Professional Documents

Culture Documents

Ideco TL-200 - 120

Ideco TL-200 - 120

Uploaded by

Gustavo Rivera0 ratings0% found this document useful (0 votes)

629 views12 pagesOriginal Title

IDECO TL-200 -120

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

629 views12 pagesIdeco TL-200 - 120

Ideco TL-200 - 120

Uploaded by

Gustavo RiveraCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

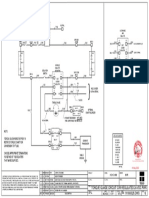

BULLETIN NO. TL-2g0-81

PARTS BOOK

and MAINTENANCE GUIDE

Pm

- TRU-LINE

SWIVELS ©

TL-200

MODEL “B”

TL-120

MODEL “A”

TL-120

MODEL “Cs”

|

For parts and service contact your

IDECO district sales office in your area

When ordering parts always furnish the following infor-

mation to assure prompt delivery:

1, Serial number of machine. , .

2. Part name, part number and quantity es

required.

3. Whether to ship by freight, express, or

parcel post.

Claims tor shortages or errors should be made imme-

diately upon receipt of material.

i

INTERNATIONAL

PO Boe 101

Pampa, Texas 70065

Phone (605) 685370,

‘olor: 910-699-440

Fe (805) 6653216:

WARNING: THE SWIVELS ARE SHIPPED WITH A RUST INHIBITING OILIN

‘THE RESERVOIR AND WITH A 4” PIPE PLUG INSTALLED IN

THE AIR VENT LOCATION "G”. BEFORE OPERATING SWIVEL af

THIS OIL SHOULD BE DRAINED AND THE PIPE PLUG REMOVED AND x A

REPLACED WITH THE FURNISHED AIR VENT FITTING. LUBRICANT

‘SHOULD THEN BE ADDED IN ACCORDANCE WITH INSTRUCTIONS.

GIVEN BELOW.

1. DRAIN AT "B* AND "C" AND REFILL TO WITHIN 1/2" (13 mm)

TO 1" (25 mm) FROM BOTTOM OF FILLER PLUG "A" AFTER

TL-120C.S., TL-120A & TL-200B

LUBRICATION

INSTRUCTIONS

THE LUBRICATION INVOLVES ONE CENTRAL

RESERVOIR FOR ALL BEARINGS AND ALEMITE

FITTINGS FOR ALL OTHER COMPONENTS.

EVERY WELL OR EVERY 30 DAYS

2. GREASE DAILY AT POINTS "D*, "E*, AND "F*.

3. USE RECOMMENDED LUBRICANTS OR EQUIVALENT.

TL-120

TL-200

CAPACITIES

‘TL-120 C.S. APPROXIMATELY 5 GALLONS

APPROXIMATELY 5 GALLONS.

APPROXIMATELY 9 GALLONS,

Swivel)

RECOMMENDED LUBRICANTS

Buus

aA Fn (ALES,

EXXON

seaatib crea

SEARO ox

GuLF

MOBIL

SHELL

TEXACO

PARTS LIST FOR

TL-120 MODEL “A”, TL-120 MODEL“C. s?

TL-200 MODEL “B”

TTEM] PART NO. | PART NO. | PART NO. | NO. + DESCRIPTION

NO. | TL-200 | TL-120 | TL-120CS | REQ.

1 | 531-01 559-06 559-06 1 |BoDY

2 | 531-02 559-07 559-36 1 [STEM

3 | 531-03 | 559-19 1s-404 1 ~ 6%" REG. LH.

531-21 559-20 18-406 1 |SUB. - 4%" REG. LI

4 | 1B-631 1B-642 1B-642 2. | ALIGNMENT BEARING x

5 | 10-305 | 10-318 10-318 4 {OWL SEAL

6 | 531-04 559-09 559-09 1 | LOWER ALIGNMENT BEARING RETAINER

7 6 | 3%" N.C. CPS.X1%" LG. WLW. (TL-200)

6 | %"N.C. CPS. X 1%" LG. WLW. (TL-120)

8 | 531-05 | 559-15 559-15 1 | 4/32" THICK GASKET

9 | ise 18-438, 1B-436 1 |MAIN BEARING

40 | 18-411 1-415 18-415 1 |UPTHRUST BEARING

11 | 531-06 559-08 559-08 1 | UPPER ALIGNMENT BEARING RETAINTER. #

+13, | 531-07 | 59-14 559-14 1_|1/32" THIGK GASKET z

531-08-01 | 559-16-01 | 559-16-01 | A/R | SHIM .005” THICK 5

531-08-02 | 5599-16-02 | 55-16-02 | A/R | SHIM .010" THICK

531-08-03 | 559-16-03 | 559-16-03 | A/R | SHIM .0312" THICK

531-08-04 | 559-16-04 | 559-16-04 | A/R | SHIM .003” THICK

14 | 339-HB 42 | STUD W/%" N.C. FLEX-LOC NUT (TL-200)

330-HB | 399-HB 8 | STUD W/W" N.G. FLEX-LOG NUT (TL-120)

