Professional Documents

Culture Documents

Isa 5.1 Adicional 2012

Uploaded by

jhon jairo GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Isa 5.1 Adicional 2012

Uploaded by

jhon jairo GonzalezCopyright:

Available Formats

TECHNICAL REPORT

ISA-TR5.1.01/ISA-TR77.40.01-2012

Functional Diagram Usage

Approved 10 August 2012

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 -2-

ISA-TR5.1.01/ISA-TR77.40.01-2012

Functional Diagram Usage

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

ISBN: 978-1-937560-06-5

Copyright © 2012 by ISA. All rights reserved. Not for resale. Printed in the United States of

America. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means (electronic mechanical, photocopying, recording, or

otherwise), without the prior written permission of the Publisher.

ISA

67 Alexander Drive

P.O. Box 12277

Research Triangle Park, North Carolina 27709

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

-3- ISA-TR5.1.01/ISA-TR77.40.01-2012

Preface

This preface, as well as all footnotes and annexes, is included for information purposes and is

not part of ISA-TR5.1.01/ISA-TR77.40.01-2012.

This document has been prepared as part of the service of ISA toward a goal of uniformity in

the field of instrumentation. To be of real value, this document should not be static but should

be subject to periodic review. Toward this end, the Society welcomes all comments and

criticisms and asks that they be addressed to the Secretary, Standards and Practices Board;

ISA; 67 Alexander Drive; P. O. Box 12277; Research Triangle Park, NC 27709; Telephone

(919) 549-8411; Fax (919) 549-8288; E-mail: standards@isa.org.

The ISA Standards and Practices Department is aware of the growing need for attention to the

metric system of units in general, and the International System of Units (S I) in particular, in

the preparation of instrumentation standards . The Department is further aware of the benefits

to USA users of ISA standards of incorporating suitable references to the SI (and the metric

system) in their business and professional dealings with other countries. Toward this end, this

Department will endeavor to introduce SI-acceptable metric units in all new and revised

standards, recommended practices, and technical reports to the greatest extent possible .

Standard for Use of the International System of Units (SI): The Modern Metric System ,

published by the American Society for Testing & Materials as IEEE/ASTM SI 10-10, and future

revisions, will be the reference guide for definitions, symbols, abbreviations, and conversion

factors.

It is the policy of ISA to encourage and welcome the participation of all concerned individuals

and interests in the development of ISA standards, recommended practices, and technical

reports. Participation in the ISA standards-making process by an individual in no way

constitutes endorsement by the employer of that individual, of ISA, or of any of the standards,

recommended practices, and technical reports that ISA develops.

CAUTION — ISA DOES NOT TAKE ANY POSITION WITH RESPECT TO THE EXISTENCE

OR VALIDITY OF ANY PATENT RIGHTS ASSERTED IN CONNECTION WITH THIS

DOCUMENT, AND ISA DISCLAIMS LIABILITY FOR THE INFRINGEMENT OF ANY PATENT

RESULTING FROM THE USE OF THIS DOCUMENT. USERS ARE ADVISED THAT

DETERMINATION OF THE VALIDITY OF ANY PATENT RIGHTS, AND THE RISK OF

INFRINGEMENT OF SUCH RIGHTS, IS ENTIRELY THEIR OWN RESPONSIBILITY.

PURSUANT TO ISA’S PATENT POLICY, ONE OR MORE PATENT HOLDERS OR PATENT

APPLICANTS MAY HAVE DISCLOSED PATENTS THAT COULD BE INFRINGED BY USE

OF THIS DOCUMENT AND EXECUTED A LETTER OF ASSURANCE COMMITTING TO THE

GRANTING OF A LICENSE ON A WORLDWIDE, NON-DISCRIMINATORY BASIS, WITH A

FAIR AND REASONABLE ROYALTY RATE AND FAIR AND REASONABLE TERMS AND

CONDITIONS. FOR MORE INFORMATION ON SUCH DISCLOSURES AND LETTERS OF

ASSURANCE, CONTACT ISA OR VISIT www.isa.org/StandardsPatents.

OTHER PATENTS OR PATENT CLAIMS MAY EXIST FOR WHICH A DISCLOSURE OR

LETTER OF ASSURANCE HAS NOT BEEN RECEIVED. ISA IS NOT RESPONSIBLE FOR

IDENTIFYING PATENTS OR PATENT APPLICATIONS FOR WHICH A LICENSE MAY BE

REQUIRED, FOR CONDUCTING INQUIRIES INTO THE LEGAL VALIDITY OR SCOPE OF

PATENTS, OR DETERMINING WHETHER ANY LICENSING TERMS OR CONDITIONS

PROVIDED IN CONNECTION WITH SUBMISSION OF A LETTER OF ASSURANCE, IF ANY,

OR IN ANY LICENSING AGREEMENTS ARE REASONABLE OR NON-DISCRIMINATORY.

ISA REQUESTS THAT ANYONE REVIEWING THIS DOCUMENT WHO IS AWARE OF ANY

PATENTS THAT MAY IMPACT IMPLEMENTATION OF THE DOCUMENT NOTIFY THE ISA

STANDARDS AND PRACTICES DEPARTMENT OF THE PATENT AND ITS OWNER.

ADDITIONALLY, THE USE OF THIS DOCUMENT MAY INVOLVE HAZARDOUS MATERIALS, OR

EQUIPMENT. THE DOCUMENT CANNOT ANTICIPATE ALL POSSIBLE APPLICATIONS OR

ADDRESS ALL POSSIBLE SAFETY ISSUES ASSOCIATED WITH USE IN HAZARDOUS

Copyright 2012 ISA. All rights reserved.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 -4-

CONDITIONS. THE USER OF THIS DOCUMENT MUST EXERCISE SOUND PROFESSIONAL

JUDGMENT CONCERNING ITS USE AND APPLICABILITY UNDER THE USER’S PARTICULAR

CIRCUMSTANCES. THE USER MUST ALSO CONSIDER THE APPLICABILITY OF ANY

GOVERNMENTAL REGULATORY LIMITATIONS AND ESTABLISHED SAFETY AND HEALTH

PRACTICES BEFORE IMPLEMENTING THIS STANDARD.

