGINEERING SPECIFICATION

Maintenance Shop: Mechanical

‘The Mechanical Workshops shall be a two storey, fully equipped

building with associated offices, changing, toilet and washing facilities,

The

‘workshop facilities shall be designed to allow staff service of up to 85

persons.

‘The workshop shall be naturally ventilated with enclosed air-conditioned

areas for specialist maintenance including all necessary exhaust

air/dedicated extract systems. Ancillary areas shall be provided with

‘dedicated air-conditioning units including all necessary fresh and

‘exhaust air systems. External covered work areas shall be provided

adjacent to the Workshop entrances.

Construction shall be structural stee! framework with pitched roofs,

reinforced in-situ concrete floors, painted rendered masonry plinth walls,

and insulated paint finished profiled steel root/wall cladding over. To

Concrete ceiling units. Natural ventilation shall be included within the

clad walls and by the provision of ridge ventilators. Proprietary industrial

painted steel sliding doors shall be provided to the Workshops with

other doors painted stee! and glazed anodised aluminium framed

windows,

Internally, finishes shall be robust, durable and easily maintained with

paint sealed concrete floors, painted masonry walls and self-finished

profiled steel lining panels to external walls and roof areas.

Changing/tollevwash areas shall be provided with non-slip ceramic tiled

floors, ceramic tiled walls/splashbacks and painted concrete soffts.

Maintenance Shop: Electrical, Instrumentation and

‘Communications

‘The Workshop shall be a three storey, fully equipped building with

associated offices, changing, toilet and washing facilities.

The Electrical workshop facilities shall be designed to allow staff service

of up to 40 persons and the Instrumentation and Communications

Workshop shall be designed to allow staff service of up to 50 persons.

‘The workshop shall be naturally ventilated with enclosed air-conditioned

areas for specialist maintenance including all necessary exhaust

ait/dedicated extract systems. Ancillary areas shall be provided with

dedicated air-conditioning unis including all necessary fresh and

exhaust air systems, External covered work areas shall be provided

adjacent to the Workshop entrances,

~ dof @

Technip AT

{6960-8300-SP-0018

PAGE: 10

REV: D5

412

4.43

FOSTER WHEELER BUILDINGS

ENGINEERING SPECIFICATION _ SPECIFICATION

Construction shall be structural steel framework with pitched roofs,

reinforced in-situ concrete floors, painted rendered masonry plinth walls

and insulated paint finished profiled stee! root/wall cladding over

Ancillary spaces shall be provided with lightweight precast concrete

ceiling units. Natural ventilation shall be included within the clad walls

land by the provision of ridge ventilators. Proprietary industrial painted

steel sliding doors shall be provided to the Workshop with other doors

painted steel and glazed anodised aluminium framed windows.

Internally, finishes shall be robust, durable and easily maintained with

paint sealed concrete floors, painted masonry walls and setf-inished

profiled stee! lining panels to extemal walls and roof areas.

Changing/toilevwash areas shall be provided with non-slip ceramic tiled

floors. ceramic tiled walls/splashbacks and painted concrete soffits.

Maintenance Warehouse

‘The Warehouse Building shall be a single storey, fully equipped building

with areas dedicated to spare part storage, maintenance shop stores

and associated offices, changing, toilets and washing facilities. All

facilities shall be provided with dedicated air-conditioning units including

all necessary fresh and exhaust air systems. External covered work

areas shall be provided adjacent to the warehouse goods entrances.

Construction shall be structural steel framework with pitched roofs,

reinforced in-situ concrete floors, painted rendered masonry plinth walls.

and insulated paint finished profiled steel root/wall cladding over.

Ancillary spaces shall be provided with lightweight precast concrete

ceiling units. Proprietary industrial painted steel stiding doors shall be

provided to the Warehouse with other doors painted steel and glazed

anodised aluminium framed windows.

