Professional Documents

Culture Documents

BlueBill PDF

BlueBill PDF

Uploaded by

pamela41220 ratings0% found this document useful (0 votes)

58 views6 pagesOriginal Title

BlueBill.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views6 pagesBlueBill PDF

BlueBill PDF

Uploaded by

pamela4122Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

BOAT BUILDER'S ANNUAL

“BLUE BILL” A 13-Foot Combination

. Kayak-Canoe

Craft Print Project No. 80

Uses: Extremely wide adaptation to various

uses. May be used as duck boat, cance,

kayak, outboard kayak. Is adapted to shel

tered waters. May be paddled or propelled

with outboard motors from 1 to 6 hp.

LENGTH: 18 ft. 6 in,

BEAM: 3 ft. 2 in.

DEPTH: 12 in.

WEIGHT Complete: 75 Ibs.

SEATING CAPACITY: 3 person

CONSTRUCTION: Wood frame canvas

covered.

TYPE: Flat bottom, knuckle joints.

MATERIAL LIST

Finished

e ee Parte Pieces Dimensions

utdoor folks who és ,

Keel ai aa ara 4" at

need en ule ght. Chines er) re ran ae

weight porteble boat Sheor and Blige Bations.--. ) a Vert ada!

Should not find it i Bottom. Bations sae 2 ren" ay

it to make this Deck Battone v4 gran a2

—_ mat ere Inside Coaming a 3g x1 be":

nd canes. Outside Coaming ae ara”

Side Deck Support 1 14" x19" x8

Deck Booms a Sgr eat

Floor Boards. 18 ara x8"

OMBINING thefestaregof both kayak Petes ppwind cet ewe |

and canoe, “Blue Bill” is offered to Stems (Marine plywood) seneeees D Sytxl 2x4”

those out-of-doots men who hunt or Raised Canoe Bow Sections Be pone tg

: Mouldings --..0-'-- a Yarra

the sportsmen who need an ultra light- Form ; tects

weight portable boat for use upon any

waters, Besides being usable for build-

ing a double-end paddling model, a few

changes permit the plans to be used for

making a canoe that will accommodate

outboard motors up to 6 hp. for swift,

speedy transportation on any stream or

waterway.

Weighing only 75 Ibs. complete, “Blue

Bill” is eabily transported atop an auto

anywhere. All details of “Blue Bill” have

been simplified for easy fabrication and

the construction cost is within reach of

Kinds ef Wood: Spruce, fir, cedar, cypress, white pine, red-

wood, yellow pine, Make form from rough lumber.

FASTENINGS AND OTHER MATERIALS

1Gro.1"Wo.8£.

1 Groc14’No. 8

1 Gro 134” No.8

2 One. 14" takes.

2Gals. Airplane wing dope.

1 Lb, Casein glue.

1Qt Enamel.

15 Yas. 30° canvas, 8 oF 10-02.

Cadmium plated, brass, or galvanized.

Cadmium plated, brass, or galvanized,

Cadmiumplated, brass, orgalvanized,

——————————

everyone's pocketbook.

At the outset, either of the two models

(paddling or outboard) must be selected. With

the type selected, the form is sawed to shape as

indicated upon the plans and notched for frames.

Mount this form upon legs similar to a sawhorse

at a convenient working height. If the outboard

model is constructed, let the form extend

straight out 6’ 8" aft of No. 5 frame position.

‘As all frames are the same for the outboard

model aft of No. 5, make four additional No. 5

frames and one transom piece as shown. For the

paddling model, make one No. 3 frame and two

of every other as all frames forward and aft

from amidships are alike. To facilitate construc-

tion of frames draw full-size paper patterns of

frames from No. 1 to No. 5, lay frame material

upon patterns, prick outline through, saw to

shape, and laying the frame parts upon the

patterns so as to conform to outline, daub

joints with glue and fasten with 14" No. 8 fh,

screws.

With all frames made, assemble on form up- |

side down and proceed to attach keel to center

‘of bottom frame cross members with two 14"

No, 8 £h. serews to each joint, First drill and

BOAT BUILDER'S ANNUAL 3

STEM :

STEM |, THICKNESS $

fr squanes | HER BATTEN. SN

SHEER BATTEN] “(STEM

ATTACHES | BEVELING BEVEL STEM ON EITHER TYPE

HERE CONSTRUCTION

MAKE TWO OF !