The following members of ISA-TR77.40 WG1 developed this document in 2011:

NAME COMPANY

D. Lee, Chairman ABB

D. Andrasik GenOn Energy, Inc.

C. Carter Lee College

G. Cohee Applied Control Systems

A. Davison Fluor Daniel Canada Ltd.

O. Fasasi Shell P & T Dev Co Ltd.

M. Graube Relcom Inc.

R. Marshall Sega Inc.

N. Pandey Technisource

M. Pandya Southern Company Services Inc.

D. Roney Washington Group

K. Sefton Qatar Petroleum

R. Swart NEM BV

D. Turner FFEUC Aust. Inc.

I. Verhappen Industrial Automation Networks, Inc.

V. Yi PDVSA

A. Zadiraka Babcock & Wilcox

The following members of ISA77 approved this document for publication in 2011:

NAME COMPANY

G. McFarland, Managing Director Emerson Process Management

L. Altcheh Israel Electric Corp.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

J. Batug PPL Generation LLC

G. Cohee Applied Control Systems

D. Crow Invensys Foxboro

M. Cushing Siemens Process Instrumentation

R. Eng Hitachi Power Systems America

A. Erickson Bibb & Associates

A. Gavrilos ABB Inc.

J. Gilman JFG Technology Transfer LLC

W. Hocking Invensys Process Systems*

R. Hubby Robert N. Hubby Consulting

H. Johansen Bechtel Power Corp.

R. Johnson IC Engineering

D. Lee ABB Inc.

X. Lou Alstom Power

J. Olson Tennessee Valley Authority

M. Pandya Southern Company Services Inc.

D. Roney URS Corporation

W. Shin BC Hydro

M. Skoncey First Energy Generation Corp.

L. Somak SRP

T. Stevenson Constellation Energy

C. Taft Taft Engineering Inc.

P. Toigo Burns & McDonnell

J. Vavrek Sargent & Lundy LLC

A. Zadiraka Consultant

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

-5- ISA-TR5.1.01/ISA-TR77.40.01-2012

The following members of ISA5 approved this document for publication in 2011:

NAME COMPANY

I. Verhappen, Managing Director Industrial Automation Networks, Inc.

J. Federlein Federlein & Associates Inc.

D. Frey Reliatech Inc.

A. Habib Custom Automation

T. McAvinew Instrumentation & Control Engineering LLC

G. Ramachandran Systems Research International Inc.

This standard was approved for publication by the ISA Standards and Practices Board

on 10 August 2012.

NAME COMPANY

D. Dunn, Vice President Aramco Services Co.

E. Cosman, Vice President-Elect The Dow Chemical Co.

D. Bartusiak ExxonMobil Chemical Company

P. Brett Honeywell Inc.

J. Campbell Consultant

M. Coppler Det Norske Veritas Certification Inc..

B. Dumortier Schneider Electric

J. Federlein Federlein & Assoc. Inc.

J. Gilsinn U.S. NIST

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

E. Icayan ACES Inc.

J. Jamison EnCana Corporation Ltd.

K. Lindner Endress+Hauser Process Solutions AG

V. Maggioli Feltronics Corp.

T. McAvinew Instrumentation & Control Engineering LLC

R. Reimer Rockwell Automation

S. Russell Valero Energy Corp.

N. Sands DuPont

H. Sasajima Azbil Corp.

T. Schnaare Rosemount Inc.

J. Tatera Tatera & Associates Inc.

I. Verhappen Industrial Automation Networks, Inc.

W. Weidman WCW Consulting

J. Weiss Applied Control Solutions LLC

M. Wilkins Yokogawa IA Global Marketing USMK

D. Zetterberg Chevron Energy Technology Company

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 -6-

This page intentionally left blank.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

-7- ISA-TR5.1.01/ISA-TR77.40.01-2012

Table of Contents

1 Scope ............................................................................................................................. 11

2 Purpose .......................................................................................................................... 11

3 Definitions ...................................................................................................................... 11

4 Abbreviations (Acronyms) ............................................................................................... 12

5 Preparation of functional diagrams ................................................................................. 13

5.1

Basic symbols ....................................................................................................... 13

5.2

Advanced symbols ................................................................................................ 13

5.2.1 Combination of symbols ............................................................................ 14

5.2.2 Multiple functions ...................................................................................... 15

5.2.3 New algorithms .......................................................................................... 15

5.3 Diagram format ..................................................................................................... 18

5.3.1 Diagram organization ................................................................................ 18

5.3.2 Diagram interconnection ............................................................................ 18

5.3.3 Diagram layout .......................................................................................... 20

5.4 Symbol use case examples ................................................................................... 21

5.4.1 Single loop ................................................................................................ 23

5.4.2 Two-element loop ...................................................................................... 23

5.4.3 Cascade loop ............................................................................................ 25

5.4.4 Advanced controller with multivariable control ........................................... 26

5.4.5 Motor-operated valve logic ........................................................................ 30

5.4.6 Motor breaker logic .................................................................................... 31

Annex A - Functional diagram historical usage ...................................................................... 33

Annex B - References ........................................................................................................... 35

B.1 ISA references ................................................................................................ 35

B.2 ISO references ................................................................................................ 35

B.3 Symbol tables ................................................................................................. 35

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`--- Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 -8-

This page intentionally left blank.

Copyright 2012 ISA. All rights reserved. --```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

-9- ISA-TR5.1.01/ISA-TR77.40.01-2012

Foreword

Functional diagrams were first employed when discrete a nd electric analog control systems

were designed. Associations and professional societies, such as Scientific Apparatus Makers

Association (SAMA), ISA, and ISO, provided guidelines as to industry use of functional

diagrams. SAMA has ceased to exist, but its popular standard, PMC 22.1-1981, Functional

Diagramming of Instrument and Control Systems , is currently available through The

Measurement, Control and Automation Association as well as ISA. Current ISA standards

available for industry use include ANSI/ISA-5.1-2009, Instrument Symbols and Identification,

and ISA-5.2-1976 (R1992), Binary Logic Diagrams for Process Operations . Symbols from

SAMA PMC 22.1-1981, Functional Diagramming of Instrument and Control Systems , have

been incorporated into ANSI/ISA-5.1-2009. The work within this technical report maintains

historical practices of the previous and current documents and expands on new algorithms

and practices.

Abstract

This technical report is an extension of ANSI/ISA-5.1-2009. The intent of this report is to

provide further information and practical examples on the usage of functional diagrams for

documenting application software. It is hoped that this report will be a handy reference to

design engineers who are directly involved in the generation or revie w of functional diagrams.

Key words

functional diagram, function block symbols, application software, control algorithm, cascade

controller, multiple input multiple output controller, symbol legend, PID controller

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 10 -

This page intentionally left blank.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 11 - ISA-TR5.1.01/ISA-TR77.40.01-2012

1 Scope

The scope of this technical report is to expand on and illustrate usage of functi on block

symbols and functions and to prepare examples in development of complex function block

symbols and functions.

2 Purpose

The purpose of this technical report is to provide advice and guidance in documenting

application software through functional diagrams.

3 Definitions

3.1 alarm:

an audible and/or visible means of indicating to the operator an equipment malfunction,

process deviation, or abnormal condition requiring a response [ANSI/ISA-18.2-2009]

3.2 application software:

software specific to a user application that is configurable and in general contains logic

sequences, permissive and limit expressions, control algorithms , and other codes required to

control the appropriate input, output, calculations, and decisions

3.3 binary:

a term applied to a signal or device that has only two discrete positions or states. When us ed

in its simplest form, as in binary signal (as opposed to analog signal), the term denotes an on-

off or high-low state, i.e., one which does not represent continuously varying quantities.