Internally, finishes shall be durable, robust and easily maintained with

paint sealed concrete floors, painted masonry walls and self-inished

profiled steel lining panels to external walls/roof areas,

Changingftoilevwash areas shall be provided with non-slip ceramic tiled

floors, ceramic tiled walls/splashbacks and painted concrete soffits.

Chemical Store

‘The Chemical Store Building shall be combined with the Catalyst Store

(Clause 4.14) and shall be a single storey air-conditioned building

including all necessary exhaustiextract air systems.

Construction shall be structural steo! framework with pitched roofs,

reinforced in-situ concrete floor, painted rendered masonry plinth walls,

and insulated paint finished profiled stee! roofiwall cladding over

Technip WE ta

6960-8300-SP-0018

BUILDINGS PAGE: 11

FOSTER WHEELER REV DF

SPECIFICATION ENGINEERING SPECIFICATION

Proprietary industrial painted steel sliding doors shall provide access

together with painted steel personnel doors

Internally, the floor shail be paint sealed with painted masonry walls and

self-finished roof/wall cladding over

Final design and dimensions of Chemical Store will be based on actual

storage requirements and nature of chemicals and catalysts to be

determined during detailed engineering phase. PROJECT

SPECIFICATION design information is preliminary. This will be subject

to OWNER's APPROVAL.

ana Catalyst Sto

‘The Catalyst Store Building shall be combined with the Chemical Store

(Clause 4.13) and shall be a single storey air-conditioned building

including all necessary exhaust/extract air systems.

Construction shall be structural steel framework with pitched roofs,

reinforced in-situ concrete floor, painted rendered masonry plinth walls

and insulated paint finished profiled steel roofiwalll cladding over.

Proprietary industrial painted stee! sliding doors shall provide access

together with painted steel personnel doors,

Internally, the floor shall be paint sealed with painted masonry walls and

self-finished roofiwall cladding over.

Final design and dimensions of Catalyst Store will be based on actual

storage requirements and nature of chemicals and catalysts to be

determined during detailed engineering phase. PROJECT

SPECIFICATION design information is preliminary. This will be subject

to OWNER's APPROVAL.

~

415 Main Electrical Substation/MCC

| Deleted.

| 4.16 Electrical Substations (1,2,3.4,5.6,7.8 10,10A,14,12)

The Substations for the Refinery shall be elevated single storey oe

mechanically cooled buildings

Construction shail be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered and painted masonry infil walls.

The wall construction shall afford a minimum two hours fire resistance

with fully Sealed and insulated steel doors. The cable basement shall be

provided with galvanised steel mesh infil panellingiaccess gates with

painted rendered masonry infill walls to the transformer bays

wy

Technip WEA

6960-8300-SP-0018

PAGE: 12 FOSTER WHEELER BUILDINGS

REVe0SE es ENGINEERING SPECIFICATION _SPECIFICATION

Battery rooms shall be provided with exhaust air systems and with

portable, wall-mounted eyewash units.

The transformer bays shall be provided with masonry dividing walls and

with a demountable galvanised steel mesh compound fence with

lockable access gates

Reinforced concrete access stairs and personnel/equipment platforms

with demountable stainless stee! handrails shall be provided to each

‘access door into the Substations. Handrails to equipment platforms

shall be partially demountable

~ Internally, finishes shall be robust, durable and easily maintained with

epoxy sealant to floor screed designed to accommodate switchgear

‘mounting channel inserts, rendered acrylic painted walls and acrylic

painted fairfaced concrete roof soffits.

4a7 Gatehouse/Truck Loading Contro! Building

The Product Tank Farm Gatehouse and Contro! Building shall be an

elevated, single storey, fully air-conditioned facility containing the

gatehouse and truck loading control room; mess and male/female

tollevwash/locker facilities including all necessary fresh and exhaust air

systems,

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infil walls and partitions,

glazed anodised aluminium framed windows and painted steel doors.

