Professional Documents

Culture Documents

25325-200-3PS-G000-00001 Rev000

25325-200-3PS-G000-00001 Rev000

Uploaded by

anishgirme0 ratings0% found this document useful (0 votes)

38 views22 pagesOriginal Title

25325-200-3PS-G000-00001 REV000

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views22 pages25325-200-3PS-G000-00001 Rev000

25325-200-3PS-G000-00001 Rev000

Uploaded by

anishgirmeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

‘SPECIFICATION

FOR

SELLER / CONTRACTOR EQUIPMENT AND COMPONENT

NUMBERING AND TAGGING

FOR

10 CONCENTRATE EXPANSION PROJECT

LABRADOR CITY, NEWFOUNDLAND AND LABRADOR

60 OSAPATO

(Ok [09SEP Oa

“TaN si Pcs ae Olgir of aaeay EE ran OCA TON oy TINT TNE

neste fe et pout eng prsnet omen pennsays tet it ee

‘Sojesooroy coe oe es at neat nape Acar Ft Ltt Ps nti

tate ope ec tps ne eel uy of compe no ry aac noma cs py

‘tmnt Sat oe ts hens nant an shen a Eh ep ates Eel aan See ee

Ligue tarpon on eo at 60 Nha ers a a. Mase Ba aap ce

Lee

Dssuman No 25825 200-9. 400.0501 Rev 60 Page tot 2e

‘Speccaton Sle? Cone augment and Congooer Nunn and Tage io 2505 09" cou c00t Re, 000

10

20

30

40

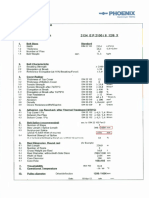

‘TABLE OF CONTENTS:

PURPOSE

NUMBERING SYSTEM ...

24 General .

2.2 Mechanical and Electrical Equipment,

224 Fort. i

222 Facility Designator .

223 Equipment Sesignator

224 Sequence Number.

23 MOO nn

23.1 Format... oe

24 Instruments...

244 Format

242 Facility asignator

243. Functional Description Designatsx

244 Sequence Numbor

245 Sutc

25 Piping.

25.1 Format

252 Commodity

25.3 Lina Diamator.

254 Faclly Code:

25.9 Pipe CASS.

25.6 Soquential Lino Number.

25.7 Pipe Spods..

2.6 Electrical Instrumentation Cabling.

261 Format oe

2.7 Electrical Raceway : os

27.1 Format.

EQUIPMENT LISTS..

EQUIPMENT TAGGING.

41 General o os

42 Application. Seca 13

bec Copaton 208

Cora comer ant roofer eaten Bec ae sted Sampara nthe nd decane pce ay

{eat ny ara Pry wet Baap won armas, Kaen

nave No: 25525.0037S-60000001 Ra 0 Page aot 22

‘Spector eter! Cac Cauzert nd Congoran Number ra Tago 2535 00 966:600 0001 Fv. 000

43 Tag/ Nameplate manufacturing... 13

44 Tag/ Nameplate Details seomnnennninnnaennsnane

44.1 Goneral sont 14

4.4.2 _Liting Equipment ccc 4

443 Piping Componenis... 4

45 Location and Moutng Requiem. 16

4.5.1 Major and Auxiliary Equipment. et 18

ATTACHMENTS

APPENDIX A LIST OF APPROVED FACILITY DESIGNATORS

APPENDIX 8 LIST OF APPROVED EQUIPMENT DESIGNATORS

(Speciation 208

‘eras cont an pole ecmaon Bact te ocd sors whi al rote and decd oan in

cea ty ary rar Baca Psy wut Betas pc etn urna Nise

‘Specter tr Soe’ Conests Eauomer and Cenpner Nunbtng 2 ‘2025.20.96 20 2001 Fv. 000

1.0 PURPOSE

“The purpose of this specication isto provide the folowing two functions fr the |OC

Concentrate Expansion Project.

