Professional Documents

Culture Documents

Burner Management System Codes and Standards Update

Burner Management System Codes and Standards Update

Uploaded by

Romel Rodriguez0 ratings0% found this document useful (0 votes)

8 views30 pagesBMS

Original Title

Website-AKISAAPI556NFPA87

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBMS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views30 pagesBurner Management System Codes and Standards Update

Burner Management System Codes and Standards Update

Uploaded by

Romel RodriguezBMS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 30

Burner Management System

Codes and Standards Update

Presenter Introduction

• Michael Scott, PE, CFSE

• VP – Process Safety; General Mgr AK

• 24 Years Experience

• ISA Committees - S84, WG6 Chair, WG3

Core Team Member

• IEC61511

• Past ISA Safety Division BMS Chairman

• ISA Course Developer / Instructor

• Past PIP Safety System Task Team

Member

• BSME, University of Maryland

• ME, University of South Carolina

Presentation Overview

• Understand industry direction with respect to BMS

designs

• API 556 - Instrumentation, Control, and Protective

Systems for Fired Heaters and Steam Generators 2011

Edition

• NFPA 87 – Recommended Practice for Fluid Heaters

2011 Edition

API 556

• API 556 - Instrumentation and Controls for Fire

Heaters and Steam Generators

• Latest revision 2011

• Incorporates concepts from ISA BMS Technical

Report

• Invokes concepts of Safety Instrumented Systems

• Provides guidance on hazards and associated

shutdown functions

API 556

• Covers instrument, control, and protective function

installations for gas fired heaters and steam

generators in petroleum refinery, hydrocarbon

processing, petrochemical and chemical plants.

• Does NOT cover

• Oil fired and combination fired heaters

• Water tube boilers designed for utility operation

• HRSG

• Ovens / furnaces used for incinerating (NFPA 86)

• Water bath or oil bath indirect fired heaters

• CO boiler, ethylene furnace and other specialty heaters

API 556

• Includes guidance on the following:

• Protective function (interlock) requirements with

background material on hazards being

mitigated against

• Process safety time requirements

• Application of instrumentation – pro’s / con’s

• Process Control – air / fuel ratio, charge flow,

firebox draft control

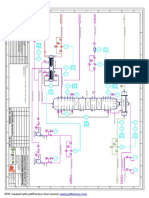

• P&ID’s

API 556

• Includes guidance on the following:

• Cause & Effects

• Safe State Table

• Alarm Summary with basis for alarm and

operator action requirements

• Startup sequence documentation for natural

draft, force draft and balanced draft heaters

API 556

• Does not provide guidance on:

• SIL Selection

• Logic Solver Requirements

API 556

API 556

API 556

NFPA 87

• Covers - A fluid heater is considered to be any thermal

fluid heater or process heater with the following features:

• Fluid is flowing under pressure

• Fluid is indirectly heated

• Release of energy from combustion of a liquid or

gaseous fuel or an electrical source within the unit

• Invokes concepts of Safety Instrumented Systems

NFPA 87

• Covers - A fluid heater is considered to be any thermal

fluid heater or process heater with the following features:

• Fluid is flowing under pressure

• Fluid is indirectly heated

• Release of energy from combustion of a liquid or

gaseous fuel or an electrical source within the unit

• Invokes concepts of Safety Instrumented Systems

NFPA 87

• Does NOT cover

• Boilers

• Ovens / furnaces used for incinerating (NFPA 86)

• Refinery process heaters

• Reformers, furnaces or cracking furnaces

• Space heaters

• LP-Gas Vaporizers

• Coal or other solid fuel firing systems

• Listed equipment with heat input less than 150,000

BTU/hr

NFPA 87

• Includes guidance on the following:

• Interlock requirements

• Provides NO background material on hazards being

mitigated against

• Generic process safety time requirements

• Process Control – limited guidance

• P&ID’s

NFPA 87

• Includes guidance on the following:

• Guidance on leakage criteria for safety shutoff valves

NFPA 87

NFPA 87

NFPA 87

• Does not provide guidance on:

• SIL Selection

• However does provide extensive prescriptive

guidance on Logic Solver Requirements

NFPA 87 Logic Solver Requirements

Allows use of 5 types of logic solvers:

• Hardwired System

• Listed Safety Relays

• Listed PLCs – None Exist in Marketplace at this time

• Non-Listed PLCs

• Safety PLC implemented per ISA S84

NFPA 87 Logic Solver Requirements

Non-Listed PLC Requirements:

i. PLC should detect the following conditions:

1. Failure to execute any program or task containing safety logic

2. Failure to communicate with any safety input or output

3. Changes in software set points of safety functions

4. Failure of outputs related to safety functions

5. Failure of timing related to safety functions

ii. A shutdown condition should occur within 3 seconds of

detecting the above conditions.