Reinforced concrete access stairs/personnel and equipment platforms

shall be provided with partially demountable stainless stest handrails

Internally, all finishes shall be hardwearing and easily maintained with

ceramiciterrazzo tiled floors with non-slip tiling to wet areas. painted

rendered walls with ceramic tiling to wet areas and proprietary,

suspended tiled ceilings. A proprietary anti-static raised access floor

system shall be provided for the Control room,

4.18 Pump Shelters

‘The Product Tank Farm Pump Shelters shall be single storey, naturally

ventilated structural steel framed shelters, incorporating a manually

operated hoist, SWL to sult operational requirements, with reinforced

in-situ concrete floors and paint finished profiled steel rooffpartial fascia

cladding with matching ridge ventilators.

BUILDINGS

SPECIFICATION ENGINEERING SPECIFICATION

449

4.20

424

Technip REA

6960-8300-SP-0018.

PAGE: 13

FOSTER WHEELER REV: D5

Driver's Facilities Building

The Product Tank Farm Drivers’ Facilities Building shall be a single

storey, air-conditioned facility containing the drivers’ rest room and toilet

facilities including all necessary fresh and exhaust air systems.

Construction shall be reinforced in-sito concrete frame, floor and

insulated roof with painted, rendered masonry infill walls and partitions,

glazed anodised aluminium framed windows and painted steel doors,

Internally, all finishes shalt be hardwearing and easily maintained with

‘ceramiciterazzo filed floors, painted rendered walls and proprietary

suspended tiled ceilings.

Satel

Control Complex

The Project Tank Farm Satellite Control Complex shall be an elevated

single storey, air-conditioned facility containing the product tankage

control and auxiliary rooms, mess and toilet facilities and UPS/ACMV

plant rooms including all necessary fresh and exhaust air systems,

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infill walls and partition,

glazed anodised aluminium framed windows and painted steel doors.

Reinforced concrete access stairs/personnel and equipment platforms

shall be provided with partially demountable stainless stee! handrails,

Internally, all finishes shall be hardwearing and easily maintained with

ceramiciterrazzo tiles floors, painted rendered walls and proprietary,

suspended tiled ceilings. A Proprietary anti-static raised access floor

system shall be provided for the control and auxiliary rooms.

Main Control Building

The Main Control Building shall be a single storey, blast resistant

building with a finished floor level raised 600mm ~ 800mm above the

adjacent extemal ground level. The building shall be a fully air

conditioned facility including all necessary fresh and exhaust air

systems,

The facility shall contain the Central Control Complex, with Control

room, instrument auxiliary room, computer room, supervising manager's

office, training/simulation room, communications room, permit office,

UPS/battery rooms and the ACMY plant room. Accommodation shall

include managers’ offices, mess room, locker/washcooms, toilets,

archivestlibrary, first aid room, copying/printing room, conference and

visitors’ room, storage. janitor’s room and entrance air locks with safety

equipmenticlothing racks.

{6960-8300-SP-0018

PAGE: 14

REV: DS.

4.22

4.23

Technip BEET

FOSTER WHEELER BUILDINGS

ENGINEERING SPECIFICATION _ SPECIFICATION

The building shall be designed to be blast resistant with insitu reinforced

concrete foundations, structural frame, walls, floor and roof. ‘externally

the frame shall be paint finished and the walls rendered and painted.

The roof shall be laid to falls for drainage and shall be insulated with

proprietary, mechanically fixed, rigid board system over a fully adhered

weathering membrane and finished with a solar reflective painted

reinforced screed layer. A section of the roof structure shall be extended

to provide an enclosed reinforced concrete ventilation chamber for

ACMV exhaust louvers, blast/suction proof valves and a fresh air intake

stack. All external doors shall be minimum two hour fire rated and blast

resistant, proprietary, painted galvanised steel fitted with air tight seals

and securely bolted into the concrete openings.