3.4 controller:

a device having an output that varies to regulate a controlled variable in a specified manner. A

controller may be a self-contained analog or digital instrument, or it may be the equivalent of

such an instrument in a shared control system. An automatic controller varies its output

automatically in response to a direct or indirect input of a measured process variable. A

manual controller is a manual loading station, and its output is not dependent on a measured

process variable but can be varied only by manual adjustment. A controller may be integral

with other functional elements of a control loop.

3.5 control station:

a manual loading station that provides control-loop switching between manual and automatic

control mode. It is also known as an auto-manual station. In addition, the operator interface of

a distributed control system may be regarded as a control station.

3.6 converter:

a device that receives instrument signal information in one form and transmits an output

signal in another form. An instrument that changes a sensor's output to a standard signal is

properly designated as a transmitter, not a converter. Typi cally, a temperature element (TE)

may connect to a transmitter (TT), not to a converter (TY).

3.7 digital:

a term applied to a signal or device that uses binary digits to represent continuous values or

discrete states

3.8 distributed control system:

a system that, while being functionally integrated, consists of subsystems that may be

physically separate and remotely located from one another

3.9 function:

the purpose of or an action performed by a device

Copyright 2012 ISA. All rights reserved.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 12 -

3.10 functional diagram:

the practice of diagramming application software in its basic functional form, exclusive of its

operating media or specific equipment detail

3.11 legend sheet:

a sheet of the individual symbols and identification with explanation

3.12 logic signal:

representation of information by a set of discrete values in accordance with a prescribe d law.

These values are represented by numbers. [ISA-51.1-1979 (R1993)]

3.13 logic system:

decision-making and translation elements of a control system ; provides outputs in response to

external inputs and internal logic (NFPA 85: Boiler and Combustion Systems Hazards Code,

2011 Edition)

3.14 macro:

a set of functions combined as a specific program to be run as a single task. The task is a

subset of the controller’s program but executes repeatedly for similar devices or applications

with unique inputs and outputs.

3.15 measurement:

the determination of the existence or the magnitude of a variable [ISA-51.1-1979 (R1993)]

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

3.16 multiple input multiple output:

an algorithm/program, such as model predictive control, neural net, expert system, etc. , that

computes one or more output demands, biases, or setpoints based on multiple inputs

3.17 process:

any operation or sequence of operations involving a change of energy, state, composition,

dimension, or other properties that may be defined with respect to a datum [ISA-51.1-1979

(R1993)]

3.18 process measurement:

the acquisition of information that establishes the magnitude of process qualities. [ISA-51.1-

1979 (R1993)]

3.19 process variable:

any variable property of a process; used in this standard to apply to all variables other than

instrument signals [ISA-51.1-1979 (R1993)]

3.20 program:

a repeatable sequence of actions that defines the status of outputs as a fixed

relationship to a set of inputs

3.21 setpoint:

an input variable that sets the desired value of the controlled variable ; may be manually set,

automatically set, or programmed. Its value is expressed in the same units as the controlled

variable.

4 Abbreviations (Acronyms)

HMI – human machine interface

I/O – input/output

MIMO – multiple input multiple output

MOV – motor operated valve

PID - proportional integral derivative

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 13 - ISA-TR5.1.01/ISA-TR77.40.01-2012

5 Preparation of functional diagrams

This report is concerned with the functional diagrams normally prepared in the early stages of

system conception from the mechanical or process flow sheet. Functional diagrams normally

are revised and kept current over the complete system life cycle as system design progresses

through the various stages of negotiations, quotation, contract award, reduction to final

equipment, system checkout, installation, and ongoing system enhancements. They are also

included as part of the system instructions.

The functional diagrams define functions of a control configuration that are independent of the

hardware and firmware of the control system used for process automation. Functional

diagrams are a method to document application software and transfer information for

implementation into the selected control system.

A functional diagram may be more or less detailed, depending on its intended use. The

amount of detail in a logic diagram depends on the degree of refinement of the logic and on

whether auxiliary, essentially non-logic, information is included. Simplified diagrams can be

drawn by omitting details that may be obvious.

This report is intended to provide sufficient information to enable anyone with a reasonable

amount of process and instrumentation knowledge, who is reviewing documents depicting

process measurement and control, to understand the means of measurement and control of

the process.

This report is suitable for use whenever reference to measurement and/or control

instrumentation, control devices and/or functions, or software applications and/or functions is

required for the purposes of symbolizing and identification.

5.1 Basic symbols

A logic symbol comprises an outline or a combination of outlines together with one or more

qualifying identifications and/or qualifying texts. Basic and complex logic symbols with

minimum inputs need not specify input names. Logic symbols with multiple inputs can have

input name identifiers to specify the signal functions within the algorithm. New function or

algorithm symbols should represent an encapsulated software component (i.e., function block)

that exists within a system’s library.

5.2 Advanced symbols

With the introduction of microprocessor-based systems, suppliers have developed advanced

algorithms that are not represented by previous PMC 22.1, the German Institute for

Standardization (DIN), the International Electrotechnical Commission (IEC), or ISA-5.1

standards. While following the intent of these standards, suppliers either create a new symbol

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

or group existing symbols to represent the new algorithm. The problem occurs in

understanding what function that symbol really represents and the symbol’s boundaries. Thus,

advanced symbols depict new control algorithm s via a combination of existing symbols, new

control algorithms with multiple functions, and new control algorithm s previously unavailable

with electric analog systems.

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 14 -

5.2.1 Combination of symbols

A control algorithm containing multiple

mathematical functions may be

represented by combining multiple

symbols within one block, as shown in

Figure 5.2.1.a (PID controller), or by P I D

having the blocks physically touching ><

each other along the longer dimension

of the block, as shown in Figure

PID controller Mathematical function

5.2.1.b (Mathematical function). The

Figure 5.2.1.a Figure 5.2.1.b

combination of mathematical symbols

should only be used where there is no possibility of misunderstanding the function being

represented.

Combining symbols is often necessary to conserve space on a diagram. With the exception of

arithmetic blocks, only single-input, single-output blocks should be combined with each other,

and the inputs to the difference and summing blocks must always be shown as separate

inputs and not as a combination with any other symbol or block. These combination symbols

clearly explain the intended control algorithm.

If a simplified combination of symbols is used to represent a complex control algorithm, the

chosen simplified combination of symbols must represent one and only one control algorithm.

