Professional Documents

Culture Documents

US10542978

US10542978

Uploaded by

Vansala Ganesan0 ratings0% found this document useful (0 votes)

7 views11 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views11 pagesUS10542978

US10542978

Uploaded by

Vansala GanesanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

2) United States Patent

Chowaniec et al

(34) METHOD OF INT

SEALING A HANDI

RNALLY POTTING OR

pLD MEDICAL DEVICE,

(75) Inventors: Matthew Chowanies, Middletown, CT

(US); Ningrul Chen, Hamden, CT

(US); Michael Zemlok, Prospect, CT

(us)

(73) Assignoe: Covidien LP, Mansfield, MA (US)

(9). Notice:

Subject to any dislaimer the term of this

patent is extended or adjusted under 35

USC. 154) by 1213 days

21) Appl. Now 13/017,410

(22) Filed: May 27, 2011

6s) Prior Publication Data

US 201210303002 Al Nov. 29, 2012

(1) Incr.

AGLB 1700 (2006.01)

(6ib 17072 (2006.01)

(2) USL

orc A6IB 17107207 (201301)

(58) Field of Classification Search

CPC sos AGIB 17/00017: AGIB 17/00115; AGLB.

17/00128; GIB 17/00398; AGB.

17/00734: A61B 17107207; AGILE.

17/2927; AGIP 205010813

usp 29/5271 527.4, 611, B41

Se application file for complete search history.

cd

66) References

USS. PATENT DOCUMENTS.

AASS6I3 A 51979 Bran HOI 1196

US010542978B2

(10) Patent No.:

(4s) Date of Patent:

US 10,542,978 B2

Jan. 28, 2020

ATMO A * IDI9ES Arends Gosn 1923

31058

520.7 A+ 21904 Rydell ‘was

S5S48a1 A | 911996 Paterson al

@3onoe BL* $2002 Ane ae

Faas BL* $2010 Roche oo.tis

232686) B2 62010. Brandsaier ea.

7si046 BE 103010 Le

7sasaoT BE 122010 Wan eta

S378572 2" Tina et ist

sasou6 Bo Chin ‘Reis ass

6.206,

2n040ns6sa8 AL Duet al

20080288678 AL Ductal

aono00076 AL Zero tal

dononriea29 Al* Gisjia ssa

21018370 AL 12011 Duet al

FOREIGN PATENT DOCUMENTS

en o1s706 AL 1011985

Gh HISIOS AU 'S/1968

(Cominved)

(OTHER PUBLICATIONS

Furopean Search Report for EP 121604400-2310 date of comple

tion fs Aug. 23, 2012 (9 page)

(Continved)

Primary Bvaminer

(74) Attornes, Agent, or Firm

LLP

Michael 1 D Abreu

Carte, DeL.nea & Farrell

on ABSTRACT

The present disclosure provides @ powered surgical insta

‘ment incloding a housing defining an inner cavity therein; at

Teast one internal component disposed within the housing

‘nd potting material injected into the inner cavity encapst-

Jating at least a portion of the at least one inter compo-

5 Claims, 5 Drawing Sheets

US 10,542,978 B2

Page 2

66) References Cited

PORFIGN PATENT DOCUMENTS

WO Wo set09s7 AL 41996

WO wo 2mn7o0ris0 A2 12007

(OTHER PUBLICATIONS

EPO-TEK 3771 Techctl Data Shes, Jan. 31, 2007, pp. 1

‘PS5038972, reve om the Internet: URL: hips apoek

‘com ses tases. 37h pa [treve on fan. 2002).* “graph

ite fied epoxy”, “ESDEMI shilling of semiconductor devices

td clctonis”*

Extended European Search Report for app. No. 161897111 dated

Feb. §, 2017,

Anonymous “Resin dispensing Wikipedia”, Wikpetia, Nov. 6.

