Professional Documents

Culture Documents

39

Uploaded by

Bill Hunter0 ratings0% found this document useful (0 votes)

14 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views4 pages39

Uploaded by

Bill HunterCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Construction of EQCM

Bul, Korean Chem. Soe. 1996, Vol. 17, No 1 39

Construction of Low Noise Electrochemical

Quartz Crystal Microbalance

Euijin Hwang* and Youngran Lim

Electrochemistry Group, Korea Research Institute of Standards and Science, Taejon 305-340, Korea

Received Seplember 22, 1995

A new oscillator for electrochemical quartz crystal microbalance (EQCM) was developed by using an operational ampli

fier without any LC component. The home-made EQCM using this oscillator showed only 002 He frequency noise

at 03 8 gate time when a 6 MHz AT-cut crystal wes used. Pb underpotential deposition on gold substrate in nitric

‘acid media was examined to demonstrate the performance of this EQCM. The derivative of frequency change could

be obtained without averaging multiple scans.

Introduction

Recently EQCM is being widely used as an in situ micro-

gravimetric technique in electrochemistry to measure the

changes of electrode mass concurrently with the electro-

chemical current and/or the electrode potential. Application

of the in sitw EQCM has been reviewed elsewhere.” Al.

though the impedance measurement of the quartz crystal

using an external impedance analyzer serves detailed infor-

mation about each component of the impedance network.'*

the oscillator in which the quartz crystal is an active element

Js being commonly used for in sifu microgravimetry or to

‘monitor mass change continuously by simply measuring the

frequency change!”

Various kinds of oscillator have been reported for the

quartz. crystal_microbalance to be used in liquid sys-

tem! The oscillators based on transistor and LC

tank circuit consist of some inductors and capacitors as well

as some resistors" The temperature coefficients of in

dductor(L) and capacitor(©) are relatively large compared with

that of resistor) and the gain of transistor is not sufficient.

ly high. To provide the necessary gain a two-stage transistor

amplifier has been designed with many R, L, and C com

ponents

‘The use of integrated circuit (IC) makes the oscillator un-

complicated. Bruckenstein used transistor-transistor logic

(TTL) ICs" for his EQCM study. In his circuit the electrode

‘of quartz crystal that is also used as working electrode in

‘electrochemical system was not grounded. Therefore, his cir-

cuit has to be isolated from the potentiostat to prevent flow-

ing direct current (DC) by involving blocking capacitor or

transformer. The different ground of oscillator from potentio-

stat can cause unexpected noise and careful attention has

to be paid to stabilize the EQCM system.

Buttry used a video amplifier for the EQCM oscillator

he advantage of Buttrys circuit is that the working elec-

trode is grounded with both oscillator and potentiosta. Video

amplifiers, however, are not quantitative compared with the

‘operational amplifiers (Qp. Amp.) which are more familiar

with scientists. Furthermore this circuit requires LC com-

ponents to be stabilized when a large mass is loaded on

the quartz crystal,

"To whom correspondence should be addressed.

Bit a mE

Si Te} “Tee

Fie ae

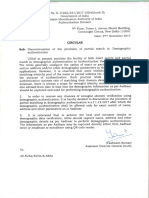

Figure 1. Block diagram of two oscillators and a frequency dil

ference circuitry between these oscillators.

This contribution describes a new oscillator circuit for

EQCM by introducing wide band Op. Amp. without any

LC component. This Op. Amp. circuit is very simple and

the operation principle is easily understandable to the scien-

tists. Further this circuit can be reproduced without expert

knowledge on electronics,

Experimental

Circuit. As shown in Figure 1 the EQCM system con-

sists of two oscillators and a frequency difference circuitry.

‘One of these two oscillators was used for the reference quar-

tz crystal and the other for the one to be tested. The fre-

‘quency difference circuitry measures the instantaneous fre-

quency difference between the two oscillators and output

this difference. This configuration is advantageous to com-

pensate the frequency drift due to the temperature change

and/or to measure the frequency change precisely within

the uncertainty of frequency counter.

Each oscillator was simply constructed using an Op. Amp.

(ADBIIAN) and some resistors without any LC component,

In this circuit the quartz crystal determines the negative

feedback gain, At the resonance frequency the quartz crystal

hhas the minimum value of its impedance. At this frequency

the closed loop gain of the Op. Amp. according to the nega

tive feedback goes larger than that of positive feedback and

this circuit keeps oscillation. Positive feedback gain can be

40 Bull. Korean Chem. Soc. 1996, Vol. 17, No. 1

Euijin Hioang and Youngran Lim

2 oo

HON,

ye oxen || 4

Figure 2. Circuit diagram of Wenking-style potentiostat

J atsniee ei

7d

pape 172

crtilion ve

adjusted using 100 0 variable resistor. Transistors (2N3904)

were used to make analog signals compatible with subse-

quent TTL inputs. A simple frequency difference circuitry

using a Detype fliplop (74574), that has been reported by

Bruckenstein? was introduced to get the frequency differ-

ence between two oscillators. The TTL 7ALSM4 (Hex Schmitt

trigger inverter) served as input and output buffers.