Internally, all finishes shall be suitable for the functions to be carried out

within the respective areas. Generally, floors shall be ceramiciterrazz0

tiled with non-slip versions to all potentially wet areas. The Central

Controt Complex accommodation of control room, computer room,

communications room, supervising manager's _ office,

training/simulations room, instrument auxiliary room and UPS room

shall be provided with a proprietary anti-static raised access floor

system. Paritions shall be rendered and acrylic painted masonry with

ceramic tiling to all potentially wet areas. A proprietary lining system

shall be provided to the normally occupied rooms within the Central

Control Complex accommodation and painted galvanised steel framed,

safety glazed vision panels shall be provided to the perimeter wails of

the control room. Coilings shall be proprietary suspended tiled systems

with painted concrete soffits or suspended moisture resistant boarding

to ancillary areas. Internal doors shall be hardwood with painted steel

frames providing the required fire rating and pressure resistance.

Main Control Building sizes are preliminary and will be optimized during

engineering phase to accommodate all necessary equipment, personnel

and Ergonomic requirement. This will be subject to OWNER's:

APPROVAL.

Utilities Control Facility

Deleted (now part of the Main Control Building).

Laboratory

The laboratory shall be a single storey, fully air-conditioned building

including all necessary fresh and exhaust air systems, containing the

main laboratory suite for the refinery. The facilities shall include a fully

fitted equipped and serviced plant laboratory with associated tume

cupboards, hoods, benching, sinks, equipmenvinstrumentation, and

furniture, Supervisors’, chemists’ and managers’ offices, chemicals!

samples and equipment stores, records office, communications room,

dey

g

BUILDINGS

SPECIFICATION

424

Technip ATT tig

6960-8300-SP.0018

PAGE: 15

FOSTER WHEELER REV: be

ENGINEERING SPECIFICATION

toilets, locker/washrooms, reception/secretarial area and ACMY plant

room,

Construction shall be insitu reinforced concrete frame, floor and

insulated roof with rendered and painted masonry infill walls and internat

partitions, glazed anodised aluminium framed windows and painted

external galvanised stect door sets.

Internally, all finishes shall be suitable for the functions to be carried out

within their respective areas. Generally, floors shall be ceramiciterrazzo

tiled with non-slip versions in potentially wet areas. Walls shall be acrylic,

painted render with coramic tiling for toilettwash areas. Ceilings shall be

proprietary, suspended tiled systems with painted concrete soffits or

‘suspended moisture resistant boarding to ancillary areas. Internat doors

shall be hardwood with painted steel frames.

Laboratory building sizes are preliminary and will be optimized during

‘engineering phase to accommodate all necessary equipment, personnel

and Ergonomic requirement. This will be subject to OWNER's

APPROVAL,

Process Interface Buildings (PIB1, PIB4, PIB6) and Marshalli

Rack Rooms (MRR1, MRR2)

The Process Interface Buildings and Marshalling Rack Rooms shall be

single storey, blast resistant facilities with finished floor levels raised

600mm to 860mm above the adjacent external ground level. The

buildings shall be provided with mechanical cooling to the instrument

rooms, UPS rooms and ACMV plant rooms and with an exhaust air

system to the battery rooms, Personnel access shall be via security

controlled air locks into the instrument rooms.

‘The building shall be designed to be blast resistant with insitu reinforced

concrete foundations, structural frame, walls, floor and roof. Extemally,

the frame shall be paint finished and the walls rendered and painted.