2010 (Nov. 6, 2010), pp 1-6, XPOSS330617, Wikipdiaveuieved

fromthe Internet: URL ps: en.wikipedia.org winds pte

Resin-dspensingoldid-395241833#Sealing of electronic pats

Ircicved om Jan, 27, 2017] "Chapter 8.1 Scaling of electronic

pus

‘Canadian Ofice Action dated Apr. 28,2018 isu in corresponding

‘Astaltn Appl, No. 2.776.740,

* cited by examiner

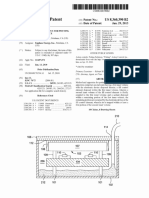

U.S. Patent Jan. 28,2020 Sheet 1 of §

FIG. 1

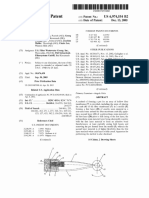

U.S. Patent Jan. 28, 2020 Sheet 2 of 5 US 10,542,978 B2

U.S. Patent Jan. 28, 2020 Sheet 3 of 5 US 10,542,978 B2

FIG. 3

US 10,542,978 B2

Sheet 4 of 5

Jan. 28, 2020

U.S. Patent

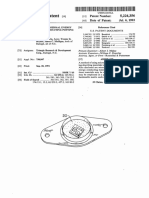

U.S. Patent Jan. 28, 2020 Sheet 5 of 5 US 10,542,978 B2

(aa $10

SEAL HOUSING

| “a $20

INJECT POTTING MATERIAL INTO

HOUSING

| me $30

SOLIDIFY POTTING MATERIAL

FIG. 5

US 10,542,978 B2

1

METHOD OF INTERNALLY POTTING OR

SEALING A HANDHELD MEDICAL DEVICE

BACKGROUND

‘Technical Pld

The present disclosure relates to @ powered surgical

instrument having housing enclosing a plurality of intemal

‘components, including a drive mechanism an a contol

‘ircuit. More particularly, he present disclosure relates to 3

surgical instrument including intemal components that are

‘encapsulated ina potting material within the housing.

ackground of Related Art

‘Surgical devices whereia tissues first grasped or clamped

between opposing jaw stricture and then joined by surgical

fasteners are well known ia the at. In some instruments @

knife is provided to cut the tissue which has been joined by

the fasteners. The fasteners are typically in the form of

surgical staples but two part polymeric fasteners can also be 2

utilized.

Instruments for this purpose may include two elongated

embers which are respectively used to capture or clamp

tissue. Typically, one of the members caries a staple ca

teidge which houses plurality of staples arranged in atleast

‘wo Tateral rows while the other member has an anil that

‘defines surface for forming the staple Tegs as the staples are

driven from the staple cartridge. Generally, the stapling

‘operation is effected hy cam bars that travel longitudinally

through the staple cartridge, withthe cam bars acting upon

staple pushers to sequentially eject the staples from the

staple cartridge. A knife can travel between the staple rows

to longitudinally eot andor open the taped tissue between

the rows of staples.

