Professional Documents

Culture Documents

Benfield

Uploaded by

Osmar Dias0 ratings0% found this document useful (0 votes)

14 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views3 pagesBenfield

Uploaded by

Osmar DiasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

sig

©eeece.

Severe Cracking

of CO, Absorber

Exit Line

by

2.u. Nightingale

i Chemicals & Polymers Limited

C1 Fertilizers

Gillingham Fertilizer Works

O Box8

illingham

leveland

23 118

¥ngland

e

|UMMARY

lecently major cracking was found in the line exit the CO, Absorber on the No. 4

imonia Plant operated by IC! at Billingham (UK). This paper describes the

perating conditions, the extent of the cracking and the likely mechanism. It also

Weals with the short and long term solution.

©

4

resented at the 1988 Ammonia Symposium

Safety in Ammonia Piants and Related Facilities

©

(AMERICAN INSTITUTE OF

CHEMICAL ENGINEERS

enver

Gugust 1988

©

»

w

theSCRIPTION OF THE PLANT

{© 4 ammonia Piant at Bitingham was designed for a

fewsheet rate of 1100 tes/day and was commissioned in

G7, he Mant has subsequently been debottienecked

‘now runs at 1400 tes/day

& COz removal system is carried out in Bentiold

lution (27-29% Potassium carbonate) with 1-2% DEA

fied as a CO2 absorption promoter. Vanadium (0.3-

Q git is added as a corrosion inhibitor

-abpsorption tower operates at apressure of 26 barand

exit temperature up to early 1987 was about 75°C. in

irch 1987 @ process change made to improve plant

ciency rosuted inthis temperature being raised to

‘80 and 85°C. At the time this proposed change

‘fers checked out with ourmetallurgists/vessel engineers.

YJ? did not foresee a problem

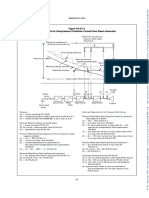

gure t shows diagrammatically the line which runs

Ggtween the top (ex) af the COz absorber and the

thanator feed heater, C304. Line details are as follows.

& = 0.406m (16") diameter 9.525mm (98")

wall 120m (400’) long

Material APISL. Grade B, normalised (carbon

’ steel)

‘Gess Relief ~None

line

= ~ 30.8 bar g (RV402)

ature = 80°C,

7085 Fluid - Synthesis Gas

ViEWLOOKING NORTH

MECC CEES CER

HISTORY OF EVENTS:

On 22/9/87 a leak was discovered at Point A (see figure 1

and picture 1),

PICTURE 1

The defect appeared ta be a 0.15-0.18m (6-7 inches) long

semi-continuous jagged crack running longitudinally

along the line at the nine o'clock position.

‘The leak was significant and the plant was shut-down on

23 September to cut out a 2.5m (8 foot) long section up fo

the buttweld onthe upstream bend. Cracks were found in

the butt weld, some orientated circumferentially, butthey

proved to be shallow and were ground out.

‘The section of pipe that was removed was split and the

inside of the pipe showed severe multiple cracking, The

orientation of the dozens of fine cracks which were found

was principally longitudinal with some tendency towards,

a 45° plane also (see picture 2).

flercecececcececeeececcs

eceeceeece

PICTURE 5

‘The Plant was recommissioned on 22 March 1988.

LIKELY MECHANISM.

The carbonate/bicarbonate system is know fo cause

general corrosion and stress corrosion of carbon steel

and because of this vanadium is added as a Corrosion

inhibitor andito keep the potential of the steel outside the

cracking range. A proportion of the vanadium must be in

the V5+ oxidation state, but due to the normal operating

conditions of the system favouring the formation of the

reduced state, V4+, Some oxidationisneeded.Intheearly

years doping with potassium nitrite was done, but more

recently the V5+ oxidation state has been maintained by

aeration.

The recent major cracking found in line PG404 (APISL Gr

B, 16" x 0.375" w/t) was caused by stress corrosion

cracking characteristic of that produced by carbonate/

bicarbonate system. Some solution carry over must

therefore have occurred. Microscope examination of the

cracks showed that secondary corrosion of the cracks

had not occurred. From this it was concluded that

cracking had been initiated relatively recently and could

nothave been due tocanditions present overthetullifeof

the plant.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- ASME I Fig. PG-67.4 PDFDocument1 pageASME I Fig. PG-67.4 PDFOsmar DiasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Camprofile TeaditDocument1 pageCamprofile TeaditOsmar DiasNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- VanadatoDocument1 pageVanadatoOsmar DiasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Long-Term Reliability: Unipetrol, Refinery Litvínov, Czech Republic Case StoryDocument2 pagesLong-Term Reliability: Unipetrol, Refinery Litvínov, Czech Republic Case StoryOsmar DiasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- World Fertilizer NovDec2020 PDFDocument4 pagesWorld Fertilizer NovDec2020 PDFOsmar DiasNo ratings yet

- Service Manual Trucks Group 922-502 Fifth Wheel VN, VHDDocument52 pagesService Manual Trucks Group 922-502 Fifth Wheel VN, VHDNeojai jaiyuNo ratings yet

- Time For A More Durable, More Efficient Heat ExchangerDocument4 pagesTime For A More Durable, More Efficient Heat ExchangerOsmar DiasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 09122011-180355 - JOST Guia de Manutencao JSK 37C PDFDocument24 pages09122011-180355 - JOST Guia de Manutencao JSK 37C PDFOsmar DiasNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 3212016-24855-pm - Flyer Engate Esferico JOST PDFDocument4 pages3212016-24855-pm - Flyer Engate Esferico JOST PDFOsmar DiasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- PV776 810 600 01SB PDFDocument2 pagesPV776 810 600 01SB PDFOsmar DiasNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Tabela de Pesos de TubulaçãoDocument1 pageTabela de Pesos de TubulaçãoOsmar DiasNo ratings yet

- CALCULO E CONSUMIVEIS TubosDocument2 pagesCALCULO E CONSUMIVEIS TubosOsmar DiasNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Izn PDFDocument8 pagesIzn PDFOsmar DiasNo ratings yet

- 402 Colma DX Ammonia Piping Handbook PDFDocument55 pages402 Colma DX Ammonia Piping Handbook PDFOsmar DiasNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)