Professional Documents

Culture Documents

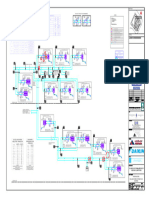

Typical Applications: (Built To UL508A Standards)

Uploaded by

Luis Fernando Gomez SalasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical Applications: (Built To UL508A Standards)

Uploaded by

Luis Fernando Gomez SalasCopyright:

Available Formats

SCADA software can be used to program, startup and diagnose the iQpump Controller

The iQpump controller PC SCADA package, allows the user to perform such functions as programming, Typical Applications

system trending, status readout and monitoring of pump system performance. The software also offers an Sludge Pumps

easy to use pump system setup wizard and a built-in online PI tuner for performance tuning of the pump Settling Ponds

system. The PC SCADA software can be downloaded for free at http://iQpump.yaskawa.com. Metering Pumps

Fluid Storage Tanks

Booster Pump Systems

Submersible Deep Wells

Commercial & Residential Irrigation

Pump Simulator Status and Fault History

Simulate drive parameters using the pump - Show pump system status - Feedback gauge

application simulator. - Set-point gauge - Digital input monitoring

- Digital output monitoring - Active fault Configured Packages Engineered Options

- Fault history (Built to UL508A Standards) - Circuit Breaker

- NEMA 1 (UL Type 1) - Input Line Reactor

Trending - NEMA 12 FVFF - Output Line Reactor

- Trend up to six signals - Trend storage - NEMA 3R (UL Type 3R) - Output dV/dt Filter

- Trend analog signals - Trend digital inputs - Fused Disconnect

- Triggering - Real-time clock Serial Communications - VFD Bypass

- Date-stamp - Custom scaling Options - EMI/RFI Filter

- Playback option - Ethernet/IP - Space Heater

- DeviceNet - Surge Arrestor

Pump Parameter Setup - Profibus DP - Single Phase AC Input Filter

- Edit pump parameters - Modbus Plus

- Save/Load pump setup - Modbus TCP/IP

- Search parameter function

- Transmit group, page or single parameter

- Read, write and compare parameter sets

- Modified parameters

- Parameter overview

- Upload Parameters Yaskawa Electric America, Inc.

PI Tuner and Signal Monitor The Drive for Quality™

2121 Norman Drive South

Waukegan, IL 60085

- Monitor up to four signals - Five types of meters Pump Setup Wizard For Product Information visit http://iQpump.yaskawa.com

- Real-time PI tuning - PI trending Used to program and troubleshoot from your PC.

- Adjustable time-base - Save/Load monitor setup Nine easy steps to be up and running. YEA Document Number: BL.iQp.01

03/01/07 © 2007 Yaskawa Electric America, Inc.

The iQpump controller was designed with the pump service operators and pump system owners in mind. iQpump offers iQpump can be used to replace existing mechanical pump systems using Throttling Valves, Bypass Valves or other means The iQpump integrated pump specific software allows the operator to quickly set up specific control values for

ease of setup and comprehensive pump and motor protection features. The integrated pump specific software and set up of control to improve regulation and save energy. iQpump was designed to control these typical pumping applications that a wide range of applications. The controller then automatically adjusts pump operation as the system

parameters, allow the operator to setup specific control values for a wide range of applications. The iQpump controller will require systems to regulate Constant Pressure, Constant Flow, or Variable Flow/Pressure. variables change while still maintaining optimum pump performance and protection.

automatically adjust pump operating conditions, as the process variables change while still maintaining optimum pump

performance and protection. iQpump can also replace phase converters when converting from a single phase to a three Improved Process Control Ease of Installation and Set Up Programmable Set Point & Scaling Multiplex Automatic Stabilization

phase pump motor. By matching pump output flow or pressure directly to the process iQpump uses pump terminology on all setup parameters and monitors. 12 different plain text engineering units are available, including iQpump automatically balances multi-pump systems to stabilize

requirements, small variations in the process can be corrected more Also included is a “Pump Quick Setup” menu. PSI and GPM. performance and reduce cycling.

rapidly by an iQpump than by other control forms.