In no case should the combination of symbols or blocks be used as a means of representing a

specific supplier’s implementation of an algorithm or controller . Either the supplier’s

implementation should be fully detailed in the le gend sheet in which it is used, or combined

symbols should be shown as a new algorithm block , as defined in 5.2.3. For example, Figure

5.2.1.c includes a PID combination symbol. This symbol could represent control algorithm “b”

or control algorithm “a.” If the PID combination symbol represents control algorithm “a”, a

legend sheet should be provided to clearly describe the symbol’s function.

D

D D

P I P I

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

P I

PID combination

symbol

Control algorithm a Control algorithm b

Figure 5.2.1.c

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 15 - ISA-TR5.1.01/ISA-TR77.40.01-2012

5.2.2 Multiple functions

Functional diagrams illustrate a control strategy by interconnecting symbols that depict a

specific control algorithm. With advances in technology, control algorithms have expanded to

include multiple functions that can be enabled or disabled or that can be set to a defa ult

condition by the designer. As such, a symbol should show the basic functionality of the control

algorithm to explain the control strategy. The designer need not provide a symbol for each

function within the control algorithm. Rather, the designer needs only to provide the necessary

information to explain the control strategy design. The necessary information can be

additional text near the symbols or a suffix or prefix notation in the symbols or external to the

symbols. In cases where control algorithms have multiple functions, a supplemental write-up

should be provided to further explain the multiple functions or complex functions of the control

algorithm.

For example, a controller algorithm can calculate results as a classical controller, non -

interacting controller, classical with external reset controller, or manual reset controller. The

controller’s behaviour also can be modified for saturation recovery limits, directional inhibit,

adaptive tuning, and self-tuning. Thus, while functional diagrams show the control strategy’s

intent, additional text or specialized symbols may be required to define th e desired operation

and behavior.

5.2.3 New algorithms

The early symbols used in functional diagrams depict the control algorithms that were

originally available to the industry. Today, advances in software techniques and network

communication have expanded the capability of control algorithms to perform enhanced

functions. Thus, new symbols are often required to illustrate this new capability on function al

diagrams. The new symbol should employ the conventional rectangular block symbol. The

block should include a text identifier or an icon identifier. The block should show nodes for all

inputs and outputs to the “overall” function being conveyed. The block may s how

interconnections to modes and the status of the functions being conveyed. The following are

examples of new algorithms available with today’s technology.

5.2.3.1 Advanced controller

Advanced controller symbol Definition

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Required “Normal for Control” function inputs The output provides a continuous

function based on measured input

variables. The general qualifying

… symbol (*) includes but is not

limited to the following

expressions;

On/Off, alignment, etc.

… ISC – Inferential Smith Controller

(*) Boolean & continuous FLC – FUZZY Logic Controller

Status, alignment, etc. IMC – Internal Model Controller

… MVC – Multivariable Controller

Boolean & continuous

MPC – Model Predictive Controller

NN – Neural Network

…

Required “Normal for Control" function outputs

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 16 -

5.2.3.2 Discrete device driver

Discrete device station symbol Definition

Inputs

The output provides means of controlling field

devices or control schemes that have more than

.... one mode. The general mode (*) is user definable

State 1

and includes a minimum of two modes (e.g., two

State 2 Status button memory stations) and as many as N

(*) modes (multiple state stations).

State 3

State 4

State or truth table

....

Outputs

5.2.3.3 Status alarm

Status symbol Definition

The output provides means of reading a signal’s propagated status

* information. The general qualifying symbol (*) is user definable and

includes but is not limited to the following signal information:

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Quality Alarm

Sub-status Status

Limits Example: Alarm Status

5.2.3.4 Digital transfer

Digital Equation Graph/Example Definition

transfer

symbol

D = A for C = zero,

T-Dig or A The output equals the input

D = B for C = one B logic state, which has been

D selected by transfer. The

C state of the transfer is

State 1 State 2

established by an external

condition. True input can be

shown by signal convention

Signal A or by external indicator (e.g.,

T for true) as shown in the

example symbol.

Signal B T Signal D

T-Dig

Condition C

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 17 - ISA-TR5.1.01/ISA-TR77.40.01-2012

5.2.3.5 Manual/Auto station variation

Function Symbols

Operator manual The output is an analog signal (setpoint or

A

signal bias) developed within the generator and

adjustable by the operator.

Manual/Auto station The output is the manual transfer to or from a

A T

manually adjusted signal (manual-automatic

control station).

Manual/Auto station The output is the manual transfer to or from a

A T A

w/ setpoint/bias manually adjusted signal with an operator-

adjustable setpoint or bias (manual-automatic

control station).

Cascade station T A T A The output is the manual transfer to or from a

manually adjusted signal with a manual

transfer of inner-loop setpoint between an

operator adjustable setpoint or automatic

outer-loop setpoint demand (cascade-

automatic control station).

5.2.3.6 Mathematical expressions

Mathematical Definition

symbol

The output provides the results of a mathematical expression. The

general qualifying text (*) includes but is not limited to the following

* expressions:

Interpolation nx

Logarithm

Polynomial Example of power symbol

Power

Trigonometric

5.2.3.7 Special filters

Filter symbol Definition

The output provides the results of the time function and input value.

The general qualifying symbol (*) includes but is not limited to the

* following special filters:

Lead/Lag (first-order lead and lag) LEAD

LAG

Delay (pure time delay)

MovAvg (moving average [sample]) Example of

TimeAvg (moving average [time]) Lead/Lag symbol

Copyright 2012 ISA. All rights reserved.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 18 -

5.2.3.8 Signal conditioning

Signal conditioning Definition

symbol

The output provides the results of the same composed point

calculation based on multiple input signals. The general qualifying

* symbol (*) includes but is not limited to the following signal

conditioning:

A/B/Avg Select (Transmitter A, B, or average selector)

Median Select (3 or more transmitter median selectors)

2oo3 Select (Minimum of 2 digital inputs agree)

<>

Example of Median Select

5.3 Diagram format

This section discusses several methods to prepare a functional diagram.

5.3.1 Diagram organization

A set of functional diagrams typically consists of multiple sheets: 1) title page, including the

name of the functional group, revision, status, and date of the doc ument; 2) table of contents,

indicating the names of the subsections, the revisions, dia gram numbers, and sheets; 3)

legend sheet(s); and 4) individual functional diagrams.

5.3.2 Diagram interconnection

5.3.2.1 Inputs and outputs may show connections to or from the actual process as well as

other diagrams within the same logic system or other logic systems.

5.3.2.2 Process measurements or interconnections from another logic system required on

another sheet should have single output interconnections with single/multiple

reference to other sheets.

5.3.2.3 Process measurements should be identified by their instrum ent tag name. Tag

descriptions, tag ranges, etc., may also be provided.

5.3.2.4 Process measurements and inputs from other logic systems should appear only on

one sheet of a diagram.