‘+ Define the Project's equipment / component / materials numbering system such thatthe

‘Seller / Contractor is able to number items in a manner consistent nth the Project

standard format

+ Dofino the Project's cquipment/ component / material idonification requirements auch

that all tags, nameplates, and labels wil folow a consistent structure in tems of content,

format, and materials

2.0 REFERENCE DOCUMENTS, CODES, AND STANDARDS

21 PROJECT DOCUMENTS

‘This specication shall be read in conjunction with the folowing Project documents:

28825-200-3PS-NX00.00001 Speciation for Protective Coatings

2§305-200-3PS.PX00.00001_Spectiation for Supply of Piping, Valves, and Fitings

26828-200-P1.0000-00003 identification Standards — Electrical Isolation Device

‘Tagging ~ Lamacoid Detail Draving

'25826-200-P1.0000.00004 Equipment Identification ~ Tagging Standards ~ Detail

Drawing Sheet 1

'25925-200-P1-0000-00005 Equipment Identification ~ Tagging Standards ~ Detail

Drawing Sheet 2

25825-200-GFA-GEE-00001 Electrical Equipment List Template

25325-200-GFA-GEJ-00001 Instrument List Template

25826-200-GFA-GEM.00001 Mechanical Equipment List Template

'25826-200-GFA-GEX-00001 Spare Pars List for One Year Operation Template

25825-200-GFA-GEX.00017 Special Tools List Template

22 OTHER DOCUMENTS

‘Safety labeling and signage shall comply wth the requirements of ANSI 2535.4 2002,

[Seca Gaon 208,

Cortina one array lon oats aeocoryis hich hac bo vee, Sched pode hay

"anata Beton Psy wi oes wt amin Ap osewe).

Donut No: 25005 20035-60000 Av 00 Page satan

Ie CONCENTRATE EXPANSION PROUECT

3.0

324

322

NUMBERING SYSTEM

3.1 GENERAL

‘This specification establishes the methodology for numbering of equipment, motos,

instruments, piping and pipe components, electrical and instrumentation cabling, and electrical,

raceway.

Each item must be assigned a unique number that can be used for accurate identification on

Grawings, data sheets, and al other documentation related tothe specttcitem. These numbers

are used for identification through al stages of engineering, procurement, construction, and

‘operation ofthe plant. This specication describes the standard numbering procedure that has

been developed forthe Project, and approved for use by IOC, and which must be followed for

assigning numbers to all tems covered by this specification.

In tho event that clarification is required on any numbering requirements, the Seller / Contractor

shall immediately contact Buyer for confirmation ofthe correct requirements,

Buyer is typically responsible for assigning numbers to major items (those tems spectically

listed in material requistions). The Seller / Contractor is responsibie for assigring numbers to

‘minor items or sub-items that are within the scope of supply but not spectficaly listed inthe

material requisition. All numbers assigned by Sallar/ Contractor (or batches of numbers) must

bbe reserved and confirmed with Buyer prior to use.

3.2 MECHANICAL AND ELECTRICAL EQUIPMENT

Fomat

‘The number vl consist of a facity designator, equipment designator, and sequence number.

‘The standard equipment number format is

YOOX - YWYY

T+ soquonce Number

L__. Equipment Designator

{___ Faciity Designator

Eznclty Designator

‘All new equipment willbe assigned a four (4) digit facility number to be used as the facility

{designator in the equipment numer. A lst of al facility numbers applicable tothe IOC

‘Concentrate Expansion Projects included in Appendix A.

ects Capron 208,

ovine nt ardor rp omaton Bx rd ae iri ih al eb ad, coed orp a ary

Tatty arena Party Bsfs rmitan pom. Ait esse

‘Spstenon or Se" Concer Sauer and Conponet Nuon Tagging 2588 200 00001 Rr. Co0

22.3 Equipment Designator

324

33.1

The equipment designator will consist of one (1), two (2), three (3), oF four (4 alphabetical

characters, in accordance with the IOC equipment designation system, A Ist of all equipment

designation codes is included in Appendix B.