# PLY woop CANOE BOW CONSTRUCTION ie eAnUS

ony LUMBER CANOE BOW CONSTRUCTION Faywoo] if

a lao

[= wake To Fir

W

a ‘SIDE FRAME PATTERN

Fu NOTCHES FOR FRAMES ea

ri

FORM FOR ASSEMBLING FRAMES,

MOTOR BOARD

CANOE BOW OUTBOARD MOTOR MODEL

SIDE SUPPORTS INSIDE COAMING MOTOR MODEL QUTLINE

BREAST PLATE

DECK BATTENS:

Deck BEAM:

OUTSIDE COAMING

BOTTOM BATTEN KEEL-

[CHINE

SIDE BATTENS

isl} peck BEAMS

SHEER BATTEN: COAMING. SIDE BATTENS

il =

jot STEM Io ff [ne |" [eKEEL7 [#7 fs lg STEM "

25k Veoh 1g ae ay ig bg 2]

countersink for all fastenings. A coating of

casein glue wherever possible on joints will

strengthen things considerably. The stems are

sawed to shape and notched for the keel to

which they are attached with two 134" fh.

screws. The %4” x 34” chines are now clamped in

place at No. 5 frame, simultaneously bent both

forward and aft and serew fastened with one 194”

No, 8 fh. screw to each joint. Trim chine ends to

fit against stem and keel joint and fasten simi-

larly at both ends of framework. Ai this point

it is necessary to trim all edges of side frames

fo conform with sweep of side battens to be at-

tached. A light batten laid around frames will cTRALSoM Bt OUTREARE BODE

™

indicate the correct

bevel

‘The ¥%4” x 1” sheer

battens are attached

to frames with one

1%" No, 8 fh. screw

to each joint, “Start

amidships and work

towards each end

aligning and attach-

ing sheer battens as

work progresses. The

\" x 1” side battens

ate next distributed

equally between

sheer batten and

chines and similarly

fastened, beve king

ends of battens to fit

sides of, stems about

one inch back from

outer stem edge. This

edge of stem is later

beveled off so canvas

Framework is shown on

form with part of side

Dations attached.

BOAT BUILDER'S ANNUAL

MASTER BOAT BUILDER

ILLIAM JACKSON,

who designed ‘most

‘of the boats described and

Hlustrated in this issue of

the Boat Builder's Annual,

may justly claim the title

master boat builder, For

twenty years he has de-

signed and built more than

400 boats which are in use

in every part of the world

—on the Danube River,

Nile River, Black Sea, In-

WILLIAM: JACKSON dian Ocean, Australia,

Greenland, Borneo, and in

Alrieg. Back from the wars, he is hard at work now on

more beats at his home and boat plant at Bass Lake, In-

diana, His great grandfather was a boat builder in

Russia, his grandfather a boat builder in England, and

his father a famous boat builder on the Atlantic Coast

and Mexico and the Pacific Coast, Mr. Jackson has sailed

in many waters, been marooned, shipwrecked, and won

speedboat races.

fits nicely at this

point.

With all battens

attached, remove

framework from

form and complete

interior construction,

Saw the deck beams

to, shape and right

here a selection of

either canoe or kayak

bow construction

should, be made. A

canoe forward bow

and kayak after bow

looks well as in’ the

original. Or, the ends

may be identical. The

raised bow of the

canoe type is easily

made by adding

raised pieces to -the

sheer battens for-

ward and attaching to

‘The center of the keel carries the seam when the boat is cam:

‘vassed, one-hall at a timo,

How the “Blue Bill” looks when bottom and decks are convassed.

BOAT BUILDER

INSIDE COAMING #32". OECK.

QUISIDE COAMING #25 BATTEN,

SECTION AMIDSHIPS

COCKPIT SUPPORT FLOOR BOARDS|

on ne

WBE ween Faik) Bat

ume anv eort0n4

Barrens dad

oe TIT

rf

Fads

rT

MOTOR BOARD SAME DLMIENSIONS AS "5,

-—103—

[MAKE TWO OF EACH,

stem os’shown. Same deck beams are used for

either bow construction. ' Fasten deck beams to

sheer battens at points shown and cut to fit side

deck supports, fastening all pieces in place with

1s" No. 8 £h. screws. The deck battens are

notched into frame beams No. 2 and No. 8, while

the ends towards each bow are simply butted

against sheer battens. Bend the inner coaming

in place and screw fasten with 1” No. 8 £h.

serews. At this point bevel the stem edges for-

ward to conform to sweep of battens and with

all constructional details finished.

