Professional Documents

Culture Documents

Cargo Handling PDF

Cargo Handling PDF

Uploaded by

vinda0 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

185630030 cargo handling.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageCargo Handling PDF

Cargo Handling PDF

Uploaded by

vindaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

‘Nama : Dian Eka Prayogi

Nrp _ : 185630030

Kelas : Nautika Bravo

Mata kuliah : Cargo Handling

Dosen

: Joko Dwi ANT-IL

DECK WATER SEAL

Deck seals are a safety device fitted on oil tankers to prevent explosive hydrocarbon vapours

to travel from the Cargo area to the Engine area (where the sources of Ignition are present.)

‘The purpose of the deck water seal is to prevent feedback of hydrocarbon gases from the

cargo tanks via the inert gas deck main to the engine room and boiler uptake. A small leakage

of hydrocarbon gas can built up to a dangerous concentration over a period of time. Since a

mechanical non return valve will permit a very slIGht leakage, it is necessary to provide a

liquid seal. The deck water seal is manufactured in mild steel and is internally coated with

flake.

‘Types Of Deck Seal:

1. Dry deck seal

2. Semi dry deck seal

3. Wet deck seal

Dry Deck Seal

‘The dry type deck water seal has an upper reservoir (drop tank) and a lower reservoir (sealing

tank), The flow of water from the drop tank to the sealing tank and from the sealing tank to

the overboard discharge is controlled automatically via level sensors and other control

equipment.

Semi Dry Deck Seal

The semi-dry deck water seal has a separate holding chamber which is connected by pipe to

the inert gas main via an eductor. Instead of passing through a water trap, the inert gas

flowing through the venturi creates a suction effect in the holding tank which draws the

sealing water from the loop seal into the holding tank. This mitIGates the undesirable ‘carry

over” of moisture to the cargo tanks.

Wet Deck Seal

This is the simplest type of water seal. When the inert gas plant is operating, the gas bubbles

through the water from the submerged inert gas inlet pipe, but if the tank pressure exceeds the

pressure in the inert gas inlet line the water is pressed up into this inlet pipe and thus prevents

backflow.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ilmu Pelayaran dtr2Document12 pagesIlmu Pelayaran dtr2vindaNo ratings yet

- Makalah Tentang Motivasi Belajar Bagi MahasiswaDocument24 pagesMakalah Tentang Motivasi Belajar Bagi Mahasiswavinda50% (2)

- Navigation SystemDocument7 pagesNavigation SystemvindaNo ratings yet

- Materi KenautikaanDocument43 pagesMateri Kenautikaanvinda100% (2)

- Bisnis 1Document8 pagesBisnis 1vinda100% (1)

- Amdal SonyDocument34 pagesAmdal SonyvindaNo ratings yet

- 21 - Forces and MomentDocument4 pages21 - Forces and MomentvindaNo ratings yet

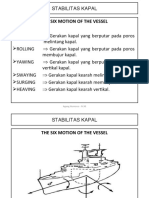

- 20 - Six Motions of The VesselDocument22 pages20 - Six Motions of The VesselvindaNo ratings yet

- Ensure Compliance With Pollution Prevention Requirements (36 Soal)Document1 pageEnsure Compliance With Pollution Prevention Requirements (36 Soal)vinda60% (5)

- Anchor Work CommunicationDocument4 pagesAnchor Work CommunicationvindaNo ratings yet

- Communication: Anchoring (On-Board Communications) Going To AnchorDocument4 pagesCommunication: Anchoring (On-Board Communications) Going To AnchorvindaNo ratings yet

- Materi 9 LATIHAN SOAL LIQUID CARGODocument4 pagesMateri 9 LATIHAN SOAL LIQUID CARGOvinda67% (3)

- Active & Passive VoiceDocument2 pagesActive & Passive VoicevindaNo ratings yet