In endoscopic or laparoscopic procedures, surgery is

performed through « small incision or through a narrow

‘cannola inserted throvgh small entrance wounds i the ski,

In onder to address the specific needs of endoscopic andor

Japaroscopie surgiesl procedures, endoscopic surgical star

pling devices have been developed

Current known devices can typically require. 10460

pounds of manual hand force to clamp tissue and deploy and

orm surgical fasteners in tissue which, over repented use,

‘can cause a surgeon’s hand to become fatigued. Gas pow=

‘ered pacumatic staplers which implant surgical fasteners

Jno tissue are known in the at, Certain ofthese instruments

tullize a pressurized gas supply which connocts to a trigger

mechanism. The tigger mechanism, when depressed, s

ply releases pressurized gas to implant fastener into tissue

‘Motor-powered surgical staplers are also Known in the ar

‘These include powered surgical staples having motors

‘which activate staple firing mechanisms, However, these

motor powered devices also inelude a variety of intemal

‘components (eg, eiteits) which requte additional protee=

tion from moisture, chemical cleaners, vapors, gases, and

biological contaminants. There i a continual need for new

and improved powered surgical staplers which provide

protection tothe internal components

SUMMARY

“The present disclosure provides a powered surgical insta

‘ment including a housing defining an inner cavity therein; st

Jeast one intemal component disposed within the housing

‘and potting material injected into the inner cavity encaps-

lating at least a portion of the atleast one internal compo=

nent

0

o

2

‘The present disclosure also provides @ method for man

‘eturing a powered surgical device. The method includes

injecting a Tiguid potting material injected into @ housing

defining an inner cavity therein, the housing including at

least one internal component disposed within the housing

and sotidifying the potting material. encapsulate at least a

portion ofthe at least one infernal comportnt.

The present disclosure further provides a powered surgi-

cal instrument. The instrament includes a howsing defining

an inner cavity therein, the housing including handle

portion: a body portion extending distally from the handle

Portion a tool assembly disposed at a distal end ofthe body

portion: a contol circuit and a drive motor disposed withia

the inner cavity, wherein the drive motor is mechanically

coupled 10 the Tool assembly and the control circuit is

configured to control the operation ofthe drive motor; and

‘8 potting material injected into the inner cavity encapstlat-

‘ng atleast a portion of atleast one ofthe contol ciruit and

the drive motor,

[BRIEF DESCRIPTION OF THE DRAWINGS

Various. embodiments of the subject instrument are

scribed hercin with reference to the drawings wherci:

FIG. 1 is & perspective view of a powered surgical

instrument aeconting tothe present disclosure

FIG, 2 is a panial enlarged perspective view of the

powered surgical instrament according to the embodiment

fof the present disclosure of FIG. 1 according tothe present

disclosure,

FIG. 3 is a partial enlarged plan view of the powered

surgical instrument according to the embodiment of the

present disclosure of FIG. 1 according to the present dis

closure: and

FIG. 4 is a partial perspective sectional view of intemal

‘components of the powered surgical instrument of FIG, 1

according to the present disclose.

FIG. § is a Mlowehart of an embodiment of a method of

injecting potting material according to the present diselo-

DETAILED DESCRIPTION

Embodiments of the presently disclosed powered surgical

instrument are now deseribed in deal with reference to the

drawings, in which like reference numerals designate iden-

tical or corresponding elements in each of the several views

As used herein the tem “stl refers to that portion ofthe

powered surgical instrument, or eomponent thereof, farther

from the user while the term “proximal” refers to that

portion of the powered surgical instrument or component

{hereo, loser to the usr.

‘A powered surgical instrument ea surgical stapler, ia

cordance with the present disclosure is refered to in the

Tigures as reference numeral 10, Refering intially o FIG.