Eliminate Complex Control Panels Control Pressure, Start Level & Start Time Pump Fault and Alarms

Simplex System Overview Improved System Reliability By installing iQpump, many of the electro mechanical controls can be Flexibility to start the pump at different feedback levels our use iQpump provides a comprehensive set of pump related alarms

Easy Installation and Set up Any reduction in speed achieved by using an iQpump has major eliminated. This will reduce the maintenance that these panels require. the integrated timer to eliminate cycling. and faults. Faults are displayed on the keypad in clear text to

1. Wire iQpump Control benefits in reducing pump wear, particularly in bearings and seals. eliminate confusion.

2. Connect pipe to pump Reduce Mechanical Stress and Damage Sleep Mode Minimum Flow Protection - Over Cycling

3. Set Pressure (PSI) Reference Reduce Total System Cost to Pumps Protects and shuts down the pump at low speeds or in low flow - No Flow

4. Calibrate Feedback Level (PSI) The iQpump controller lowers system cost by eliminating sensors, The iQpump controller has soft-start and soft-stop capabilities. conditions. - Loss of Prime

5. Start iQpump control jockey pumps, restriction valves as well as reducing cable and tank Pressure surges and water hammer are eliminated. - Transducer Loss

sizing. No Flow Detection - Over Torque

Cooler Running Pump Motor Separate from Sleep Mode, this detects changes in motor RPM - Low & High Pressure Feedback detection

Energy Savings Soft start eliminates inrush current, dramatically increasing winding relative to sudden changes in pressure or flow; protecting - Pump Over Cycling

Savings of 20 to 50% can be achieved, depending on application, insulation life. against broken pipe, excessive well drawdown or run-dry - Dry Well

by adjusting pump speed to match a lower flow/pressure, iQpump conditions.

will reduce the demand for energy. Motor Protection

Pre-Charge Control iQpump protects the motor by monitoring

This programmable feature eliminates water hammer and - Output Phase Loss

Pump Specific Operator Keypad extends system life by gradually filling a pipe line before normal - Ground Fault

Onboard LCD English read out reduces field start up and trouble shooting time, with intuitive pump related terminology. Programmable pump full pressure and flow operation. Motor speed can be controlled - Motor Overload

process set points are adjusted using “True Engineering Units” (PSI, GPM, Flow, etc.). The iQpump provides real time alarms, status and operating with a system timer, level or pressure control device to indicate - Motor Over Temperature

conditions in an easy to read format. when normal operation may begin. Broken Shaft

Thrust Bearing Control iQpump Drive Protection

Protects the bearings of submersible motors by ensuring start - Over Voltage

up speeds and times meet manufacturer's recommendations. - Input Phase Loss

Auto: Set-Point

- Under Voltage

U1-01 = 65.0 PSI Pressure Setpoint

------------------ Automatic System Restart - Phase Imbalance

U1-02= 58.00 Hz Motor Frequency Programmable timers allow the iQpump to automatically restart - Short Circuit

U1-91= 58.5 PSI Transducer Feedback the system in Auto Mode for faults relating to brown out's, no

power, power spikes, and dry well. Transducer Loss Protection

iQpump monitors the feedback device voltage or current levels

Friction Loss Compensation to determine if the transducer has failed.

Automatically adjusts to overcome increased friction loss due to

increased flows.

Hand-Off-Auto Yaskawa Quality

Selectable by digital input Low & High Pressure Feedback Detection is more than a measurement -

or controller keypad. iQpump continuously monitors the system feedback device to

provide a warning alarm or fault based on programmed level. it’s an

Triplex System Overview Experience.

- Automatically starts and stops Lead/Lag pumps on demand.

Multi-Pump Operations

iQpump systems can be set up to automatically control two or

- Automatically turns off pump when demand is reduced.

more pumps to meet specific demands.

- Motor starters or soft starters can be used for pump 2 and pump 3 in place of iQpump controller. Typical Operator Keypad Messages

The iQpump controller was designed with the pump service operators and pump system owners in mind. iQpump offers iQpump can be used to replace existing mechanical pump systems using Throttling Valves, Bypass Valves or other means The iQpump integrated pump specific software allows the operator to quickly set up specific control values for

ease of setup and comprehensive pump and motor protection features. The integrated pump specific software and set up of control to improve regulation and save energy. iQpump was designed to control these typical pumping applications that a wide range of applications. The controller then automatically adjusts pump operation as the system

parameters, allow the operator to setup specific control values for a wide range of applications. The iQpump controller will require systems to regulate Constant Pressure, Constant Flow, or Variable Flow/Pressure. variables change while still maintaining optimum pump performance and protection.