‘The roof shall be laid to falls for drainage and shall be insulated with a

proprietary, mechanically fixed, rigid board system over a fully adhered

weathering membrane and finished with a solar reflective painted

reinforced screed layer. A section of the roof structure shall be extended

to provide an enclosed reinforced concrete ventilation chamber tor

ACMV exhaust louvers, blast/suction proof valves and a fresh air intake

stack. All external doors shall be minimum two hour fire rated and blast

resistant, proprietary, painted galvanised stee! fitted with air tight seats,

and securely bolted into the concrete openings

Internally, finishes shall be robust, durable and easily maintained with a

heavy-duty proprietary anti-static, raised access floor system to the

instrument and UPS rooms, and an epoxy sealed screeded finish lo the

ACMY plant rooms and battery rooms. Partitions shall be rendered and

Technip BEAT

PAGE: 16 FOSTER WHEELER BUILDINGS

REV: D5. ENGINEERING SPECIFICATION _ SPECIFICATION

acrylic painted masonry. Ceiling shall be acrylic painted fairfaced

concrete roof softs

4.25 Jetty Control Complex

The Jetty Control Complex shall be an elevated single storey, air-

conditioned facility containing the jetty facilities control room, offi

auxiliary room, mess, male toilet'wash facilities and UPS, ACMY plant

and Battery rooms including all necessary fresh and exhaust air

systems,

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infil walis and partitions,

glazed anodised aluminium framed windows and painted steel doors.

Internatty, all finishes shall be hardwearing and easily maintained with

ceramiciterrazzo tiling to floors with non-slip filing to wet areas, sealed

Cconerete floors, painted rendered walls with ceramic tiling to wet areas,

and proprietary Suspended tiled ceilings. A proprietary anti-static raise

access floor system shall be provided for the control room, auxiliary

room and UPS room.

4.26 Jetty Substation

The Jetty Substation shall be an elevated single storey mechanically

‘cooled building containing switchgear room, UPS room and Battery

room,

Construction shall be reinforced in-situ concrete frame, floor and

insulated roof with painted, rendered masonry infil walls. The wall

construction shall afford a minimum 2 hours fire resistance with fully

tested and insulated steel doors. The cable basement shall be provided

with galvanised steel mesh infill panelling/acoess gates with painted

rendered masonry infill walls to the transformer bays. A battery room

shall be provided with an exhaust air system and with portable, wall

mounted eye wash unit

The transformer bays shall be provided with masonry dividing walls and

with a demountable galvanisad steel mesh compound fence/lockable

access gates. Reinforced concrete access stairs and

personnel/equipment platforms shall be provided to each access doors

with partially demountable stainless steel handrails,

Internally, finishes shall be robust, durable and easily maintained with

epoxy sealant to floor screed, rendered acrylic painted wallsiroof softs

and acid resistant tiling to battery room floor and walls.

al y

Techie Ata

6960-8300-SP-0018

7

Ds

BUILDINGS PaGI

FOSTER WHEELER

SPECIFICATION ENGINEERING SPECIFICATION ge

427 Jetty Workshop/Marine Equipment Store

The Jetty Workshop/Hose Store Building shall be a single storey air

conditioned facility containing the jetty maintenance workshop and

store, the loading arm hose store, the materials and parts store, office

and male locker/washvtoilet facilities.

Construction shall be steel framed with a composite profiled steel

cladding system to roof and walls above a rendered masonry plinth and

partition walls and a reinforced concrete and floor windows shall be

double glazed and modified aluminium framed. Doors shall be insulated

paint finished steel

Instantly, all finishes shall be hardwearing and easily maintained with

sealed concrete and ceramiciterazzo tiled floors with non-slip tiling to

wet areas, Painted, rendered walls shail have ceramic tling to wet

areas and proprietary suspended tiled ceiling shall be provided to the

office, locker room and corridor.

5.0 BUILDINGS, AIR-CONDITIONING AND MECHANICAL VENTILATION

(acm)

64 General Design Considerations

The buildings noted in Section 4.0 above shall be provided with natural

‘or mechanical ventilation and mechanical cooling or air conditioning. as

appropriate for their efficient operation and occupancy. The Contractor

shall produce a performance specification for ACMV requirements prior

to commencement of Detailed Design, which shall include, but may not

bbe limited to, the following design criteria

Site Details, location and operating policy.