Han equipment designator does not exist for an tem, the Seller / Contractor shall submit a

Fequest te Buyer for allocation and approval of a new equipment designator,

‘Sequence Number

“The sequence number isa sequential number for each item of equipment and is assigned such

that each item of equipment has a unique number. The sequence number will consist of four (4)

characters. Leading zeroes willbe used to provide a sequence number to 4 characters where

required

For two tems of identical equipment, e.g. duty and standby pumps, the numbers will bo

sequential. For example:

Pump 1: §423-P -0001

Pump 2: §423-P -0002

33 MOTORS

Format

‘Numbers ‘or motors wil bo based on the equipment number for its associated equipment, but

with a suffx added to It as a motor designation. The motor designation shall consist ofthe letter

“Mr followed by a sequence number.

‘An example of a pump and its motor would be as follows:

Pump: §423-P - 0001,

Pump Motor: 423 -P - 0002 - mit

Ita singloitem has more than one motor, then the mator designation would increment

sequently (0. M1, M2, MS, et.)

Al motors wil be assigned numbers as described above, except in special cases such as where

‘motors are purchased with an equipment tem and the itém is purchased complete with all

electrical materials and equipment and requires only one connection to a source of power.

(29e54Cameton 208

‘eras cnet an ropa omaon Sac ra a unpainted ree

Toca oy rb ay win Gens ta pomianen Asa

soe CONCENTRATE xBANSIOW RENEE

ian Sale Conarr Eq nd Compre ynbatn ndT 2550520099600 001 Fev. 000

344

342

343

344

345

34 INSTRUMENTS

oat

‘The instrument number will consist ofa facity designator, functional description designator,

sequence number, and alphabetical uli (required as described below),

‘The standard instrument number format is:

2OOX- WWW be

T+ sequence Number

|_______ Functional Description Designator

L__, raciity besignator

Facility Designator

Instrument numbers will use the facity designators as listed in Appendix A

Euncional Description Designator

Instn:ment numbers will use the same functional description designators as specifed by the

Instrrment Society of America (ISA), which shall consist of between one (1) and five (5)

alphabetical characters.

nce Number

‘The sequence number is a sequential number for each instrument. The sequence number will

consist of four (4) characters. Leading zeroes will be used to provide a sequence "umber to 4

characters where required for smell numbers,

‘Sut

‘Where identical instruments exist with the same instrument number, those instruments willbe

Sequential Line Number

Pipe Class

Facility Code

Line Diameter (inches)

> commodity Code

x

3.6 ELECTRICAL/ INSTRUMENTATION CABLING

Foimat

Each cable shall have an IOC cable number. A cable number's obtained by adding a cable

suffi tothe tag numer ofthe equipment or instrument being fed. In the case of outgoing

Cables from distribution panels, the cables shall be numbered using the panel number folowed

by the branch circuit number instead of the equipment number being fed,

‘peo Cpe 208

‘eran son andr sepia formance an ait songs whch a abe et cone een)

“arly aro Bect Paty ah Bes pr un pomastn Als escved

‘Stectnon bv Sele’ Coneeci Eaubt rd Cangoner Naber ed Tapog No 255 200.96 000001 ev. 060

‘The cable number is uit according tothe following rules:

‘+ First segment isthe equipment or instrument number

‘+ Second segment isthe service level ofthe cable defined as follows:

Instrumentation

© 120V discrete signals

J signals s 50V (thermocouples, RTDs, 4-20mA, etc)

X_ special signals such as optical, communications, tc.

voltage greater than SkY

1M. voltage at SKV (nominal)

voltage from 120V to 600V

+The ast segment of he cable numbers a sequential number trom 109

Example ofa cable number fora unique piece of equipment:

5420-TR.0002 -P 4

Sequential number

Service Level

LS Eatipment Number

Example ofa cable number fora piece of equipment with multiple motors:

15428.WM-0002.M1-P1

'5428-WM-0002.M2-P1

Example of an analog signal cable to an instrument

5420-FV-004t1

Example ofa cable number for a 120V signal rom atimit swith:

5423-2SL-0028A-C2

Examples of a power cable to an instrument:

5423-FE.0041A-P1

Conese en craton ec rn Spain wh al ete won, Screen

Teale obs Pay sao Bool pron pumas Apes ease

LOC CONCENTRATE EXPANSION PROVECT

‘Spsseaton Sel! Contac Cau nd Canoonent Nunbeirg a Tagg Ne 256.200: 600.0601 Fer. 000

‘+ Multiconduector cable shall be prefixed withthe letter °C

Example:

© 5428-JB-0041 -J1

Lk sucuota cunbe-

Servoe Level

1+ instrument Number

Profix"C"

37 ELECTRICAL RACEWAY

8.7.1 Eomat

Each electrical raceway, ladder / tray, and conduit shall have an 1OC raceway aumber. A

raceway number consists of four fields; facity designator, raceway designation code, raceway

service level, and raceway sulx

1. The facility designators are listed in Appendix A

2. Raceway designation code is selected from the folowing:

= T Cable tray (ladder type)

= B Cable tray with barior

© Conduit

3, Raceway service level is solected based on the voltage level from the following:

Power cables at more than Sk

Power cables at 5 KV (nominal)

Power cables at 120V or 600V

Instrumentation cables with 120V discret signals

Instrumentation cables with 50V or less

covez

4. The last segment is a 3 digit sequential number from 001 upwards

bac Crperatn 2008

Soni edt artery emation Bae an ead care wi sl ot be eed, candor mpc ay

‘Stato sro Berts Pay win eles pr nn pom Adres aon

‘hector Se Conese Eqdenen and Compares Numoamng and Taggeg __ No 25385 2006P5.60090260% Rev, 020

40

50

Example for of an electrical raceway number:

5423-7 P-001

| | [ > seauena number

Serco Level

> Raceway Designator

1+ Facity Designator

Example of an instrumentation tray with a barser:

5423-6-C-028

When a barteri installed in a tray, the ray will be numbered using the higher service level

present. During instalation ofthe banner, the service level of each section willbe identified on

tether side ofthe bari at regular intervals.

usts.

‘Buyer wil assign numbers for major items and those numbers wil be presented in Section 1 of

the applicable purchase order documentation. The Seller / Contractor shall be rasponsible for

assigning numbers to any other equipment / materials included in the scape of supply but not

speatcally sted in Section 1 of te purchase order.

‘All numbers assigned to items by Soller / Contractor shal bo issued to Buyer prior to thelr use

{or review and approval. All numbers shall follow the applicable formats described in Section 2

above, and shall be presented using the templates ised in Section 2 o this specification,

‘Soller / Contractor shall complete all applicable fields within the above listed templates in order

to provide as much information as possible for each item,

EQUIPMENT TAGGING

5.1 GENERAL,

This section describes the minimum workmanship and matorial quality standards for the

‘manufacturing, supply, and instalation ofthe physical identification systems for equipment and

materials supplied lor ne IOC Concentrate Expansion Project - nameplates, tags, and labels.

Original equipment manufacturers’ nameplates are not covered by this specification

‘All nameplates must be fly affixed, legible, and durable for the ife of the equipment

{© Set Comaren 208

Toma ron Sect Paty anata wan pomascn Al ges erooe

loc coucentnATE expansion praveer

ia Slr Const Eau! ed Caroorent Runde so 2tas 2204s oop 200% Rey. 0c0

‘The IOC Concentrate Expansion Project tag must be supplied in addition to the OEM tag,

tniess the OEM tag satisfies the requitements ofthis spectication.

‘The Saller shall conform to Canadian federal and provincial codes applicable to equipment and

component labeling, in addition to the requirements ofthis specication,

5.2 APPLICATION

The unique number assigned to each piece of equipment / component must be clearly marked

{or accurate identiication on drawings, specifications, bills of materials, requisitions, purchase

‘orders, and all other documentation related tothe specfic equipment / component.