NFPA 87 Logic Solver Requirements

Non-Listed PLC Requirements:

iii. A dedicated PLC output should initiate a safety shutdown for

faults detected by the PLC.

iv. The following devices and logic should be hardwired

external to the PLC as follows:

Manual emergency switch, Combustion safeguards, Safe

start checks

Ignition transformers, Trial for ignition periods, Excess

temperature controllers, 1400 DegF bypass controller,

Valve proving systems

v. Memory that retains information on loss of system power

should be provided for software

NFPA 86 / 87 Logic Solver Requirements

Non-Listed PLC Requirements:

vi. The PLC should have a minimum MTBF of 250,000 hours.

vii. Only one safety device should be connected to a PLC input or output

viii. Output checking should be provided for PLC outputs controlling fuel

safety shutoff valves

ix. Access to the PLC and its logic should be restricted to authorized

personnel

x. The following power supplies should be monitored:

1. PLC inputs and outputs that control furnace safety

functions

2. Pressure and flow transmitters

NFPA 87 Logic Solver Requirements

Non-Listed PLC Requirements:

xi. If power supply fails, the dedicated PLC output should be

de-activated.

Xii. If the power supply voltage is detected outside the

manufacturer’s recommended range, the dedicated PLC output

above should be de-activated.

xiii. PLCs that do not comply with the above should comply with

the following:

1. PLC should not perform required safety functions

2. PLC should not interfere with or prevent the operation of the

safety interlocks

3. Only isolated PLC contacts should be used in the required

safety circuits

NFPA 86 / 87 Logic Solver Requirements

Non-Listed PLC Requirements:

xiv. Where PLC uses flow transmitters in place of flow switches and

pressure transmitters in place of pressure switches for safety functions,

the following should apply:

1. The transmitter should be listed, possess a MTBF of 250,000

hours or possess a safety integrity level rating of SIL 2.

2. Upon transmitter failure the PLC should detect the failure and

initiate a safety shutdown

3. The transmitter should be dedicated to safety service unless listed

for simultaneous process and safety service.

NFPA 87 Logic Solver Requirements

5th Approved Type of Logic Solver:

Furnace controls that meet the performance-based

requirements of standards such as ANSI/ISA 84.00.01

Application of Safety Instrumented Systems for the Process

Industries, can be considered equivalent. The determination of

equivalency involves complete conformance to the safety

lifecycle including risk analysis, safety integrity level selection,

and safety integrity level verification, which should be submitted

to the authority having jurisdiction.

BMS OEM Supplied Logic Solvers

• Typically a BMS includes at least one SIL 2 rated

Safety Instrumented Function

• Most OEM logic solvers will not be capable of meeting

SIL 2

• Thus, if you plan to select Safety Integrity Levels

associated with your BMS, the OEM provide logic

solver is often considered unacceptable

• This invokes budget, schedule and warranty issues on

the project

• Early involvement of appropriate Technical Authorities

with the project team is required to prevent project

woes!!!!

Before

After

Questions

&

Answers

Providing the Highest Value in Automation

You might also like

- Boiler Control Systems Engineering, Second EditionFrom EverandBoiler Control Systems Engineering, Second EditionRating: 4.5 out of 5 stars4.5/5 (15)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- NFPA25 ITM of Water Based FPSDocument159 pagesNFPA25 ITM of Water Based FPSLenard Erasmo Mari Magsino100% (1)

- FS HippsDocument8 pagesFS Hippsscribd_thakurNo ratings yet

- Automation Network Selection - IsADocument113 pagesAutomation Network Selection - IsAerstendrain100% (1)

- Ul 508aDocument56 pagesUl 508aRobert Zenon100% (2)

- Chap01 - A Career in Process ControlDocument44 pagesChap01 - A Career in Process ControlKeith MaddenNo ratings yet