Both two +5 V power supplies for two oscillators and

a +5 V power supply for TTL circuit were isolated by the

use of individual voltage regulators to prevent any possible

‘coupling or locking-in caused by the limited power supply

rejection of Op. Amp. Each ground was connected to a

‘ground plane

One side of the crystal was grounded in the oscillator

circuit and it was also used as a working electrode in a

Wenking-type potentiostat as shown in Figure 2, OPA27EJ

(Op. Amp) served as a summing amplifier and an OPA2111

BM (dual Op. Amp.) was used for an electrometer and an

input buffer. An instrumentation amplifier was composed of

a ifferential amplifier (2627AM) with an OPAZLIIBM to

‘measure the current flow through the precision resistor con-

nected to the auiliary electrode in series.

Cell. ‘Two different type of electrochemical cells were

designed. The cross sectional views of these cells are prese-

nted in Figure 3. Crystal Gt in the figure) is mounted bet-

‘ween two o-rings. It allows that the cell is watertight and

the softness of o-ings can relieve the mounting stress of

the crystal. Electrical connections to both sides of crystal

were made with bent ring-shaped springs(g) made of Cu-Be

(6%) wire. The springs under the crystal were soldered on

the brass pieces). The spring above the crystal in type A.

cell was also soldered on the brass plate(). External contact

to the spring above the crystal in type B cell was made

with a wire (not shown in the figure) inserted through a

thin hole from the side of the main Teflon body. Type A

cell was assembled by pressing down the cell mounting ring

© against the aluminum block (not shown in the figure)

using bolts, The assembly of type B cell was pressed against

the ledge of the main Teflon body with a PVC screw(t).

‘Two identical cells of each type were prepared for both re-

ference and test cells.

A counter electrode made of gold wire and two Teflon

Figure 3. Cross sectional views of the cell used in this study

(A) TypeA cell, (B) Type-B cell. a, celltop mount (polypro:

pylene); b, cell top (Teflon); c, ong: cell body (Teflon):

cell mounting ring (aluminum); f, contact plate (brass): g, contact

spring (Cu-Be alloy); b, quartz crystal; I, crystal mount (brass:

4s cell bottom (polypropylene); k, crystal mounting screw (PV

tubes were housed through orifices drilled in the cell top)

used for a test cell. One of two Teflon tubes was used to

connect the solution inside to an external reference electrode

(SCE) and the other was served only to maintain the internal

pressure identical with the external pressure,

6 MHz AT-cut quartz erystals (Phelps Electronics Pe 102-

03) were used in this study. The electrode in contact with

solution is totally covered with gold and the opposite elec-

trode is double-anchor shaped.

1 mM lead nitrate in 0.1 M nitric acid was prepared from

99.999% lead nitrate (Aldrich) and pro analysi nitric acid

(Merck GR) which were used as received. Deionized water

‘was doubly distilled in alkaline permanganate solution with

2 droplet trap for the preparation of solutions. Reference

cell was filled with pure water.

Instrumentation. Electrode potential was programmed

using the sweep generator of bipotentiostat (Pine AFRDE4).

A Universal Counter (Hewlett Packard S3131A) was used

to measure the frequency and a Measurement Plotting Sys-

tem(Hewiett Packard 70008) served as a data acquisition

system, both of which were connected to a personal com-

puter via GPIB. Both reference and test cells were mounted

‘on a common aluminum block that was placed on a vibration-

free table (Dae Il Systems) with the EQCM. The connections

between two cells and the EQCM were made as short as

possible All the experiments were performed at the ambient

temperature of 2512 €.

Results and Discussion

‘Type A cell was originally designed to make both the elec:

tric connection and the crystal mounting easy. As shown

in Figure 4, however, the frequency drift of type A cell was

‘much larger than that of type B cell. Furthermore, compared

with type B cell, much more time was required for type

Construction of EQCM

i ‘or0000

‘Time fin

Figure 4. Frequency drifts of EQCMs using type-A or type-B

cells filed with water, Brequeney gating time. 1 s; sampling inte

ral, 20's

Lo

a

BL

Times

Figure 5. Frequency drifts of QCM using type-B cells for both

oscillators (QCM1 and QCM2). The frequency dlflerence bet

‘ween QCM1 and QCM2 is also shown. Frequency gating time,

03 5; sampling interval, 1s.