“The number must appear on a nameplate permanent affixed to the equipment / component by

the Seller / Contractor, in compliance with the requirements ofthis specification

“The Soller / Contractor must ensure that all symbols, descriptions, and materials used for

Identification are approved by the Buyers representative

53 TAG/NAMEPLATE MANUFACTURING

"Nameplates for equipment shall comply with the detals described in drawings 25325-200-P1-

(0000-00004 and 25326-200-P1-0000-00006. The mataral shall be brushed finish aluminium

{and thicxness shall range from 12 gauge to 16 gauge, as spectied on those drawings. Tho

‘nameplates shall be attached to the equipment using four (4) screws o rvats. The scrows or

fivets shall be selected to ensure secure fastening ofthe namopiate forthe lie ofthe

equipment.

‘Tags and nameplates for electrical equipment / components shall comply with the detais

described in drawing 25325-200-P1-0000-00008. ‘Seller shall select the applicable tag /

‘nameplate type from the categories shown on that drawing. The material shall be lamacoid,

‘and the tags / nameplates shall be attached using two screws / vats, selected to provide

‘Secure fastening for the feof the equinment,

“Tags for other items not addressed by the drawings listed above (e.g. valves and other pipe

fitings) shal be stamped stainless steel and shall be securely atached to the item using

stainless steel wie,

In spectic instances, it may not be practical to use metal o plastic nameplates. In such cases,

paint shal be used instead, with lettering appearing in back paint. If the color ofthe equipment

{does not provide enough contrast to the lettering, a white rectangle shal fist be painted onto

the equipment, wit the lettering being postioned on that rectangle. The selected painting

system must comply wit the requicements of specification 25325-200-3PS-NX00-00001,

‘Speciation for Protective Coatings. Seller shall seek Buyer's approval prior to use of painted

Identiication systems.

‘cna cenit ani roi Plrmaon te Onl ann secede nd a

toca oy none Pay wit Gal prior wan pamason Ais moses

Dosen: 26525.203295-GID90000 Re O50 ne 130122

1c CONCENTRATE EXPANSION PROUECT

‘Speco lv See) Conse ue and Consent Naberng 2 agp 2505 9898-0 0001 Rew 009

541

642

543

For all identification systoms, lettering must be in capital letters only, centered, and in Arial font.

For aluminium nameplates, lettering shall appear in black colour. For larracoid and painted

tags / nameplates, lettering shall appear in black colour wih a white background.

5.4 TAG/ NAMEPLATE DETAILS

General

‘The different nameplate details for ctferent categories of equipment are described by the

{following drawings:

28325-200-P 10000-00003 Identification Standards ~ Eletical Isolation

Device Tagging ~ Lamacoid Detal Drawing

28826-200-P1-0000-00008 Equipment Idantfication ~ Tagging Standards —

Detail Drawing Sheet 1

'25825-200-P1-0000-00005 Equipment Identiication ~ Tagging Standards —

Detal Drawing Sheet 2

‘Soler / Contractor shail select the type of nameplate trom these drawings, as applicable to each

individual item of equipment.

Liting Equipment

To avoid beam piercing, nameplates shal be attached to ling equipmen' using an Industrial

strength epoxy adhesive, or equivalent, that is suited tothe site conditions.

Major iting equipment such as overhead cranes and jb cranes must be dented with stencil

painted lettering 2” high. The equipment number must be indicated next t the Working Load

Limit (WL) capacity.

Piping Components

‘Tags for piping components shall be attached to each individual item by means of stainless

steel wire.

‘One (1) tag per component is required

‘2 Bee Capen 2008

Conia conc ander tmaton Bsns tractor wich hel ot be ond dened aac ry

aoa ay reba Pty mab Gels pow mason A ia exeved

Dyce No 25225 20040S-G00900001 Rev O00 age 140420

‘Sestenton i Ste? Conache Une and Comparer Numb od Teno No 25305.2923P5-00092001 Fev. 060

5.5 LOCATION AND MOUNTING REQUIREMENTS

55.1 Malor and Auxitary Equloment

“The nameplates /tags must be installed in a clearly visible position on the item to be dented.

During maintenance and equipment relocation, the nameplates /tags must remain inthe

ctiginal location

'Namepiates shall be attached such that they will not become loose or detach under any

‘operating conditions fr the life of the equipment

Very lang or tall equipment must be idantiied at each end.

Labels shall be provided fo indicate the presence of and access method to any boxes, devices,

and instruments that may nat be easily visible.