automatically adjust pump operating conditions, as the process variables change while still maintaining optimum pump

performance and protection. iQpump can also replace phase converters when converting from a single phase to a three Improved Process Control Ease of Installation and Set Up Programmable Set Point & Scaling Multiplex Automatic Stabilization

phase pump motor. By matching pump output flow or pressure directly to the process iQpump uses pump terminology on all setup parameters and monitors. 12 different plain text engineering units are available, including iQpump automatically balances multi-pump systems to stabilize

requirements, small variations in the process can be corrected more Also included is a “Pump Quick Setup” menu. PSI and GPM. performance and reduce cycling.

rapidly by an iQpump than by other control forms.

Eliminate Complex Control Panels Control Pressure, Start Level & Start Time Pump Fault and Alarms

Simplex System Overview Improved System Reliability By installing iQpump, many of the electro mechanical controls can be Flexibility to start the pump at different feedback levels our use iQpump provides a comprehensive set of pump related alarms

Easy Installation and Set up Any reduction in speed achieved by using an iQpump has major eliminated. This will reduce the maintenance that these panels require. the integrated timer to eliminate cycling. and faults. Faults are displayed on the keypad in clear text to

1. Wire iQpump Control benefits in reducing pump wear, particularly in bearings and seals. eliminate confusion.

2. Connect pipe to pump Reduce Mechanical Stress and Damage Sleep Mode Minimum Flow Protection - Over Cycling

3. Set Pressure (PSI) Reference Reduce Total System Cost to Pumps Protects and shuts down the pump at low speeds or in low flow - No Flow

4. Calibrate Feedback Level (PSI) The iQpump controller lowers system cost by eliminating sensors, The iQpump controller has soft-start and soft-stop capabilities. conditions. - Loss of Prime

5. Start iQpump control jockey pumps, restriction valves as well as reducing cable and tank Pressure surges and water hammer are eliminated. - Transducer Loss

sizing. No Flow Detection - Over Torque

Cooler Running Pump Motor Separate from Sleep Mode, this detects changes in motor RPM - Low & High Pressure Feedback detection

Energy Savings Soft start eliminates inrush current, dramatically increasing winding relative to sudden changes in pressure or flow; protecting - Pump Over Cycling

Savings of 20 to 50% can be achieved, depending on application, insulation life. against broken pipe, excessive well drawdown or run-dry - Dry Well

by adjusting pump speed to match a lower flow/pressure, iQpump conditions.

will reduce the demand for energy. Motor Protection

Pre-Charge Control iQpump protects the motor by monitoring

This programmable feature eliminates water hammer and - Output Phase Loss

Pump Specific Operator Keypad extends system life by gradually filling a pipe line before normal - Ground Fault

Onboard LCD English read out reduces field start up and trouble shooting time, with intuitive pump related terminology. Programmable pump full pressure and flow operation. Motor speed can be controlled - Motor Overload

process set points are adjusted using “True Engineering Units” (PSI, GPM, Flow, etc.). The iQpump provides real time alarms, status and operating with a system timer, level or pressure control device to indicate - Motor Over Temperature

conditions in an easy to read format. when normal operation may begin. Broken Shaft

Thrust Bearing Control iQpump Drive Protection

Protects the bearings of submersible motors by ensuring start - Over Voltage

up speeds and times meet manufacturer's recommendations. - Input Phase Loss

Auto: Set-Point

- Under Voltage

U1-01 = 65.0 PSI Pressure Setpoint

------------------ Automatic System Restart - Phase Imbalance

U1-02= 58.00 Hz Motor Frequency Programmable timers allow the iQpump to automatically restart - Short Circuit

U1-91= 58.5 PSI Transducer Feedback the system in Auto Mode for faults relating to brown out's, no

power, power spikes, and dry well. Transducer Loss Protection

iQpump monitors the feedback device voltage or current levels

Friction Loss Compensation to determine if the transducer has failed.

Automatically adjusts to overcome increased friction loss due to

increased flows.

Hand-Off-Auto Yaskawa Quality

Selectable by digital input Low & High Pressure Feedback Detection is more than a measurement -

or controller keypad. iQpump continuously monitors the system feedback device to

provide a warning alarm or fault based on programmed level. it’s an

Triplex System Overview Experience.