5.3.2.5 Signal lines between instruments and function symbols or between function

symbols shown on different diagrams should be drawn with an interconnecting

symbol (arrow, box, etc.). In cases of signals connected to more than one sheet,

the connection reference must identify all signal destinations by a method that

includes sheet reference and unique connection identification detail. Those signals

originating from another page are to reference the source sheet by a method that

includes the sheet reference and unique connection identification detail. The

methods may include symbols and/or text at the input/output connections

themselves, listing tables on the diagram itself, or listing tables on a separate

diagram that is used only for such listing tables . The interconnection symbols/tables

should indicate:

Copyright 2012 ISA. All rights reserved.

--```,,,``,,,````,`,`,,,```,

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 19 - ISA-TR5.1.01/ISA-TR77.40.01-2012

a) Direction of signal flow, going to a symbol or coming from a symbol on another

diagram. Arrowheads depicting direction of signal flow are used for clarity in

diagram connections, including inputs and outputs.

b) A page identifier (e.g., diagram number, sheet number) should identify where

logic signals go to or come from. Grid zone location is optional.

c) An input signal description/statement should be stated in a noun -verb text. A

binary output signal description/statement should be stated in a verb -noun text.

The noun represents the function or device tag number or name. The verb

represents the signal’s function (i.e., status, override, command, etc.).

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

d) Diagrams containing both continuous and binary signals sh ould be distinguished

with the continuously variable signal as a solid line and a bin ary (on-off) signal

as a dashed line. The binary signal lines may be a solid line if on a separate

binary logic diagram that does not contain continuously variable signal

representation or if on an inset detail diagram.

5.3.2.6 When the description for binary signal is true, the value of the binary signal is logic

one.

5.3.2.7 There may be misunderstanding of binary logic statement s involving devices or

functions that are not recognizable as inherently having only two specific alternative

states. For example, if it is stated that a valve is not closed, this could mean either

(a) that the valve is open fully or (b) the valve is simply not closed, namely, that the

valve may be in any position from almost closed to wide open. To aid accurate

communication between writer and reader of the diagrams, the diagrams should be

interpreted literally. Therefore, possibility (b) is the correct one.

If a valve is an open-closed valve, then, to avoid misunderstanding, it is necessary

to do one of the following:

a) Develop the diagram in such a way that it says exactly what is intended. If the

valve is intended to be open, then is should be so stated and not be stated as

being not closed.

b) Have a separate note specifying that the valve always assumes either the

closed or the open position.

By contrast, a device such as a motor-driven pump is either operating or stopped,

barring some special situations. To say that the pump is not operating usually

clearly denotes that it has stopped.

The following definitions apply to devices that have o pen, closed, or intermediate

positions. The positions stated are nominal to the extent that there are differential

gaps and dead-band in the instrument that senses the position of the device :

open position: a position that is 100 percent open

not-open position: a position that is less than 100 percent open. A device

that is not open may or may not be closed .

closed position: a position that is zero percent open

not-closed position: a position that is more than zero percent open. A device

that is not closed may or may not be open.

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 20 -

intermediate position: a specified position that is neither fully open nor fully

closed

For a logic system having an input statement that is derived inferentially or

indirectly, a condition may arise that will lead to an erron eous conclusion. For

example, an assumption that flow exists because a pump motor is energized may

be false because of a closed valve, a broken shaft, or other mishap. Factual

statements, that is, statements based on positive measurements that a certain

condition specifically exists or does not exist, are generally more reliable.

5.3.2.8 A logic signal may correspond physically to either the existence or the non -

existence of an instrument signal, depending on the particular type of hardware

system and the circuit design philosophy selected. For example, a high-flow alarm

may be chosen to be actuated by an electric switch who se contacts open on high-

flow. On the other hand, the high-flow alarm may be designed to be actuated by an

electric switch whose contacts close on high flow. Thus, the high-flow conditions

may be represented physically by the absence of an electric signal or by the

presence of the electric signal. The technical report does not attempt to relate the

logic signal to an instrument signal of any spec ific kind.

5.3.3 Diagram layout

Functional diagrams may be prepared in either a horizontal or vertical layout.

5.3.3.1 Vertical diagrams

5.3.3.1.1 In the vertical format, the input signals are located at the top with the flow of the

diagram downward. The logic and mathematical functions are in the center area,

and the output signals (i.e., final control element, device command, logic signal)

are at the bottom. Main loops are indicated, as much as possible, in a straight

vertical line. In some cases, interconnections can run in o pposite directions, for

instance, in case of feedback signals. In general, the main signals enter the top of

the symbol enclosures (input) and exit at the bottom (output).

5.3.3.1.2 Auxiliary functions, such as manual operations, setpoint, biasing, etc., enter the

symbol enclosure at either side.

5.3.3.1.3 If desired, input signals for readout functions, or other auxiliary connections, can

be taken off horizontally from the point of measurement.

5.3.3.2 Horizontal diagrams

5.3.3.2.1 In the horizontal format, the input signals are located at the left with the flow of the

diagram to the right. The logic and mathematical functions are in the center area,

and the output signals (i.e., final control element, device commands, and logic

signals) are at the right. In some cases, interconnections can run in opposite

directions, for instance, in case of a binary output signal used for additional logic

operations.

5.3.3.2.2 In general, the main signals enter at the left of the symbols, or symbol enclosures

(input), and exit at the right (output). If necessary, au xiliary functions may enter the

symbol enclosure at the top or bottom.

5.3.3.2.3 If desired, input signals for readout functions, or other auxiliary connections, can

be taken off vertically from the point of measurement.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 21 - ISA-TR5.1.01/ISA-TR77.40.01-2012

5.4 Symbol use-case examples

The following case examples illustrate function diagrams in ISA format. The intent is to

illustrate the similarities and differences between these formats for a given control strategy. In

addition to the tables in Annex B: Mathematical Symbols (Table B.3.1), Binary Symbols (Table

B.3.2), and Miscellaneous Symbols (Table B.3.3), the following symbols are used in the case

examples.

Symbol legend

Drawing interconnection

This symbol represents a page connector for an input or output signal

Standard feedback controller with feedforward function.

This multiple function controller algorithm computes the difference of two

inputs, computes a proportional, integral, and derivative on the error, and sums

a feedforward input.

Optional:

1) Input polarities (+) and (-) should be shown external to the different symbols

identifying the controller's direct mode (PV - SP) or reverse mode (SP - PV).

2) Controller track reference (TR) and track switch (TS) should be shown

external to the PID symbol identifying the controller's tracking mode

operation.

Advanced feedback controller with feedforward and limiter function.

This multiple function controller algorithm computes the difference between two

inputs; computes a proportional, integral, and derivative on the error; sums a

feedforward input; and limits the controller's output.

Optional:

1) Input polarities (+) and (-) should be shown external to the different symbols

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

identifying the controller's direct mode (PV - SP) or reverse mode (SP - PV).