- Basic Lopa and SilDocument9 pagesBasic Lopa and SilBrian Dunagan100% (2)

- White Paper Rouse 2h Sil Verification For Rosemount Type B Transmitters With Type A Components DataDocument16 pagesWhite Paper Rouse 2h Sil Verification For Rosemount Type B Transmitters With Type A Components DataCARLOS PEREZNo ratings yet

- LOPADocument84 pagesLOPAM100% (4)

- PART 2-A SIS Applications in BoilersDocument29 pagesPART 2-A SIS Applications in BoilersAdila AnbreenNo ratings yet

- SIL Awareness: Introduction To Safety Life-Cycle IEC-61508 and IEC-61511Document187 pagesSIL Awareness: Introduction To Safety Life-Cycle IEC-61508 and IEC-61511mohammed el erian100% (1)

- An Eurotherm HVACDocument46 pagesAn Eurotherm HVACrobert_kerr_29No ratings yet

- Process Control & Tuning of Industrial Control LoopsDocument2 pagesProcess Control & Tuning of Industrial Control LoopsHasen BebbaNo ratings yet

- PLCDocument2 pagesPLCFaez YasinNo ratings yet

- Process Safety ManagementDocument41 pagesProcess Safety ManagementJohn Lasswell100% (2)

- Commissioning Documents For Instrumentation EngineersDocument7 pagesCommissioning Documents For Instrumentation EngineersVraja Kisori100% (1)

- Designs For Process SafetyDocument32 pagesDesigns For Process SafetyRobert WilsonNo ratings yet

- Process Control and Automation Network Selection 1674135121Document113 pagesProcess Control and Automation Network Selection 1674135121Fabricio FebresNo ratings yet

- 3D - Jeff GuricanDocument29 pages3D - Jeff GuricanJorge SicattNo ratings yet

- 1 What Is Functional Safety, SIF, SISDocument17 pages1 What Is Functional Safety, SIF, SISAlice LinNo ratings yet

- Goble Safety Expo06Document23 pagesGoble Safety Expo06Anas SakrNo ratings yet

- Receiving Elements: Instrumentation & ControlDocument47 pagesReceiving Elements: Instrumentation & ControlSka dooshNo ratings yet

- FSSS Boiler Protection System Basic Concepts and StandardsDocument24 pagesFSSS Boiler Protection System Basic Concepts and StandardsAshwani Dogra100% (1)

- Roche Track 2 TuesdayDocument24 pagesRoche Track 2 Tuesdayari78No ratings yet

- Overview of Control System.Document24 pagesOverview of Control System.la.wajeehakhurshidNo ratings yet

- Chapter 1Document24 pagesChapter 1Anonymous tytJlPojNo ratings yet

- CCI Innovative Solutions For HIPPS SystemsDocument8 pagesCCI Innovative Solutions For HIPPS SystemsRengga Ahmad PrasetiaNo ratings yet

- HSE Chapter 5Document13 pagesHSE Chapter 5bil3rab.desNo ratings yet

- BL-22-IG-262 - 0 - Alarm Protective Equipment ManagementDocument12 pagesBL-22-IG-262 - 0 - Alarm Protective Equipment ManagementAanantharaj LourdesamyNo ratings yet

- 3BUS095609 en Whitepaper - Is Your SIS CompliantDocument7 pages3BUS095609 en Whitepaper - Is Your SIS CompliantamjadnawazNo ratings yet

- 2 Tid Stromverteilung 146 237 GB LRDocument92 pages2 Tid Stromverteilung 146 237 GB LRArun KumarNo ratings yet

- Lecture 4 HandoutsDocument26 pagesLecture 4 HandoutsRakesh ThapliyalNo ratings yet

- SAFED-Boiler Guidelines PSG2Document30 pagesSAFED-Boiler Guidelines PSG2Martin RileyNo ratings yet

- 08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroDocument40 pages08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroCalNo ratings yet

- Dan Dettmers - Understanding RAGAGEPDocument58 pagesDan Dettmers - Understanding RAGAGEPRASHEED YUSUF100% (1)

- Controllogix System: Selection GuideDocument40 pagesControllogix System: Selection Guidevlcmstne04No ratings yet

- Industrial Maintenance BrochureDocument16 pagesIndustrial Maintenance Brochuremokhtariomid_6303816No ratings yet