- Automatically starts and stops Lead/Lag pumps on demand.

Multi-Pump Operations

iQpump systems can be set up to automatically control two or

- Automatically turns off pump when demand is reduced.

more pumps to meet specific demands.

- Motor starters or soft starters can be used for pump 2 and pump 3 in place of iQpump controller. Typical Operator Keypad Messages

SCADA software can be used to program, startup and diagnose the iQpump Controller

The iQpump controller PC SCADA package, allows the user to perform such functions as programming, Typical Applications

system trending, status readout and monitoring of pump system performance. The software also offers an Sludge Pumps

easy to use pump system setup wizard and a built-in online PI tuner for performance tuning of the pump Settling Ponds

system. The PC SCADA software can be downloaded for free at http://iQpump.yaskawa.com. Metering Pumps

Fluid Storage Tanks

Booster Pump Systems

Submersible Deep Wells

Commercial & Residential Irrigation

Pump Simulator Status and Fault History

Simulate drive parameters using the pump - Show pump system status - Feedback gauge

application simulator. - Set-point gauge - Digital input monitoring

- Digital output monitoring - Active fault Configured Packages Engineered Options

- Fault history (Built to UL508A Standards) - Circuit Breaker

- NEMA 1 (UL Type 1) - Input Line Reactor

Trending - NEMA 12 FVFF - Output Line Reactor

- Trend up to six signals - Trend storage - NEMA 3R (UL Type 3R) - Output dV/dt Filter

- Trend analog signals - Trend digital inputs - Fused Disconnect

- Triggering - Real-time clock Serial Communications - VFD Bypass

- Date-stamp - Custom scaling Options - EMI/RFI Filter

- Playback option - Ethernet/IP - Space Heater

- DeviceNet - Surge Arrestor

Pump Parameter Setup - Profibus DP - Single Phase AC Input Filter

- Edit pump parameters - Modbus Plus

- Save/Load pump setup - Modbus TCP/IP

- Search parameter function

- Transmit group, page or single parameter

- Read, write and compare parameter sets

- Modified parameters

- Parameter overview

- Upload Parameters Yaskawa Electric America, Inc.

PI Tuner and Signal Monitor The Drive for Quality™

2121 Norman Drive South

Waukegan, IL 60085

- Monitor up to four signals - Five types of meters Pump Setup Wizard For Product Information visit http://iQpump.yaskawa.com

- Real-time PI tuning - PI trending Used to program and troubleshoot from your PC.

- Adjustable time-base - Save/Load monitor setup Nine easy steps to be up and running. YEA Document Number: BL.iQp.01

03/01/07 © 2007 Yaskawa Electric America, Inc.

The iQpump controller was designed with the pump service operators and pump system owners in mind. iQpump offers iQpump can be used to replace existing mechanical pump systems using Throttling Valves, Bypass Valves or other means The iQpump integrated pump specific software allows the operator to quickly set up specific control values for

ease of setup and comprehensive pump and motor protection features. The integrated pump specific software and set up of control to improve regulation and save energy. iQpump was designed to control these typical pumping applications that a wide range of applications. The controller then automatically adjusts pump operation as the system

parameters, allow the operator to setup specific control values for a wide range of applications. The iQpump controller will require systems to regulate Constant Pressure, Constant Flow, or Variable Flow/Pressure. variables change while still maintaining optimum pump performance and protection.

automatically adjust pump operating conditions, as the process variables change while still maintaining optimum pump

performance and protection. iQpump can also replace phase converters when converting from a single phase to a three Improved Process Control Ease of Installation and Set Up Programmable Set Point & Scaling Multiplex Automatic Stabilization

phase pump motor. By matching pump output flow or pressure directly to the process iQpump uses pump terminology on all setup parameters and monitors. 12 different plain text engineering units are available, including iQpump automatically balances multi-pump systems to stabilize

requirements, small variations in the process can be corrected more Also included is a “Pump Quick Setup” menu. PSI and GPM. performance and reduce cycling.

rapidly by an iQpump than by other control forms.