2) Controller track reference (TR) and track switch (TS) should be shown

external to the PID symbol identifying the controller's tracking mode

operation.

Median select

The median select algorithm computes the median signal for three inputs. If

one input is bad quality, then the average of two good-quality signals is <>

computed. If two inputs are bad quality, then the one good-quality signal is

selected.

MIMO

The multiple input multiple output algorithm/program computes output PV

demands, biases, or setpoints. The node identifiers are defined by the user.

MIMO

The number of node identifiers is based on the application.

DV

Node Identifiers are:

MV

DV = feedforward variable(s)

MV = manipulated variable(s)

PV = process variable

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 22 -

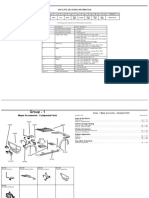

Motor-operated valve station

The motor-operated valve (MOV) station is a faceplate on the HMI as shown in

the following illustration:

Node identifiers are;

ZSO = position switch open

ZSC = position switch closed

FLT = fault condition detected

OPN = open requested

CLS = close requested

Motor-operated valve macro

The motor-operated valve (MOV) macro algorithm supervises the control of the

motor-operated valve. The macro typically includes specific input/output notes

and logic as shown in the following illustration.

Node identifiers are:

OP = open permit

OO = open override

CP = closed permit

CO = closed override

OR = open request

CR = closed request

OPNG = opening

CLSG = closing

ZSO = position switch open

ZCO = position switch closed

OPC = open command

CLC = closed command

FLT = fault condition detected

MOV (Macro)

OP A A A

OPC

N OR N t PD S N

D D D

R

NOT NOT

OR

OR

OO A

NOT

N

D

CP

NOT

A A

CLC

N OR t PD S N

D D

R

NOT

CR

CO

Open fault

alarm

STOP OR

ZSO

A FLT

N OR OR

D

ZSC NOT

OPNG t GT

Closed fault

alarm

CLSG A

N OR

D

NOT

t GT

Shared discrete variable

Binary signal from pushbutton visible on human machine interface.

Copyright 2012 ISA. All rights reserved.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 23 - ISA-TR5.1.01/ISA-TR77.40.01-2012

5.4.1 Single loop

Process

The functional diagram of Figure 5.4.1 illustrates a single- variable

loop control strategy consisting of:

- One process variable Alarm

- One final control element

- One PID controller (direct acting)

H/

- One operator station with setpoint +

- One high alarm for process variable to operator -

console

PID

This functional diagram shows a single-process variable

with a high alarm to an operator console. The standard

feedback controller is shown with a feedforward capability

but with no feedforward signal. An operator station includes

a manual-automatic mode selector and an operator- A T A

adjustable setpoint. The operator manual adjustment or the

feedback controller operates a final control element.

F(x)

The controller's track reference and mode logic are not

shown in the diagram because mode changes are Manipulated

variable

understood to be smooth and bumpless transfers. Variables

and modes for indication on HMI are not shown because all Figure 5.4.1 single loop

pertinent values (PV, SP, CO, Alarm, Mode, etc.) are

understood to be available. However, tag name and tag descriptions for variables, alarms, and

stations are not illustrated but should be illustrated on functional diagrams and follow ISA or

project conventions.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

5.4.2 Two-element loop

The functional diagrams of Figure 5.4.2.a, b, and c illustrate the two-element control strategy

consisting of:

- Three process variables (median select)

- Program setpoint based on index signal with operator bias

- One feedforward demand based on index signal

- One manipulated variable

- One PID controller (direct acting)

- Open override mode based on external signal

- One operator station with bias

- One high alarm for controller process variable to panel-board annunciator

Figure 5.4.2.a and Figure 5.4.2.b both illustrate the same control strategy; Figure 5.4.2.a

illustrates a vertical layout, and Figure 5.4.2.b illustrates a horizontal layout. Both diagrams

follow the diagram layout convention discussed in 5.3.3.

In these diagrams, the logic system has an advanced control algorithm that computes the

median of three process variables. Median select algorithm can be shown as a symbol with a

graphical identifier, as illustrated in Figure 5.4.2.a, or as a symbol with a text identifier, as

illustrated in Figure 5.4.2.b. All specific control algorithm symbols and functions must be

defined in a separate document or legend. In Figure 5.4.2.b, the symbol with a text identifier

indicates individual transmitters are selectable. The process variable us ed for control has a

high-alarm digital output to an operator console or panel board.

The controller's setpoint is developed as a program based on a load index and is adjustable

by an operator bias. The standard feedback controller is shown with a feedforward capability

and a feedforward demand developed as a program based on a load index. An operator

station includes a manual-automatic mode selector. The operator manual adjustment or the

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 24 -

feedback controller operates a single manipulated variable. If the external logic signal is true ,

the manipulated variable is interlocked closed, as indicated by the true (T) identifier with the

transfer input. Manipulated variable interlock value s can be shown as a numerical value

(Figure 5.4.2.a) or with text (Figure 5.4.2.b), e.g., 0% closed, 100 % open, X% determined in

commissioning.

Logic index

F(x) F(x)

Close

Process

variables A

A

- A T

A/B/C/

B

Median PID T T F(x)

+

A

C Manipulated

H/ Alarm variable

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Logic signal

Figure 5.4.2.b Two-element loop - horizontal

The controller's track reference and mode logic are not shown in the diagram because mode

changes are understood to be smooth and bumpless. Variables and modes for indication on

CRT graphics are not shown because all pertinent values (PV, SP, CO, Alarm, Mode etc.) are

understood to be available. However, tag names and tag descriptions for variables, alarms,

and stations are not illustrated but should be shown on functional diagrams and should follow

ISA or project conventions.

In Figure 5.4.2.c, the controller's track reference and track -switch logic are shown for the

closed interlock condition. The additional logic uses the same mathematical symbols and

includes new signal inputs to the controller. The input acronyms TR (track reference) and TS

(track switch) need to be explained in the functional description of the control algorithm.

Process variable

A B C

Load index

F(x) <>

H/ Alarm

- +

F(x)

TR

TS

PID

+ A T A

0%

Logic signal T

T A

F(x)

Manipulated

variable

Figure 5.4.2.c Two-element loop

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 25 - ISA-TR5.1.01/ISA-TR77.40.01-2012

5.4.3 Cascade loop

The following functional diagram illustrates a cascade-loop control strategy for:

- Two process variables (inner and outer loop)

- Two PIDs in cascade arrangement

- Both loops are single-element loops

- Outer loop has adaptive gain tuning

- Inner loop has demand high and low limits

- One operator station with outer-loop setpoint

- One manipulated variable

Outer-loop Inner-loop Outer-loop Inner-loop

process variable process variable process variable process variable

+ + Setpoint

- -

Adaptive A

gain PID Load index

F(x) PID

+ +

- -

PID

PID

>< ><

A T A

A T

F(x) F(x)

Manipulated Manipulated

variable variable

Figure 5.4.3.a - Cascade loop Figure 5.4.3.b - Cascade loop

Figure 5.4.3.a and Figure 5.4.3.b illustrate two methods to document a cascade loop. Both

loops have an outer-loop controller with adapted gain, which establishes the setpoint for the

inner-loop controller. The inner loop includes a manual-automatic station that operates a

manipulated variable. In Figure 5.4.3.a the adaptive gain is identified without logic definition,

whereas in Figure 5.4.3.b, the adaptive gain is identified with logic definition. This variation

illustrates how a functional diagram may be more or less detailed , depending on its intended

use.