15 | sar-10. | 559-12 559-12 2 |BAIL PIN

ve F117 F117 F117 2 | GREASE ALEMITE

7 1 | 1" SOC. HO. PIPE PLUG

18 | §31-40 | 559-01 559-55 4 | BAIL

to | sai-12 | 559-05 559-05 1, | GOOSENECK

NA 559-21 559-21 1 | GOOSENECK W/2" SQ. HD. PIPE PLUG

20 7. | "N.C. CPS. X.3%" LG. W/FLEX-LOC NUT (TL-200)

7 |W N.C. CPS. X31" LG. W/FLEX-LOC NUT (TL-120)

21 | v.120 1-120 1-120 1 | AIR. VENT

22 | 531-13 | 559-10 559-10 1 | UPPER PACKING NUT

23 | 531-1401 1 | UPPER CARTRIDGE

24 | 491-07 | 390-33 339-33 1 | WASHPIPE

25 | 1P-159 1P-166 1P-166 1 | UPPER PACKING ASSEMBLY

26 1 | 1%" SOC. HD. MAGNETIC DRAIN PLUG

27 | so117 | 559-13 559-13 1 | OLSEAL SPACER

28 6 | 4" N.C. SOC. HD. CPS. X 1%" LG. W/LW. (TL-200)

3. | %#" N.C. SOC. HD. GPS. X 1%" LG. W/L.W. (TL-120)

29 | iP-802 w-a77 IPA77 1 | LOWER PACKING ASSEMBLY

30 5 1 | #" SOC. HD. MAGNETIC DRAIN PLUG

31 | IF-116 1F-116 IF-116 1 | GREASE ALEMITE

32 | 531-23 | 559-2302 | 559-23-02 | 1 | LOWER CARTRIDGE

33 | sa1-19 | 559.04 | 559-04 1 | BONNET

34 18-405 1

| SEAL (TL-1208)

“INSTALL ITEM #13 ON ASSEMBLY TO GIVE VERTICAL PLAY OF STEM OF .001” TO .004” LOOSE.

@ ‘

WW

@

OQOCOC®OO®

@

TL-120 6s

STEM AND SUB

‘UPPER ALIGNMENT BEARING

UP OF TOP SEAL FACES UB

UP OF BOTTOM SEAL FACES DOWN.

Hl

LOWER ALLIGNMENT BEARING

UP OF BOTH SEALS FACE UB

|

Fi

i

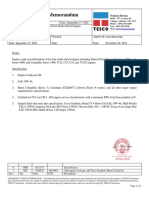

TL-200

Tru-Line Swivel

Instructions for Installing Floating Washpipe and Washpipe Packing.

* To Remove Washpipe

‘and Packing Assembly:

‘A. Remove Grease Fitting 19. Unscrew Lower

Cartridge 10. This nut has left hand threads.

Unscrew Upper Nut 8. This nut has right hand

threads,

BL Push 8, 7 and 10 together in the center of the

‘washpipe, andslipthe assembly out the back ofthe

bonnet (side opposite rotary hose).

Slide tema, 7 and 10 down the washpipe untilthe

Split Retainer Ring S may beremoved. Sipitems8,

6, 7 and 10 off of the washpipe. Both cartridge

assemblies are ready to be cleaned and new packing

and washpipe installed.

Assembly and Instructions:

. Clean the inside of the Upper Cartridge 7 and

Lower Cartridge 10 and the threads of the

Gooseneck 1 and stem 18. :

. install new packing and Spacers 11-17 packaged |

a3 IP-802 In the Lower Cartridge 10, and insert

Grease Fitting 19. Pack the packing andallcavities

fon the inside “clameter of the packing with the

molybedenum disulide base grease furnished with

tach set of lower packing.

F._ Push the washpipe into the packing cartridge until

the end is even with the bottom of the cartridge.

G._ Place the Upper Nut 8 and Upper Cartridge 7 over

the top ofthe washpipe.insertitems6, 5, 4and3 (in

that order) into the Upper Cartridge and around the

washpipe. Meke certain the Split Retainer Ring 5 is

seated in the groove in the washpipe.

H.Lightty grease "O” Ring 2 and place on the groove.

of the gooseneck.

1. Align the fat sides on the top of the washpipe with

Slot in the bottom of the gooseneck. Push the

assembly into place and tighten the top nut until slack.

is outof the Upper Cartridge. PushtheLower Canidge

‘and serew tight onthe stem, Then tightentop nutdown

wren | escrow tignt Use around bar = 14" « 12" = and hammer with

Caen sledge narnmer to tighten the cartridge nuts.

foes

"3 [eee Recommended Greases:

[eng Mobil Mobil Special wiMoly

7S win ig Shell = hall MDS or Darna AX

= Rss eg Gulf - Gultex Moly

7 [Wier ease ‘Texaco Molytex #2

pp exon - Beacon O2

TS Moly - Lub. Inc. or Equivalent Molybedenum

Disulfide Base Grease

a rome NOTE: Swivel packing should be greased without

@ ten’ ump pressure against packing every 8-12 hours ot

& Poona Set ‘ring operation.

“Pactoge am P-159

TL-120 & TL-120 C.S.