Turn hull right side up and begin covering

hull by tacking canvas evenly along the keel,

stretching cloth towards bow and stern. Con-

tinue tacking along keel and commence stretch-

ing cloth towards sheer, pulling excess cloth

‘over sheer batien and tacking. The cloth is

pulled over the stem, tacked and trimmed. In

this way each half of the hull is covered with

the canvas meeting slong the keel. With bot-

tom and sides finished turn hull over and cover

decks similarly. If necessary, piece cloth and

later cover the joints with cloth tape.

‘The edges of canvas along the coaming are

covered with the %4” x 2” outer coaming which

is screw fastened with 1” No. 8 Eh. screws. The

‘edges along the sheer batten are concealed and

78 BOAT BUILDER'S ANNUAL

trimmed with the 14” x %" moulding which is

also screw fastened in place with 1” No, 8 fh.

screws spaced about eight inches apart. The

cloth along the stem edges is best covered with

narrow strips of wood or brass bands.

As paint ‘applied to canvas results only in a

heavy, lifeless surface, the entire canvas cover-

ing must be doped with airplane dope which fills

the canvas weave, tautens the cloth, and renders

the whole waterproof. Apply three or four ap-

plications of the airplane dope to the canvas

face, allowing one-half-hour intervals for drying

and sanding lightly. ‘The final finish may be

either pigment colors added to the dope or a coat

of lacquer. Before applying paints or enamels

to the doped surface allow hull to air a few days,

then apply a coat of varnish and follow with one

_9F two coats of porch or floor enamel.

The %” x 4" floor boards are screw fastened

‘with 1” No. 8 fh. screws to the frames. A rex:

ular canoe paddle will propel the boat easily.

Craft Print No. $0 in enlar

jae Bill” is. availa 23 ac

int Dept. B-48, Sci

perior St, Chicago

size for build

‘Address

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 212 Woodenboat-Issue PDFDocument148 pages212 Woodenboat-Issue PDFpamela4122No ratings yet

- American Pattern Grader Ed 2Document192 pagesAmerican Pattern Grader Ed 2pamela4122No ratings yet

- Caldwell D. - and All Was Revealed - Ladies Underwear 1907-1980Document75 pagesCaldwell D. - and All Was Revealed - Ladies Underwear 1907-1980pamela4122No ratings yet

- Tailoring Suits The Professional Way by PoulinDocument216 pagesTailoring Suits The Professional Way by Poulinpamela4122No ratings yet

- The Cutters Practical Guide To The Cutting & Making All Kinds of Trousers Breeches & KnickersDocument108 pagesThe Cutters Practical Guide To The Cutting & Making All Kinds of Trousers Breeches & Knickerspamela4122No ratings yet

- The Americanized French Cutting Method 1903Document72 pagesThe Americanized French Cutting Method 1903pamela4122No ratings yet

- Make An Impact: Architecture For TomorrowDocument172 pagesMake An Impact: Architecture For Tomorrowpamela4122No ratings yet

- The Science of Coat and Vest CuttingDocument202 pagesThe Science of Coat and Vest Cuttingpamela4122No ratings yet

- The Corset and The Crinoline A Book of Modes and Costumes From Remote Periods To The Present TimeDocument254 pagesThe Corset and The Crinoline A Book of Modes and Costumes From Remote Periods To The Present Timepamela4122No ratings yet

- 6 NovemberDecember PDFDocument148 pages6 NovemberDecember PDFpamela4122No ratings yet

- 2 MarchApril PDFDocument160 pages2 MarchApril PDFpamela4122No ratings yet

- 5 SeptemberOctober PDFDocument160 pages5 SeptemberOctober PDFpamela4122No ratings yet

- Roundwood House BookDocument67 pagesRoundwood House Bookpamela4122No ratings yet

- Adf19 03 PDFDocument100 pagesAdf19 03 PDFpamela4122No ratings yet

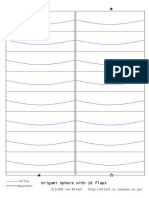

- Origami Sphere With 16 FlapsDocument1 pageOrigami Sphere With 16 Flapspamela4122No ratings yet

- Triangle of Whipped Cream 2010 Jun MitaniDocument1 pageTriangle of Whipped Cream 2010 Jun Mitanipamela4122No ratings yet

- Calder Wood Section 6Document60 pagesCalder Wood Section 6pamela4122No ratings yet