An operator station with one tag may be shown as one symbol , as illustrated in Figure 5.4.3.a,

or shown as two symbols, as illustrated in Figure 5.4.3.b, with the same tag names. If the

setpoint and manual-automatic station are separate tags, separate symbols and tags should

be shown, as illustrated in Figure 5.4.3.b.

In this case, the inner-loop controller includes a limiter function not available in the out er-loop

controller. A different controller's symbol is used to differentiate function blocks with different

control algorithms.

Copyright 2012 ISA. All rights reserved.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 26 -

The controller's reference tracking and mode logic are not shown in the diagram because

mode changes are understood to be smooth with bumpless transfers. Variables and modes for

indication on CRT graphics are not shown because all pertinent values (PV, SP, CO, Alarm,

Mode etc.) are understood to be available. However, tag names and tag descriptions for

station and variables are not illustrated but should be shown on function diagrams and should

follow ISA or project tagging/identification conventions.

5.4.4 Advanced controller with multivariable control

The following functional diagram illustrates the multivariable controller, which can be model-

based or model-free MIMO controls, loop-control strategy for:

- One process variable

- One single-loop control

- One master station

- Six (6) slave stations

- Six (6) MIMO bias signals

This functional diagram illustrates the use of a multivariable control program with multiple

inputs and multiple outputs combined with the standard mathematical and miscellaneous

symbols. In Figure 5.4.4.1, a single-process variable and feedback controller establishes the

automatic demand for six individual manipulated variables. The feedback loop has an operator

station with a manual-automatic mode selection and an operator-adjustable setpoint. The

operator manual adjustment or the feedback controller establishes the master demand. Each

individual manipulated variable has an individual operator station with a manual -automatic

mode selector and an operator-adjustable bias. The master demand is biased by a signal

established by an operator adjustment or the MIMO program. The bias mode selection is

determined by logic within the MIMO program.

In this case, the multivariable control program's symbol is illustrated with a text identifier of

the advanced program and corresponding node identifiers for signal inputs and outputs. A

separate functional description is required to explain the control algorithm, alarms, operator

interface, and corresponding node functions. The process variables and controller mode

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

selector are shown as inputs on top of the advanced controller's symbol. The bias and bias

modes are shown as outputs on the bottom of the MIMO program's symbol. Mode status

signals are shown as inputs on both sides of the MIMO program's symbol.

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 27 - ISA-TR5.1.01/ISA-TR77.40.01-2012

Operator Process

Process inputs on/off variable

selector

B

MV A Station in auto

MV B Station in auto

PV1 PV2 PV3 PV4 PV5 PV6

MA

MV C Station in auto MB

MO

MC PID

MV D Station in auto MD MIMO FDB

ME

MV E Station in auto MF

MP

MV F Station in auto PV A T A

A B E

D

AM

D

BM CD CM DD DM

D

EM FD FM Station

PV Station in auto

T T T T T T

A T A T A T A T A T A T

MV A MV B MV C MV D MV E MV F

Bias Bias Bias Bias Bias Bias

MV A MV B MV C MV D MV E MV F

A T Station A T A T Station A T Station A T Station A T

Notes: Station Station

1) Bias tracking

not shown

F(x) F(x) F(x) F(x) F(x) F(x)

Manipulated variables

Figure 5.4.4.1 Functional diagram showing MIMO controller

Copyright 2012 ISA. All rights reserved.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 28 -

The following functional diagram illustrates the multivariable controller control strategy for

One (1) advanced multivariable controller with five (5) process variables

and necessary feedback signals.

Multivariable controller mode selector.

Four (4) demand/setpoint outputs with four (4) mode selections. For the

four different control loops, the demand/setpoints are developed as follows :

a) One (1) manipulated variable with operator station. Automatic demand,

developed on a separate sheet, is biased by an operator bias sette r or

the multivariable controller.

b) One (1) manipulated variable with operator station. Automatic demand is

developed by logic on a separate sheet or the multivariable controller.

c) One (1) single-loop controller with setpoint developed by logic on a

separate sheet or the multivariable controller.

d) One (1) single-loop controller with cascaded setpoint from the advanced

controller.

Figure 5.4.4.2 illustrates the control strategy of a multivariable controller adjusting four

different control loops. In this case, the multivariable controller's symbol is illustrated with the

text identifier of the control algorithm and corresponding node identifiers for signal inputs and

outputs. A separate functional description is required to explain the control algorithm, alarms ,

operator interface, and corresponding node functions. The process variables and controller

mode selector is shown as inputs on top of the advanced controller's symbol. The

demand/setpoints are shown as outputs on the bottom of the advanced controller's s ymbol.

Mode status and feedback status signals are shown as inputs on both sides of the advanced

controller's symbol. The relationship between the advanced controller's operations is further

explained by the interconnections with four (4) differen t control loops as follows:

Loop A consists of an operator station with its automatic -demand logic developed on another

sheet. The demand is biased by a signal established by an operator adjustment or the

advanced controller. The bias mode selection is determined by logic within the advanced

controller. The actual bias is a feedback to the advanced controller to ensure a bumpless

transfer on mode selections of the advanced controller. In this case, the operator adjustment

does not indicate any tracking logic.

Loop B consists of an operator station with its automatic-demand logic developed on another

sheet or the advanced controller. The demand-mode selection is determined by the advanced

controller algorithm. The final demand is fed back to the advanced controller to ensure a

bumpless transfer on mode change of the advanced controller.

Loop C consists of a single-loop controller with a single-process variable. The operator-

manual adjustment or the feedback controller operates a single manipulated variable. An

operator station includes a manual-automatic mode selection. The setpoint is developed by

logic on another sheet or logic within the advanced controller. The setpoint mode selection is

determined by logic within the advanced controller. The final setpoint is f ed back to the

advanced controller to ensure a bumpless transfer on mode change of the advanced

controller.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Loop D consists of a single-loop controller with a single-process variable. The operator-

manual adjustment or the feedback controller operates a single manipulated variable. An

operator station includes a manual-automatic mode selection, an operator setpoint, and an

operator-setpoint mode selector (cascade mode). The cascaded setpoint is developed by logic

within the advanced controller. The setpoint mode selection is determined by the setpoint

mode selector on the operator station. The final setpoint is fed back to the advanced controller

to ensure a bumpless transfer on mode change of the advanced controller.

