Professional Documents

Culture Documents

Rapid Air Dry 10

Uploaded by

Moin AltafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rapid Air Dry 10

Uploaded by

Moin AltafCopyright:

Available Formats

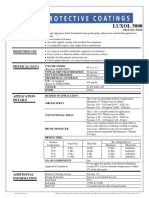

RAPID AIR DRY 10

Quick Drying Primer

PRODUCT A high quality primer coat based on quick drying synthetic polyester resin incorporating

DESCRIPTION anticorrosive pigments.

• Rapid drying.

• Good anticorrosive properties.

• Improves shop floor productivity.

• Good durability and weathering properties appropriate to the product requirement.

DESIGNED USE • Suitable as quick drying primer for interior structural steel

• Suitable as quick drying primer for upto C3 Environment as per ISO12944 Part 2 along with

suitable topcoats

PHYSICAL DATA VOLUME SOLIDS

54% + 2 %

(Based on ASTM D2697)

TYPICAL DRY FILM THICKNESS 60 microns

WET FILM THICKNESS 110 microns

THEORETICAL COVERAGE 9 m2/litre @ 60 microns DFT

VOC “As Supplied”

393 gms/ltr

(Based on ASTM D3960)

COLOUR Red Oxide/ Grey

FINISH Matt

APPLICATION METHOD OF APPLICATION :

DETAILS This is the recommended method of application:

Maximum 5% Thinner may be added.

AIRLESS SPRAY

Tip Size: 0.48 - 0.58 mm (0.019 - 0.023 in)

Pressure: 100 - 120 kg/cm2 (1500 - 1700 psi)

This is also a suitable method of application.

CONVENTIONAL SPRAY Maximum 20% Thinner may be added

Tip Size: 1.80 - 2.20 mm (0.071 - 0.087 in)

Pressure: 2.75 - 3.45 kg/cm2 (40 - 50 psi)

May be used for difficult shapes or touch-up.

However, additional coats may be required to achieve

BRUSH OR ROLLER

the recommended film thickness. Dipping is also

another method of application.

DRYING TIME:

Surface Over coating Interval

Touch Dry Hard Dry

Temperature Minimum Maximum

15°C 20 mins 6 Hrs 6 Hrs Indefinite

25°C 10 mins 3 Hrs 3 Hrs Indefinite

35°C 5 mins 1½ Hrs 1½ Hrs Indefinite

45°C 2 mins 10 mins 15 mins Indefinite

NO. OF COMPONENTS One

Do not apply this product if the Relative Humidity

Application Conditions exceeds 85% or if the substrate temperature is within

3°C of the dew point

ADDITIONAL Thinner / Cleaning solvent Solvalux 7-25

Storage Instruction Store in a cool shaded dry area

INFORMATION Flash Point 30°C

Packaging 5 USG & 200 litres

Shelf Life 12 months from the date of manufacture.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

RAPID AIR DRY 10

Quick Drying Primer

SURFACE For best results the surface should be treated as follows prior to application.

PREPARATION • Remove all wax, oil and grease by solvent cleaning in accordance with the guidelines given by

SSPC-SPI.

• Where necessary remove weld spatter and round off all rough weld seams and sharp edges

to a smooth surface.

• Abrasive blast clean the surface to a minimum standard of Sa l Swedish standard SIS 05 59 00

or ISO 8501-1 : 1988 or mechanical cleaning using hand or power tools to a minimum

standard of St 2 Swedish standard SIS 05 59 00 or ISO 8501-1: 1988 is also acceptable.

However take necessary care to avoid polishing.

• The average surface profile of 35 micron is acceptable but this average should not exceed 50

microns.

• After blasting remove dust from the surface. The surface to be coated must be clean and dry.

TYPICAL COATING System Priming 2nd Coat 3rd Coat (Optional)

SYSTEMS Single Coat Rapid Air Dry 10

Multiple Coats Rapid Air Dry 10 Rapid Air Dry 15 Rapid Air Dry 15

PRODUCT USE • Dry film thickness may vary depending on the method of application.

RESTRICTIONS • For exterior use the product should be suitably top coated.