Each numbered item must be indicated by a nameplate or ta.

amin contra ado rary onan ac ated cues ob od daa aren nny

Toca oye oct Pay wt cl pr aun poms Henson

Onsen No: 25928:20039S-G0m 6901 RCO age 150122

Specleton lr Sue Conte Eger and Consort Nurbeng 2 T9309 2505 90978-0000 0001 Rw 000

APPENDIX A

LIST OF APPROVED FACILITY DESIGNATORS

FACILITY NO.

(0000

4075

4240

5200

5230

5423

5428

5600

5610

5612

5700

5708

FACILITY DESCRIPTION

GENERAL,

MINE SWITCHING STATION # 4

MINE SWITCHING STATION #1

INDEXER

| PARALLEL ORE DELIVERY SySTEM (PODS)

AUTOGENOUS MILL AGI4

| SPIRALS PLANT EXPANSION

[NEW BOILER AT CONCENTRATOR STEAM PLANT

HEMATITE PLANT ~ CIRCUIT C

BALL MILL BM105

TAILINGS DISPOSAL & PHASE (3190-2) & MODIFICATIONS.

(c10-1153)

TAILINGS DISPOSAL — NTPH ~ 250THICKENER —

| MODIFICATIONS (CTD-078)

THICKENER FACILITY

WATER SUPPLY & PROCESS WATER (3190) COLLINS

COVE (CTD-079)

EXPANSION TO PROCESS WATER PUMPHOUSE (2>WPH)

‘SUBSTATION FOR PWPH (Sub 605)

COTHP SUBSTATION 606

PROCESS WATER PUMP HOUSE SUBSTATION

{onan Copan 208,

Caras creda a popetayeeaten Bec asad camper Wt a tbe eed. doe of ped ay

eral yy Be

ny mat eal os sn poms Ai ese

ganas Ns 252620 35-6260 0001 Fev 00) age 180122

Se

or aN

00s | QYERLANO CONVEYOR SUBSTATION ~ EXPANSION TO

tt | emien eer orem

6020 _| EXPANSION OF SUBSTATION 6000 FOR BM105

6140 | NTPH SUBSTATION 616

6200 _| PODS SUBSTATION AT CONCENTRATOR (Sub 620 South)

7108 | 8 TRAIN LONGER TRAIN

2 | alte Frat

it ren ir

ber Copaton 208

eras cartes ar pop soto Bact a shes Sonar hen hat rate ek. hd pad ay

ay ry arb Pay wnt ec ps wit aro: Bis eo

Spector Cont Equpmert to Coupon Norby ss No 258 0966 0000908 Re 009

APPENDIX B

LIST OF APPROVED EQUIPMENT DESIGNATORS,

‘symol |Description

‘AC [AIR CONDITIONER, VENTILATION, AIR COMPRESSOR

AD |AIRDRYER

AF |AIR FILTER,

AG [AGITATOR AND MIXER,

BA _|BATTERY AND BATTERY CHARGER —

8C [BELT CONVEYOR -

bk |pRAKE

3kR__ |FEEDER BREAKER

sin [Bower —

BLW [BLOWER

eM (BALL MILL

BN |BINORHOPPER

8S |eus- ELECTRICAL

BU [BALL BUCKET

Bw [BELT WASHER, -

CAP _ [POWER FACTOR CORRECTION CAPACITORHARMONIC FILTER

cs |couection Box

CC [s00v CONTROL CENTRE

co [CONDENSER

cH |cHuTE:CHUTE GATE

cume |uit FEED CHUTE

ci [evaririen

ck |cooueR

cl |ouassirier

om |coLumn

cP |coNTROL PANEL

9 |caracrton

‘© Bet Crpoatin 2008

ora coral andr prepay ersten acta sd Spares ich hl tbe oa, econ or pics any

Totaly ron onan Pry eo Goce po ae, Ms as

Spucieton by See’ Cont Equant a Consonant Nanbring 2 agp 206 200006 Guo 6001 Rev 009