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 29 - ISA-TR5.1.01/ISA-TR77.40.01-2012

Operator on/off Process variables Process Process

selector variable variable

MO PV1 PV2 PV3 PV4 PV5

MV A Station in auto FBD

MA

FBC

MV B Station in auto

MB MIMO FBB

MV C Station in auto FBA

MC

MV D Station in cascade

MD

AD AM BD BM CD CM DD

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Regulatory control C

Regulatory control B

Regulatory control A

T

Operator T

bias A T PID PID

A T T

T

A T A T A T T A T A

F(x) F(x) F(x) F(x)

Manipulated Manipulated Manipulated Manipulated

variable A variable B variable C variable D

Figure 5.4.4.2 Functional diagram showing MIMO controller

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 30 -

5.4.5 Motor-operated valve logic

The followingfunctional diagram illustrates the control strategy for:

- Open-closed, motor-operated valve

- Human machine interface open-close commands

- MOV macro core logic with the following outputs

1) Digital outputs for:

1. MOV open command (OPC)

2. MOV close command (CLC)

3. MOV fault (FLT)

- MOV steering logic with the following inputs

1) Digital inputs for:

1. MOV open permit condition (OP)

2. MOV close permit condition (CP)

3. MOV not closed (ZSO)

4. MOV not 100% open (ZSC)

5. MOV traveling (OPNG & CLSG)

2) External logic signal for:

1. MOV operator open command (OR)

2. MOV open override logic (OO)

3. MOV operator close command (CR)

4. MOV close override logic (CO)

A

MOV open input N

D

MOV open permit logic

MOV open override logic

MOV

(Macro)

A

MOV close input N MOV open command

D

OPC

MOV close permit logic

OP

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

MOV close override logic MOV close command

OO CLC

CP

MOV

(Station) CO

MOV fault

ZSO OPN OR FLT

ZSC CLS CR

MOV fault

FLT OPNG

CLSG

MOV not closed

ZSO

MOV not 100% open

ZSC

MOV opening

A

MOV traveling N OR

D

A

N OR

D

MOV closing

Figure 5.4.5 Motor-operated valve steering logic

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 31 - ISA-TR5.1.01/ISA-TR77.40.01-2012

Figure 5.4.5 illustrates a functional diagram that defines the operation of a field device whose

core logic is shown as a control macro. In this functional diagram, the motor-operated valve’s

operation is defined by an HMI MOV station symbol, MOV control-macro symbol, steering

logic with binary symbol, and miscellaneous connector symbols. The MOV station symbol

illustrates the control algorithm and interface to an operator faceplate configured on the

operator console. The MOV control-macro symbol illustrates the control algorithm that is

previously defined and tested by the designer. In this case, the symbol legend defines the

control algorithm for this motor-operated valve. The macro symbol is a means to simplify the

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

functional diagram when repetitive logic exists with multiple devices. The external steering

logic defined by conventional binary symbols or connector symbols connects to the macro’s

defined input and output ports. In this case, the hard-wired field feedback inputs and

command outputs are illustrated by the discrete input/output symbol. The logic signals that

are developed on another page or sent to another page are illustrated by the drawing

interconnection symbol.

5.4.6 Motor breaker logic

The following functional diagram illustrates the control strategy for :

- A motor-starter field device

1) Two device modes (auto, manual)

2) Three field inputs

1. Auto start

2. Motor not overloaded

3. Motor running

3) One field output

1. Motor run command

- An HMI station faceplate

1) Two command pushbuttons (start, stop)

2) Two alarms (trip, trouble)

3) Graphic status indication

1. Amber (A) for manual mode

2. Blue (B) for auto mode

3. White (W) for trouble

4. Red (R ) for motor running

5. Green (G) for motor not running

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 32 -

NOT A

Auto mode

So B

Manual mode

R

A

N

Auto start D

Motor-run command

Start OR So

t PD

R

Stop

t PD OR Motor-trip

alarm

A

So t DT N

D

R

Motor not overloaded NOT W

Trouble

Alarm

R

Motor running

NOT

Figure 5.4.6 Motor-breaker logic

Figure 5.4.6 illustrates a functional diagram that defines the operation of a field device whose

core logic is shown in combination with the steering logic. In this functional diagram, the

motor starter’s operation is defined by an HMI motor station signal symbol, a binary symbol,

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

and miscellaneous connector symbols. The hard input and output signals are shown on the

drawing edge. The control algorithm and interface to an operator faceplate config ured on the

operator console is shown in the drawing middle.

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

- 33 - ISA-TR5.1.01/ISA-TR77.40.01-2012

Annex A

Functional diagram historical usage

Although functional diagrams were declared to be independent of hardware implementation

methods, the diagram’s symbols displayed easily understandable equipment relationship s for

either analog or digital systems. Thus, functional diagrams represented logic boundaries

associated with specific hardware for inputs and outputs (I/O), operator interface devic es, and

control logic modules. Diagrams showed field instruments, field actuators, panel instruments,

panel alarms, and subsystem interconnections, establishing, in essence, the system I/O. The

diagrams identified operator hand stations that required mount ing on the control panel and the

control strategy on a subloop basis. Some used functional diagrams to clearly define smooth

and bumpless transfer, data acquisition functions , and other operator-interface needs.

Since a correlation exists between control functions and hardware, functional diagrams

served a commercial purpose in defining a system’s cost. Proposal engineers used functional

diagrams to quantify a proposed system cost necessary to satisfy a customer’s specification.

During the engineering design phase, designers used functional diagram revisions as the

basis for commercial change orders.

With microprocessor technology, control strategy is no longer a major parameter in

determining system hardware costs. Since microprocessor modules have enough memory to

implement simple or advanced control strategies, proposal engineers base hardware

requirements on the system’s partitioning rules and total I/O count. Suppliers have developed

advanced algorithms that are not represented by conventional PMC 22 .1 or ISA-5.1

standards. While following the intent of these standards, suppliers either create a new symbol

or employ an existing symbol to represent the new algorithm. The problem occurs in

understanding what the functional diagram’s symbol really repres ents and the symbol’s

boundaries. Thus, with technology advances, this report extends the symbol’s boundaries

from a hardware perspective to a software perspective.

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT

--```,,,``,,,````,`,`,,,```,```-`-`,,`,,`,`,,`---

ISA-TR5.1.01/ISA-TR77.40.01-2012 - 34 -

This page intentionally left blank.

Copyright 2012 ISA. All rights reserved.

Copyright International Society of Automation

Provided by IHS under license with ISA Licensee=BP International/5928366101

No reproduction or networking permitted without license from IHS Not for Resale, 05/13/2013 14:52:07 MDT