• The product is not suitable for top coating with two-pack epoxy and polyurethane coatings.

• Dry heat resistant up to 800C.

• "Indefinite" over coating interval indicates fairly long time but within the life span of the

coating.

• May also be applied between 50 and 75 Microns DFT

• Contact Berger Representative for suggesting suitable paint system

SAFETY • Avoid contact with the skin and eyes. Wear suitable protective clothing such as overalls, goggles, dust

masks and gloves. Use a barrier cream.

PRECAUTIONS • Ensure that there is adequate ventilation in the area where the product is being applied. Do not breathe

vapor or spray.

• This product is flammable. Keep away from sources of ignition. Do not smoke. Take precautionary

measures against static discharge. In case of fire – blanket flames with foam, carbon dioxide or dry

chemicals

• Refer to MSDS for further information.

FIRST AID • Eyes: In the event of accidental splashes, flush eyes with water immediately and obtain medical advice

• Skin: Wash skin thoroughly with soap and water or approved industrial cleaner.

• DO NOT USE solvent or thinners.

• Inhalation: Remove to fresh air, loosen collar and keep patient rested.

• Ingestion: In case of accidental ingestion, DO NOT INDUCE VOMITING.

Obtain immediate medical attention

The information provided on this data sheet is not intended to be complete and is provided as general advice only. It is the responsibility

DISCLAIMER of the user to ensure that the product is suitable for the purpose for which he wishes to use it. As we have no control over the treatment of

the product, the standard of surface preparation of the substrate, or other factors affecting the use of this product, we are not responsible

for its performance nor would we accept any liability whatsoever or howsoever arising from the use of this product unless specifically

agreed to in writing by us. The information contained in this data sheet may be modified by us from time to time, and without notice, in

the light of our experience and continuous product development.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

You might also like

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- LUXATHERM 6200 Silicone Acrylic Heat Resisting Finish (220°CDocument2 pagesLUXATHERM 6200 Silicone Acrylic Heat Resisting Finish (220°CPraveenNo ratings yet

- Epimastic 7200: Product DescriptionDocument2 pagesEpimastic 7200: Product DescriptionSu KaNo ratings yet

- Pds Luxaprime 1000 VocDocument2 pagesPds Luxaprime 1000 VocmuthukumarNo ratings yet

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- Epoxy Primer for Corrosion ProtectionDocument2 pagesEpoxy Primer for Corrosion ProtectionsreeNo ratings yet

- Pds Luxaprime 1400 VocDocument2 pagesPds Luxaprime 1400 VocmuthukumarNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Epoxy Undercoat Protects Steel and ConcreteDocument2 pagesEpoxy Undercoat Protects Steel and ConcreteMoin AltafNo ratings yet

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- EPILUX 5 Coal Tar Epoxy Anti-Corrosion CoatingDocument2 pagesEPILUX 5 Coal Tar Epoxy Anti-Corrosion CoatingShyam ShrishNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Pds Epilux 218 Hs VocDocument2 pagesPds Epilux 218 Hs VocmuthukumarNo ratings yet

- LUXATHANE 5160 Polyurethane Finish Product DetailsDocument2 pagesLUXATHANE 5160 Polyurethane Finish Product DetailsshameelNo ratings yet

- Pds Luxaprime 1500 VocDocument2 pagesPds Luxaprime 1500 VocmuthukumarNo ratings yet

- High Quality Alkyd UndercoatDocument2 pagesHigh Quality Alkyd UndercoatmuthukumarNo ratings yet

- High Solids Epoxy Zinc Rich Primer for Corrosion ProtectionDocument2 pagesHigh Solids Epoxy Zinc Rich Primer for Corrosion ProtectionmuthukumarNo ratings yet

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- Epilux 58 - 9702Document2 pagesEpilux 58 - 9702anandNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- RobbiathaneDocument2 pagesRobbiathaneAnson FranklinNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- pm002 4446Document2 pagespm002 4446Dhanush Kumar RamanNo ratings yet

- Epimastic 4100Document2 pagesEpimastic 4100Moin AltafNo ratings yet

- SigmaZinc 100 zinc primer guideDocument4 pagesSigmaZinc 100 zinc primer guideJohnson Chng Hou KiatNo ratings yet