Design standards,

© Internal design conditions.

Including: temperatures, humidities, air change rates, pressures,

noise levels, fresh air rates, etc

Fire and gas protection and detection philosophy.

Automatic Controls and monitoring philosophy

Description of systems

Standby and spare capacity philosophy.

Relationship to specification of materials and workmanship.

The Contractor shall note that prior to the completion of detailed design.

the Contractor shall produce a detailed Materials and Workmanship

Specification which shall provide full details of all materials and

equipment (including insulation and vapour seals) proposed for use on

~~ ae ’

Technip RT

6960-8300-SP-0018

PAGE: 18

REV: DS

52

Table

pais

[av ay

| in on!

‘Rv Dalyan

FOSTER WHEELER BUILDINGS

ENGINEERING SPECIFICATION _ SPECIFICATION

the project, together with full details of the quality and standards of

‘workmanship to be achieved during installation,

It shall provide full details of the Scope of Work including requirements

for testing, balancing and commissioning of all systems and for supply

of spares.

ft shal detail the requirements for all_ manufacturers ‘and vendors’

drawings and documents to be supplied together with details for

requirements for off-site tests.

It shall detail the requirements for hand over documentation, including

record drawings, operating and maintenance manuals, testing and

commissioning reports, suppliers’ details etc.

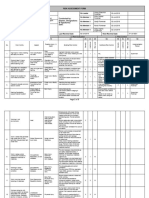

External Design Conditions

Meteorological Data

‘The following meteorological data shall be used to determine the design

temperatures to be used (or the estimation of the heat gains and losses

to the buildings,

Quang Ngai

EO

253 | 252

[Diurrat

| Range

Ae Rontiy

Max DB

‘io. 08

‘Absole

| Max DB

[Aosoiue

| sino

| Monin

La

7 Monty

Hh

as | s9 | 39 | 90

256 | 274

reo | ia | 247,

| 40.3 |

woe | 200 | ans

The absolute maximum dry bulb temperature for the period = 41.4°C

The absolute minimum dry bulb temperature for the period = 12.4°C

External Design Temperatures

Design Dry Bulb Temperature for the selection of air cooled chillers,

condensers and condensing units shall be a minimum of 42°C shade

temperature.

wy

Technip REO

6960-8300-SP-0018

JUILDINGS teers

FOSTER WHEELER REV: DS

PECIFICATION ENGINEERING SPECIFICATION

Design Dry Bulb Temperature for the estimation of winter heat losses shall

be 124°C.

The following Monthly Design Ory and Wet Bulb Temperatures shall be

used for the calculation of the required cooling loads to the vital buildings,

zones and rooms:-

CaS NT

roe

Byewe”” | ase | aoa | ors | a4 | os | are

| Diy Gu, are | 293 | 8 | we | s25 | 313 | a3 | s13 | 284 | m3 | 260

nS +

Weteum” | zs | 27 | a5s | ars | 262 | 200 | 202 | 209 | sro | 58 | ase | car

Min Design 7 T

Weveue” | 210 | 2s | 299 | 253 | 260 | aoe | ase | 22 | ose | 24 | 250 | re

NOTE: Vital rooms are those containing vital electronic equipment whose

failure could cause a process upset, an unsafe condition to exist.

jeopardise life and/or cause major damage to the installation.

NOTE: The following Monthly Dry and Wet Bulb Temperatures shall be

used for the calculation of the required cooling loads for the non-

vital buildings, zones and rooms:-

NOTE: The temperatures in Table 5.2c are not the absolute maximum

temperatures which can occur and, when exceeded for short

periods, the internal design temperatures could rise above the

internal design temperatures proportionally

NOTE: The above temperatures are the maximum and minimum

temperatures of the sinusoidal curves representing the variations

in Dry and Wet Bulb Temperatures for the Design Day for each

month of the year,

Note atso that the Wet Bulb Temperatures where derived from the

moisture content of the air at the Mean Daily Maximum Dry Bulb

Temperatures and the monthly average minimum RH% and the

Design Dry Bulb Temperatures.

