You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- ROMER CimCore Product Catalog PDFDocument23 pagesROMER CimCore Product Catalog PDFCesar ArellanoNo ratings yet

- RDS User Manual V4.0.0.086 PDFDocument185 pagesRDS User Manual V4.0.0.086 PDFCesar ArellanoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Instructivo FARO - CAM2 Q PDFDocument362 pagesInstructivo FARO - CAM2 Q PDFCesar ArellanoNo ratings yet

- Gage R&R For Attributes: InstructionsDocument31 pagesGage R&R For Attributes: InstructionsCesar ArellanoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- A01-00056 - RevA - StartUp - GuideDocument1 pageA01-00056 - RevA - StartUp - GuideCesar ArellanoNo ratings yet

- Checklist de Cuidados Básicos para Robot UR5Document1 pageChecklist de Cuidados Básicos para Robot UR5Cesar ArellanoNo ratings yet

- Examen Agile Doc ControlDocument19 pagesExamen Agile Doc ControlCesar ArellanoNo ratings yet

- Gantt Inspection - Common BaseDocument1 pageGantt Inspection - Common BaseCesar ArellanoNo ratings yet

- Cambios FrameDocument156 pagesCambios FrameCesar ArellanoNo ratings yet

- Certificate of Completion For CCN Agile PQM FA TechDocument1 pageCertificate of Completion For CCN Agile PQM FA TechCesar ArellanoNo ratings yet

- PCDMISv2011 Español Rev1CMMDocument186 pagesPCDMISv2011 Español Rev1CMMCesar ArellanoNo ratings yet

- SANMINA-SCI's Agile Training ApproachDocument11 pagesSANMINA-SCI's Agile Training ApproachCesar ArellanoNo ratings yet

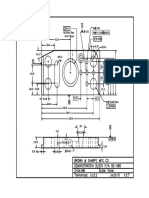

- Print Demo BlockMMDocument2 pagesPrint Demo BlockMMCesar ArellanoNo ratings yet

- Introduccion A CMMs - SPANISH PDFDocument28 pagesIntroduccion A CMMs - SPANISH PDFCesar ArellanoNo ratings yet