1, possered surgical instrament 100 includes a housing 110,

an endoscopic portion 140 defining a first longitudinal axis

‘A-Acextending therethrough, and an arteulating too! assem

bly (ex. end effector 160), defining a second longitudinal

axis B-B extending therethrough. Endoscopic portion 140

extends distally from housing 110 and the end effector 160

js disposed adjacent a distal portion of endoseopie portion

140. In an embodiment, the components of the housing 110

fare sealed against infiration of particulate andor Avid

contamination and help prevent damage ofthe components

by sterilization processes, The instrament 100 also inclxdes

a power source 300

US 10,542,978 B2

3

According to an embodiment of the present disclosure,

‘end efector 160 includes a first jaw member having one oF

more surgical fsteners (ex, cartridge assembly 168) and a

second opposing jaw member ineliding an anvil portion for

‘deploying and forming the surgical festeners (eg. an anvil

assembly 162). In certsin embodiments, the staples are

housed in cartridge assembly 166 to apply linear rows of

staples to hody tissue either in simultancous or sequential

‘manner. Ether one or both ofthe anvil assembly 162 and the

cartridge assembly 164 are movable in relation to one

‘another between an open positon, in which the anvil assem

bly 162 is spaced from vartidge assembly 164, and ua

approximated or clamped position, in. which the anvil

assembly 162 is in juxtsposed alignment with canridge

assembly 164,

Tris further envisioned that end effector 160 is attached 10

‘8 mounting portion 166, which is pivotably attached to 2

body portion 168. Body portion 168 may be integral with

‘enxdoscopie portion 140 of powered surgical instrument 100,

for may be removably attached to the instrument 100 16

provide a replaceable, disposable loading unit (DLU) or

ingle use loading unit (SULU) eg, loading unit 169). Ia

certain embodiments, the reusable portion may be config

lured for sterilization and re-use in subsequent stngical

procedure.

The loading unit 169 may be connectable to endoscopic

Portion 140 through bayonet connection. Iti envisioned

that dhe loading unit 169 has an areulston Tink connected

to mounting portion 166 of the loading unit 169 and the

‘antculation link is connected ta Finkage rod so thatthe end

effector 160 is articulated as the linkage rd is translated in

the dista-proximal direction along fit longitudinal axis

ASA. Other means of connccting end effector 160 to end

scopic portion 140 to allow articulation may’ be wsed, sve!

fe 8 Bexible the or a tube comprising a plurality of

pivotable members.

“The loading unit 169 may incorporate or be configured to

incomporate various end effectors, such as vessel sealing

devices, lincar stapling devices, circular stapling devices,

‘utters, graspers, ete, Such end effectors may’ be coupled 10

‘enudoscopic portion 140 of powered surgical instrament 100,

An intermediate flexible shaft may be included between

handle portion 112 and loading unt, It is envisioned that the

incoporation of a flexible shaft may facilitate access 10

‘andioe within certain areas of the body.

‘With reference to FIGS. {and 2, an enlarged view of the

housing 110s illustrated according to an embodiment ofthe

present disclosure, In the illustrated embodiment, housing

110 includes « handle portion 112 having a main drive

switch I14 disposed theteon. The switeh 114 may include

first and second switches 114 and 1148 formed together as

a toggle switch. The handle portion 112, which defines &

handle sais 1-H, is configured o be grasped by fingers of @

tier. The handle portion 112 has an ergonomic shape pro-

viding ample palm grip leverage which helps prevent the

handle portion 112 from heing squcezed out ofthe user's

hand during operation. Fach switch 114 and 114bis shown

as being disposed at suitable location on handle portion

112 to facilitate its depression by a users finger o fingers.