Eliminate Complex Control Panels Control Pressure, Start Level & Start Time Pump Fault and Alarms

Simplex System Overview Improved System Reliability By installing iQpump, many of the electro mechanical controls can be Flexibility to start the pump at different feedback levels our use iQpump provides a comprehensive set of pump related alarms

Easy Installation and Set up Any reduction in speed achieved by using an iQpump has major eliminated. This will reduce the maintenance that these panels require. the integrated timer to eliminate cycling. and faults. Faults are displayed on the keypad in clear text to

1. Wire iQpump Control benefits in reducing pump wear, particularly in bearings and seals. eliminate confusion.

2. Connect pipe to pump Reduce Mechanical Stress and Damage Sleep Mode Minimum Flow Protection - Over Cycling

3. Set Pressure (PSI) Reference Reduce Total System Cost to Pumps Protects and shuts down the pump at low speeds or in low flow - No Flow

4. Calibrate Feedback Level (PSI) The iQpump controller lowers system cost by eliminating sensors, The iQpump controller has soft-start and soft-stop capabilities. conditions. - Loss of Prime

5. Start iQpump control jockey pumps, restriction valves as well as reducing cable and tank Pressure surges and water hammer are eliminated. - Transducer Loss

sizing. No Flow Detection - Over Torque

Cooler Running Pump Motor Separate from Sleep Mode, this detects changes in motor RPM - Low & High Pressure Feedback detection

Energy Savings Soft start eliminates inrush current, dramatically increasing winding relative to sudden changes in pressure or flow; protecting - Pump Over Cycling

Savings of 20 to 50% can be achieved, depending on application, insulation life. against broken pipe, excessive well drawdown or run-dry - Dry Well

by adjusting pump speed to match a lower flow/pressure, iQpump conditions.

will reduce the demand for energy. Motor Protection

Pre-Charge Control iQpump protects the motor by monitoring

This programmable feature eliminates water hammer and - Output Phase Loss

Pump Specific Operator Keypad extends system life by gradually filling a pipe line before normal - Ground Fault

Onboard LCD English read out reduces field start up and trouble shooting time, with intuitive pump related terminology. Programmable pump full pressure and flow operation. Motor speed can be controlled - Motor Overload

process set points are adjusted using “True Engineering Units” (PSI, GPM, Flow, etc.). The iQpump provides real time alarms, status and operating with a system timer, level or pressure control device to indicate - Motor Over Temperature

conditions in an easy to read format. when normal operation may begin. Broken Shaft

Thrust Bearing Control iQpump Drive Protection

Protects the bearings of submersible motors by ensuring start - Over Voltage

up speeds and times meet manufacturer's recommendations. - Input Phase Loss

Auto: Set-Point

- Under Voltage

U1-01 = 65.0 PSI Pressure Setpoint

------------------ Automatic System Restart - Phase Imbalance

U1-02= 58.00 Hz Motor Frequency Programmable timers allow the iQpump to automatically restart - Short Circuit

U1-91= 58.5 PSI Transducer Feedback the system in Auto Mode for faults relating to brown out's, no

power, power spikes, and dry well. Transducer Loss Protection

iQpump monitors the feedback device voltage or current levels

Friction Loss Compensation to determine if the transducer has failed.

Automatically adjusts to overcome increased friction loss due to

increased flows.

Hand-Off-Auto Yaskawa Quality

Selectable by digital input Low & High Pressure Feedback Detection is more than a measurement -

or controller keypad. iQpump continuously monitors the system feedback device to

provide a warning alarm or fault based on programmed level. it’s an

Triplex System Overview Experience.

- Automatically starts and stops Lead/Lag pumps on demand.

Multi-Pump Operations

iQpump systems can be set up to automatically control two or

- Automatically turns off pump when demand is reduced.

more pumps to meet specific demands.