‘syMBOL [DESCRIPTION

CA [ORUSHER

cx JoRLonINATOR

cy fovcuone

cz [oooune rower

os [oistrisutoa

oc [oust ano Fune GouecTon

DE peaeRaToR

DMG |DEMAGNETIZING COIL

DP [pisTRIBUTOR Panes (IGHTINGINSTRUNENTATION

on _forver

08 foisconnecr swincs

DU lbucTWoRK

OV |oRIVE COMPONENT

Econ [ecoNoMizeR

co [ENGINE onweR

tx_|ELEVATOR. FREIGHT ANO PASSENGER

eS” EMERGENCY sHoweR

ev _ levaronaton

= iFaN

ro _|PunNace

Fon RECIPROCATING FEEDER

FH IRE HOSe 00x, HYDRANT

F.FUTER

rit frutenpaw

re ie PROTECTION

en [Fecoen

G0 jlesex GevenaTon

Ge |oeneraror

GA [GROUND AesiSTOR

1 _fetecv mocrsTARTER LINE UP

[ect Coponton 208

Cortana ender pony oman Bec ed Soros wk sha et beak, dachead acon

‘Stal yar an notes Pry wu Gets ps ilo rms Kise

Deca 282520039-080-0001 Rv 00

Page 100122

See TET ccmsmeretitged Tiga —— seanssenert onostn fee

svusot [bescRiTiON

He. JUNIT SUBSTATION

Hs uoeneD serrLen - SS

sw [HAN swircH

ra HEATER

Hx MEAT EXCHANGER, RECUPERATOR

Je buncTion sox

K [onaneonnosr SSS

ic ono cenrne

Loe [ucHTine oisTRIBUTION PANEL

Ut [uNeR HANOLERS

> wee Pune

tn Aunoen

Ls |LUse system -

Lvew Low voLTAGe 6oov SwiToHGEAReREAKER

w Moron

wa want

we [PULPING Box

woo _woToR CONTROL CENTRE

woov _|ucHine suppressor

we —_|Moeite EoUIPMENT

wc fea macner

INos _ [MAGNETIC SEPARATOR

wwe MUL LINERS

wa hwononAt.

wwe axeR

NGA NEUTRAL GROUNDING RESISTOR

ns |nsuLarion

0¢ [oveRHeAo crane

‘ce [oincurr REAKeR sexy

e_fpuwe

"paren Copanten 008

‘ers corto are pn ran Bae anf sine companies ich sa at ese dcr eres ary

‘Gay any onc Paya Sls po won posse. Mie seve

Socunert Ne staar2200F3-SoeotE Re O00

Pane 200122

‘Spesicten ly Sle! Cones Equgmert nd Camgoner Naber we Ta99n9, 25305 00 36-6000. Fv 000

‘SYMBOL [DESCRIPTION

PA [PACKAGING EQUIPMENT

PB [PUMP BOX

Pc |PLocaBINeT

PD |poweR DooR,

PE |PELLETIZING EQUIPMENT

Pr [PRESSURE FILTER

PLC _|PROGRAMMABLE LOGIC CONTROLLER

PS |PARTICLE SIZE ANALYZER

PT

Px.

RC

RE |SPEED REDUCER

RF |ROTARY VALVE

RH |RHEOSTAT

RP RELAY PANEL

AV |AIRRECEIVER

sa |sampuen

se |s.uary ox

sc__|screw conveyor

scr __|ScROLL DRIVE

8G [SWITCH GEAR (4.16KV)

SIN |siLeNceR

st |scae

sn [SCREEN

SO _|SOFTENER- WATER

SP__|SEPARATORISPLITTER BOX/SPIRAL

‘spr |spraveR

st _ |STEeLWoRK

stk _|stack

sv__ [SLURRY VALVE

‘© cis Cxpen 2008

Conia conn rr merit cmaonm Bec sloedconer whic she

bo ven, dosed or apeaceinary

‘Gearon sone ary wets po wan pamiseon, Meares

Deoanat Ne 2525 2002PS-6000 0001 Fav 099

Page ze

Speen els! Cnr Eger rd Cangenen Number rd Tangrg No 2s 200.5 600.0100 Rev. 060

SYMBOL [DESCRIPTION

SW |SWITCH- ELECTRICAL

Te _ {TERMINAL BOX

Te __ [TREATMENT EQUIPMENT

TH _ |POWER TRANSFORMER

TK (TANK

TR [TRANSFORMER

up |umurry pane.