‘Additionally, and with continued reference to FIGS. Land

2, switehes 14a, 1146 may be used for stating andor

‘stopping movement of # drive mechanism (eg, drive motor

200) (FIG. 4). The drive motor 200 is configured t0 actuate

the end effector 160, including but not limited t, articuls

tion, closing of the jaw members, ejection of fasteners

citing, andthe like. in one embodiment. the switch Ida is

‘configured to aetvate the drive motor 200 in first direction

0

o

4

fo advance fring rod (not explicitly shown) in a distal

direction thereby approximating the anvil and the eardge

asseublies 162 and 164, Conversely, the switeh 1146 may

be configured to retract the firing od to open the anvil and

cartidge assemblies 162 and 164 by activating the drive

‘motor 200 in a reverse direction, The retraction mode

initiates mechanical lock out, preventing futher progres-

sion of stapling and cutting by the loading unit 169. The

foggle has a fist position for activating switeh M14, @

sevond postion lor activating switch 114B, and a neutral

position between the first and second positions, Further, the

Switches 14a and 114 may have high tactile feedback

requiring increased pressure for activation,

Tn one embodiment, the switches 14a and 1146 are

configured as multi-speed (eg, 1 or more), ineremental or

Variable speed switches which control the speed ofthe drive

‘motor 200 an! the fring rod in a non-linear manner. For

ample, switches Ida, 114b can be pressure-seasitive,

This type of contol interface allows for gradual increase in

the rate of speed ofthe drive components From a slower and

‘more precise mode to a faster operation. To prevent acc

ental aetivation of retraction, the switch 4% may be

‘sconnected electronically util a fail safe switch Ide is

pressed

The switehes 14a and 114) are coupled to a noa-linear

speed control circuit 400 which may inehude a noa-linear

speed control circuit implemented as a voltage regulation

circuit, a variable resistance circuit, or microelectronic

pulse width modulation eireut. The switches Ia and 144

‘may interface with the contol cieuit 400 by displacing oF

actuating variable contro! devices, such as thoostatic

‘devices, multiple position switeh cient, Hinear andor olary

variable displacement transducers, linear andlor rotary

potentiometers optical encoders, ferromagnetic sensors, and

Hall Effect sensors. Ths allows the switehes 14a and 114

tw operate the drive motor 200 in multiple speed modes, such

fas gradually increasing the speed of the drive motor 200

cither inecomentally oF graduslly depending on the type of

‘the control circuit being used, based on the depression of the

switches Hea and 1140,

FIGS, 2-4 illustrate an articulation mechanism 170

including an ariculation howsing 172, a powered articul-

tion switch 174, an articulation motor 132 and # manval

aniculation knob 176. Translation of the powered articul-

‘ion switch 174 or pivoting of the manual articulation kaob

176 activates the aniculation motor 1¥2 which then actuates

‘an articulation gear 233 of the atculation mechanism 170

‘as shown in FIG. 4, Actuation of articulation mechanism 170

teases the end effector 160 {0 move from its Hest position,

‘where longitudinal axis B-B is substantially aligned with

longitudinal axis A-A, towands a position in whieh longitu-

inal axis B-B is disposed stn angle to fongitudinal sxis

\-A. The powered articulation switch 174 may also incor-

porate similar non-linear spesd controls as the clamping

srechanism,

‘Additionally, articulation hovsing 172 and powered

aniculaion switch 174 are mounted to a rotating housing

assembly 180, Rotation of a rotation knob 182 about first

Tongitudinal axis A-A causes housing assembly 180 28 well

ay articulation housing 172 and powered articulation switch

174 (0 rotate about first longitudinal axis AA, and thus

rotating the end effector 160 about first longitudinal sxis

A-A. Tho articulation mechanism 170 is electeo-mechani-

cally coupled to one or more conductive rings that are

disposed on a housing nose assembly 188 (FIG. 4). The

‘onctive rings may be saldered andor crimped onto the

rose assembly 155 an are in electical contaet with the

US 10,542,978 B2

5

power source 300 thereby providing electrical power to the

ficlation mechanism 170, The nose assembly 188 may be

modular and may be attached to the housing 110 during

assembly to allow for easier soldering and/or erimping ofthe

Fings. The articulation mechanism 170 may include one oF

‘more brush andlor spring oaded contacts in contact with the

‘conductive rings such that a8 the housing assembly 180 is

rotated along with the articulation housing 172 the arcu

Jation mechanism 170 is in continuous contact with the

‘conductive rings thereby receiving electrical power fom the

power source 300,

Further dels’ of anieulation housing 172, powered

‘anicultion switch 174, manual articulation knob 176 and,

providing articulation to end effector 160 are described in

‘deta in commoaly-ovned US. patent application Se. No,

11/724,733 filed Mar. 15, 2007, the eontents of whieh are

hereby incorporated by reference in their entirety. It is

‘eavisioned that any combinations of limit switches, prox-

lmity sensors (ea, optical and/or ferromagnetic), linear

Variable displacement transducers and shaft encoders which

may be disposed within housing 110, may be wilized to

‘control andiar recont an articulation angle of end effector

160 and/or postion of the fring rod 220,

‘As showin in FIG. 4, the instrament 100 also ineludes the

‘contol circuit 400 electrically coupled to the motor 200 and,

various sensors disposed inthe insteument 100. The sensors

defect various operating parameters of the instrument 100

(ex, linear speed, rotation speed, aniculaion position,

temperature, battery charge, and the like), which are then

reported to the control circuit 400, The conto} circuit 400

may then respond accordingly to the measured opersting

parameters to contol the setuation of the end effector 160

(ea adjust the sped of the motor 200, contro articulation

angle, shut-off the power supply, report eeror conditions,

ete)