- Luxathane 5160-Voc March 2021 V1Document2 pagesLuxathane 5160-Voc March 2021 V1PraveenNo ratings yet

- Luxathane 5000 High Gloss Polyurethane FinishDocument2 pagesLuxathane 5000 High Gloss Polyurethane Finishmuthukumar100% (1)

- Steel Shield 1100Document3 pagesSteel Shield 1100Moin AltafNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- Paragloss v2Document2 pagesParagloss v2Adam FauzanNo ratings yet

- Bergerlac Aluminium Finish PDFDocument2 pagesBergerlac Aluminium Finish PDFMuthuKumarNo ratings yet

- Sigmacover 525: Description Principal CharacteristicsDocument2 pagesSigmacover 525: Description Principal CharacteristicsEngTamerNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- KANSAI PAINT Paralux - 15HBDocument2 pagesKANSAI PAINT Paralux - 15HBYogalingam ArumugamNo ratings yet

- 3500-00 Simathane GlossDocument3 pages3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNo ratings yet

- Sigma Marine Coatings Manual - Part56Document2 pagesSigma Marine Coatings Manual - Part56EngTamerNo ratings yet

- Tds Parapex No3Document2 pagesTds Parapex No3Anonymous Nb6t2ezcZ100% (1)

- HEMPADUR ZINC 15360 15360 en-GB PDFDocument2 pagesHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinNo ratings yet

- ISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetDocument3 pagesISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetHendri Dwi cahyonoNo ratings yet

- High Build Epoxy Coating for Steel and ConcreteDocument2 pagesHigh Build Epoxy Coating for Steel and ConcreteTejinder KumarNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- SigmaCover 410 Protective Coating GuideDocument4 pagesSigmaCover 410 Protective Coating GuideMohammed AdilNo ratings yet

- BT 0832 Rethane FWP SB 672 - InglêsDocument2 pagesBT 0832 Rethane FWP SB 672 - InglêsProtection Representacoes Valter HugoNo ratings yet

- Sigmadur GlossDocument5 pagesSigmadur Glossgst ajahNo ratings yet

- Sam Classic FinishDocument2 pagesSam Classic FinishMo MosadNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- b6) Zincanode690 2886Document2 pagesb6) Zincanode690 2886Anonymous XVEucVMsENo ratings yet

- PARATHERM 600 HEAT RESISTING FINISHDocument2 pagesPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- PDS en-GB 45751Document2 pagesPDS en-GB 45751Anuar SalehNo ratings yet

- Duremax Gpe ZP Aug 2018Document3 pagesDuremax Gpe ZP Aug 2018Biju_PottayilNo ratings yet

- DEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesDocument30 pagesDEP-31403039 - Spec - 2017-02 - A01 - Internal FBE Coating For Water Injection LinesMoin AltafNo ratings yet

- HilonDeco Cryl 9200-MCDocument2 pagesHilonDeco Cryl 9200-MCMoin AltafNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- 2023-RegisterBook Version 202212Document95 pages2023-RegisterBook Version 202212Moin AltafNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- PDS-Supreme Eggshell - Silk Version 1Document2 pagesPDS-Supreme Eggshell - Silk Version 1Moin AltafNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Steel Shield 1100Document3 pagesSteel Shield 1100Moin AltafNo ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- Epoxy Undercoat Protects Steel and ConcreteDocument2 pagesEpoxy Undercoat Protects Steel and ConcreteMoin AltafNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- LUXATHANE 5160 Polyurethane Finish Product DetailsDocument2 pagesLUXATHANE 5160 Polyurethane Finish Product DetailsshameelNo ratings yet

- Epimastic 4100Document2 pagesEpimastic 4100Moin AltafNo ratings yet

- Epimastic 4100Document2 pagesEpimastic 4100Moin AltafNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Can a SUNNI man marry a SHIA girl? The beliefs of SHIAs inconsistent with SunnisDocument2 pagesCan a SUNNI man marry a SHIA girl? The beliefs of SHIAs inconsistent with SunnisMoin AltafNo ratings yet

