Professional Documents

Culture Documents

Ic Engine - 7

Ic Engine - 7

Uploaded by

Ricky Sarkar0 ratings0% found this document useful (0 votes)

12 views3 pagesOriginal Title

IC ENGINE - 7

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views3 pagesIc Engine - 7

Ic Engine - 7

Uploaded by

Ricky SarkarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

2. Fuel Air Cycles and Actual Cycles Internal Combustion Engine (2161902)

040

Indicated thermal ficiency

o4 06 08 10 12 14 16

Equivalence ratio

Fig. 2.6 Effect of mixture strength o1 thermal efficiency for various compression ratios

= The maximum pressure and temperature increase with compression ratio since the

temperature, Tz, and pressure, pz, tthe end of compression are higher. However, it

can be noted from the experimental results that the ratio of fuel-air cycle efficiency to

air-standard efficiency is independent of the compression ratio for given equivalence

ratio for the constant volume fuet-air cycle.

2.7.2. Fuel Air ratio

a) Efficiency

= As the mixture is made lean (less

fuel) the temperature rise due to

combustion will be lowered as a

result of reduced energy input per

unit mass of mixture. This will result

in lower specific heat.

— Further, it will lower the losses due

to dissociation and variation in

specific heat. The efficiency is

therefore, higher and, in fact,

epproaches the air-cycle efficiency

as the fuel-air ratio is reduced as

shown in Fig. 2.7.

b) Maximum Power

= Fig. 2.8 gives the cycle power as affected by fuel-air ratio. By alr-standard theory

maximum power is at chemically correct mixture, but by fuel-air theory maximum

‘Thermal efficiency

Mixture strength

1. 2.7 Effect of mixture strength on thermal

efficiency

Ai

Prepared By: Darshit S. Dadhaniya Department of Mechanical Engineering

Page 2.12 Darshan Institute of Engineering & Technology, Rajkot

Internal Combustion Engine (2161902) 2, Fuel Air Cycles and Actual Cycles

power is when the mixture is about 10% rich. As the mixture becomes richer the

efficiency falls rapidly.

Cycle power

ow 9% 10 10 1%

‘Mistare strength expressed a a percentage of chemically correct

Fig, 2.8 Effect of fuel-oir ratio on power

= This is because in addition to higher specific heats and chemical equilibrium losses,

there is insufficient air which will result in formation of CO and H2 in combustibles,

Which represents a direct wastage of fuel.

©) Maximum temperature

= Ale given compression ratio the Hass

temperature after combustion ra

reaches a maximum when the 4 7

‘

mixture is slightly rich, i.e., around nee $

6 % OF $0 (F/A = 0.072 oF Ay avo

as shown in Fig. 2.9. aa

=~ At chemically correct ratio there is ‘0

still some oxygen present at the point A

3 because of chemical equilibrium te ie 10

effects a rich mixture will cause more 80

8

fuel to combine with oxygen at that 3° 6 feete AE

point thereby raising the aa hi Il 7

temperature Ts. However, at richer ae

mixtures increased formation of CO oie eee epee ee tt

counters this effect. © 80 100 12 140160

4d) Maximum Pressure ‘Mixture strength expressed as a percentage

fof ctoishiomotie mixtaro

— The pressure of a gas in a given space

depends upon its temperature and

the number of molecules The curve of ps, therefore follows Ts, but because of the

increasing number of molecules ps does not start to decrease until the mixture is,

somewhat richer than that for maximum Ts (at F/A = 0.083 or A/F = 12:1), ie. about

20 per cent rich (Fig,2.9)