ups _ [INTERRUPTED POWER SUPPLY

vA \VACUUMEQUIPMENT

ve erator

vs _ |pREssUrE vesseL

VSD _|VARIABLE SPEED DRIVE

we WATER CLOSET

wa |GrINoING MILL- WET

WMG [GRINDING MILL RING GEAR - -

WMI [GRINDING MILL INCHING DRIVE

wap |MILL PINION

ww |MILLGEAR REDUCER

WR |WELDING RECEPTACLE

ws WATER SOFTENER

XR |REACTOR- CURRENT LIMITING

ZE _|MISCELLANEOUS ELECTRICAL EQUIPMENT

ZM__|MISCELLANEOUS MECHANICAL EQUIPMENT

zP__|PIPING AND VALVES:

ces Copan 208

Cotas conens ant pepe Hlomaton i ecil iltaedcomparee whch shal athe wa, eestor peed nay

Icealy ny nn nes Pry wat ets porta ursanon Ma ear

age 220120

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Annual Book of Astm StandardsDocument12 pagesAnnual Book of Astm StandardsanishgirmeNo ratings yet

- HsaDocument5 pagesHsaanishgirmeNo ratings yet

- Belt Technical Data SheetDocument1 pageBelt Technical Data SheetanishgirmeNo ratings yet

- Applied Probability in Operations Research PDFDocument68 pagesApplied Probability in Operations Research PDFanishgirmeNo ratings yet

- Application of The Safety Codes Act To Pressurized EquipmentDocument28 pagesApplication of The Safety Codes Act To Pressurized EquipmentanishgirmeNo ratings yet

- DCRules-Final 2013Document399 pagesDCRules-Final 2013anishgirmeNo ratings yet

- Section 5 - Supplier Quality Surveillance: 1.0 GeneralDocument3 pagesSection 5 - Supplier Quality Surveillance: 1.0 Generalanishgirme100% (1)

- ISO 9001:2008 RE-CERTIFICATION: When?Document16 pagesISO 9001:2008 RE-CERTIFICATION: When?anishgirmeNo ratings yet

- Design Memorandum - 9962-001-IS-155-PVM-Z-005-03Document63 pagesDesign Memorandum - 9962-001-IS-155-PVM-Z-005-03anishgirmeNo ratings yet

- BHEL-Technical Enquiry SpecsDocument46 pagesBHEL-Technical Enquiry Specsanishgirme0% (1)

- 694 09 Fenner Gearboxes SeriesCDocument28 pages694 09 Fenner Gearboxes SeriesCanishgirmeNo ratings yet

- BHEL Panki VOL III (Mechanical)Document116 pagesBHEL Panki VOL III (Mechanical)anishgirmeNo ratings yet

- Autocad Training 2014 - 3D1Document49 pagesAutocad Training 2014 - 3D1anishgirmeNo ratings yet

- Specification For Crane Rail Section-3443Document19 pagesSpecification For Crane Rail Section-3443anishgirmeNo ratings yet

- Mhe System Intercom-Loop: Sr. No. Name Ext. No. Loop Status 7 Available (Yes/No)Document1 pageMhe System Intercom-Loop: Sr. No. Name Ext. No. Loop Status 7 Available (Yes/No)anishgirmeNo ratings yet

- Business Process FlowDocument1 pageBusiness Process FlowanishgirmeNo ratings yet

- DFTmeasure Paint InspectionDocument1 pageDFTmeasure Paint Inspectionanishgirme100% (1)

- Business Process Flow-Rev1Document1 pageBusiness Process Flow-Rev1anishgirmeNo ratings yet

- American Society of Mechanical Engineers (ASME) CodesDocument6 pagesAmerican Society of Mechanical Engineers (ASME) CodesanishgirmeNo ratings yet