“As shown in FIGS, 3 and 4, the conteolczcuit 400 is also

‘coupled to one or more visual devices which may include

‘one oF more colored visible lights or light emitting diodes

401 CLED") to relay feedback to the user. The LEDs 401

‘may disposed on top of the honsing 110 such thatthe LEDs

4401 are mised and protrde in relation tthe housing 110

providing for better visibility thereof as shown in FIG. 4 In

‘embodiments, the LEDs 401 may be disposed within the

housing. 110 as shown ia FIG, 4. The LEDs 401 may be

‘setivaed in a various combinations to denote

‘The multiple Fights may be activated in a certain combi

nation to lustatea specific operational mode tothe use. Ia

‘one embodiment, the LEDs 401 jnchude a phiality of

multi-colored lights—a first light (ex. yellow), a second

Tight (est, green) and a third light (ered), The hts are

‘operated in # particular combination associated with 3

Particular operational mode as liste in Table 1 below.

Tails OF or Storeng Senne

fection Rot Neti wa

Taig OF”

0

o

6

TABLE L-sontinued

suse Sue _ Open Mode

Fie ige NA Totnancm 100 dete wd pene

Second it OF fun ang spc or emang

Thiig Na,

Fine Lit On" Ane loatiog i 10 ode he et

Stcod ight On eto 16 ly laps ad the

Thiol Ligit Of inant 100 tm fe spe al tig

ides,

Fine Lie On Due high tating fres«pulse mode

Secu ight Fishing in eect proving ra ted de

Thin Ligh OF hich de compet

Fitige NA. Resssen emom doested

Sccondisk NA

Thin OF

Fine Lig On Tie sks adr Sing ot high

Sccondisht On the waming sub overden

Fiore NA Pansona symm enor ie tetas

Sccond‘ight NA 1 ehoul be eae

In another embodiment, the LEDs 401 may he mul

colored LEDs which display a particular color associated

‘with the operational modes as discussed above with respoct

to the fis, sooond and third lights in Table 1

‘The housing 110 defines an inner eavity 402 in whieh the

contol eireit 400 and the motor 200 as well as other

‘components of the instrament 100 are disposed, With re

ference 10 FIG. 5, during step $20, a potting material 404 is

injected into the cavity 402 s0 thatthe material flows into

‘nd through the cavity 402, thereby coating and encapst-

lating the intemal components (eg, the contol circuit 400

and the motor 200) ofthe instrument 100. The material 404

‘may be injected such thatthe cavity 402 s either partially or

‘wholly filled with the material 404, Encapsulation of the

internal components eliminates voids within the inner cavity

4402, which may collect moisture and condensation. Further,

the material 404 als seals the components, therchy provide

‘ng protection from moisture, chemical compounds (¢g.

cleaners) vapors, g25S¢5, and biological contaminants. This

‘would also allow for sterilization of the instrument 100

providing for multiple uses,

Prior to injecting the material 404 into de housing 110

uring slep S20, the housing 110 may be suitably sealed

‘during step $10 to withstand pressures ofthe sealing process

as well 2s to hemmetcaly seal the housing 110 as described

above. The material 404 may be any material that may be

‘any liquid or amorphous material that solidifies upon injee-

‘ion into the cavity 402, In embodiments, the material 404

may be any material or combination of materials (ex.