- UAE Limited Liability CompanyDocument2 pagesUAE Limited Liability CompanyMoin AltafNo ratings yet

- Tabla Uw-12Document1 pageTabla Uw-12Christian Lopez Mendez100% (1)

- Fabric Wrapped Panel SystemDocument5 pagesFabric Wrapped Panel SystemMohammed SayeeduddinNo ratings yet

- 2 Folding BarsDocument3 pages2 Folding BarsAlfred KuwodzaNo ratings yet

- Wps 22Document2 pagesWps 22Avishek GuptaNo ratings yet

- MillingDocument36 pagesMillingSerhat DoğandemirNo ratings yet

- Microelectromechanical Assignment HelpDocument23 pagesMicroelectromechanical Assignment HelpMechanical Engineering Assignment HelpNo ratings yet

- Data Mekanik (Update 14052020)Document6 pagesData Mekanik (Update 14052020)wedus wedusNo ratings yet

- How To Solder A Through-Hole Component: InstructablesDocument6 pagesHow To Solder A Through-Hole Component: InstructablesBobKatNo ratings yet

- VBTDocument5 pagesVBTMohdHuzairiRusliNo ratings yet

- Data Sheet Mechanical SealDocument1 pageData Sheet Mechanical SealJ SaadatNo ratings yet

- Super Laykold Waterproofing EmulsionDocument2 pagesSuper Laykold Waterproofing Emulsionengramir07No ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- HDPE管道施工工法 (中英文)Document32 pagesHDPE管道施工工法 (中英文)Long CreationNo ratings yet

- Prosedur Pengelasan Pipa HDPE-SHDS 160SDocument10 pagesProsedur Pengelasan Pipa HDPE-SHDS 160SIJEN GEOTHERMALNo ratings yet

- Manufacturing Methods: An IntroductionDocument18 pagesManufacturing Methods: An IntroductionRafiqueNo ratings yet

- Three basic welding torch flame types: neutral, carburizing, oxidizingDocument4 pagesThree basic welding torch flame types: neutral, carburizing, oxidizingRoween SernalNo ratings yet

- AsaDocument35 pagesAsamarz95No ratings yet

- Welding Technology Exam QuestionsDocument11 pagesWelding Technology Exam QuestionsVijaya BaraniNo ratings yet

- Synopsis of Changes in NBIC Part 3 E2023Document42 pagesSynopsis of Changes in NBIC Part 3 E2023yathi sNo ratings yet

- Flanges: KPC CorporationDocument6 pagesFlanges: KPC Corporationdj22500No ratings yet

- South 24 ParganasDocument26 pagesSouth 24 ParganasDFBDHHNo ratings yet

- EE 2114 Chapter 2 Basic Measurement BenchworkDocument77 pagesEE 2114 Chapter 2 Basic Measurement BenchworkAbdul Munir Abdul KarimNo ratings yet

- Docol 1300M: General Product DescriptionDocument2 pagesDocol 1300M: General Product DescriptionAnonymous wR1jrmpYANo ratings yet

- Electrolytic Etching Process v1Document37 pagesElectrolytic Etching Process v1Miguel MejíaNo ratings yet

- Field Erected Tanks - API Cantoni System (Innovative Method) - Above Ground Storage Tank API 650 - YouTubeDocument2 pagesField Erected Tanks - API Cantoni System (Innovative Method) - Above Ground Storage Tank API 650 - YouTubeSlim Kanoun100% (1)

- Carboxane 2000 Product Performance Summary 092619Document3 pagesCarboxane 2000 Product Performance Summary 092619BERSE MAJU INDONESIANo ratings yet

- Friction Stir Welding ThesisDocument4 pagesFriction Stir Welding Thesisaflowlupyfcyye100% (2)

- SP7000M00W15 000 ADocument10 pagesSP7000M00W15 000 APedro Casimiro GámizNo ratings yet

- Parker Sea Recovery CatalogueDocument2 pagesParker Sea Recovery CatalogueFrancisco SantanaNo ratings yet

- Rubber Lining Application PDFDocument9 pagesRubber Lining Application PDFLasandu WanniarachchiNo ratings yet