A cell to be stabilized. It is seemed to be associated with

the temperature dependence of cell mounting stress. Type

‘A cell has more pieces made of various materials than type

B cell and it explains that the stress change of type A cell

caused by the temperature change was more serious. If the

stresses of the reference and test cells are same, the fre-

quency difference between these two QCM has to be cons-

Bull. Korean Chem, Soc. 1996, Vol. 17, No.1 41

“ty °

a oat Pon »

rt! _Z a

g. |

70 Frequency Change |” Li

Potential vs. SCE/V

Figure 6, Current-potential and frequency-potential curves of

EQCM in 0.1 M HNO, with and without 1 mM PO(NO:: Scan

rate, 10 mV/s gate time, 01 s: sampling interval, 02

tant. In the case of type A cells the drifts of both reference

and test cells could not show always same directions. Type

B cells, however, have almost same trends of drift and Fig-

‘ure 5 shows the cancellation effect clearly. In this figure

QCM and QCM2 mean the frequencies of both oscillators.

‘The short term noise of the frequency difference was only.

002 Hz at 03 s of gating time.

Fiqure 6 shows performance of this EQCM system by in

volving a well-known monolayer process, the UPD of Pb on

‘Au electrode. The solution was 1 mM lead nitrate in 0.1

M nitric acid. The curves were obtained after reaching

steady state by continuous cycling of potential scan. The scan

rate was 10 mV/s, the gating time of frequency counter was

(11, and the sampling interval was 02 s It is clearly shown

that the frequency decreases during the Pb deposition and

it increases while the reverse reaction occurs. The back-

ground current in the absence of Pb ion shows only reduc-

tion of dissolved oxygen molecules. Because this reaction

does not cause the mass change of the electrode, there are

only slight changes in frequency, which may be associated

‘with the specific adsorption of electrolytes and water mole-

cules. The negative limit is dictated by the reduction of hyd!

rogen ions.

‘To compare the frequency change with the current, the

first order derivative of the frequency data was obtained.

Deakin and Melroy have averaged 20 scans to obtain 2

‘smooth derivative curve. In this study, however, only one

scan was sufficient to differentiate the frequency change. AS

shown in Figure 7, the current curve and the derivative

curve of the frequency change have almost same shapes.

‘The peaks a and b are corresponding to the UPD of lead

‘monolayer on the gold substrate, and the peak c is associated

‘with the bulk deposition of lead on the deposited lead layer

in advance. Peak d is assigned to the stripping pair of peak

42, Bull. Korean Chem. Soc. 1996, Vol. 17, No. 1

Curent / nA

Potential vs. SCE/V

Figure 7. Current-potential curve and the frst order derivative

curve of frequency change. Data are from figure 6.

6, and the peaks ¢ and f are the corresponding oxidation

pairs of peaks 6 and a, respectively

‘The broad shoulder g in the current-potential curve, how

fever, has no corresponding part in the derivative curve of

frequency change. It means that a reduction process occurs,

at that potential without mass change. Ifthe lead ions pre-

sent in the solution are reduced at the electrode surface,

the electrode mass has to be increased. Based on the obser-

vation that there is no current in the background, it is be-

lieved that the lead ions had been adsorbed on the electrode

surface at the anodic potential region and then were reduced

at this potential. This phenomenon was not observed in per-

chloric acid media.™* The catalytic reduetion of nitrate or

dissolved oxygen by the adsorbed lead species might be a

possible cause for this prewave. Further works are being

carried out to explain it explicitly.

References

1. Buttry, D. A. In Blectroanalytical Chemistry:

10.

UL

12

13,

Euijin Hueang and Youngran Lim

Ei

pl

Deakin, M. R; Buttry, D. A. Anal Chem. 1989, 61, 11478.

Marcel Dekker: New York, U. S. A, 1991; Vol. 17,

| Ward, M. D; Buttry, D. A. Science 1990, 249, 1000.

Reed, C. Es Kanazawa, K. K; Kaufman, J. H. J. Appl

Phys. 1990, 68, 1993,

5. Martin, S. Jz Granstaff, V. E Frye, G. C. Anal. Chem.

1991, 63, 2272.

Lin, 2 Yip, C. Mu Joseph, I.

1993, 65, 1546.

Yang, M; Thompson, M.; Duncan-Hewitt, W. C. Lang-

muir 1993, 9, 802.

Noél, M. A. Mz Topart, P. A. Amal. Chem, 1994, 66, 484

Bruckenstein, S; Shay, M. Elecrockim, Acta 1985, 30,

1296.

Bruckenstein,

188, 131

Melroy, 0; Kanazawa, K Gordon Il, J. Gs Buttry, D.

A. Langmuir 1986, 2, 697.

Deakin, M. Ri Melroy, O. J. Blectroanal. Chem. 1988,

239, 321.

Lakkaraju, S; Bennahmias, M. Js Borges, G. L: Gordon

IL J. G; Lazaga, M; Stone, BM: Ashley, K. Appl Optics

1990, 29, 4943

Gabrielli, C Keddam, M. Torresi, R.J. Electrochem. Soe

1991, 138, 2657.