- Checklist To Carry Out PLC Preventive Maintenance ActivityDocument1 pageChecklist To Carry Out PLC Preventive Maintenance ActivityjamesmundondoNo ratings yet

- ISA - The Total Solution For A HIPPS RequirementsDocument17 pagesISA - The Total Solution For A HIPPS RequirementsRatnin PanityingNo ratings yet

- Haake Polylab System: Torque Rheometer Haake RheocordDocument12 pagesHaake Polylab System: Torque Rheometer Haake RheocordJorgeRiascosNo ratings yet

- PPCM - 0110 AMS 1 Ammonia Injection HRSG 1 SystemDocument10 pagesPPCM - 0110 AMS 1 Ammonia Injection HRSG 1 SystemAli EsshaqNo ratings yet

- Central Battery Equipment For Emergency LightingDocument16 pagesCentral Battery Equipment For Emergency LightingsherifNo ratings yet

- Guidelines T C Fire Alarm - Topic#2Document15 pagesGuidelines T C Fire Alarm - Topic#2Sk NgNo ratings yet

- Safety Instrumentation and Shut-Down SystemsDocument2 pagesSafety Instrumentation and Shut-Down SystemsRa'ed Mothanny Al-huraid100% (1)

- SIL Products & Services: Redefining Flow ControlDocument16 pagesSIL Products & Services: Redefining Flow ControlsantoshjayantiNo ratings yet

- Bartelt Industrial Automated Systems Chapter 01Document15 pagesBartelt Industrial Automated Systems Chapter 01w32y0% (2)

- Automation Control System Specification Design and Installation Guide PDFDocument93 pagesAutomation Control System Specification Design and Installation Guide PDFsabeerNo ratings yet

- Pressure System Awareness Training - Revised 2013Document43 pagesPressure System Awareness Training - Revised 2013anarNo ratings yet

- CN Power Broch Gea19389b EnglishDocument20 pagesCN Power Broch Gea19389b EnglishChristos BountourisNo ratings yet

- NewnameDocument7 pagesNewnameDANIEL ANDRES ARROYO ESPITIANo ratings yet

- 9132 7491 W A3 Ammonia Refrigeration RagagepDocument108 pages9132 7491 W A3 Ammonia Refrigeration RagagepArdago LenggaNo ratings yet

- Chemical and Bio-Process Control: James B. Riggs M. Nazmul KarimDocument44 pagesChemical and Bio-Process Control: James B. Riggs M. Nazmul KarimRiani ZipNo ratings yet

- Penerapan Safety Instrumentation System Di Industri ProsesDocument51 pagesPenerapan Safety Instrumentation System Di Industri ProsesPrazzt Tyo100% (1)

- A10 4 Example RAGAGEP Certification Letter 070414Document1 pageA10 4 Example RAGAGEP Certification Letter 070414Dave CNo ratings yet

- In - APC Training PresentationDocument32 pagesIn - APC Training PresentationSabina AzizliNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Lo21-21-P-Pi-16 - Rev.pDocument1 pageLo21-21-P-Pi-16 - Rev.psvnaik14No ratings yet

- Lo21-21-P-Pi-13 - Rev.pDocument1 pageLo21-21-P-Pi-13 - Rev.psvnaik14No ratings yet

- Process Courses and Seminars March 21Document1 pageProcess Courses and Seminars March 21svnaik14No ratings yet

- Lo21-21-P-Pi-04 - Rev.pDocument1 pageLo21-21-P-Pi-04 - Rev.psvnaik14No ratings yet

- Process Control Philosophy 05-01-23Document8 pagesProcess Control Philosophy 05-01-23svnaik14No ratings yet

- Gas Line Size-1Document12 pagesGas Line Size-1svnaik14No ratings yet

- Lo21-21-P-Pi-21 - Rev.pDocument2 pagesLo21-21-P-Pi-21 - Rev.psvnaik14100% (1)

- Summary Flare Gas Monetization ProjectsDocument2 pagesSummary Flare Gas Monetization Projectssvnaik14No ratings yet

- Reliance - Flare Gas Recovery IMPDocument6 pagesReliance - Flare Gas Recovery IMPsvnaik14No ratings yet

- KKS Component Coding Manual 40-0000294 - D - 002 PDFDocument18 pagesKKS Component Coding Manual 40-0000294 - D - 002 PDFsvnaik14100% (1)