The time lag from noon for the Wet and Ory Bulb Maximum

‘Temperatures shall be taken as 1 hour.

Rechnip WE ta

6960-8300-SP-0018

PAGE: 20 FOSTER WHEELER BUILDINGS

REV: DS ENGINEERING SPECIFICATION _ SPECIFICATION

NOTE: All temperatures are in °C and Wet Bulb Temperatures are screen

Wet Bulb Temperatures.

Solar Radiation/Intensities

Intensities of solar radiation shall be calculated using the process and data

given in Section A2 of the CIBSE Guides, or similar authenticated data.

‘The Buildings’ locations shall be taken as +11.0 metres above sea level at

latitude 15° 20° N and longitude 108° 50" E.

Exposure Condition

For the purpose of 'U’ value calculations, the exposure value for the

buildings shall be taken as ‘severe’ in accordance with the definition given

in Section A3 of the CIBSE Guides.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- RMH-RA-GP-1002-HVAC Ducting, Dampers, Ventilation Fan, Mushroom, Louver, Insulation and Other Accessories Installation (Reviewed 01042019)Document4 pagesRMH-RA-GP-1002-HVAC Ducting, Dampers, Ventilation Fan, Mushroom, Louver, Insulation and Other Accessories Installation (Reviewed 01042019)Kumar sssssNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Document3 pagesRMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Kumar sssssNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- RMH-RA-GP-1001-Marking Penetration, Support Bracket LocationDocument3 pagesRMH-RA-GP-1001-Marking Penetration, Support Bracket LocationKumar sssssNo ratings yet

- Job Specification For Supply: 8474L 000 JSS 1691 001 0Document12 pagesJob Specification For Supply: 8474L 000 JSS 1691 001 0Kumar sssssNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- LQ Modifications-SketchDocument13 pagesLQ Modifications-SketchKumar sssssNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Legend: US Army Corps of Engineers Middle East DistrictDocument1 pageLegend: US Army Corps of Engineers Middle East DistrictKumar sssssNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 8474L 000 JSD 3400 001 0Document30 pages8474L 000 JSD 3400 001 0Kumar sssssNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Pressure-Relief DamperDocument4 pagesPressure-Relief DamperKumar sssssNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Air Compressor Room Exhaust (8000CMH)Document1 pageAir Compressor Room Exhaust (8000CMH)Kumar sssssNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Air System Sizing Summary For Main Deck AHUDocument12 pagesAir System Sizing Summary For Main Deck AHUKumar sssssNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Instruction Manual PDFDocument10 pagesInstruction Manual PDFKumar sssssNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Chiller SRDocument1 pageChiller SRKumar sssssNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 50TC-A07 Spare PartsDocument17 pages50TC-A07 Spare PartsKumar sssssNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Installation, Start-Up and Service Instructions: 38AH044-134 Air-Cooled Condensing Units 50/60 HZDocument56 pagesInstallation, Start-Up and Service Instructions: 38AH044-134 Air-Cooled Condensing Units 50/60 HZKumar sssssNo ratings yet

- BE Specs VG1000 M9000 TableDocument3 pagesBE Specs VG1000 M9000 TableKumar sssssNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Installation, Start-Up and Service Instructions: 42C, D, S, V Series Fan Coil Air ConditionersDocument88 pagesInstallation, Start-Up and Service Instructions: 42C, D, S, V Series Fan Coil Air ConditionersKumar sssssNo ratings yet

- Installation, Start-Up and Service Instructions: Central Station Air Handling UnitsDocument20 pagesInstallation, Start-Up and Service Instructions: Central Station Air Handling UnitsKumar sssssNo ratings yet

- Bae72 S eDocument1 pageBae72 S eKumar sssssNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)