) Tru-Line Swivel

Instructions for Installing Floating Washpipe and Washpipe Packing:

To Remove Washpipe

and Packing Assembly:

A. Remove Grease Fitting 19. Unscrew Lower

Cartridge 10. This cartridge has left hand threads.

Unscrew Upper Cartridge 8. This piace has right

§ hang threads.

8. Push 8 and 10 together in the center of the

‘washpipe and sip assembly out of the back of the

bonnet (side opposite rotary hose)

._Slige lems 8 and 10 down the washpipe unt the

Split Retainer 6 may be removed. Slide Items 7, 8

and 10 off of the wasnpipe. Both cartridge assemblies

fare ready 10 be cleansti-and dressed out with new

packing assemblies and washpipe.

Assembly and Installation

©. Clean the inside of the Upper Cartridge 8 and

ower Carridge 10 and threads ofthe Gooseneck

‘and Stem 18. -

. Install pew packing and Spacers 11-16 packaged

| © abiptrr'in te Lower Cartidge 1. and insert

‘Srease Fiting 1. Pack packing nos filingall cavities

Int inside ameter ofthe packing essemby with he

motybeaenum daulide base presse furnished wih

tach et of packing.

F Puan the washpipe into the Lower Packing

Cane unite en i even with he bottom at

the cartage

GG. Place no"O:RingSinthegrooveonthewasnpipe

and one (1)“O" Ang 3 inthe groove ofthe Seal

Aaapter Place the “O" Ring 2 the groove of he

Gooseneck 1

HPPiace Upper Canvisge 8 over the top of the

‘eashpie. nse item 76 and inthis rea) nto

the Upper Garde and around the washpipe Make

Certain the Spt Retainer ing 6s seatedin the groove Part Numbers Corresponding

Inthe wesnppe andthe “O- Rings 2,3and5 remain in "To Above item Numbers

their respective grooves. Grease the °O" Rings hghty

betore installation ‘ren | cesemrrion | ear,

1° ign th flat sides on the fop af the washpipe with 7 [Bem ses

the slot in th bottom ofa Gooseneck. Push the 2 [orig os

assembly ilo place and staeetha Top Canidge and 3 [erg ‘0.8

tighten seugly. Push the Lower Cartridge down and a [encase

{crew ight onthe stom. Then ightonthe Top Carvidge 5 [-o' fing ios

‘Assemblies - use a short round bar 1" X 12" stock - “6 | fing fing [spo

and nummer tight win a sledge hammer mari

Recommended Greases: ies

Mobil Mobi Speci w/oly ee coe

Shall ial MOS or Barna AX 1 ps a

Gut Gumiex ky peta |

Texaco - Molytex #2 ” ing Somer wore

Exaon - Beacon O2 SARIS ( Fotre se

TS Moly - Lub. Inc. of Equivalent Molybedenum Sng

Disitide Base Grease eee

a seer

NOTE: Swivel packing should be greased without at errae

ump pressure against packing every 8-12 hours of

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BOMBAS DE LODO CapacidadDocument9 pagesBOMBAS DE LODO CapacidadGustavo RiveraNo ratings yet

- Partes para Bombas Triplex PZDocument2 pagesPartes para Bombas Triplex PZGustavo Rivera100% (1)

- TL 120 200BDocument10 pagesTL 120 200BGustavo Rivera50% (2)

- Partes para Bombas Triplex Continental EmscoDocument4 pagesPartes para Bombas Triplex Continental EmscoGustavo RiveraNo ratings yet

- Instrucciones de ManejoDocument2 pagesInstrucciones de ManejoGustavo RiveraNo ratings yet

- Iron Roughneck PW163 PDFDocument51 pagesIron Roughneck PW163 PDFGustavo RiveraNo ratings yet

- Pieter Eras Mus: R ErasmDocument1 pagePieter Eras Mus: R ErasmGustavo RiveraNo ratings yet

- Manual de Partes Unit 1168 HMI PDFDocument231 pagesManual de Partes Unit 1168 HMI PDFGustavo RiveraNo ratings yet

- 91000015rev4 PDFDocument1 page91000015rev4 PDFGustavo RiveraNo ratings yet

- EM000039Rev1 PDFDocument1 pageEM000039Rev1 PDFGustavo RiveraNo ratings yet

- 881006RevA PDFDocument1 page881006RevA PDFGustavo RiveraNo ratings yet

- EG-3P/EG-6P/EG-10P: Proportional ActuatorsDocument4 pagesEG-3P/EG-6P/EG-10P: Proportional ActuatorsGustavo RiveraNo ratings yet

- C BOP Parts List PDFDocument9 pagesC BOP Parts List PDFGustavo RiveraNo ratings yet

- Aceites Codigo JDE Parte Numero SHELL Parte Numero MOBIL UM: Mobilux EP-2Document2 pagesAceites Codigo JDE Parte Numero SHELL Parte Numero MOBIL UM: Mobilux EP-2Gustavo RiveraNo ratings yet

- Copia de Choke - Manifold.SparesDocument4 pagesCopia de Choke - Manifold.SparesGustavo RiveraNo ratings yet