Fig. 2.9 Effect of equivalence ratio on Ts and Py

Department of Mechanical Engineering Prepared By: Darshit S. Dadhaniya

Darshan Institute of Engineering & Technology, Rajkot Page 2.13

2. Fuel Air Cycles and Actual Cycles Internal Combustion Engine (2161902)

e) Exhaust Temperature

The exhaust gas temperature, Ts is 200,

maximum at the chemically correct

mixture as show in Fig, 2.20. AL

this point there is reassociation as 704

the temperature decrease so heat ~

will be released these heat cannot S180

be used in engine cylinder so the

exhaust gases carry these heat with 2

them andit result in higher exhaust ie g |,

temperature. é BE

‘At lean mixtures, because of less 1409] SE

fuel, Ts is less and hence Ts is less. 2

‘At rich mixtures less sensible

energy is developed and hence Ts is 120 ‘0 1 0

less, That is, Ts varies with fuel-air Bes cen of hocecdcal el

ratio in the same manner as Ts

except that maximum Ts isa the 8° 220 et of feta ratio onthe ext gs

chemically correct fuel-air ratio in

place of slightly rich fuel-air ratio (6 %) as in case of Ts,

However, the behaviour of Ts with compression ratio is different from that of Ts as

shown in Fig. 2.10 Unlike Ts, the exhaust gas temperature, Ta is lower at high

compression ratios, because the increased expansion causes the gas to do more work

on the piston leaving less heat to be rejected at the end of the stroke. The same effect

is present in the case of air-cycle analysis also.

2.8 Comparison of air standard and actual cycles

The actual cycles for internal comtustion engines differ from alr-standard cycles in

many respects. These differences are mainly due to:

The working substance being @ mixture of air and fuel vapour or finely atomized liquid

fuel in air combined with the products of combustion left from the previous cycle.

The change in chemical composition of the working substance.

The variation of specific heats with temperature.

The change in the composition, temperature and actual amount of fresh charge

because of the residual gases

The progressive combustion rather than the instantaneous combustion.

The heat transfer to and from the working medium

The substantial exhaust blowdown loss, ie, loss of work on the expan-sion stroke due

to early opening of the exhaust valve.

Gas leakage, fluid friction ete, in actual engines.

Prepared By: Darshit S. Dadhaniya Department of Mechanical Engineering

Page 2.14 Darshan Institute of Engineering & Technology, Rajkot

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Hydraulics.31 40Document10 pagesHydraulics.31 40Ricky SarkarNo ratings yet

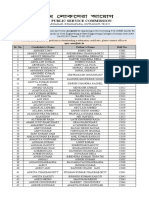

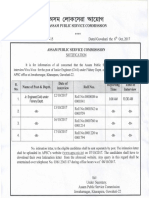

- Sel - Asstt - Prof - Civil Engg - 17oct2019Document11 pagesSel - Asstt - Prof - Civil Engg - 17oct2019Ricky SarkarNo ratings yet

- TT SCHEDULE Yealry 2020 PDFDocument3 pagesTT SCHEDULE Yealry 2020 PDFRicky SarkarNo ratings yet

- Ic Engine - 6Document3 pagesIc Engine - 6Ricky SarkarNo ratings yet

- Module 5 PDFDocument98 pagesModule 5 PDFRicky SarkarNo ratings yet

- Ad JR Instr SC Asstt-2017Document2 pagesAd JR Instr SC Asstt-2017Ricky SarkarNo ratings yet

- Applications and Processing of Metals and Alloys: Module-09Document19 pagesApplications and Processing of Metals and Alloys: Module-09Ricky SarkarNo ratings yet

- Notification Urban Dev. Deptt 6 Feb 18Document1 pageNotification Urban Dev. Deptt 6 Feb 18Ricky SarkarNo ratings yet

- Types of Parking Brakes:: Self-Locking: at Certain Critical Value of FC, The Term (B-FC) Becomes Zero, I.e., No ActuationDocument1 pageTypes of Parking Brakes:: Self-Locking: at Certain Critical Value of FC, The Term (B-FC) Becomes Zero, I.e., No ActuationRicky SarkarNo ratings yet

- ASSAM Diploma New SyllabusDocument51 pagesASSAM Diploma New SyllabusRicky SarkarNo ratings yet

- Notification JE (Civil)Document1 pageNotification JE (Civil)Ricky SarkarNo ratings yet