- Motor starters or soft starters can be used for pump 2 and pump 3 in place of iQpump controller. Typical Operator Keypad Messages

SCADA software can be used to program, startup and diagnose the iQpump Controller

The iQpump controller PC SCADA package, allows the user to perform such functions as programming, Typical Applications

system trending, status readout and monitoring of pump system performance. The software also offers an Sludge Pumps

easy to use pump system setup wizard and a built-in online PI tuner for performance tuning of the pump Settling Ponds

system. The PC SCADA software can be downloaded for free at http://iQpump.yaskawa.com. Metering Pumps

Fluid Storage Tanks

Booster Pump Systems

Submersible Deep Wells

Commercial & Residential Irrigation

Pump Simulator Status and Fault History

Simulate drive parameters using the pump - Show pump system status - Feedback gauge

application simulator. - Set-point gauge - Digital input monitoring

- Digital output monitoring - Active fault Configured Packages Engineered Options

- Fault history (Built to UL508A Standards) - Circuit Breaker

- NEMA 1 (UL Type 1) - Input Line Reactor

Trending - NEMA 12 FVFF - Output Line Reactor

- Trend up to six signals - Trend storage - NEMA 3R (UL Type 3R) - Output dV/dt Filter

- Trend analog signals - Trend digital inputs - Fused Disconnect

- Triggering - Real-time clock Serial Communications - VFD Bypass

- Date-stamp - Custom scaling Options - EMI/RFI Filter

- Playback option - Ethernet/IP - Space Heater

- DeviceNet - Surge Arrestor

Pump Parameter Setup - Profibus DP - Single Phase AC Input Filter

- Edit pump parameters - Modbus Plus

- Save/Load pump setup - Modbus TCP/IP

- Search parameter function

- Transmit group, page or single parameter

- Read, write and compare parameter sets

- Modified parameters

- Parameter overview

- Upload Parameters Yaskawa Electric America, Inc.

PI Tuner and Signal Monitor The Drive for Quality™

2121 Norman Drive South

Waukegan, IL 60085

- Monitor up to four signals - Five types of meters Pump Setup Wizard For Product Information visit http://iQpump.yaskawa.com

- Real-time PI tuning - PI trending Used to program and troubleshoot from your PC.

- Adjustable time-base - Save/Load monitor setup Nine easy steps to be up and running. YEA Document Number: BL.iQp.01

03/01/07 © 2007 Yaskawa Electric America, Inc.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- For Reference Only Unless Properly Endorsed For Additional Details and Specifications, Consult ManualDocument1 pageFor Reference Only Unless Properly Endorsed For Additional Details and Specifications, Consult ManualLuis Fernando Gomez SalasNo ratings yet

- For Reference Only Unless Properly Endorsed For Additional Details and Specifications, Consult ManualDocument1 pageFor Reference Only Unless Properly Endorsed For Additional Details and Specifications, Consult ManualLuis Fernando Gomez SalasNo ratings yet

- Manual IQPUMPDocument486 pagesManual IQPUMPLuis Fernando Gomez SalasNo ratings yet

- Iqpump Controller: User ManualDocument266 pagesIqpump Controller: User ManualLuis Fernando Gomez SalasNo ratings yet

- Profibus-DP Option Kit CM061Document4 pagesProfibus-DP Option Kit CM061Luis Fernando Gomez SalasNo ratings yet

- Profibus-Dp Option Technical Manual: Models: CIMR-G5, F7, P7, G7 Document Number TM - AFD.12Document68 pagesProfibus-Dp Option Technical Manual: Models: CIMR-G5, F7, P7, G7 Document Number TM - AFD.12Luis Fernando Gomez SalasNo ratings yet

- Dimension Drawing V1000 NEMA 1: 7/15/07 Data Subject To Change Without Notice Yaskawa Electric AmericaDocument1 pageDimension Drawing V1000 NEMA 1: 7/15/07 Data Subject To Change Without Notice Yaskawa Electric AmericaLuis Fernando Gomez SalasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Applications: Mathematics and ArtDocument2 pagesApplications: Mathematics and ArtJohn Kenneth BentirNo ratings yet

- EE4533 Tutorial 11 Solutions PDFDocument6 pagesEE4533 Tutorial 11 Solutions PDFcheeling1530No ratings yet

- Ocean Engineering: Ali Mahrooghi, Esmail LakzianDocument17 pagesOcean Engineering: Ali Mahrooghi, Esmail LakzianAlmir RodriguesNo ratings yet

- Pd-Scan BR en PDFDocument12 pagesPd-Scan BR en PDFSharin Bin Ab GhaniNo ratings yet

- XEC-DR20SU T24 Manual V1.6 202012 ENDocument328 pagesXEC-DR20SU T24 Manual V1.6 202012 ENApeco WorkshopNo ratings yet

- Chapter 8: More Number TheoryDocument5 pagesChapter 8: More Number TheoryOmnia GalalNo ratings yet