epoxy) that may change its phase after injection into the

‘housing 110, such hat the material 404 is initially ina iguid

phase and then transitions into solid phase to eneapsulste

‘he components, Once solidified during step $30, the mate-

rial 404 may be relatively rigid to protect the components

{rom shock, maintain compliance and to reduce stress under

‘temperature extrenes an! other environmental conditions

ezsbodiments, the material 404 maybe aliquid sari

that may be solidified by one of the following processes

\hiel include, but are not imited to, room temperature

vuleanization, a thermosetting polymer reaction (e,

epoxy), curing (eg, anaerobic or ultfa-viole) and combi-

nations thereof. The material 404 may be a polymer, which

‘may include, but not limited to, polyesters, silicones, rub-

bers, epocies, nylons, polyphthalamide, lguid crystal poly-

anes, and combinations thereo

US 10,542,978 B2

7

The material 404 once solidified may have a hardness as

smessured bya durometer fom about § Shore Aw abot 100

Shore A in embosinents from about 10 Shore to about 30

Shore: In embodiments, the material 404 may be compl

‘ant anor elastic. This prevent hgh physical stoss that thes

‘nsirament 100 is subjected o from being transfered to the

internal components sno in embodiments where compo-

nents or mlerils of the instrament 100 have diserepant

thermal expansion properties. In addition, elasticity ofthe

taleial 404 absorbs noise aad vibration yeneratd by the

‘ive moror 200 and oiber drive mechanisms, which

‘eahances the handling caractrisis of the instrument 100

“The material 404 may ince one or more thermally

conductive andlor dickectie additives to draw themmal

‘energy from the components a Well st electrically isolate

‘lectonie and other sensitive components (e, deve

mechanisms, batteries, et) In ation, material 44 thats

themully conductive also reduces theaaal shock and tee

perature extremes associated with strlization (eg suo-

‘having) processes The motel 404 may bave « them >

‘conductance from abou 0.024 watts per meters C. (Winn?

C) and ahove, The material 404 may have an clactecal

resistance fm about 3 millivolts per cer unr standard

temperature and pressure (STP) (nVim) and above. The

material 404 may have a coeficient of thermal expansion

from about 1 pacts per millon” C. (ppm? C.) t about 30

ppm” C, in embodiments from about 5 ppm” Co about

20 ppav C. The material may have a surface energy fom

abot 10 dynes por centimater (dynesem’) to abou 45

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- United States Patent (10) Patent No.: US 8,360,390 B2Document9 pagesUnited States Patent (10) Patent No.: US 8,360,390 B2Vansala GanesanNo ratings yet

- United States Patent (10) Patent No.: US 7.460,350 B2: Talbot Et Al. (45) Date of Patent: Dec. 2, 2008Document27 pagesUnited States Patent (10) Patent No.: US 7.460,350 B2: Talbot Et Al. (45) Date of Patent: Dec. 2, 2008Vansala GanesanNo ratings yet

- US7897234Document6 pagesUS7897234Vansala GanesanNo ratings yet

- US20190027305A1Document52 pagesUS20190027305A1Vansala GanesanNo ratings yet

- United States Patent: Ledgerwood Et Al. Jun. 14, 2016Document16 pagesUnited States Patent: Ledgerwood Et Al. Jun. 14, 2016Vansala GanesanNo ratings yet

- United States Patent (10) Patent No.: US 7,208,943 B2: Godoy Et Al. (45) Date of Patent: Apr. 24, 2007Document15 pagesUnited States Patent (10) Patent No.: US 7,208,943 B2: Godoy Et Al. (45) Date of Patent: Apr. 24, 2007Vansala GanesanNo ratings yet

- US6801420Document27 pagesUS6801420Vansala GanesanNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,183,661 B2 Bogner Et Al. (45) Date of Patent: Feb. 27, 2007Document7 pagesUnited States Patent: (12) (10) Patent No.: US 7,183,661 B2 Bogner Et Al. (45) Date of Patent: Feb. 27, 2007Vansala GanesanNo ratings yet

- United States Patent: Zy 2X ZZZZZZZZDocument8 pagesUnited States Patent: Zy 2X ZZZZZZZZVansala GanesanNo ratings yet