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- Specification For Fire and Gas Detection System PDFDocument48 pagesSpecification For Fire and Gas Detection System PDFgalih santoso100% (2)

- Your Assets: ProtectingDocument6 pagesYour Assets: ProtectingTayyab ZubairNo ratings yet

- Topic I Layers of Protection and Analysis - Safety Integrity LevelDocument16 pagesTopic I Layers of Protection and Analysis - Safety Integrity LevelJulius ChavezNo ratings yet

- ISA-TR84.00.04-2005 Part 2Document84 pagesISA-TR84.00.04-2005 Part 2ballasreedhar100% (2)

- 08.1 - 20056 - C - A - PPT - 06 - Safety Instrumented Systems PDFDocument41 pages08.1 - 20056 - C - A - PPT - 06 - Safety Instrumented Systems PDFRestoration2010100% (3)

- BP SP 50 001 A4 General Instrument SpecificationDocument41 pagesBP SP 50 001 A4 General Instrument SpecificationTeguh YuliantoNo ratings yet

- AutroSafe Safety ManualDocument22 pagesAutroSafe Safety ManualJyothish PaulNo ratings yet

- Common Cause and Common SenseDocument14 pagesCommon Cause and Common SenseRomel RodriguezNo ratings yet

- HIPPS - High Integrity Pressure Protection SystemDocument8 pagesHIPPS - High Integrity Pressure Protection SystemKommu RohithNo ratings yet

- Voting Logic in Safety Instrumented SystemDocument5 pagesVoting Logic in Safety Instrumented SystemChukwuma OnukuNo ratings yet

- Functional Safety Assessment AbbDocument16 pagesFunctional Safety Assessment AbbWalid FattahNo ratings yet

- Safety Integrity Level SILDocument12 pagesSafety Integrity Level SILKuwat Riyanto100% (2)

- SAF-11 Emergency Shut Down, Isolation and DepressuringDocument7 pagesSAF-11 Emergency Shut Down, Isolation and DepressuringlukeNo ratings yet

- ISA-84.00.02 Part 4 (2002)Document58 pagesISA-84.00.02 Part 4 (2002)Sergio LungrinNo ratings yet

- Shutdown System (ESS) and Safety Shutdown (SSD)Document19 pagesShutdown System (ESS) and Safety Shutdown (SSD)mostafaNo ratings yet

- In Sil en PDFDocument28 pagesIn Sil en PDFDinesh ChouguleNo ratings yet

- 2nd Assignment Progress-HoangThanh (May 31)Document97 pages2nd Assignment Progress-HoangThanh (May 31)Nguyễn Hoàng ThànhNo ratings yet

- High Integrity Protection Systems For Flare Load MitigationDocument8 pagesHigh Integrity Protection Systems For Flare Load MitigationKALPUSHNo ratings yet

- Sintef A26922 Common Cause Failures in Safety Instrumented Systems Beta...Document74 pagesSintef A26922 Common Cause Failures in Safety Instrumented Systems Beta...rwerwerw0% (1)

- As IEC 61511.1-2004 Functional Safety - Safety Instrumented Systems For The Process Industry Sector FrameworkDocument12 pagesAs IEC 61511.1-2004 Functional Safety - Safety Instrumented Systems For The Process Industry Sector FrameworkSAI Global - APACNo ratings yet

- Safety Instrumented Systems SummersDocument19 pagesSafety Instrumented Systems SummersOussama AbderrahimNo ratings yet

- As IEC 61511.2-2004 Functional Safety - Safety Instrumented Systems For The Process Industry Sector GuidelineDocument10 pagesAs IEC 61511.2-2004 Functional Safety - Safety Instrumented Systems For The Process Industry Sector GuidelineSAI Global - APACNo ratings yet

- CRR 02428Document74 pagesCRR 02428kglorstadNo ratings yet

- Safety System - Emergency Shutdown System P1Document41 pagesSafety System - Emergency Shutdown System P1عزت عبد المنعم100% (2)

- 06.standard Specification PDFDocument308 pages06.standard Specification PDFshareyhouNo ratings yet

- Exsilentia 4 2020Document8 pagesExsilentia 4 2020hadjerNo ratings yet

- SIS - Safety Instrumented Systems - A Practical ViewDocument4 pagesSIS - Safety Instrumented Systems - A Practical ViewMugesh KannaNo ratings yet