Nivens, D. Es Chambers, J. Q: Anderson, T. R; White,

D.C. Anal, Chem. 1993, 65, 65.

Ward, M. D. Anal. Chem.

s Shay, M. J. Electroanal. Chem. 1988,

Rivera, I, Mu Cabrera, C. Re J. Electrochem, Soc. 1993,

140, 136,

Lee, W-W.; White, H. S; Ward, M.D. Anal. Chem. 1993,

65, 3232.

Komplin, G. C:; Schleifer, F; Pietro, W. J. Rev. Sci In

strum, 1993, 64, 1530,

Bruckenstein, S.; Michalski, M.; Fensore, A. Li, Z. Anal

Chem. 1994, 66, 1847.

Shana, Z. A; Josse, F. Anal. Chem. 1994, 66, 1955,

|. Mo, Yi Hwang, E.; Scherson, D. A. Anal. Chem. 1995,

67, 2A15.

Nomura, T:; Okuhara, M. Anal Chim, Acta 1982, 142,

281,

Bourkane, S.; Gabrielli, C.; Keddam, M. Hletrochim. Acta

1989, 34, 1081.

Josse, F; Shana, ZA; Radtke, D. E; Haworth, D. T.

IEEE Trans. Ultras. Ferrel. Freq, Control 1990, 37, 359.

You might also like

- MCSCF Study of Chemical Reactions in Solution Within The Polarizable Continuum Model and VB Analysis of The Reaction MechanismDocument1 pageMCSCF Study of Chemical Reactions in Solution Within The Polarizable Continuum Model and VB Analysis of The Reaction MechanismBill HunterNo ratings yet

- Women in Science FinalDocument6 pagesWomen in Science FinalBill HunterNo ratings yet

- Zeta Potential AnalysisDocument3 pagesZeta Potential AnalysisBill HunterNo ratings yet

- Comparative Assessment of A New Nonempirical Density Functional: Molecules and Hydrogen-Bonded ComplexesDocument9 pagesComparative Assessment of A New Nonempirical Density Functional: Molecules and Hydrogen-Bonded ComplexesBill HunterNo ratings yet

- Non-Aquous SolventsDocument2 pagesNon-Aquous SolventsBill HunterNo ratings yet

- Gouy Magnetic Susceptibility BalanceDocument11 pagesGouy Magnetic Susceptibility BalanceBill HunterNo ratings yet

- Kundalini Sadhana PDFDocument12 pagesKundalini Sadhana PDFBill Hunter100% (3)

- S.No Company Na Price On 7 April Buy Amounquantitycurrent Priprofit/LosDocument3 pagesS.No Company Na Price On 7 April Buy Amounquantitycurrent Priprofit/LosBill HunterNo ratings yet

- Pivot Calculation: (Hemant)Document9 pagesPivot Calculation: (Hemant)Bill Hunter0% (1)

- This Is The Famous Nāsadīya Sūkta The 129 Suukta of The 10 Mandala of The RigvedaDocument2 pagesThis Is The Famous Nāsadīya Sūkta The 129 Suukta of The 10 Mandala of The RigvedaBill HunterNo ratings yet

- Gartley's Gap Theory ExplainedDocument2 pagesGartley's Gap Theory ExplainedBill HunterNo ratings yet

- UIDAI CircularDocument1 pageUIDAI CircularBill HunterNo ratings yet

- Gann Intraday Calculator 694Document2 pagesGann Intraday Calculator 694Bill HunterNo ratings yet

- Establishment of Mints in INDIA: Security Printing and Minting Corporation of India Limited (SPMCIL)Document14 pagesEstablishment of Mints in INDIA: Security Printing and Minting Corporation of India Limited (SPMCIL)Bill HunterNo ratings yet

- Abonacci SystemDocument5 pagesAbonacci SystemBill HunterNo ratings yet

- ConnorsRSI Pullbacks GuidebookDocument46 pagesConnorsRSI Pullbacks GuidebookBill Hunter80% (5)

- Taxpayer'S Counterfoil: PannoDocument1 pageTaxpayer'S Counterfoil: PannoBill HunterNo ratings yet

- Technical Analysis FibonacciDocument11 pagesTechnical Analysis FibonacciBill HunterNo ratings yet

- Cat Ear PatternDocument1 pageCat Ear PatternBill HunterNo ratings yet

- Symbol MKT Lot Spanmgn/Lot Expmgn/Lot Totalmgn/Lot Totalmgn%Document6 pagesSymbol MKT Lot Spanmgn/Lot Expmgn/Lot Totalmgn/Lot Totalmgn%Bill HunterNo ratings yet

- Trendline AmibrokerDocument9 pagesTrendline AmibrokerBill HunterNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)