- United States Patent: Rubinsztajn Et Al. Oct. 14, 2003Document14 pagesUnited States Patent: Rubinsztajn Et Al. Oct. 14, 2003Vansala GanesanNo ratings yet

- IIII: United States PatentDocument9 pagesIIII: United States PatentVansala GanesanNo ratings yet

- United States Patent: (10) Patent No.: US 6,974,554 B2Document8 pagesUnited States Patent: (10) Patent No.: US 6,974,554 B2Vansala GanesanNo ratings yet

- United States Patent (10) Patent No.: US 6,702,561 B2Document11 pagesUnited States Patent (10) Patent No.: US 6,702,561 B2Vansala GanesanNo ratings yet

- United States Patent (10) Patent No.: US 6,685,832 B2: Mahendran Et Al. (45) Date of Patent: Feb. 3, 2004Document31 pagesUnited States Patent (10) Patent No.: US 6,685,832 B2: Mahendran Et Al. (45) Date of Patent: Feb. 3, 2004Vansala GanesanNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument15 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentVansala GanesanNo ratings yet

- United States Patent (10) Patent No.: US 6,611,186 B2Document12 pagesUnited States Patent (10) Patent No.: US 6,611,186 B2Vansala GanesanNo ratings yet

- United States Patent (19) : Molthop 11) 4,389,363Document6 pagesUnited States Patent (19) : Molthop 11) 4,389,363Vansala GanesanNo ratings yet

- United States Patent (19) 11) Patent Number: 5,224,356: Bryant James C. Mulligan, Both of 3. - SE 5ta. IIDocument7 pagesUnited States Patent (19) 11) Patent Number: 5,224,356: Bryant James C. Mulligan, Both of 3. - SE 5ta. IIVansala GanesanNo ratings yet

- United States Patent (19) 11 Patent Number: 6,113,782Document22 pagesUnited States Patent (19) 11 Patent Number: 6,113,782Vansala GanesanNo ratings yet

- United States Patent (19) : 11 Patent Number: 4,479,990 45 Date of Patent: Oct. 30, 1984Document7 pagesUnited States Patent (19) : 11 Patent Number: 4,479,990 45 Date of Patent: Oct. 30, 1984Vansala GanesanNo ratings yet

- United States Patent (19) : Heyke Et Al. Feb. 23, 1993Document4 pagesUnited States Patent (19) : Heyke Et Al. Feb. 23, 1993Vansala GanesanNo ratings yet

- United States Patent 19: May 7, 1981 (Del Fed. Rep. of Germany. 3118130Document4 pagesUnited States Patent 19: May 7, 1981 (Del Fed. Rep. of Germany. 3118130Vansala GanesanNo ratings yet

- United States Patent (19) 11 Patent Number: 4,738,892: Canova (45) Date of Patent: Apr. 19, 1988Document5 pagesUnited States Patent (19) 11 Patent Number: 4,738,892: Canova (45) Date of Patent: Apr. 19, 1988Vansala GanesanNo ratings yet

- United States Patent (191: Fujimoto (11) 4,190,411Document7 pagesUnited States Patent (191: Fujimoto (11) 4,190,411Vansala GanesanNo ratings yet

- United States Patent (19) : Owens Et AlDocument5 pagesUnited States Patent (19) : Owens Et AlVansala GanesanNo ratings yet

- United States Patent (19) : EaringDocument7 pagesUnited States Patent (19) : EaringVansala GanesanNo ratings yet

- US3747037Document13 pagesUS3747037Vansala GanesanNo ratings yet

- United States Patent: (45) June 6, 1972Document7 pagesUnited States Patent: (45) June 6, 1972Vansala GanesanNo ratings yet

- US3929717Document4 pagesUS3929717Vansala GanesanNo ratings yet

- United States Patent (19) : Brady (45) Aug. 28, 1973Document4 pagesUnited States Patent (19) : Brady (45) Aug. 28, 1973Vansala GanesanNo ratings yet