- DRDRA Assessment - Part46Document1 pageDRDRA Assessment - Part46azereth bartonNo ratings yet

- Dalle Vacche Angela - André Bazin's Film Theory. Art, Science, Religion - 2020Document235 pagesDalle Vacche Angela - André Bazin's Film Theory. Art, Science, Religion - 2020Иван Владиленович КузинNo ratings yet

- Pemanfaatan Digital History Untuk Pembelajaran Sejarah LokalDocument11 pagesPemanfaatan Digital History Untuk Pembelajaran Sejarah LokalNugieNo ratings yet

- Mutasim Ali Mohamed Saleh Mansour Malaysia, Kulalmpor: Sex - NationalityDocument2 pagesMutasim Ali Mohamed Saleh Mansour Malaysia, Kulalmpor: Sex - Nationalityahmed aliNo ratings yet

- DMLS Vs SLM 3D Printing For Metal ManufacturingDocument1 pageDMLS Vs SLM 3D Printing For Metal Manufacturing曹大伟No ratings yet

- DPB10023 Principles of Management Problem Scenario Chapter 6 Staffing Chapter 7 Decision MakingDocument8 pagesDPB10023 Principles of Management Problem Scenario Chapter 6 Staffing Chapter 7 Decision MakingSiti NurSyahirah 1071No ratings yet

- Cfu On Diversity and Future Directions in Ob Case 1Document3 pagesCfu On Diversity and Future Directions in Ob Case 1Vincent CariñoNo ratings yet

- Shelley Kaye Quema - Observation 6 Reflective Journal Prompt NotesDocument4 pagesShelley Kaye Quema - Observation 6 Reflective Journal Prompt Notesapi-361088335No ratings yet

- Definition, History, and Rationale: BM1902 Fundamental Concepts of Facility ManagementDocument3 pagesDefinition, History, and Rationale: BM1902 Fundamental Concepts of Facility Managementlevix hyuniNo ratings yet

- KJ 117 o en Sac 00 Zme 0301Document1 pageKJ 117 o en Sac 00 Zme 0301Abdullah ObeidatNo ratings yet

- Final Microbes Definition Edits 1Document9 pagesFinal Microbes Definition Edits 1api-510503468No ratings yet

- The Linguistic Turn: July 2021Document8 pagesThe Linguistic Turn: July 2021PARTRICA leeNo ratings yet

- Zorlu Zemin Şartlarında EPB TBM Tünelciliği: Ataköy - İkitelli Metro Tünelinde Örnek Bir Çalışma, TürkiyeDocument7 pagesZorlu Zemin Şartlarında EPB TBM Tünelciliği: Ataköy - İkitelli Metro Tünelinde Örnek Bir Çalışma, TürkiyecemalbalciNo ratings yet

- Urban MorphologyDocument10 pagesUrban MorphologyAnchal kumariNo ratings yet

- The Cure For BoredomDocument3 pagesThe Cure For BoredomNarette SolanoyNo ratings yet

- ASTM C881 2013 - Epoxy Resin Base Bonding System For ConcreteDocument6 pagesASTM C881 2013 - Epoxy Resin Base Bonding System For Concretetsalemnoush100% (1)

- College Math For Business, Economics, Life Science... - (Part 2 Finite Mat Hematics)Document9 pagesCollege Math For Business, Economics, Life Science... - (Part 2 Finite Mat Hematics)wyleunganNo ratings yet

- HD1520ADocument1 pageHD1520AgordansimNo ratings yet

- Method Statement For Tank Survey (MFL) and RepairDocument14 pagesMethod Statement For Tank Survey (MFL) and RepairMG67% (3)

- The Roman Conquest of Wales AD 47-410Document64 pagesThe Roman Conquest of Wales AD 47-410Gamer4242No ratings yet

- 41 R16 Adv Supply May 2022Document4 pages41 R16 Adv Supply May 2022Supriyo DeyNo ratings yet

- Chapter 1 (5 Lectures)Document15 pagesChapter 1 (5 Lectures)PriyanshuNo ratings yet

- Applications of TrigonometryDocument10 pagesApplications of Trigonometrydiya jainNo ratings yet

- Electric PotentialDocument92 pagesElectric PotentialBanani BhattacharyaNo ratings yet